Pump station with their own hands: wiring diagrams and self-assembly. Pump station: wiring diagrams and installation procedure by one's own hands

SNiP 2.04.01-85 *

Building regulations

Internal water supply and sewerage of buildings.

Systems of internal cold and hot water supply

12. Pumping installations

12.1. With constant or periodic lack of pressure in water supply systems, as well as when it is necessary to maintain forced circulation in centralized hot water systems, it is necessary to envisage the arrangement of pumping units.

12.2. The type of pumping unit and its operating mode should be determined on the basis of a technical and economic comparison of the developed options:

continuously or periodically operating pumps in the absence of regulating tanks;

pumps with a capacity equal to or greater than the maximum hourly flow of water operating in a short-term mode in conjunction with hydropneumatic or water tanks;

continuously or periodically operating pumps with a capacity of less than the maximum hourly flow of water, working together with the regulating capacity.

12.3. Pumping installations that supply water for domestic, drinking, fire and circulation needs should, as a rule, be located in the premises of heat points, boiler rooms and boiler houses.

12.4. It is not allowed to place pumping units (except firefighters) directly under residential apartments, children's or group rooms of kindergartens and nurseries, classes of general education schools, hospital rooms, working rooms of administrative buildings, classrooms of educational institutions and other similar premises.

Pumping units with fire pumps and hydropneumatic tanks for internal fire extinguishing may be located in the first and basement floors of buildings of I and II degrees of fire resistance from non-combustible materials. In this case, the rooms of pump installations and hydropneumatic tanks should be heated, protected by fire walls (partitions) and ceilings and have a separate outlet to the outside or to the stairwell.

Notes: 1. In some cases, in agreement with the local authorities of the Sanitary and Epidemiological Service, it is allowed to dispose of pumping units near the listed premises, with the total noise level in the premises not exceeding 30 dB.

2. Premises with hydropneumatic tanks should be located directly (near, top, bottom) with rooms where a large number of people can stay simultaneously - 50 people. and more (auditorium, stage, wardrobe, etc.) is not allowed.

Hydropneumatic tanks are allowed to be located in the technical floors.

When designing hydropneumatic tanks, the requirements of the "Rules for the Arrangement and Safe Operation of Vessels Working Under Pressure" of the Gosgortechnadzor of Russia should be taken into account. In this case, the need to register hydropneumatic tanks is established pp. 6-2-1 and 6-2-2 of the said Rules.

3. It is not allowed to place fire-fighting pumping units in buildings where the supply of electricity ceases during the absence of maintenance personnel.

12.5. Pumping installations serving individual blocks of urban buildings, as well as production pumping units, should be designed in accordance with SNiP 2.04.02-84 *.

Device zones health protection for pumping plants that supply water for domestic, drinking or domestic fire prevention purposes, operating without a rupture of the jet, provision is not required.

12.6. Pumping installations for production needs should be placed, as a rule, directly in the shops that consume water. If necessary, the enclosure of the pumping unit should be provided.

12.7. The productivity of household, drinking and industrial pumping units should be taken as follows:

in the absence of a regulating tank - not less than a maximum of a second water discharge;

in the presence of a water-pressure or hydropneumatic tank and pumps operating in a short-time mode - not less than the maximum hourly flow of water;

with the maximum use of the regulating capacity of the water tank or tank - according to Sec. 13.

12.8. If there are systems of cold and centralized hot water supply in buildings and facilities closed circuit heat supply should, as a rule, provide for an upgrading pumping unit to supply the total water flow to cold and hot water supply.

12.9. The head for the cold and hot water supply system Hp, developed by the booster pump, should be determined taking into account the least guaranteed head in the outdoor water supply network according to the formula

where - the sum of pressure losses in the pipelines of the water supply system, m, determined in accordance with Sect. 7, 8 and 11.

Note. If necessary, it is necessary to check the pressure in the system during hours of minimum water consumption, taking into account the maximum pressure in the external water supply network.

12.10. The required pressure of the boosting system for the hot water supply system in which the difference in pressure in the cold and hot water supply system exceeds 0.1 MPa with the use of circulation-boosting pumps is determined by the formula

where - the head of the circulation-boost pump, m.

12.11. In centralized systems of hot water supply, if there is insufficient water pressure in the city water supply system during night hours, circulating pumps installed on the supply pipeline should be used as additional booster pumps.

12.12. In the local high-rise pumping unit, parallel operation of the pumps must be envisaged.

When pressure fluctuations in the external water supply network exceed 0.2 MPa (20 m) for residential buildings, it is necessary to provide for the sequential operation of boost pumps with automatic switching, depending on the required pressure.

12.13. When the pressure in the external water supply network is less than 0.05 MPa (0.5 kgf / cm2), it is necessary to envisage the installation of a receiving reservoir before the pumping unit, the capacity of which should be determined in accordance with Sec. 13.

12.14. Increase the circulation pump at the design flow rate hot water , determined in accordance with clause 8.1.

12.15. Design of pumping units and determination of the number of standby units should be carried out in accordance with SNiP 2.04.02-84 * taking into account the parallel or sequential operation of pumps in each stage.

12.16. On the pressure line, each pump should include a non-return valve, a latch and a pressure gauge, and a suction valve should be fitted with a valve and a manometer.

When the pump is running without a back-up on the suction line, a latch must not be installed on it.

12.17. Pumping units should be installed on vibration isolating bases. On the pressure and suction lines, installation of vibration isolating inserts should be provided.

Vibration insulating bases and vibration isolating inserts are allowed not to provide:

in production buildings where noise protection is not required;

in fire fighting pumping units;

in free-standing buildings of central heating points (TSC) with their location to the nearest building not less than 25 m.

12.18. Pumping units with hydropneumatic tanks should be designed with variable pressure. Replenishment of the air reserve in the tank must be carried out, as a rule, by compressors with automatic or manual start-up or from a general compressor plant.

12.19. In hot water systems of industrial enterprises, a standby circulation pump may not be installed. In buildings and facilities with a mode of operation in one or two shifts, it should be possible to turn off the circulation pumps of hot water systems. The inclusion of circulating pumps should ensure that the calculated water temperature at the sanitary appliances is at the beginning of the draw-off.

12.20. When designing circulation pumps, it is necessary to provide for the protection of hot water systems from high pressures during or after a small water draw-off.

12.21. Pumping installations for fire prevention purposes should be designed with manual or remote control, and for buildings with a height of more than 50 m, cultural buildings, conference halls, assembly halls and for buildings equipped with sprinkler and deluge installations - with manual, automatic and remote control.

Notes: 1. An automatic or remote start signal must be sent to the pump units after automatic checking of the water pressure in the system. With sufficient pressure in the system, the start-up of the pump should be automatically canceled until the pressure drops, which requires the pump unit to start up.

2. It is allowed to use fire pumps for fire extinguishing, provided that the design flow rate is applied and the water pressure is automatically checked. Household pumps must satisfy the requirements for fire pumps. When the pressure drops below the allowable value, the fire pump must be switched on automatically.

3. Simultaneously with the signal of automatic or remote start-up of pumps for fire prevention purposes, the opening of a fire cock, the opening of a sprinkler sprinkler or the inclusion of a (manual or automatic) deluge system should receive a signal to open an electrically-operated gate valve on the water meter's bypass line at the water inlet.

12.22. When remote start-up of fire-fighting pumping systems, the start buttons should be installed in the cabinets of fire hydrants. When the fire pumps are switched on automatically and remotely, it is necessary to simultaneously give a signal (light and sound) to the fire station or another room with 24-hour service personnel.

12.23. For pumping installations that supply water for domestic, drinking, industrial and fire safety needs, it is necessary to adopt the following category of power supply reliability:

I - when the water consumption for internal fire extinguishing exceeds 2.5 l / s, as well as for pumping units, the interruption of which is not allowed;

II - with water consumption for internal firefighting 2.5 l / s; for residential buildings with a height of 10-16 floors with a total water flow of 5 l / s, as well as for pumping units that allow a short break in work for the time necessary to manually switch on the backup power.

Notes: 1. If it is impossible by local conditions to power the pumping units of category I from two independent power sources, it is allowed to supply them from one source provided that they are connected to different 0.4 kV lines and to different transformers of the two-transformer substation or transformers of the two nearest single-transformer substations (with the ATS device).

2. If it is not possible to provide the necessary reliability of power supply for pumping units, it is allowed to install backup pumps with a drive from internal combustion engines. It is not allowed to place them in the basement.

12.24. Pumping installations of cold water supply systems, circulating and circulating-boosting pumping systems for hot water supply should be designed with manual, remote or automatic control.

When the booster pump is operated automatically, the following shall be provided:

automatic start and stop of working pumps, depending on the required pressure in the system;

automatic activation of the backup pump when the working pump is disconnected;

giving an audible or light signal about emergency shutdown of the working pump.

12.25. When collecting water from the reservoir, provision should be made for the installation of pumps "under the bay." If pumps are placed above the water level in the reservoir, devices for pouring pumps or installing self-priming pumps should be provided.

12.26. When water is taken from the reservoirs by pumps, at least two suction lines should be provided. Calculation of each of them should be carried out for the passage of the estimated flow of water, including fire.

The installation of one suction line is allowed when installing pumps without standby units.

12.27. Pipelines in pumping stations, as well as suction lines outside pumping stations, should be designed from steel pipes for welding with flange connections for connection to pumps and fittings.

In buried and semi-buried pumping stations, measures should be envisaged for the collection and disposal of casual water drains in accordance with the requirements of SNiP 2.04.02-84 *.

Staying outside the city, in the country residence, has additional difficulties, since not everywhere there are centralized communications. The inhabitants of the periphery improve the living conditions in the cottage or house so that it does not differ from the urban comfortable housing. One of the points of comfortable life concerns the constant availability of water in sufficient quantity. In this case, special equipment will help - the pump station with their own hands. Due to the self-installation you can save your family budget.

The device and the principle of operation of the unit

The main number of wells in country plots has a depth of up to 20 m - optimal for the installation of automatic equipment. With these parameters, you do not need to purchase borehole pump, an automatic control system or intermediate capacity: water directly from the well (or well) to the points of analysis. To ensure the correct connection of the pumping station, it is necessary to understand what it consists of and how it works.

The main functional nodes of the station are the following equipment:

- A centrifugal pump providing water lifting and transporting it to the house.

- Hydraulic accumulator, softening hydraulic shock. It consists of two parts separated by a membrane.

- An electric motor connected to a pressure switch and a pump.

- A pressure switch that controls its level in the system. If the pressure drops below a certain parameter - it starts the motor, if there is an over-pressure - turns it off.

- A manometer is a device for determining the pressure. With its help produce adjustment.

- The water intake system equipped with check valve (located in a well or well).

- The main line connecting the water intake and the pump.

With the help of this formula it is possible to determine the maximum suction depth: the diagram demonstrates clearly what measurements need to be done for this

The most common version of the pump station is a hydraulic accumulator with a surface pump mounted on top and a unit including a pressure gauge, a pressure switch and a dry running protection

As can be seen from the table, the cost of pumping stations can be different. It depends on power, maximum head, throughput, manufacturer

Before installing the pumping equipment, it is necessary to purchase all the functional parts according to the parameters of the well and the water supply system.

Self-assembly of the pumping station

At first glance, there are a lot of places for mounting equipment - this is any free corner in the house or outside it. In fact, everything turns out differently. However, only a well-thought-out installation of the pumping station guarantees its full operation, therefore it is necessary to observe certain conditions.

Mounting conditions:

- proximity to the well or well provides stable water absorption;

- the room must be warm, dry and ventilated;

- placement should not be close, as preventive and repair work is required;

- the room should hide the noise that the pumping equipment issues.

One of the options for installing a pumping station is on a shelf specially attached to the wall. The room for installation is a boiler room, boiler room or utility room

It is difficult to comply with all conditions, but it is desirable to adhere to at least some. So, consider a few suitable places for installation.

Option # 1 - room inside the house

A well-insulated boiler house on the territory of the cottage is an ideal area for installation in case of permanent residence. The main disadvantage is a good audibility with poor-quality room noise insulation.

If the pumping station is located in a separate dacha house, the well is best placed directly under the building

Option # 2 - basement

A basement or a basement can be equipped for the installation of a pumping station, but this should be considered when designing. If the room is not heated, and the floors and walls are not isolated, you will have to spend a lot of effort to prepare it.

A well-equipped basement is excellent for mounting a pumping station. During the laying of the pipeline in the foundation of the house, make a hole for the communications

Option # 3 - special well

Possible option, having a couple of pitfalls. The first is the difficulty in maintaining the required level of pressure in the house, the second is the difficulty of performing repair work.

When the pump station is located in a well, on a specially equipped site, the pressure level should be adjusted, which depends on the equipment's capacity and pressure pipe parameters

Option # 4 - caisson

A special platform near the well exit is also suitable for installation, the main thing is to correctly calculate the depth of its location. The necessary temperature will create the heat of the earth.

Pumping station, located in the caisson of the well, has two advantages: complete noise isolation and frost protection during frosts

In the absence of specially designated places, the unit is installed in common areas (in the hallway, bathroom, corridor, in the kitchen), but this is an extreme option. Loud station noise and comfortable rest are incompatible concepts, therefore it is better to prepare a separate room for installation in the dacha.

Pipeline laying

Well, as a rule, is located near the house. In order for the pumping station to function properly and without interruptions, it is necessary to ensure unhindered flow of water from the source to equipment that is located in a specially designated place. For this purpose, a pipeline is laid.

Low winter temperatures can lead to the freezing of pipes, so they are buried in the ground, preferably to a depth that is below the freezing level of the soil. Otherwise, the line must be insulated. The works are as follows:

- trench digging with a slight bias towards the well;

- device in the foundation of the hole for the pipe at the optimum height (if necessary);

- pipe laying;

- connection of the pipeline to the pumping equipment.

During the arrangement of the highway, one can face such a problem as the presence of high-standing surface waters. Pipes in this case are mounted above the critical level, and for thermal protection use a heat-insulating material or a heating cable.

Benefits polyethylene pipes and fittings in front of metal analogs: no corrosion, ease of installation and repair, low price (30-40 rubles per meter)

This scheme of installation of the pumping station shows a version of the insulation of pipes above the freezing level of the ground

![]()

The optimal option for the thermal insulation of external water pipes is a hard "shell" made of expanded polystyrene (thickness - 8 cm), wrapped in foil

For thermal insulation of pipes that are laid above the freezing level of soil, often use inexpensive and environmentally friendly material - mineral wool on a basalt basis.

External work

From the outside polypropylene pipes fix a metal mesh that will serve as a filter coarse cleaning. In addition, a check valve is needed to ensure a stable filling of the pipe with water.

It is possible to purchase a ready-made hose with a check valve and a coarse filter, but equipped with their own hands will be much cheaper

Without this part, the pipe will remain empty, therefore, the pump can not pump water. The non-return valve is fixed by means of a coupling with external thread. The end of the pipe equipped in this way is placed in the well.

The coarse filter for the supply hose is a metal mesh with a shallow cell. Without it, the correct operation of the pumping station is impossible

After performing these actions, it is possible to engage in upgrading the well head.

Connecting equipment

So, how to properly connect the home pumping station, in order to avoid further technical inconsistencies? First of all, install the unit on a specially prepared base. It can be brick, concrete or wooden. To ensure stability, screw the legs of the station with the help of anchor bolts.

For the installation of the pumping station, special pedestal legs are provided, however, in order to provide additional stability, the equipment must be fixed with bolts

If you place a rubber mat under the equipment, you can extinguish unnecessary vibrations.

For more convenient maintenance, the pumping station is installed on a base height with a regular table made of a durable material - concrete, brick

The next step is to connect the pipe from the well. Most often this polyethylene product with a diameter of 32 mm. For connection, a male thread (1 inch), a 1-inch male corner, a non-return valve with a similar diameter, and a direct American tap are required. We connect all the details: fix the pipe with a clutch, fix the "American" with thread.

One of the check valves is in the well, the second is mounted directly to the pump station. Both valves serve to protect the system from water hammers and ensure the correct direction of water movement

The second output is intended for communication with the water supply network. Usually it is located at the top of the equipment. The connection pipes are also made of polyethylene, as this is an inexpensive, ductile, durable material. Fixing occurs in a similar way - with the help of an "American" and a combined sleeve (1 inch, 90 ° angle) with external thread. First, the "American" is screwed to the exit of the station, then in the crane we mount the coupling from propylene, finally water pipe we fix in the coupling by the soldering method.

To fully seal the connections, they must be sealed. Traditionally, a winding made of flax is used, a special sealing paste

After you have connected the pumping station to the water intake and water supply system, it is necessary to check the quality of its operation.

We carry out a trial run

Before starting the station, it must be filled with water. Through the filling hole let the water so that it filled the hydraulic accumulator, trunk lines and pump. Open the valves and turn on the power supply. The engine starts and the water starts to fill the pressure pipe until all the air has gone off. The pressure will rise until the set point is reached - 1.5-3 atm, then the equipment automatically turns off.

In some cases, it is necessary to adjust the pressure value. To this end, remove the cover from the relay and twist the nut

As you can see, it is quite easy to make installation of a home pumping station with your own hands, the main thing is to follow the installation instructions.

Organization of an autonomous water supply system in a country house requires knowledge of the choice, installation and operation of pumping equipment. To supply water from the source to the points of water extraction it is necessary to choose such mechanisms, specifications which fully meet the needs of owners. Let's try to figure out which pumping station for the house will become the best option under various operating conditions.

Own source on the countryside can fully provide water to a residential building, a house territory, a garden, a garden. In order to create an uninterrupted, well-functioning water supply system, it is necessary to consider the feeding process, that is, to select the device for pumping liquid from the source to the house (or to other points of draw-off) and to lay communications.

There are three generally accepted ways of transferring water:

- pumping via a pump directly to the consumer;

- use of a storage tank and pump;

- use of accumulator and pump.

The pump connection scheme is considered to be the simplest, since water is supplied directly from the well to the place of use - a kitchen faucet, a watering hose, etc. When choosing the equipment for connection, it is necessary to carefully study its technical characteristics and ensure the availability of a power source. Frequent start-up (if automation is provided, then every time the faucet is opened), the pump quickly breaks down.

An example of installing a surface pump, which is used to water lawns, flower beds, beds. For the provision of garden water supply, a model of medium capacity

The pump without additional equipment is good for small dachas, which are visited during the warm season or are visited occasionally, for example, on weekends.

The second option is characterized by the presence of a storage tank - a tank installed at the top of the building (most often in the attic). The advantage of this design is a water reserve equal to the volume of the tank. Even during power outages, you can freely wash dishes or take a shower.

Image Gallery

- a necessary condition is the presence of a warmed attic sufficient to install a tank area,

- is important big size capacity, so you need to strengthen the overlap;

- in the event of an accident, a qualitative waterproofing should be made.

Sometimes additional costs are required to purchase a second pump. It is necessary to maintain certain pressure parameters. The more mechanisms, the more complex the system and the higher the probability of failures in the process of operation.

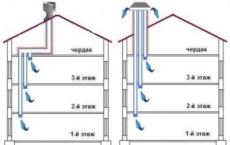

Comparative diagram of two versions of the house water supply: 1 - with a submersible pump and a storage tank, 2 - with a pumping station that pumps water from the well (+)

The third option is the most acceptable for those who constantly live outside the city and want to improve their home to the maximum. The hydraulic accumulator provides the building and other objects of consumption the required quantity water, creating the right pressure. In addition, two important for the technology principle are observed: economy and high productivity.

Pump station design features

The pump station can be purchased in ready-made form or independently assembled from the components: hydraulic accumulator tank, pump (submersible or surface), pressure switch and automatic control unit. Specialists recommend to stop on a ready-made installation, in which all elements are ideally suited to each other in terms of technical characteristics, material and dimensions.

An approximate scheme for installing a pumping station with the designation of all necessary parts (including pipes and connecting elements) and indicating the location of the equipment - in the basement

A submersible pump with a filter and check valve can be replaced by a surface model - both options have their advantages. The filter is necessary to protect the communications from the sand falling on the bottom and suspended impurities, the check valve prevents the outflow of water in the opposite direction when the unit is automatically switched off.

The shutdown occurs at the pressure switch signal, which is triggered when the pressure reaches the maximum level. As soon as the liquid in the accumulator tank becomes smaller, the pressure stabilizes, the mechanism switches on again and starts to pump water.

For the operation of the station, it is necessary to supply 220 V. The cross-section of the pipes must be selected so that the water freely travels through the channels connecting the pump equipment and the points of consumption.

Powerful equipment is capable of providing water to a building in which a family of 5-6 people lives, and a point of draw-off outside the house (in a garage, in a summer kitchen, in a garden or a garden).

Image Gallery

![]()

Selecting a model for specific characteristics

The variety of models on the market is explained by the fact that the connection conditions can be quite different: one requires a version with a surface pump installed in the caisson near the well, others need a submersible mechanism or a more powerful model with an ejector capable of pumping water from a depth of 20-25 m.

When choosing pumping equipment in a shop, the properties of the samples should be compared with individual requirements.

Productivity: how to calculate yourself

With the calculation of productivity there are difficulties, because many do not know what should be based on. In fact, for objective calculations, several factors should be considered. For example, it is important to take into account the volume of well reduction - a one-time intake of water at zero production rate, the rate of recovery of the volume of liquid in the source, the regime of active operation of the water supply system,

To find out the average, enough data for 1 day. This is possible due to the complete recovery of the water volume in the well for 5-6 hours (the time when the liquid is not consumed at all). The most busy "peak hours" are pieces of time when there is an active use of sanitary facilities or watering the infield. They are the most suitable for the objectivity of calculations.

To calculate, it is necessary to add the parameters of all consumption points, without forgetting the correction factor, output the unit of productivity - l / min or l / h

Suppose a well has a production rate of 200 liters, and a reduction volume of 50 liters. If three members of the family take a bath (200 liters) in succession, and we need the water to flow freely to other points of the draw-off, the productivity should not be lower than 300 l / h.

Sometimes the calculation is made based on the amount of water consumption by all family members or by calculating the maximum water use - peak consumption. It is assumed that at the same time all the points of water extraction are used, the average consumption of which is:

- washbasin mixer - 0,1 l / s;

- kitchen mixer - 0,15 m / s;

- a drain tank - 0,1 m / s;

- shower - 0,25 l / s;

- washing machine - 0.3 l / s.

Maximum depth of water intake

In order to clarify this parameter, it is necessary to accurately know the size of the well (well) and to measure the distance from the installation location of the accumulator to the source. The main value is taken from the height of the water surface to the axis of the pump installed near the well or well. If the station is located at some distance (for example, in the basement of the house), then the horizontal section must also be kept in mind.

When making calculations, it is necessary to rely on the value of not the static but the dynamic level - the average value with a regular fluid intake for 1-2 days

There is an error correction due to the resistance of the pipes, check valve and filters. This means that you need to add another 15% to the amount received. By the way, the resistance of stainless steel pipes, which is used increasingly rarely, is much higher than that of plastic communications.

The vertical arrangement of the pipes refers to the horizontal arrangement in the proportion 1:10. For example, the distance to the installation site of the accumulator is 20 m, the depth of the well to the water mirror is 8 m, therefore, equipment with minimum depth fence 8 m + 20 m: 10 = 10 m

Volume of accumulator tank

When choosing a pumping station for a private house, do not forget to ask about the volume of the accumulator, since the full capacity of the water depends on the size of the tank. The larger the tank, the more space the equipment occupies and the more expensive the entire assembly is. It is believed that large tanks have rarer on / off cycles, which makes their life time much longer.

Pump station Jilex Jambo with integrated ejector and automatic control: power - 1100 W, capacity of accumulator - 24 l. Suitable for use in wells and wells

For a lonely tenant or a couple, a volume of 24-30 liters is sufficient. Small capacity is also appropriate when the need for water comes periodically (for example, on weekends). The volume of 50 liters is an average capacity suitable for serving a group or a family of 3-5 people permanently living in a country house. For housing, which has united under its roof more than five people, you should purchase equipment with a 100-liter tank.

Capacities less than 24 liters are unreasonable, since they wear out quickly, respectively, have a short service life.

Water pressure in the water supply system

The functioning of the system will be full and comfortable only if there is sufficient water pressure at each point of water consumption. This means that the pressure in the network ensures an uninterrupted, correct supply. For example, for kitchen faucet a pressure of 1 / 1.5 atmospheres is sufficient, which equals 10/15 m of the water column. More serious equipment requires increased parameters.

The Grundfos JPBasic2 PT pump station with a power of 600 W and a maximum head of 42 m. The purpose is to increase the pressure in household systems, watering of country cottages or a garden

The value of the water pressure can be found in the instruction. Units with a maximum head of 45-50 m can equally well be used both in country cottages, and at small enterprises. They have increased capacity (up to 4500 l / h) and are often equipped with an additional storage tank

Power and voltage

These indicators are necessary for the correct connection of pumping equipment. The standard voltage of power supply - 220 V - is typical for the majority of household pumping stations, since single-phase networks AC are much more common. Voltage 380 V is necessary for high-performance operation of equipment on an industrial scale, and in the residential sector it can be found only in multi-storey buildings.

The Parma model SN-600P is equipped with a self-priming pump and is used to supply water to the house or to the household plot from the tank, pool or well. Voltage AC - 220 V, power - 600 W

The capacity of household units with a hydroaccumulator is from 600 to 2000 W. It affects the choice protective devices and the power cable. If there is an overheating, a short circuit, a start in the "dry run" mode, the modern models are automatically switched off.

Constructive and functional features

Models of one manufacturer, and even more so, of different brands, differ in appearance and potential. Suppose a pressure switch that provides timely equipment shutdown can be connected in two ways: by means of a flexible hose or directly to the housing. The principle of action does not change, only the external design is different.

More serious differences relate to the type of pump - the main working part. The most common self-priming devices, which easily tolerate the light pollution of water and the presence of air in the pipes. The main disadvantage of this type of equipment is the limited height of the liquid from the source (from 6 to 9 m). Another small drawback is the high noise level, but it is solved by installing the pump in a separate room.

Some models are equipped with an ejector, built-in or external. Built-in allows you to increase the depth of water supply to 15 m, while the external one is able to extract liquid from a depth of 45-50 m. The disadvantage is reduced efficiency and noise.

Ejector provides recirculation (looped) movement of water thanks to a special design - an additional submerged hose with a special nozzle

For wells and wells up to 10 m deep, quieter multistage devices are used. They are more expensive and more difficult to construct, have a powerful head and a high degree of productivity. The main external difference between aggregates of this type is the elongated shape of the working chamber, which holds several wheels instead of one.

For suburban areas with a small house and a shallow well (6-7 m), vortex pumping stations are suitable. They have a high head (which allows them to be used to increase pressure in the system), quiet operation, efficiency, but low productivity

Overview of popular models

Choosing this or that model, you always pay attention to the manufacturer and try to remember how reliable his products are. This is the right approach, because the lines of work of the pumping station are measured over the years, and there is no sense in poor-quality purchases.

Now almost all companies engaged in the production of pumping equipment are focused on consumer interest and have in their arsenal a whole set of models that differ in their technical characteristics. Famous domestic brands Gileks, Zubr, Vortex in the number of presented rulers compete with the Italians Marina, Ergus, Pedrollo.

However, the palm belongs to the German brands Gardena, Metabo, Wilo SE, Kärcher, Grundfos, which always had excellent quality and maximum functionality. All brands, rooted in Russia, adapted their equipment to local climatic conditions. Consider a few popular models to get an idea of pumping devices became more complete.

Caliber SVD-850P. Serves for supplying water from wells, basins, water intake structures with depth no more than 8 m.

- Power - 850 W

- The presence of an ejector is not

- The capacity of the tank is 20 l

- Productivity - 60 l / min

- Lifting height - 40 m

The plastic pump body requires protection from UV irradiation and other atmospheric aggression. In addition to standard consumers, the station can serve water heating installations, irrigation and irrigation systems, dishwashers and washing units.

Pumps and pump stations of the brand Caliber are the favorite models of summer residents who are engaged in seasonal cultivation of garden and garden crops

PATRIOT R 1200/24 INOX - model for pumping clean water with a pumping part made of stainless steel.

- Power - 1200 W

- The presence of an ejector is not

- The capacity of the tank is 24 l

- Productivity - 63 l / min

- Lifting height - 30 m

The body, made of stainless steel, excludes the penetration of atmospheric water. The unit can operate temporarily in an open area in conditions of high humidity. For fixed installation outside the room, a box device is recommended.

The rather powerful Patriot 1200/24 INOX installation is an excellent option for servicing wells and wells in the immediate vicinity of the residential building

- ZNAR ZNAS-1200-C is an automatic pumping station, suitable for providing a small country house with water.

- Power - 1200 W

- The presence of an ejector is not

- The capacity of the tank is 20 l

- Productivity - 63 l / min

- Lifting height - 50 m

The pump unit is designed for a tenfold or more interruption and start of work per day. The model is automated, maintains operating pressure parameters in the system, is equipped with protection against overheating.

High-performance model Zubr ZNAZ-1200-S is able to raise water to a high altitude, so it is often used for the construction of water supply systems of two-story mansions

Gilex Jambo 50/28 Ch-18 is a high-quality device made of extra strong materials.

- Power - 500 W

- The presence of an ejector is

- The capacity of the tank is 18 liters

- Productivity - 50 l / min

- Lifting height - 28 m

In addition to taking water from underground sources, the station is capable of pumping water from open reservoirs. Equipped with automatic control devices, can be customized for the specific needs of home owners.

Pumping device Gilex Jambo 50/28 Ch-18 does not have high performance, but it is convenient to use and equipped with an ejector and a reliable automation kit

Karcher BPP 4000/48 - an excellent model for the technical water supply system.

- Power - 900 W

- The presence of an ejector is not

- The capacity of the tank is 18 liters

- Productivity - 60 l / min

- Lifting height - 43 m

The station is designed for pumping technical, rain, spring, well water with an insignificant degree of contamination. It is allowed to install in boiler houses or specially built pavilions for it. The disadvantage of the system is the absence of a device for interrupting the operation under conditions of "dry running".

Pumping equipment brand Karcher differs neat appearance, ergonomics and ease of use. Virtually all models are equipped with handles for moving

Marina-Speroni CAM 198/60 is a device with a powerful engine and protection against dry running.

- Power - 1600 W

- The presence of an ejector is not

- The capacity of the tank is 60 l

- Productivity - 90 l / min

- Lifting height - 32 m

It is used for pumping water from open and underground sources.

Completely automated, due to which does not need constant participation in the work of home owners. There is a system for adjusting the pressure parameters necessary for the uninterrupted supply of water.

The powerful installation of the Marina-Speroni CAM 198/60, fully automated, protected against overload and able to work for a long time without interruption, is ideal for out-of-town water supply

As you can see, for different models the difference in performance, lift height and power can be significant.

Video review of pumping stations

Useful training video reviews will help you better understand the information about the purpose, technical characteristics and selection of pumping stations.

Detailed informative video about modern models from the manufacturer Aurora:

All about the technical characteristics of household pumping equipment:

Overview of pumping stations Aquario:

Model overview 1100-25 JET with ejector:

If you own a private house, you will definitely need modern pumping equipment. Before buying, carefully study the technical data of the automatic pumping station and find out if it is suitable for your home. Installation of the unit can be made independently, however, only experienced professionals are able to take into account all the tricks of installation.

Water pumping stations for the house, as well as various models of pumps, are used to lift water to the surface from underground water intakes. And although these units get water maximum from a depth of 9 m, their use to feed into the house, especially if it is at several levels, is most effective.

The manual in this article will tell you what mini-units are for the dacha, as well as boost pump stations for apartment building.

What you need to know about pumping stations

A household pumping station is an aggregate composed of two main elements: a centrifugal surface pump, and a storage tank called the accumulator (see). It creates a certain water supply, which allows you to save the pump from running and stopping each time the crane is opened.

This not only saves electricity, but also extends the life of the equipment:

- The most important advantage of a hydraulic accumulator is that it prevents pressure jumps in the pipeline, not allowing it to: neither fall nor increase excessively. As already mentioned, the pumping station can not get water from a deep well or well. For this purpose, submersible pumps, but even in this case, when distributing water inside the house, it is impossible to do without a hydraulic accumulator.

- To provide stable head water, you still have to select and install a suitable capacity. Sometimes, to provide water points on each floor, more than one accumulator is required, and several.

But if there is a shallow water intake on your site, what is the point of acquiring and assembling all the equipment separately, when it can be made easier - to install a pumping station.

With proper selection of the power of the pumping station, which should be carried out taking into account the water withdrawal rate, vertical and horizontal water supply distances, and its standard consumption, problems with distribution and pressure of water, there will be no house.

So:

- Use such equipment is possible and in the event that the house is supplied with water not from an autonomous water intake, but from a backbone network. In this case, a mini-house can be installed solely for the sake of increasing the pressure of water, which usually falls during peak hours. The power of such an aggregate is only 12 volts, and the average price is within 4500 rubles.

- Insufficient water pressure in the pipes is a sick subject and for apartment buildings, especially old buildings. The internal pipelines of such buildings are half-clogged with scale and rust, and as a result, their throughput is reduced. What here pressure?

- In a similar situation, a mini-unit for increasing water pressure is the best solution Problems. You can, of course, put an upward pump on each pipe, but if there is no water in the pipes, then there is nothing to raise.

And in the storage capacity of the accumulator there will always be a supply of water, and you can use it at any time convenient for you.

- The problem of water pressure in apartment buildings, solve and globally. Housing-operational organizations are installing more powerful, automatic pumping stations in the basement of the house.

Usually this is a complex of several pumps with a parallel installation scheme, and one large storage tank. - Its internal cavity is divided by a membrane: in one part there is water, and in the other - compressed air. It is he who provides the necessary pressure to water. The hydraulic accumulator is equipped with a float sensor that turns on the pumps only when the water level in the tank drops to a certain level.

- Speaking about household pumping stations, it should be noted that they usually provide two modes of operation. This is an independent intake of water from an underground water intake or accumulator, and an increase in the pressure of water coming from a centralized water supply network. When installing the unit, it just needs to be set up correctly.

- It is only important to remember that every 10 meters of a horizontal pipeline through which water moves, reduce by 1 meter the depth from which surface pump can get water. Therefore, in order not to have to install additional equipment, it is desirable to equip the water intake as close as possible to the house.

If the distance from the well to the house, say, 15-20 meters, the pumping station is mounted in the pit near its head.

But if the well is not far from the house, then the connection scheme can be as shown in the photo above: the unit is located in the basement of the house, and the suction hose with a check valve and filter below the freezing point is taken to the water intake. This scheme eliminates the need to insulate the pumping station - only take care of the pipeline.

It should be noted that household pumping stations are quite easy to maintain. Installation, adjustment, prevention and repair - all this is usually done by hand, according to the operating manual of the unit.

So:

- Perhaps to clarify the issues that arise in the process of these actions, you will just have to watch the video in this article. And we'll talk a little about the device of the station and the nuances of its installation.

- As we have already said, the base of the station is a pump. In the modifications designed for domestic use in water supply, it is a centrifugal option. There are, of course, station modifications equipped, but they are more often used in sewage systems.

- The design of the pumping station for the house looks like this. The main element is a surface pump equipped with an asynchronous single-phase motor consisting of a steel casing, a capacitor box, a rotor, a stator with a built-in thermal sensor, and, of course, a fan.

- The body of the station itself is made of either reinforced polypropylene or stainless steel, and sometimes brass. In the pumping part of the housing there is a built-in ejector, and one or more working wheels - the power of the unit depends on this.

- The accumulator is usually made of strong steel, and has a removable diaphragm and a nipple for injecting air under pressure. It is equipped with a pressure gauge and low and high pressure sensors, which start-stop the station. These cycles are repeated automatically, during the flow of water from the system.

- TO electrical network the station is connected via a cable, the cross-section of which is selected based on its length, and, naturally, the power of the pump. A grounding is mandatory. The equipment is equipped with a check valve and a screen filter for water.

- But the cable, like the hoses, does not enter the set of the unit, because their performance characteristics and length are always individual. For suction and water supply can be used not only hoses, but pipes - it all depends on constructive features network.

On some nuances should pay special attention:

| What is important to pay attention to when installing a pump station | |

| 1. | Both suction and supply hoses must be reinforced, but in different ways. There is reinforcement on the head, but there is reinforcement for vacuum. In order to avoid vacuum compression when sucking water, it is important not to confuse the hoses during installation. |

| 2. | The key to efficient operation of the pumping station is the high-quality implementation and sealing of all connections. |

| 3. | The unit must be mounted on a frame or other rigid base, and carefully fixed. |

| 4. | When installing the supply pipeline, bends should be avoided, as well as installation of extra faucets in the system. |

| 5. | The longer the water flow path to the water points, the larger the diameter of the pipes. |

If these rules are observed during installation, as well as timely preventive maintenance during operation, the pump unit will last for a long time without creating problems for the inhabitants of the house.

Residents of apartment buildings often complain about the strong, discomforting noise from the pump in the basement. In order to effectively eliminate this problem, one must understand that an unpleasant sound does not arise just for that, and it is important to find the cause of its appearance. Only after it is found, the question can be solved.

As a rule, the causes of noise are water supply pumps, which in the usual house are numerous ( central heating, cold and hot water supply).

Pumps in the mode of operation can be divided into two types:

- which work constantly (water supply pumps);

- which are included systematically (pumps pumping, drainage, etc.).

If the pumps are located in free-standing buildings (as was the case in the 1970s), then residents of the house will not hear any noise. However, when placing pumping equipment in the basement, the buzz can be felt quite strongly. It negatively affects the nervous system and the general well-being of people living in the house.

The impact of technical noise on health

Houses that were built before the middle of the last century, have not very good sound insulation characteristics. In other words, everything that happens in the basement is heard in the apartments. Previously, there simply was not any regulations in which the indicators of permissible noise would be prescribed. Today, the issue of the comfort of living in homes is quite acute, so the government introduces special rules, according to which the same noise from the pump should not exceed the established figures.

Most of the complaints come, naturally, from the inhabitants of the first floors, who themselves feel all the "delights" of staying near the source of sound. In itself, noise does not affect the physical health of a person, however, it causes significant psychological stress, which ultimately affects the general state of the body. People become more irritated, chronic fatigue begins to appear. Constant pressure depletes the central nervous system. Some doctors note that psychological anxiety can become one of the causes of internal diseases.

It is also worth noting that, due to noise vibration, communications at home may suffer.

Measurement of noise in the basement.

At the first appearance of sound vibrations it is necessary to contact specialists or management company.

How does the sound of the basement reach the apartment?

Constant complaints of residents of apartment buildings forced specialists to study the causes of noise from pumping equipment in basements. Based on the results of numerous examinations, it was found that the sound level to a lesser extent depends on the power and variety of the pump, as well as on the manufacturer. Special impact is not rendered and the size of the equipment, because a serious hum can produce even a very small pump.

It was determined that the sound in living quarters from the basement comes in several ways: through the air, structurally and through water through the water pipe:

- If the noise is audible in the street, it means that it is transmitted through the air. The main reason for its appearance is a poor-quality soundproof layer in the room where the pumps are located. The residents of the first floors suffer the hardest of all, the technical rooms are located directly under the apartments. Also noise in apartments is often amplified after their illegal redevelopment.

- Structural noise propagates through the structure of the building. This can occur for various reasons: illiterate installation of pumps, contact of pipes with the walls of the house, the presence of acoustic bridges (metal elements, racks, etc.), the absence of sleeves (they should be installed in the places of passage of pipes through the structure). Specialists note that when eliminating metal bridges, the sound level is reduced by 5-6 dB.

- The noise that is transmitted from the pump in the basement along the water often results from the formation of vortices inside the pump equipment housing. In addition, the promotion of sound will be the absence of special shock absorbers.

The causes of noise can be very different. They can be understood only by specialists. If you are constantly worried about sounds coming from the basement of the house, you should immediately contact the Housing department or another managing body. Experts coming to your application should conduct an assessment of the causes of noise, as well as perform work on its complete elimination (within the limits of the current standards for multi-family houses).

When the source of sounds is the heating system

Often an unpleasant rumble arises in the case of poor design or installation of hydraulic systems, as well as in the unlawful modification of standardized designs of operating pipelines in the house. There are cases when, after unauthorized redevelopment and replacement heating system in the apartment, the installation of warm floors or new plumbing there is a strong noise in the whole house. Often the reason is that after the repair, pipes of larger diameter were installed than required by the design standards. In this case, there is a vibration, which leads to the formation of noise.

Noise may also appear due to the replacement of old pumping systems with new ones. This is because the technical characteristics of the installed equipment do not correspond to the characteristics of the hydraulic system operating in the house. In addition, a small hum can also appear because the damper of the hydraulic system is loosely closed, due to which there is additional resistance and an increase in the speed of water flow through the pipes.

The abnormal movement of water through the pipes (faster or slower), as well as the incorrect diameter of the recently installed pipes, very often become the cause of the appearance of a powerful buzz, which can be eliminated only by installing a new pipeline. That's why before any repair work related to the replacement of water supply and pumping equipment, it is necessary to consult with specialists.

Pump problems creating hum

Noise in pumps can occur for a variety of reasons. This may be incorrect installation of equipment or failure of some elements. The basic sources of noise in pumps are considered to be the engine air cooling system and rolling bearings. These potential sources of noise are inextricably linked to the power of the pump motor and the speed of rotation. Here it is worth mentioning the international ISO standards, according to which the noise produced by the pumping equipment is limited depending on the two above factors.

![]()

Pumping equipment located in the basement.

It is interesting that an increase in acoustic pressure, for example, by 6 dB, based on the real sensations of a person, will be equal to an increase in noise by a factor of two. The sound produced by the pumping system is tightly connected to the speed of rotation, so the noise reduction is possible only if it is reduced. At the same time, in the case of a reduction in the rotational speed, the productivity of the pumping equipment will also noticeably decrease. This is a very difficult moment, in which only professionals need to understand.

Also, there are other reasons why noise from the pump may arise:

- damage to bearings;

- not fixed body of the device;

- cavitation with vibration and sharp noises;

- vibration, which is transmitted to pipes and building structures.

How to make the pump run quieter?

It is not recommended to do silence repair in the house on your own, because you can do everything on the contrary. If there is noise in the basement coming from the pumping equipment or pipeline, contact the management company or private specialists immediately to help you solve the problem.

Measures that can be taken:

- Installation of the regulator of the engine speed of pumping equipment. It should be noted that the installation of the regulator will really help only if the pumping system has a certain power reserve, or work at the maximum speed is required at certain times (for example, in the morning and in the evening).

- Installation of high-quality sound insulation in a room where pumping equipment operates. Very often even in modern homes, technical rooms with large equipment are isolated from noise, not enough, resulting in residents experiencing its impact.

- In those cases where pumping unit mounted directly to the foundation and move it to another place is not possible, the base must be vibro-insulated.

- You can install antivibration elements on the pipes of water supply and heating. It is the vibration of the pipes that often becomes the strongest source of noise.

- Specialists also often solve the problem with the help of vibration isolation of supporting structures of pipelines, which are attached to the fencing pillars of the house. Suspended supports must be hinged. It is also recommended to lay rubber gaskets under the pipeline.

The noise from the pump in the basement can arise due to various factors. Therefore, immediately after its appearance, it is necessary to find out the reason. Do not think that the noise will pass - if the equipment is malfunctioning or installed incorrectly, then the sound vibrations will only grow with the years.

If the pump is installed in your private home, you can find out the cause of the noise yourself. Surely it is associated with poor-quality editing. In this case, you need to contact the company whose employees installed the equipment.

Remember that constant vibrational and structural noise can lead to serious mental disorders and depletion of the central nervous system. In addition, before buying an apartment in a new house, be sure to ask your future neighbors if their technical sounds are not disturbing.

The definition of the source of unpleasant sounds and its prompt elimination is the main action plan for any conscious person. Do not tolerate constant noise from the pump, if it prevents you from comfortable living in an apartment and rest.