Check valve for water heater. Safety valve for the water heater: why you need it, how to put it.

A non-return valve is one of the most important elements of the house's water supply system. Its main function is to prevent leakage, which can cause pressure drop inside the water pipe and malfunctions in the pumping equipment operation. The flow capacity of the valve is only used in one direction. As a result, this device does not allow water to flow back to the well or well after the pump is disconnected. Such functionality makes it irreplaceable in the organization of heating and water supply.

Location and design features

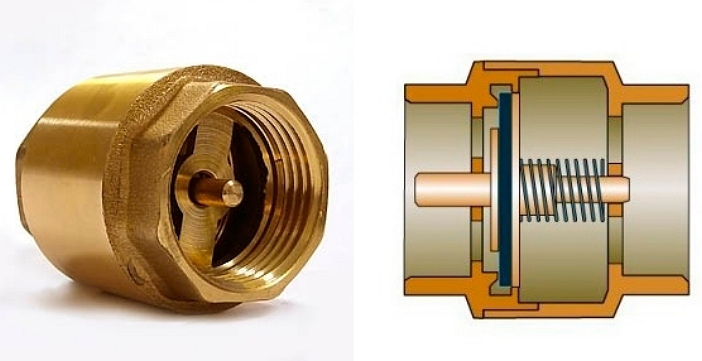

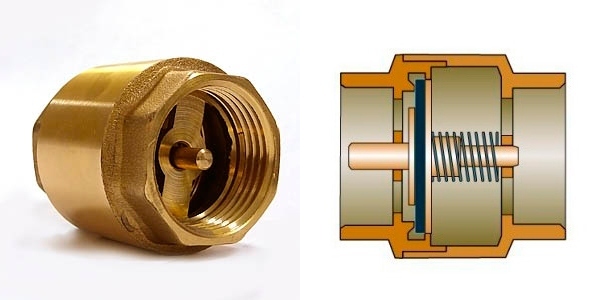

The design of the check valve consists of a spring and a circular overlapping plate, which are placed in a brass cylinder. The low spring stiffness allows flow to one side and block its movement in the opposite direction. The connection point of the device to the system can be either the inlet of the suction pipe, or the section just before pumping station.

Due to the action of the check valve, it is no longer necessary to re-fill the system with water when the pump is switched on again. This increases the service life of pumping equipment and ensures fast delivery of water to the consumer. When purchasing a valve, one should start with the diameter of the pipe into which it is planned to be placed. It should be noted that the use of this device will lead to the appearance of additional resistance to the flow of water, because of which the pressure of the pump will decrease by approximately 0.5 atm.

Correct installation of the non-return valve

The spring mechanism of the valve does not have a strong elasticity. Otherwise, due to the complete blockage of the water flow, the very meaning of its use would disappear. Unfortunately, this circumstance contributes to the fact that during the operation on the membrane and the walls of the valve, various mud deposits are formed. Clogging data over time can lead to malfunctions in the entire system. Therefore, here it is important to properly install the check valve.

For the stable operation of the heating system and the water main, it is necessary to install check valve on the water. This equipment is considered to be a stop valve, its task is to let the flow of water flow in only one direction. This function enables the wide use of this device, especially for self-priming pumps and for the installation of autonomous water supply systems.

Sometimes the check valve performs protective functions against a variety of unscheduled faults and expensive repairs during leakage. In this article, we will consider in detail the features of the choice and installation of this unrivaled device, as well as the question of how they are operated.

The device and the principle of operation

Answering the question why a check valve is needed, it is worth saying that this device does not allow the water lifted by the pump to return back to the well or well. Another advantage of using this valve is that you do not have to wait for the liquid to be displaced by the air in the hose. If the hose has already been filled with water, the feed will start immediately.

Which elements include a check valve for water:

- a dismountable body made of metal, which consists of two parts, each of which has a thread;

- metal or plastic seal with a gasket;

- spring, designed to support the bolt.

The operation of the valve is not difficult. The principle of operation of the non-return valve for water for the pump is as follows: after the water ceases to flow from the pump into the pipeline or hose, the bolt is pressed by the spring and is in the closed position. When a water pressure sufficient to wring out the spring before the valve is reached, the gate opens allowing the water to flow into the pipeline.

When the pump is switched off, the water pressure drops, the valve is again pressed back by the spring and becomes closed. In addition to the spring, the gate is pressurized with water from the pipeline side, preventing it from opening. The most popular type of check valve is for household use.

Important: according to this principle, all valves operate regardless of whether they are used with a pump on the pipeline, or without it.

Types of check valves

Check valves can differ from each other by the material from which they are made, the size, design and features of the installation. We will try to sort and classify them according to the given distinctive features.

By type of locking element:

- lifting type - in the device of this type of construction, the bolt moves up and down. During the water intake from the pump, the valve assumes an open position, when the pressure in the pipeline drops, the valve closes again under the action of the spring;

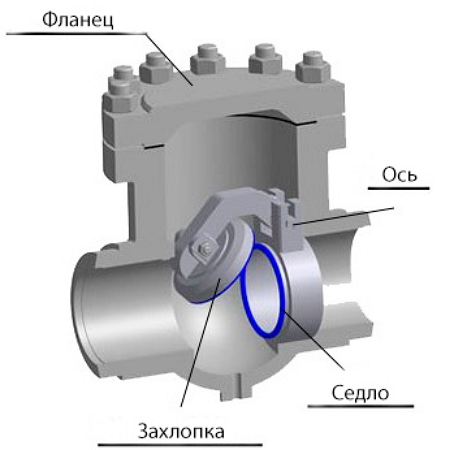

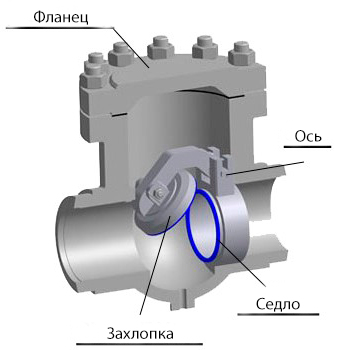

- rotary type - the shutter in the valve with such a device looks like a flap that opens when the water moves and, with the help of a return spring, closes again when the pump is switched off;

- ball type - in the valve of this type the bolt looks like a ball overlapping the passage. The ball is supported by a spring. At the pressure of water, the ball is raised and shifted, passing water into the pipeline;

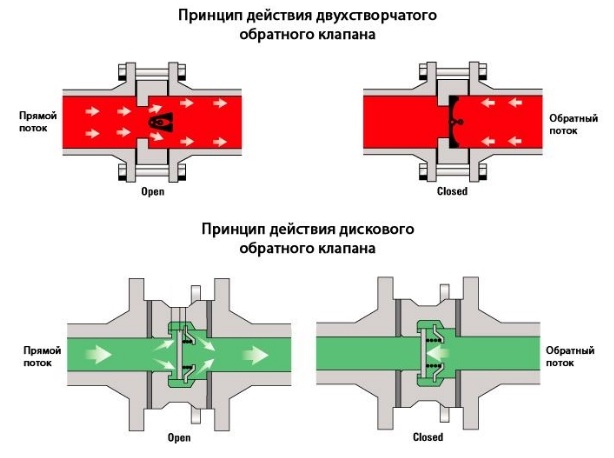

- flanged type - it is bivalve and disc. The bicuspid valve has a shutter consisting of two valves, folded when passing water and closed during its absence. The disc type of the check valve in its design has a disk gate capable of moving along its own axis under the action of a spring fixed to it.

Household water valves most often have a lifting structure, where the spring can be replaced. Since its failure is the main cause of valve failure.

According to the material of manufacture:

- from brass - reliable material is resistant to corrosion, which is quite durable and unpretentious in maintenance. It is considered to be the ideal material for domestic use;

- from pig-iron - rarely used material due to its weak resistance to corrosion and gradual fouling by deposits. Valves made of cast iron are used on large diameter pipelines. In domestic use, valves from this material are not found;

- stainless steel - valves made of this material have practically no drawbacks. They are resistant to corrosion and aggressive substances, strong and durable. The only drawback, perhaps, is the high price, but the quality of the product corresponds to the price.

Most often, the components of the check valve are made of different materials. For example, the body can be made of brass or stainless steel, usually the shutter is made of plastic, the spring is made of ordinary or stainless steel. Therefore, during the acquisition, it is advisable to ask what materials the valve parts are made of.

Tip: for domestic needs it is better to choose the brass product in view of their enough long term service and a relatively low price.

By the method of fastening:

- coupling fasteners. This way most of the check valve models are attached. The fastener consists of two threaded junctions. Their diameter is very different, depending on the diameter of the pipeline;

- flange mountings. As the name implies, the attachment to the pipeline is carried out using flanges. Most often this type of attachment is used on valves made of cast iron, which are operated on large diameter pipelines;

- wafer fasteners. With this fastening, the valves are fixed between two flanges, which are tightened by bolts. Valves with this type of attachment are also used primarily on large diameter pipelines.

To size:

- standard valves. They are used on most of the pipelines;

- miniature products, mounted inside the drums of water meters. Used in those cases where there is not enough space on the pipeline for installing a standard check valve;

- small valves mounted at the outlet of water meters;

- cast iron valves of large size, mounted on industrial or public pipelines.

Where is this device installed?

The installation of a non-return valve is done in the following places:

- at the exit submersible pump, located in the well or well. After the pump stops working, water will not return;

- at the end of the suction nozzle surface pump or pump station. After the pump set is turned off, the water will remain in the nozzle;

- at the outlet of the cold pipeline to the boiler. In this case, in the absence of water in a cold pipeline, there will not be a reverse outflow of water from the boiler;

- for different types of pipelines, especially when hot and cold pipelines are used simultaneously. Due to the difference in pressure in the pipelines, hot water in the pipeline with cold water or, conversely, through a mixer. The valve, mounted on each of the pipelines separately, will prevent its reverse outflow;

- in autonomous heating systems, when there are several separate circuits with different coolant pressures. In this case, a separate pump is installed for each circuit. If the pumps are of different capacities, it may happen that a more powerful apparatus can press the coolant into the adjacent circuit, which supplies the unit with a lower power. This is completely unacceptable, so the check valve is an obligatory part in such a system;

- on water meters, in order to prevent the movement of water in the opposite direction;

- in the sewage system to prevent backflow of waste water.

It is quite simple to install the check valve on the water yourself, it is enough to have this operation the right tool and have minimal skills in the field of plumbing.

How to choose a valve for a domestic pipeline

At the time of purchase protective device for installation on the pipeline, you need to consider several features, then the device will please the owner with its technical features. We suggest that you consider a few simple rules.

- Before you buy, carefully study the design connecting elements device. It is very important that the diameters of the pipeline and the check valve match. In current living conditions, most prefer to use coupling variants, since most of the water supply systems are assembled by this connection method.

- Analyze the principle of the non-return valve. If you do not have enough knowledge, consult the seller, or consult the documentation if the product is proprietary. If you find any malfunctions or violations from the purchase, it is better to refuse.

- If you need to purchase a ball, flange or wafer mechanism for a pump or other technical needs, be sure to compare their capabilities with the features of the environment in which they will work.

- The material from which the design is made must be selected on the basis of technical specifications water supply: for polypropylene structures, plastic is suitable. If the check valve is to be installed on a hot pipeline, the best option there will be a choice of a device made of durable metal, since most propylene structures are unstable to high temperatures.

- Brass products are an ideal alternative to all fragile structures. Products made of this material are well protected against various temperature and mechanical deformations, moreover, most designs have a ball-like mode of operation.

Attention! All devices to protect against hammering in the pipeline must be purchased with the mind, when choosing given a number of functional features, and not just the selection rules.

Installation in the main line

Installation of the non-return valve to the water in the main pipeline in the house is made after the pump (if available) and after the water meter. It should be noted that the principle of installation largely depends on the type of your chosen design.

- For coupler metal options, you can use welding or threaded connections. Both versions are quite reliable in fixing. Most experts do not note these high reliability settings, but, nevertheless, they are very functional.

- If they decided to install an inter-flange mechanism, the technology of its fastening in the pipeline between the two plates is envisaged. It should be noted that the plates should be welded to the pipes separately, the same installation method is also practiced for the pump, but all fastenings must be done strictly after the water meter.

- A ball check valve is one type of flange that works with a ball valve. Its fixing must be carried out only under suitable conditions, except it is very important to observe the working device of the non-return valve for water.

The main rule of installation is to screw the valve in the right direction. In order to facilitate this task, an arrow is placed on the body of the device, which shows the direction of movement of water through the valve.

We examined the purpose of the valve for water, its operating principle, and disassembled the varieties and features of valves of this kind. Operation of these devices can prevent accidents in heating and water supply systems, and in addition to simplify the operation of pumping stations and water pumps. Such plumbing is indispensable and always in demand.

Apr 7, 2016

Water check valves are for shut-off valves, and are designed to pass the flow of water in only one direction. This property makes it possible to widely use them, in particular, for self-priming pumps, as well as for creating autonomous water supply systems. Thus, the water return valve for the pump prevents the return of the pump-lifted water back to the well or into the well. Another convenience of using such a valve is that you do not have to wait for the fluid to displace the air in the hose. If the hose has already been filled with water, the feed will start immediately.

The device of the check valve for water is quite simple. It consists of the following elements:

- dismountable metal body, consisting of two parts, each of which is threaded;

- plastic or metal shutter with gasket;

- a spring that serves to support the bolt.

How the check valve works

There is nothing complicated in the operation of the valve. The non-return valve for water for the pump operates according to the following principle. When water does not enter the hose or pipeline through the pump, the bolt is pressed against the spring, and is in the closed position. When the water pressure in front of the valve is sufficient to press the spring, the valve opens, allowing the water to flow into the pipeline. When the pump is turned off and the water pressure drops, the spring again presses the bolt, which closes. In addition to the spring, the water in the pipeline also presses the bolt, not allowing it to open.

Important: This principle of operation has all the valves, regardless of whether they are used on the pipeline with or without a pump.

Types of check valves

A non-return valve may differ in water design, material of construction, installation features and dimensions. Let's try to classify them according to the distinctive features:

By type of locking element

Note: Household valves are predominantly of the lifting type, in which the spring is replaceable. In the event of a valve failure, its failure is the cause of the failure.

According to the material of manufacture

- of brass. It is a reliable, corrosion-resistant material, with durability and unpretentious maintenance. It is considered an ideal material for household use;

- from cast iron. This material is used comparatively rarely, as it is prone to corrosion and gradual fouling by sediments. Cast iron valves are used on pipelines of large diameters. In everyday life, cast iron valves are not used;

- stainless steel. They lack virtually all of the shortcomings. Are durable, resistant to corrosion and aggressive substances, durable. The price is set to the highest on a stainless steel check valve, but the quality of such a product is always at a high level.

In most cases, the components of the check valve are made of different materials. So, the case can be brass or stainless, the shutter is usually plastic, and the spring can be just steel or stainless. Therefore, when buying, immediately inquire what materials were used in the manufacture of the valve.

By the method of fastening

- couplings. In this way, the overwhelming majority of check valves are attached. For fixing 2 threaded junctions are used. Their diameter can be completely different, depending on the diameter of the pipeline;

- flange mounts. To the pipelines are fixed by means of flanges. These are predominantly cast iron valves used on pipelines of very large diameters;

- flange mounts. The valves are fastened between two flanges, which are tightened by bolts. Their use is also limited to pipelines of solid diameter.

To size

- standard valves. Used on most pipelines;

- miniature products inserted inside the drums of water meters. Applicable in the event that there is no place on the pipeline for installing a standard check valve;

- small valves installed at the outputs

- large cast iron valves installed on public use and industrial pipelines.

Where to install

Installation of a non-return valve to water is carried out in the following places:

It is quite easy to install the check valve on the water with your own hands correctly, because it is enough to own the minimum plumbing skills, and also to have the necessary tool. The main rule in the installation process - screw the valve in the desired direction. On the body of the device there is an arrow showing the direction of movement of water through the valve.

We have dismantled why a check valve is needed for water, and also considered the varieties and features of such valves. The use of these useful products can prevent emergencies in water and heating systems, as well as greatly facilitate the work with water pumps and pumping stations.

A non-return valve is a type of shut-off valve of direct action. It is designed to ensure the flow of water in the right direction and to prevent the flow direction from changing to the opposite direction. Protects against high pressure pipelines, pumps and other equipment, and in case of damage to individual sections it limits the amount of liquid leaking out of the system. Used in modern systems heating and water supply.

Classification

By constructive features these devices are divided into:

- Disk spring.In this version of the valve, the locking mechanism is a disc with a rod on the spring. In the presence of normal pressure, the disk is in the open position and allows a flow of water. When the pressure falls and the liquid tends in the opposite direction, it presses the disc against the seat, blocking the hole.

- Ball spring.The mechanism consists of a metal ball and a spring. In the absence of liquid pressure, the ball is pressed against the walls of the hole, blocking it. Such a device is intended for pipes with a small diameter.

- Lifting-rotary.The basis of the design is a lid fixed to the axis. With normal water movement, the lid is in the open position, with the return current - it slams.

- Lifting spools.The principle of operation is that the spring-loaded spool is pressed against the water flowing back and closes the hole.

- Bivalve. Used for large diameter pipes. Protect large systems from water hammers, soften their effect.

The basic metals from which the locking mechanisms are made are brass, cast iron, stainless steel. Experts consider brass structures to be the most suitable for household use.

Where is it installed, before or after the counter?

Since the purpose of installing the shut-off element is flow control in one direction, an arrow indicating the direction of water movement is necessarily shown on its surface.

It is advisable to install a non-return valve in the pipe section after water meters, on a pipe through which cold water enters the boiler.

In heating systems, the valve allows you to divide the contours, direct the water flow in the desired direction in each of them and prevent the already warmed liquid from getting back into the cold water supply system.

The presence of this simple and inexpensive device helps prevent serious and costly breakdowns.

Order and nuances of installation

Before installing the shut-off element after the pump, note that the power of the device will be reduced by overcoming the resistance of the spring or the shutter. But the pump does not have to constantly pressurize the system, it is created once and subsequently only supported. Thus, the operation of the unit becomes more rational.

On the water supply system, the check valve is connected in front of the pumping station, using a shift in case it is replaced, or to the suction pipe behind the ratchet.

If the device is installed on an already installed water supply system, the installation site is selected between the pump and the pumping station. It is necessary to make a rupture of the pipeline, to install one valve at one end of the pipeline and connect it with the other end.

AT sewer pipes The device is installed to prevent reverse flow of waste water and waste of life. In this way, it is possible to avoid leakage of liquid through the toilet while blocking the common sewerage. The unit is installed horizontally or vertically in an active or new sewage system, in places where there are pipes of the required diameter. The diameter of the check valve here can be from 50 to 100 mm. The connection is made using an adapter from pig iron to plastic. For tapping into a cast iron pipe, you need an angle grinder.

On a single-circuit heating system, a check valve is needed only if the flow of water in it is provided by movement due to heating, without the participation of a pump.

There are systems of parallel movement, where along with the natural flow of water a pump is used. The installation of the valve in this case is necessary.

To install the shut-off element on the water supply and heating system, tools for tapping into the pipe are required: a bulgarian for metal pipes, and a regular hacksaw for a plastic one. On the pipes of metal for the connection it is necessary to make a thread with the help of a thread-cutting tool. A non-return valve is installed using a swivel and gas wrench. After that, the pipe, to which the device is screwed, is connected to the other part with a suitable key. For connection plastic pipes special adapters are used.

If you are a little knowledgeable in plumbing and have free time, to install the unit yourself will not be difficult. Non-specialists in this matter can always delegate the work to an experienced master.

Employees of the Ministry of Emergency Measures, fire protection, housing and communal services, manufacturers of household electric heating appliances do not get tired to warn that the installation of devices must be carried out in strict accordance with the requirements for their safe operation.

Surprisingly, there are people who try to ignore the rules, simplifying the installation scheme, ignoring the installation of a special safety valve.

The explosion of an electric boiler is extremely dangerous, both for people's lives and for the building itself. And the causes of such incidents are most often the absence or malfunction of a small, inexpensive and rather simple device - a safety valve.

To understand the importance of this safety device, you need to familiarize yourself with its device and the principle of operation.

How the safety valve is arranged

The safety valve for the water heater is quite simple. Structurally, these are two cylinders with a common cavity, located perpendicular to each other.

- Inside the large cylinder there is a poppet valve, pressed by a spring, ensuring free flow of water in one direction. In fact - it's all familiar. The cylinder at both ends ends with a threaded part for connecting the valve to the heater and the pipe system.

- The second cylinder, located perpendicularly, is smaller in diameter. It is drowned from the outside, and a drainage pipe is made on its body. Inside it there is also a poppet valve, but with the opposite direction of operation.

Often this device is equipped with a handle (lever), which makes it possible to forcefully open the drainage hole.

By what principle does the valve

The principle of the safety valve is simple.

Pressure cold water in the water pipe squeezes the "plate" of the check valve and ensures the filling capacity of the heater.

By filling the tank, when the pressure inside it exceeds the external one, the valve closes, and as the flow of water again ensures its timely replenishment.

The spring of the second valve is more powerful, and is designed for increased pressure in the boiler's capacity, which necessarily increases as the water warms up.

If the pressure exceeds the maximum permissible value, the spring contracts, opening the drainage hole, where excess water is drained, thereby equalizing the pressure to normal.

The importance of normal operation of the valve

Perhaps the description of the device and the principle of the valve did not fully clarify the issue of its extreme importance. Let's try to simulate the situation, which can lead to his absence.

So, let's say at the entrance to the heater there is no valve blocking the return flow of water supplied to the tank.

Even if the pressure in the water supply system is stable, the device will not work properly. Everything is explained simply - according to the laws of thermodynamics, when the water in a tank with constant volume is heated, pressure necessarily increases.

At a certain point, it will exceed the supply head, and the hot water will be discharged into the water supply system.

At a certain point, it will exceed the supply head, and the hot water will be discharged into the water supply system.

Hot water can go from cold taps or enter the toilet bowl.

The thermostat in this case continues to work properly, and the heaters consume expensive energy for nothing.

Even more critical is the situation, if suddenly the pressure in the water supply system falls for some reason or another, which is practiced quite often, for example, when the load at water stations at night is reduced.

Or if the pipes are empty as a result of an accident or repair work. The contents of the boiler tank are banally merged into the water pipe, and the heating elements warm the air, which inevitably leads to their rapid burning out.

It may be objected that the automation should prevent the heater from idling. But, firstly, not in all models such a function is provided, and secondly, and automation can fail.

It may be objected that the automation should prevent the heater from idling. But, firstly, not in all models such a function is provided, and secondly, and automation can fail.

It would seem that to avoid such situations, you can confine yourself to the installation? Some "clever" do so, not realizing to the end, that by this they literally "pawn the bomb" in their dwelling.

It's scary to imagine what could happen if the thermostat fails.

The water reaches the boiling point in the tank, and since there is no way out of the closed volume, the pressure rises, and at an increased pressure the boiling point of water becomes much larger.

Well, if it ends with the cracking of the enamel on the inside of the tank - this will be the least evil.

When the pressure drops (crack formation, open valve, etc.), the boiling point of water drops again to normal 100 degrees, but the temperature inside is much higher.

Instantaneous boiling of the entire volume of liquid takes place with the formation of a huge amount of steam, and as a result - a powerful explosion.

All this does not happen if an operating valve is installed. So, we summarize its direct purpose:

- Do not allow the return flow of water from the heater to the water supply system.

- Smoothen possible pressure jumps in the water pipe, including - hydraulic shocks.

- To discharge surplus of a liquid at its heating, keeping thus pressure in a safe framework.

- If the valve is equipped with a lever, it can be used to drain water from the heater when carrying out maintenance work.

How to install the valve on a water heater

Choose the model you need

As a rule, good boilers are supplied to the consumer with a complete safety valve of the required parameter.

As a rule, good boilers are supplied to the consumer with a complete safety valve of the required parameter.

If not, or if you need a replacement, you will have to buy it yourself. They are inexpensive, 250-400 rubles depending on the model.

If there are no special problems with the threaded part (almost all valves have a ½ inch thread), then the working pressure of the valve is the value that is paid special attention.

The correct pressure value should be specified in the operating manual for your heater.

If you buy a valve with a lower pressure rating - it will constantly flow from it. If you choose a value higher than the allowable value - the valve may not save you from big trouble when the boiler overheats.

How to install correctly

- Before installing the safety valve for the boiler, the appliance itself must be disconnected and the water drained from it.

- The valve is installed at the inlet of cold water into the heater. The process is simple - the usual "wrapping" with a 3-4-turn key, using seals (fum-tape or pakli, as someone likes). The second threaded end is joined to the cold water system.

It is mandatory to check the direction of incoming water - on the valve body it is marked with an arrow.

- If the pressure in the water pipe is not stable, it can be excessively increased, it is better to put a water reducer before the valve.

- Not everyone likes the fact that from time to time water leaks from the valve. It is quite normal phenomenon, saying that the device is coping with its direct task. It will be reasonable to connect the drainage pipe with a flexible hose with a sewage system. The hose must be transparent so that the valve can be visually evaluated.

Sometimes attempts are made to hide the valve from the eyes, placing it away from the heater. This approach is also possible, but under two conditions:

- It is strictly prohibited to install shut-off devices between the valve and the boiler inlet.

- A long vertical section of the water pipe will in itself increase the pressure on the valve, and absolutely unnecessary "idle" leakage can begin. In any case, between the valve and the boiler should be no more than 2 meters.

What if the water flows through the drainage pipe is too abundant, even without much heat?

Perhaps the pressure in the water pipe is too high (although this is extremely rare) - in this case the installation of the reducer will help.

It should also be checked - it is possible that a valve with a too low pressure indicator, which does not correspond to the heater model, was purchased. If everything is still normal here, then the valve spring has "sat down", and it should be changed.

More worries should be caused by the fact that the valve is always and under all circumstances dry.

If even at the maximum heat, water droplets never showed up from it, with a high degree of probability it is possible to talk about its malfunction, clogging or jamming. It is better not to take risks, and get a new one.

Uncomplicated installation of this absolutely inexpensive device and secure the life and health of the owners of the house, and keep their property, and prolong the period of accident-free operation of the water heater.