Pipes for water supply in the ground. Correct laying of water pipes - long life of the pipeline

Pipeline laying is the work that almost any owner of a dacha or a country house. The fact is that surface installation of water pipes or heating is allowed only in unsuitable areas where the construction does not bother anyone or where there is no possibility to place the system underground. In all other cases, an underground installation is assumed.

How to lay a water pipe under the ground

The main problem with the transfer of liquid, especially hot - loss of heat when moving. Because of this, underground laying is recommended: air losses will be much higher, while the ground conducts heat worse. In practice this, of course, is not enough and the pipe to the ground is laid with a heater.

Apply for this quite familiar materials - basalt cotton wool, foam polyethylene, expanded polystyrene. The thickness of the thermal insulation layer is calculated taking into account the weather. In some cases, even the use of a heating cable is allowed.

The second mandatory requirement is the determination of depth. The pipeline should be located below the freezing level of the ground. Otherwise, the risk of freezing of water and, consequently, damage to the system are great. For average regions, the freezing level is about 1.4 m. The optimal depth for the water supply system is 1.6 m. Great depth is not recommended, since the product can not withstand the ground pressure, especially in the case of HDPE waterways.

The pipeline is placed in the ground in a ready-made form - assembled and insulated, so that all welding work must be completed before installation.

The very same technology of waterpipe assembly is simple, if the circuit is correctly designed.

- Complying with the plan, dig a trench to the desired depth. The width is small: for one HDPE waterway. for example, 40-50 cm is enough.

- Most often in private construction, an opening crane is installed in a well. Sometimes a water meter is installed there. In the wall of such a well a hole is made, equal to the dimensions of the water conduit, and the collected and thermally insulated pipeline is lowered into the well.

- If the meter is placed in the well, it will be correct to immediately bring the gander down. The meter itself is mounted in front of all the cranes.

- The water pipe enters the house at the same depth that it is located in the trench. Installation is only allowed inside the building.

- The trench is filled with sand until a layer of sand 5-10 cm thick is formed above the water channel. Then the trench is filled with soil.

How to lay a water pipe under the ground, the video can be found in detail.

In those cases when an obstacle arises in front of the well - a road, for example, which is not uncommon in a country house where many people use a well, the question arises as to how to lay a pipe underground without digging. This technology exists, but in practice in most cases it is cheaper to lay a trench.

To lay the pipeline without digging, it is necessary to bring the usual trench to an obstacle. Then they set up the notches on the bottom of the trench and fix the supporting area from the bar. The soil in the desired area is pierced by a 3-meter solid barbell. The bar rests against the jack, the latter rests on the platform. So you can pierce the site under the road without digging.

![]()

Laying the heating system

The heating pipe can be laid underground in the same way as the water pipe. But to the above requirements, a few more are added:

- it is allowed to place heating pipes above the freezing level. But in this case, the insulation should be much better and a protection against freezing of water is provided. Lay the system below the freezing level in the end is always cheaper;

- the return pipe must in no case be higher or level with the supply;

- it will also be appropriate to provide additional protection against ground pressure, especially in the event of danger of movement or high groundwater.

Thermal insulation materials for heating water conduits are the same. On the picture - heating system in the "shell" of expanded polystyrene.

Most of the communications are laid underground. The reason is simple: the ground is a safer environment than air. The volume of groundwater is much less than the amount of precipitation, the effect of temperatures is noticeably weaker, and the pipeline located in the ground is much more difficult to damage than the one located on the surface.

Which of the water lines is best used depends on many factors.

Water pipes: varieties

At the dacha owners have to deal with the arrangement of cold water supply and extremely rarely - hot. Usually, country plots are removed from the city and this kind of communication is not available here.

For filing cold water the following products can be used.

- Steel water pipe - high strength, affordable cost and low coefficient of thermal expansion provide the metal rolling product with unconditional leadership in the supply hot water and heating - if it comes to highways. When servicing dwellings, shortcomings often become the reason for refusing to use them. The heavy weight, complicated assembly, the reduction in the working cross-section lead to the search for an alternative over time.

The propensity of steel to corrosion when laying systems under the ground is a secondary factor: the corrosion rate is 0.1 mm per year, which ensures a service life of about 45-50 years.

- Plastic plumbing - in the category includes all products of polyethylene, polyvinyl chloride and polypropylene. In most cases, the material is not indicated in the labeling of such a pipeline, since it is more important specifications. Unconditional advantages include ease, flexibility, which allows you to build a system of high complexity, complete chemical inertness, high throughput. The disadvantage is a low mechanical strength, which when placed in the ground does not matter.

Another disadvantage is the instability to high temperatures, where it is more unpleasant. But since the dacha usually requires running water for cold water, this defect is neglected.

- Metalloplastikovye - polymer pipes, reinforced with aluminum. In strength, they are superior to plastic, as well as resistance to temperature. Products can be safely applied for hot water and heating systems. However, the cost of the reinforced pipeline is much higher. In the photo there is a sample of products.

Which pipes are better for water supply

Many factors are important for the arrangement of communications at the dacha: the distance from the source of water and its nature - well, main line, soil quality, depth of occurrence, water consumption and so on. All this must be taken into account.

Water source

- If the water pipe is connected to the central highway, the only thing to consider is the availability of existing communications. The pipe into the ground is laid to a depth below freezing of the ground. This is a prerequisite.

- Water supply from the well is rarely possible to place under the ground, and even at the required depth. In this case, the pipeline must be insulated. Preference is given to steel, since they are much more resistant to cold.

Nature of the soil

- Sandy, clayey soils are fairly light and loose and do not exert significant pressure on the pipeline. Plastic and metalloplastikovye water pipes of the appropriate diameter and with the required wall thickness are coping well with the task.

If it is necessary to install a relatively large diameter water pipe, it is better to choose corrugated products. The stiffeners increase the strength of the material, without loss of elasticity.

- The rocky ground is much more demanding. It is rare, but the soil prone to progress is a common problem. Steel conduits are required here, since plastic ones will not withstand such a strong pressure.

Depth

Plastic water pipes are produced with a different class of rigidity, which allows you to choose the optimal solution.

- SN 2 - Underground laying at a depth of up to 2 m is allowed. At the dacha this option is realized most often.

- SN 4 - installation is planned at a depth of 3 m. Both smooth and corrugated water conduits are used.

- SN 6 - maximum depth of 8 m.

- SN 8 - the water pipe can be collected underground at a depth of 10 m.

Steel water pipes do not have any depth limitations. You just need to pick up a product with sufficient wall thickness.

You always pay a fee for living in your own home, enjoying peace and quiet, and working to improve your home. Now the conversation is about different systems that provide life comfort and responsibility of their organizer and owner. If you live in apartment house, then everyone will do everything for you, but if you have a private household, be kind, answer for everything yourself. A typical example is the water supply system. What is its efficiency and function under different climates? The answer to this question is very simple, everything will be fine if you have paved it in the ground competently and according to the rules. How to properly produce and install an autonomous water supply system in a private household? That's exactly what we'll talk about in our article.

The first beginnings in the works on laying

First of all, always to begin with, create a layout scheme, the so-called project, It certainly will not be the creation of the greatest architect with the inherent style and accuracy of the image. But, nevertheless, there must be important data, and first of all, you need to pay attention to the following.

- The laying of a water main in the land depends on the type of soil in the area, loose or soft.

- The total size of the entire section, on which the pipe for the water pipe will be laid, is the one that makes it clear what the approximate number of "input holes" and forks will be.

Important! Before laying the water supply, you must.

Pipes, what material is best used?

How deep to bury the pipes? This is a constantly burning question that constantly hangs in the air and the minds of people who want to spend everything with their own hands. The correct conclusions should be made, first of all, by correctly determining the type of pipe. It is their individual characteristics and qualities that are completely unique when a pipe for a water pipe in the ground is laid. Time-accumulating skills show that the best way out of the situation is the "PN10 PND" pipe. If you say in plain language, this is a material made up of polyethylene, with low pressure, which is quite suitable for laying pipes for drinking water.

Those. Characteristics of this type of pipe.

- Do not undergo various kinds of corrosion, in contrast to metal.

- Hold a pressure of about 10 atmospheres.

- Very strong, this and unique.

- Very easily and easily bend in different directions.

- During the winter period, behave quite predictably and very well all endure.

Structuring the soil directly affects the quality of the ditch.

Attention! There are tubes of the "PN 6" brand, they are certainly more economical, but do not waste your nerves buying cheaper goods, because during use there will always be nuances and problems.

Special pipe for laying water in the ground

In addition, pipes of the first kind of "HDPE" are assembled very quickly, and their fittings are not that expensive. We do not ask you to do a certain water supply directly from our article, any option you can consider and read, everything will be as you decide, and what you will have the means and capabilities for this.

Laying a water pipe in the land price: The average cost of laying 1 m / p of water pipes from pipes HDPE do 50mm open method - 2000 rubles / 520 hryvnia / 60 dollars.

Definitions of normative documents

So, first of all we address to SNiP, that would not once again think about what depth should be at the water pipe. This documentation defines, first of all, any technical nuance, down to the depth of the ditch for bookmarking street pipes conducting water. In view of the developed regulatory legal acts, the depth of the pipes must be at least one and a half meters. Moreover, this instruction has every reason behind it:

- Most often, the ground freezes to 1.4 meters, and if the ditch is made less than 1.6 m, this can lead to freezing of water in the pipe and the impossibility of using the water pipe physically almost throughout the winter until the thaw.

- The way your territory freezes depends on your location. Better consult, at some construction company in your city. They usually dig in the ground all year round, and it is in this view that you can all accurately explain what the depth of freezing is, and what is better to do.

Attention. At a level deeper than 1.6 meters, the temperature is stable.

Some problems and nuances during the laying of plumbing in the ground

Usually the biggest trouble comes when the soil structure can not allow you to go deeper to the right distance. What do we do? We tear it all to the maximum, as far as possible. Next we lay pipes, but before that we make good thermal insulation. And, in the final analysis, an important aspect that is mandatory for the normal and proper functioning of the water pipe is the installation of heating cables, along the entire length of the pipeline system. Of course, such a version is very, very costly thing, and even the silenok takes a lot during installation. But, ultimately, this is the best option, given the conditions.

Buyers are increasingly choosing pipes on a polypropylene basis. The products are highly demanded that provide operational characteristics, no problems with installation, an affordable cost indicator.

Producers say that they serve not less than 50 years. Enough and minimal skills in order to perform such work as laying a water pipe from polypropylene pipes in the earth.

The first stage in any installation of the water supply system is to dismantle the sections of the old pipeline. Steel products often require replacement in full.

The first stage in any installation of the water supply system is to dismantle the sections of the old pipeline. Steel products often require replacement in full.

Mounting with the help of Bulgarian is the most convenient and simple solution. After this, proceed to laying polypropylene pipes of a new water pipe.

Rules for laying in the ground with your own hands

GOST says that for laying in the ground, pipes are required to have diameter not less than 32 millimeters. For convenient and quick installation a set of fittings is purchased.

This sequence of actions is performed,.

Normative documents: conditions and requirements of the pipeline

Norms determine the laying of any pipeline, regardless of what material it is from. Many technical issues are regulated in the so-called SNiPs.

They provide security, allow you to carry out any kind of work. Here are a number of requirements that must be fulfilled for laying in the ground.

- Accounting is required for the point at which the ground freezes. Its level is often 1.4 meters. In winter, the water inside the aqueduct simply freezes, if it is below. The operation of the water supply will become impossible.

- The gasket and its method will vary depending on what structures and structures are already present on the territory. And on the availability of highways, communication networks, trails. It is better to turn to specialized firms, if there is no complete certainty about where to conduct the installation.

- The features of the ground and relief are important for those who are laying water under the ground.

Possible problems

Sometimes it happens that the structure of the ground does not allow digging the earth at the required depth. Or ground freezing of the earth occurs with such force that the water pipe is damaged.

But the output can always be found. For example, to make a puncture if the earth is caught too loose. First, a steel pipe is laid in the hole, and a polypropylene pipeline is installed inside it.

Anti-frost protection - heating cables placed along the entire length. But such work is associated with additional costs.

Trenchless methods of laying, finally, will be an excellent solution for those who have encountered an obstacle that can not be bypassed.

Features of trenchless laying

Trenchless installation gives owners several advantages at once.

- There is no need to destroy buildings or plants that stand in the way.

- To a minimum, damage is done to the environment.

- Time and financial costs are reduced.

There is more than one method.

- Sanitation. It means that old pipes are changed to new ones. Works are carried out in two ways:

- Relining. Inside the old pipes lay a new, polypropylene. The main thing is to see the pipeline in advance. The main thing is to make sure there are no foreign objects and debris. It is also important that the diameters match each other.

- Renovation. A new pipeline is being laid and the old one is being destroyed simultaneously. It is carried out in situations where the original diameter is insufficient.

- Piercing. Actual for diameters over 150 millimeters. The work has several stages.

- Two excavations are dug from both sides of the object, under which we will conduct communication.

- Place hydraulic jack on one side. He pushes a polypropylene tube with a steel tip.

- The pipe gradually increases volumes, and then polypropylene products are introduced into it.

- Connection to all systems.

But the latter method is suitable only for those who are interested in laying small lengths of water pipelines.

What about warming?

But additional protection is often required when laying outside.

For this purpose, for example, special cases are used. The existing water pipe is laid inside another pipe, with a small diameter. What contributes to the formation of an air cushion between the walls of different products. Thanks to this, the heat of the water is preserved.

Either the pipeline is simply poured using polystyrene concrete or foam concrete. This is a monolithic layer, with a base in the form of concrete with a small weight and a porous structure.

Or a heating cable. The latter is laid both inside and outside the structure. The gasket is recommended to be carried out in two ways:

- Two lines parallel to each other.

- Spiral, around the aqueduct.

Not every system is designed in such a way that the pressure in it without problems increases. But this method of protection is able to boast of efficiency.

When stored internally high pressure, the liquid does not freeze. Even if there is no physical insulation.

When installing outdoor non-pressure varieties of sewer use the so-called connection in the socket. The main thing is the absence of impurities on the plastic, then the connections will get high tightness. Silicone or liquid soap lubricates the parts requiring joints.

Sealant treatment will provide additional protection during such work as laying a water pipe made of polypropylene pipes in the ground.

Only compliance with all the requirements and technologies will allow obtaining a water supply that will function for a long time. And will help reduce operating costs.

We are engaged in the installation of filters

If there is no scales or sand in the water, then much longer live items such as fittings on toilet bowls, washing machines with automatics, mixers from ceramics.

It is enough to install the simplest filters, with rough cleaning. Without water treatment filters, it is not advisable to lay the polypropylene pipes by oneself.

Do not give preference to filters that are parsed manually. Inside such structures are rubber seals, whose durability leaves much to be desired.

The preparation process depends on which type of pipe you have chosen. If it's galvanized, then we use the Bulgarian to cut the blanks of the sizes we need with our own hands. You can also do this with a hacksaw.

Metal-plastic or polypropylene products are more convenient to cut at once in place. Even small misses in size will not be terrible.

When joining, preference is given to two methods. For example, through a collector that plays the role of wiring for individual devices, when each of them has its own reinforcement. Or through a simple tee.

We work with steel products

With appropriate tools at hand, for example, such as welding, it is used to connect the structure from metal.

Stationary water supply system in a private house usually placed in the earth's thickness so that it does not take up space on the site and has a relative protection against cold and mechanical influences. For uninterrupted water supply during the winter period, it is necessary to conduct a warming of the water pipe in the ground. There are several well-proven solutions to this problem.

Underground water freezing occurs because of the negative soil temperature. One way to prevent the problem is to hold pipes at a depth where minus temperatures are unattainable.

If this requirement has not been met, it is necessary to take other measures to solve the problem of uninterrupted water supply.

As a result of the freezing of the water pipe, pipe rupture often occurs. If they are located in the ground, then their replacement will take a long time

Basic provisions of normative documents

According to paragraph 11.40 of the Code of Rules SP 31.13330.2012 the depth of the laid pipes, counting to the bottom, should be 0.5 meters more than the calculated depth of penetration into the ground zero temperature. This is necessary to prevent the formation of ice stoppers in the pipeline and the rupture of pipes in the places of crystallization of water, which increases with freezing in the volume.

The calculated depth, according to paragraph 11.41 of the same rules, should be established by field observations of the soil freezing contour, and also guided by the experience of operating pipelines in the area. Such information can be owned by the hydrometeorological center or organizations involved in water supply. In the absence of full-scale data, it is necessary to determine the depth by heat engineering calculations.

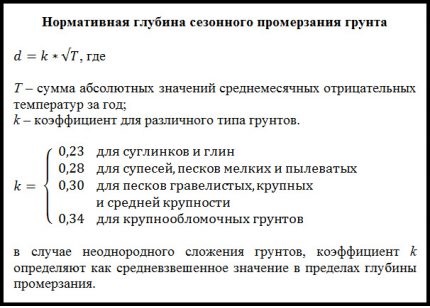

According to clause 5.5.3 of the code of rules of SP 22.13330.2011, the normative depth of seasonal freezing of soil in the absence of data of long-term observations should be determined on the basis of the heat engineering calculations presented in the figure below. The mean monthly air temperature human settlements entities Russian Federation should be taken from Table 5.1 of the code of regulations SP 131.13330.2012.

The value of the calculated normative depth of seasonal soil freezing depends on the type of soils and climatic characteristics of the cold period for this area

In case of exceeding the value of 2.5 meters, as well as for mountainous areas with a sharp change in terrain, climatic or engineering-geological conditions, it is necessary to determine the normative depth of soil freezing according to the formulas of Appendix "D" of the code of rules SP 25.13330.2012.

The estimated freezing depth according to paragraph 5.5.4 of the code of rules of SP 22.13330.2011 for areas with non-negative average annual temperature values is determined by multiplying the normative value by a factor of 1.1. For territories with negative values, this value is calculated according to SP 25.13330.2012.

Protection against low temperatures

It is not always possible to completely or partially lay the water supply system below the zero isotherm. Sometimes this can not be done for technical reasons, for example, when the withdrawal of a water pipe from a well is above the boundary of the freezing zone of the earth.

The depth of the freezing level is determined in accordance with the climatic characteristics of the region in which the water pipe is constructed. For the average strip, this value is 1.0 - 1.3 m depending on the type of soil, in the regions with severe winters, the depth of the pipe placement will, according to the rules, be more than 2.0-2.5 meters, which is very expensive as for laying, and in case of need of repair.

In areas with cold and prolonged winters, the depth of the trench for laying the water supply can be more than 2.0-2.5 meters, depending on the type of soil in which the pipeline is laid

If it is impossible or costly to locate a water pipe at great depth, other measures are used to ensure its smooth operation. They can be divided into two categories:

- Warming. Designed to reduce heat loss by the object per unit time. It is carried out with the help of materials having low thermal conductivity.

- Heating. Designed to increase the temperature of the object. An external heat source is needed to perform this procedure.

The choice of the option of warming or heating the external branch of the water supply depends on the operating conditions, temperature regime, system geometry, ease of work performed, as well as the efficiency, cost and reliability of the solution.

Ways of warming external water supply

There are many ways of warming the street water system located in the ground. If only cold water is supplied, then due to the small difference in temperature, the thermal conductivity of the materials used is not as important as their durability, strength or price.

For hot water supplied in vacation home centralized network, insulate ground routes. Due to the large temperature difference between hot water and the environment, the thermal conductivity of the material is given great attention

Using simple techniques

In the event that the pipes are located almost at the boundary of the freezing zone, then to exclude the possibility of stopping the water supply, you can perform elementary actions that do not require large investments and skilled work.

For southern regions where the depth of the water pipe is small, it is enough to excavate the pipes in autumn, fill them with environmentally friendly insulating material and again dig in a trench. For insulation, you can use leaves, straw, shavings or sawdust. They have low thermal conductivity, but by the next winter they will have time to rot in the ground, so this procedure should be repeated annually.

If, according to the calculations, the pipes are located slightly above the level allowing to guarantee the non-freezing of the system, instead of deepening the water pipe, the problem can be solved by raising the zero isotherm. This can be done in two ways:

- increase the thickness of the earth's layer by pouring it from above;

- to use for warming the fallen snow.

In both cases, the center of the strip of land or snow is located along the aqueduct, and its width should be at least twice the depth of the pipe laying.

Snow is a good natural insulation. Even a 30-centimeter layer of it can cut twice the depth of freezing of the earth

Filling the land will change the landscape of the site of the adjacent territory, and insulation with the help of plant and wood waste or snow must be carried out constantly. Therefore, for a long-term and reliable solution of the problem of water pipe insulation, special developed materials are used.

The water pipeline, laid below the seasonal freezing point in the region, is insulated only in the area passing through the thickness of the winter-frozen rocks. Thermal insulation is arranged from the specified level before entering the pipe into the house.

If the water pipe is brought into the house through an unheated cellar, located below the depth of freezing, then the insulation is carried out within the basement. Then a wooden box is arranged around the water pipe, and the space between it and the pipe is filled with sawdust or basalt cotton wool.

Types and forms of materials

To insulate the water pipe use materials that are presented in the form of shell - shaped, repeating the contours of pipes and units of the system. They are made of basalt cotton wool, glass wool, foam plastic, extruded polystyrene foam, polyurethane foam, foam glass.

In the case of using mineral wool and glass wool, an obligatory condition for underground laying is the presence of a foil sheath. It prevents the wetting of the insulation, because of which the insulating properties of the material are practically destroyed. Replace the shell can be winding pipe with a basaltic insulation of roofing material.

Because of its ability to absorb moisture without hindrance in the construction of underground networks, cotton wool insulation is not used in the form of mats cut into slabs or folded into bales without waterproofing external protection. An exception can be the laying of the pipeline in concrete trays with the backfilling of free space between the tray and the claydite pipe or similar material.

The presence of a structural seam in cylindrical heaters based on glass wool allows you to easily install the product on the water pipe

Thermal insulating shell is a ready-made billets of cylindrical shape, whose internal diameter coincides with the outer diameter of the pipes. Products, from 60 cm to 2 meters in length, consist of a single tube with a structural seam, if the insulation material is elastic or from several (more often than two) sections. The main advantage of the sectional material for insulation is the ease of mounting the product.

The joining of the halves of the relatively thin shell occurs with the application of the edge of the element to the next element to avoid the formation of unprotected sections of the pipeline. The displacement of meter lengths, as a rule, is 15-20 cm. If it is necessary to use a thickened heater, it is better to choose a shell with a chamfer facings along the end edge. The second variant of providing tight joints consists in some displacement of the parts of the shell relative to each other.

To form strong shell connections and increase the rigidity of the heat-insulating structure, portions of the shell are advised to slightly shift relative to each other

When fixing the parts of the shell, use sanitary tape. Protection of abutting of pipe branches, turns and other nodes of the system takes place by means of special shaped shapes.

Thermal insulating paint and spraying with polyurethane foam

One of the additional solutions to prevent the freezing of the external water main in the ground is liquid or sprayed heat insulation. This method allows you to reliably, without seams and cold bridges to protect areas with complex geometry, for which it is difficult to use standard materials for insulation.

Polyurethane foam has a liquid consistency and is applied to insulated objects by spraying. Possessing one of the best indicators for thermal conductivity, as well as a number of other positive properties, this material is characterized by a serious minus: special equipment is needed for its application.

Find firms that deal with thermal insulation with polyurethane foam is not difficult, since it is actively used at various sites. However, all service providers have restrictions on the minimum sputtering area, so it is unlikely to find an affordable option solely for the 10 or 20 meters of the pipeline.

Penopoliuretan is one of the best insulants for underground water supply. However, its spraying is a technologically complex process, requiring expensive equipment, adherence to safety and professional skills

A special heat-insulating paint for insulation of pipes similar to polyurethane foam can be applied by spraying. It is sold in cans, so this procedure is easy to perform on your own. There is also a variant in a liquid form, which allows you to paint the elements of the water pipe with the help of an ordinary paint brush.

Thermal insulating paint contains additives in the form of ceramic microspheres, foam glass or perlite. The thermal conductivity of this material is rather low, but due to the thin layer of application, it alone may not be enough to solve the problem of warming the section of the water pipe that crosses the thickness of the freezing ground.

Due to the high cost of applying a thick layer of heat-insulating paint is expensive. Therefore, its use for insulation is justified only in areas with complex geometry or in places where cold bridges may occur.

The use of heat-insulating paint is justified both for outdoor and for unoccupied basements or in the ground areas of the water supply system of complex geometry

However, in the case of using steel pipes, the use of paint along the entire length together with another heater may be appropriate for another reason. The presence of a porous material in the composition leads to a high adhesion index, eliminating the possibility of external corrosion, which is relevant for metal structures located in the ground.

Complete integrated solutions

The problem of freezing the street branch of the aqueduct is very relevant. Demand creates supply and, therefore, there are a large number of ready-made integrated solutions in the form of thermally insulated pipes and connecting elements. They are pipelines surrounded by a heater, which is enclosed in a hard shell.

There are both single-tube and two-pipe versions of a ready-made insulation solution for external pipe laying. For conventional cold water supply the best option The constructions containing plastic pipes are. They are cheaper than a metal analog and are characterized by a high speed of installation.

Insulated HDPE pipes are supplied in bays up to 200 meters long. Laying of water supply systems on their basis can be performed with a minimum number of joints. If the corrugated material is used as the outer shell, it is possible to conduct the pipeline without the use of corner joints. This is possible due to the ease of making small-radius bends of all parts of the kit.

There are ready-made integrated solutions for the warming of water supply systems. Variants with one and two pipes of different diameters are available

Protection of the heater against negative factors

Protection against freezing of the water pipe located in the ground has its own specifics. The material should not completely or partially lose its thermal insulation properties under the influence of external factors. Re-warming or repairing the outer layers requires expensive and time-consuming excavation, so you need to immediately take care of preserving the integrity of the protective structure.

Destructive impact of land and water

Underground water pipe tests ground pressure, therefore the material used for insulation can be crumpled. This can significantly increase its thermal conductivity. To prevent such a development of events it is necessary to create a solid outer shell with the help of pipes of larger diameter or special trays.

Mineral cotton wool is hygroscopic and can be crushed by a small effort of fingers, so the earth layer compresses the material and it will lose the property of low thermal conductivity

In the case of hygroscopic materials as a heat insulation of pipelines, it is necessary to prevent the possibility of influencing them groundwater, always located in the earth, regardless of the degree of water saturation of the soil.

For the protection of mineral and glass wool, additional means of protection are used - plastic pipes larger than tap water, which simultaneously solves the problem of crushing insulation. You can also use the following materials to create a waterproofing shell:

- rolled aluminum foil;

- reinforced (sanitary) adhesive tape;

- ruberoid;

- polyethylene film of high density.

Polyfoam, extruded polystyrene foam absorbs moisture poorly, but eventually they also become unfit for permanent defrosting. Foam glass, polyurethane foam, and also heat-insulating paint are not subject to collapse and moisture.

The protection of objects located in the ground from the impact of moisture with a roofing felt is a long-used, but not the most practical option

Solving the problem of insects and rodents

Another reason for damage to the warming of the water pipe can be rodents and insects. The ants gnaw through numerous attractive moves in attractive thermal insulation, and the mice use it to build a nest. These actions expose parts of the pipes, which adversely affects the quality of insulation.

Neither insects nor mice can spoil polyurethane foam, foam glass, but perfectly straighten out with basalt wool. Her and similar materials for external insulation of water pipes must be protected from rodents if they are located at a depth of less than 2 meters. Earth ants do not penetrate below 1 meter, and the forest at the same time build a large anthill, the elevated part of which can not be overlooked.

To protect against rodents, it is possible to wrap the insulation with a metal fine mesh net. To prevent access not only to mice, but also to the ants, it is necessary to wrap the material with aluminum foil, reinforced tape or use as an outer shell plastic pipes or trays of any shape.

The shell of polyurethane foam or foam glass withstands soil pressure, the impact of moisture in the ground, and can not be spoiled by rodents and insects

Heating of external water supply systems

If we consider any system, then thermal insulation is just a way to increase the time it takes to reduce its temperature to a value corresponding to the environment. Therefore, sometimes you have to resort to another option to prevent the freezing of the water pipe - heating. Water heating occurs at the expense of external energy sources and there are several ways to organize this process.

Organization of water circulation

The simplest source of additional thermal energy is water, the temperature of which is higher than in the insulated section of the water pipe. If the warmer water constantly replaces the chilled water, the system does not freeze. For this reason, the method of the "slightly open faucet" works, when a slow but steady flow of liquid through the pipes is organized.

For cold water supply of individual housing it is possible to organize periodic replacement of water in outer branch to a warmer one. In the case of supply from the main water supply, it is often necessary to produce a discharge in small portions to ensure replacement of the liquid. It is rational for this to use the special capacity located in the house, which also functions as a settler, from which to collect water for its needs.

Drain water to prevent freezing can be at a time when it is not necessary. Use it later will allow the storage tank

If the supply is organized from wells in which the water temperature is usually 7 to 10 degrees Celsius, it is often necessary to turn on the pump. To store water, you can also use a conventional storage tank or a hydraulic tank.

It is possible, with the help of a second pipe and a three-way valve, to organize the circulation of the liquid, draining it back into the well. At a time, it is enough to pump 1,5-2 volumes of a piece of water pipe, located in the ground between the head of the well and the entrance to the house.

In the case of water withdrawal from the well, there is also a variant with drainage by gravity back after stopping the pump. This method is inexpedient to use in the case of metal elements of the water supply system. The constant change of liquid and air leads to intense corrosion of the internal surface of the pipes and deterioration of the quality of water.

If there is a possibility of prolonged downtime of water and, as a result, its freezing, then despite the warming, it is necessary to use other methods of heating.

Using an electrical cable

Most often, as an additional source of heat for an individual water pipe located in the ground, electrical cables. They can be placed both inside the pipe that feeds water, and on its external surface. The principle of heating is to transform electric power in the thermal one.

The electrical cable heats the elements of the water pipe, the heat from which is transferred to the water. External insulation prevents heat from leaving the ground

The cables located inside the system have a higher efficiency than the external ones due to the direct heating of the liquid. The disadvantages of such an arrangement of the cable include:

- higher price per running meter due to compliance with environmental requirements;

- complexity, and sometimes the inability to conduct through the curved sections of the aqueduct;

- imperative recommendations of specialists to make connection through the RCD, despite the certificates of compliance with the increased requirements of electrical protection.

Mounting both options is approximately equal in complexity. The cable passing inside the tube is sold complete with a special end clutch. Its connection is made through a standard tee. The outer cable is fixed with aluminum tape, and from above necessarily insulate the shell, so that energy does not go to the ground.

Complete with a resistive cable that emits a constant amount of heat, to save energy, it is better to use a thermostat to automatically turn on and off the heating. When using a self-regulating cable option, it is necessary to correctly select its parameters, then there is no need to use a temperature regulating device.

There are ready-made integrated solutions that, in addition to the water pipe, insulation and rigid waterproof shell, have an embedded cable for heating. Such sets significantly reduce the time of installation of the system, but the purchase of all the elements separately will be much cheaper.

Ready solutions for underground water pipes may contain a cable for heating, which virtually eliminates the possibility of freezing the system

Heating cable can be heated as part of the system, and completely outside the pipeline, thus making it unnecessary to lay the main line below the mark of seasonal freezing of soils.

Use of warm air

Another effective way to protect the water pipe laid in the ground from freezing is heating it with warm air from home. There are two options - with natural and forced circulation air, and both require the installation of an additional closed tray or a larger diameter pipe.

In case of natural circulation Air to the water pipe put on the pipe and insulate it from the outside. It has access to a warm room and, therefore, there is a slow circulation of the water-supply system enveloping the water supply system with the transfer of heat from the basement or the ground floor of the house.

In the second case, along the entire length of the water pipe, two channel bars (n-shaped profiles) are attached along which air passes. They wrap the heater and close outer tube to avoid squeezing the heater earth and profiles. At the end of the heated section, these profiles are joined, thus obtaining, closed system with an entrance and an exit indoors. The air supply is forced by means of a hair dryer.

Schematic representation of the insulated structure of an underground waterpipe in case of its heating with warm air from the premises. Option with forced circulation includes the use of a hair dryer, directing the airflow into one of the profiles

Video examples of insulation of underground water pipes

Pipeline laying in the ground from the well to the house with its insulation and the nuance of freezing near the basement:

Warming of the water pipe realized on the basis of plastic pipe and a method for warming the knee with a larger diameter cylinder:

Detailed instructions for attaching an external heating cable, taking into account the correct circumvention of fasteners and cranes:

Qualitative warming or heating of the water supply system, located under the ground, will ensure its uninterrupted arrival in the winter. In the case of neglecting the installation and protection from the cold, a complex defrosting procedure and expensive water pipe repairs may follow.