The best sewer pipes. Installation of external pipes. Plastic products: advantages and disadvantages

Pipes made of black steel are economical, durable, easy to process and withstand the highest possible temperature. They can be used in the production of waste oil and chemical liquids having a wide temperature range. In everyday life it is not possible to use sewer pipes made of black steel because of their high weight and susceptibility to corrosion.

Cast iron pipes are particularly strong.

Cast iron is less prone to corrosion, but also costs more than steel. From it, sewer risers and external terminals are installed in the collector, and this material should be chosen for laying external sewerage. He is the strongest, having indefinitely long term operation of the target material. For high-temperature sewage, it is best to use cast-iron sewage pipes. Of the shortcomings of this material, it should be noted its great weight; complexity during installation (special materials and skills are needed for hermetic connection); also a disadvantage is that, due to the natural roughness, mud builds up on the inner walls, which reduces the permeability of the drains.

Polymer sewer pipes

Polymer sewer pipes are used in modern construction most often, they can be chosen not only for internal, but also for external sewerage, both for non-pressure and pressure.

- polyvinylchloride (PVC);

- unplasticized polyvinyl chloride (PVC-np);

- polypropylene (PP).

PVC is most often used for systems where effluent flows by gravity. These pipes have a low coefficient of surface expansion, are durable, resistant to ultraviolet radiation. Their disadvantages: at high temperatures (from 70 degrees) are deformed; at low temperatures become brittle, lose elasticity; Destroy under the influence of aggressive organic media, in the event of fire, releases a toxic gas phosgene. It follows that PVC is not recommended for internal sewerage. Recommended for risers, underground and aboveground external sewerage with a heater and only for gravity.

Corrugated pipes for local sewage systems from polyethylene.

PVC-np is more versatile. This material is used for internal and external sewerage in non-pressure and pressure systems. Can be used for cold water supply. The disadvantages are also a small temperature range and flammability. The application is similar to PVC pipes, and, in addition, it is recommended to use it in an external sewage pressure loop (fecal pump, etc.)

The most durable is the sewerage from the PP. When observing the rules of operation, it can last at least 100 years. It is easy to install, has high heat resistance, withstand high temperatures. Great for domestic sewage. Recommended for indoor use, but not recommended for external sewage systems. A common advantage for all polymer pipes is that the material perfectly repels passing drains without causing them to adhere to the inner walls. It should also be noted their simple installation. The connection is made by butt welding (without an open flame) or by crimping. From the temperature difference of the polymer tubes "walk", therefore, during installation, leave space for them so that they do not break the tight fitting trim. Such pipes can be conveniently hidden under a gypsum board, lining it with tiles.

So, let's summarize: what material for which type of sewage is better to choose? For internal sewer wiring, polypropylene is best suited; for external wiring, risers and underground sewerage communications - PVC, PVC-np, cast iron. A feature of the sewage system made of polymeric materials is that it is very rarely clogged, but if this happens, you can not use a metal cable to clean it, it will easily damage the internal surface, forming burrs on it, for which dirt will again cling. For the cleaning of sewerage from polymeric pipes use special chemical means intended for this purpose, or a cable with a nonmetallic tip.

In order to install pipes for external sewage, you need to determine the type of pipes that are made from different types of materials. Today pipes are made of reinforced concrete, cast iron, polyethylene, PVC, ceramics and polypropylene. Pipes that are laid underground should be purchased depending on the depth of the trench, its slope, and also on the properties of the pipes, first of all, the cross-section of the pipe is considered. Today in this article, we will consider the features of different types of pipes for external sewerage.

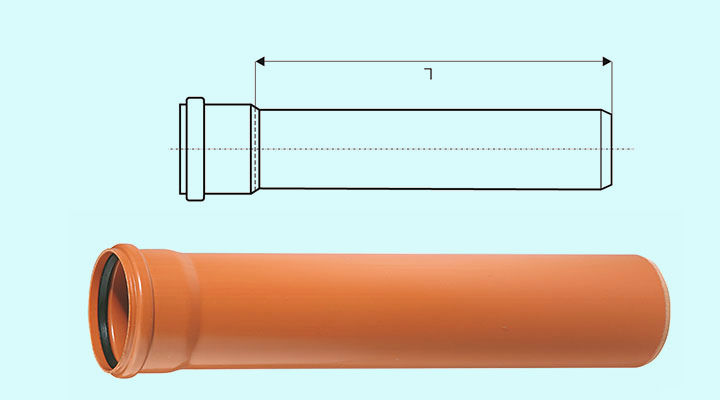

Pipe made of PVC orange

The orange pipe for sewage has a number of significant advantages, because The quality of plastic pipes is in many respects inferior to it in its qualities.

Pipes fromunmodernized polyvinyl chloride

These pipes are made for the construction of underground sewerage, it is under the buildings and under large roads, such as freeways and highways. They are often used to drain sediments in the form of storm sewage, drainage on industrial scale and sewerage. Pipes from of this material can withstand any impact, incl. chemical class. They have a number of significant advantages:

- are produced in yellow and brown;

- very light in weight, are made of special, three-layer material in various diameters;

- resistant to the effects of chemistry;

- have a long service life, more than 50 years.

In addition, these pipes have some disadvantages, such as the release of harmful substances during combustion, can be exposed to rodents, they function only at certain temperatures.

Cast-iron pipes

Cast iron pipes are used for outdoor use, because they have significant advantages.

- have very high strength;

- have a significant service life of up to 90-10o years;

- withstand loads;

- do not rust and are not subject to corrosion;

- the two types of pipes are most in demand, like smu without plug-in connections, and sme, having a detachable connection from one side.

Cast iron pipes also have drawbacks, like too heavy weight, have roughness on the inner surface, which is why they often clog. When exposed to low temperatures, the cast iron tube freezes and bursts.

Pipes from plastic

The next demanded type of pipes are plastic pipes, which for external use are not all, but only a certain type. it double-ply corrugated pipes with connecting elements, in the form of adapters and couplings. Concerning, polypropylene pipes

, which are the most common and are produced most often, gray, they are used for private construction, and for exterior work, pipes made of rigid polypropylene are used.

Also produced polyethylene pipes, which have a high density, with an increased thickness of the walls.

Thus, we see which pipe to choose for sewerage and we understand that not all types of pipes are used for external sewerage, but only those capable of withstanding the stresses of chemical agents. And also the temperature drop from high to very low.

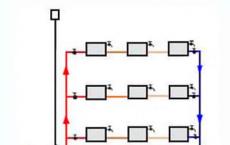

Installation of external pipes

Installation of water supply and sewage pipes, first of all, requires the preparation of a project that is carried out in several stages to ensure the withdrawal of waste water from a residential building of any type. The stages of the work consist in the selection and arrangement of a septic tank, a filter well, as well as in the insulation of sewerage and the laying of pipes. After the works, the pipes are brought to the septic tank, and the final work is carried out.

Advice! Remember that septic tanks are located at a distance of at least 9 meters from the house, and from the water intake at a distance of at least 30 m.

Advice! The filtering well should be digged at a depth of 1.5 m from the mark of the freezing level of the soil. The well is required in order to defend water, which then enters the ground.

Advice! For trench laying trenches dig at a depth of 1 m, with a slope toward the septic tank.

Advice! Pipes are not rigidly attached when connected to a cesspool, t. When the seasons change, they can burst, in this connection, the connection must be mobile!

Do not forget to conduct operational testing at system start-up, incl. under pressure. Use a foam to connect the pipes and finish all the work by carefully filling the earth.

Photo Gallery (6 photos):

installation of external pipes

A pledge of a favorable sanitary and hygienic situation in the apartment / house, the comfort of all inhabitants. The guarantee of long-term, uninterrupted operation of this engineering network is correct. They will prevent the occurrence of clogs, noise, eliminate leaks. Which pipes are suitable for internal sewerage?

Pipes made of cast iron are more reliable and durableOn the communication, draining the drains from the building, there is less workload than on the outside. Their installation is carried out in an open, or hidden way. But under any scheme of installation, there are criteria for choosing internal sewerage communications, these are:

- strength;

- heat resistance;

- resistance to biological, chemical effects;

- good cross-country ability;

- possibility of connecting plumbing equipment;

- compatibility with external sewerage;

- simple installation;

- possibility of repair, replacement.

For the laying of sewerage in private houses, apartments, products from:

- cast iron;

- polymers (plastics).

Cast-iron communications: "for" and "against"

This material is made of iron ore, which has high performance. Prior to the appearance of analogues, it was used for decades for laying external and internal drains. There are products from:

- - resistant to compression, suitable for equipping the riser, but fragile;

- malleable cast iron (Ductile Iron) - high-strength, plastic.

According to the functionality of the product made of cast iron classified into 2 types:

- SMU - with smooth ends;

- SME - one outlet of the pipe is smooth, and the other with a funneled extension (bell).

Cast-iron pipe without a spigot is used for tapping recycled water inside the building. Elements of the line are connected with clamps. The flare pipes are sealed, therefore suitable for forming an external drainage.

Dimensions of cast iron sewer pipes include the thickness of the walls of the product, diameter, weight. Communication capacity is determined by:

- nominal value. This is the inside diameter of a cast iron sewer pipe. It has the designation Дн;

- diameter of the conditional pass. It displays the rounded / conditional value of the internal product hole (DN);

- outer diameter - the distance between the external walls of communication (designation G).

The choice of pipes of a certain capacity is determined by the volume of the drains. varies between 50-150 mm. For laying 50-100-millimeter communications, for outdoor -100-200-millimeter. Standard length of the product is 2 m. Given the GOST for cast-iron sewage pipes, the weight of the product depends on its nominal diameter:

- 50 mm communication weighs 11 kg;

- 100 mm = 25 kg;

- 150 mm = 40 kg.

To the note: the weight of the product is affected by the thickness of the walls of the communication. It varies in the range of 6.7-27 mm.

Cast-iron sewage pipe has several advantages:

- strength;

- high operating period (up to 85 years);

- plasticity;

Disadvantages of communication:

- large mass. The weight of the cast iron pipe makes it difficult to transport and install the product. This requires the use of special equipment;

- rough internal walls, which causes the accumulation of sediment;

- high cost, due to the metal consumption of the product.

Plastic products: advantages and disadvantages

With the advent of polymers that make it possible to manufacture light and cheap products, the use of cast iron has become a secondary concern. Data communications from complex plastics.

Plastic sewage pipe - pluses:

- high strength;

- resistance to corrosion;

- long operational period (up to 60 years);

- ease of construction, facilitating its transportation and installation;

- high throughput of the product;

- low cost. Average prices for sewer plastic pipes of 50 mm in diameter are 65 rubles / m., 100 mm = 155 rubles / m. (for cast iron, respectively, 550 and 900 rubles / m.).

Please note: lack of communication from plastic - low resistance to temperature effects. They should not be installed at constant hot runoff (65-70˚).

Pipe sizes are standard, or individual (custom). They are selected depending on the expected load on the product. When installing an autonomous sewage system, the following diameters of sewer plastic pipes are used:

- 100-110-150 mm for risers and central lines, connections;

- 40-50 mm - for watering lines, connection of a sink / sink.

Tip: determined by a long highway, the number of joints, turns, water pressure. General parameters are specified in SNiP.

Plastic sewer is laid from pipes:

- polyvinylchloride (PVC);

- polypropylene (PP);

- polyethylene (PET).

Pipeline from polyvinyl chloride

Communications from neoplasticized PVC are used for the formation of external and internal drains (pressure / non-pressure). They are suitable for the distribution of sewerage in the house, with the removal of sewage by gravity.

The diameter of PVC sewage pipes is set in GOST 51613-2000. According to it, the length of communications should be 4-12 m, the size of the inner hole - 10-315 mm. In a private house the sewer is used to form a riser, connecting the sanitation facilities with a large discharge volume. 40-50 mm communication lines are used for laying the spreading lines and connecting the shells, 25 mm for draining the drain from the washing / dishwasher.

The PVC pipe is durable, resistant to UV rays. The lack of polyvinylchloride communications is a susceptibility to temperature fluctuations. Permanent drain hot water softens, deforms the material.

To the note: in order to avoid the destruction of PVC communications, the temperature of the sewage should not exceed 40˚.

Compared with cast iron, the plastic PVC pipe produces more noise, is subject to combustion. At the same time, a toxic gas is released.

Pipes made of polypropylene

These are products made of synthetic, thermoplastic polymers. They are characterized by increased strength, temperature resistance, acid and alkaline agents. - environmentally friendly, amenable to processing.

Polypropylene pipes for sewerage serve up to 100 years. Smooth internal walls provide good throughput of communications. it suitable option for laying internal sewerage. PP-products are characterized by low noise / vibration, allow the formation of lane lines of various configurations.

It is much easier and cheaper to make a sewerage system from plastic pipes than from cast ironPlease note: when exposed to high temperatures, PP products are lengthened. This is compensated by the use of special structures during installation.

Communication from polyethylene

They are made of polymer, extruded (high-pressure treatment). As a result, it acquires super strength. The properties of the pipeline are affected by the density of the polyethylene pipe. There are PET communications:

- low density (high-pressure line) 0,910-0,925 g / cm 3 - are used for laying external sewerage, as they are resistant to mechanical damage;

- average density - up to 0.940 g / cm 3;

- high density (low head) to 0.965 g / cm 3 - products mainly for indoor use.

To the note: externally, products from LDPE and HDPE are similar, but communications from low-density material are more solid.

Compared with PVC structures, polyethylene products are more plastic, do not create noise. These communications are not afraid of acids, alkalis, are not subject to corrosion, have a good stretch, serve up to 50 years. The disadvantage of these pipes is the softening and deformation at a temperature of 80 ° C. GOST provides the working temperature of PET pipes 40˚. The performance characteristics of polyethylene communications are reduced when exposed to UV rays.

Docking of sewer pipes

The laying of internal sewage networks involves the use of fittings. These are devices for joining line elements. There are fittings:

- threaded - used for joining cast-iron products. The part is wound on the thread of the incoming and outgoing pipes, connecting them together. Provide a strong mechanical connection;

- flanged - at the junction of the communications insert pair steel discs, connected by bolts. Non-releasable flange connection of pipes is performed by welding their ends. A special coupling is placed on the joint, which is connected to the electro-heating elements;

- compression - tightening of pipes is made by a nut having a sealant made of silicone / rubber;

- self-locking - complex devices consisting of internal rings with teeth. They are installed on the joints of the elements and fixed with a special key. When pressing, the teeth penetrate deep into the communication material, providing a strong connection. These fittings are reusable;

- welding - the ends of pipes are degreased, fixed with clamps and processed by welding with a heating disc. Fused sections are joined, forming a thin, strong edge;

- glutinous - a liquid polymer composition is deposited on the joint, which rapidly solidifies. This method is also called "cold" welding.

It is important to select the right sewer pipes and fittings to them. Communication joints - a vulnerable place of the system, the cause of leaks, blockages, cracks. Cast iron piping is mounted by means of embossing. The end of the communication with the chamfer is inserted into the funnel of the fitting. The compound is sealed with oil impregnated fibers, additionally covered with cement mortar, fused with sulfur. For tight joints, the pipes are equipped with rubber gaskets. Cast iron products are connected and using clamps. Above the joint, a coupling is fastened, which is tightened by bolts.

The ends of pipes from PET, PVC are equipped with rubber seals. To connect the parts cut off the branch pipe of the required size, remove the outer chamfer from it, smear the sealant and insert it into the communication funnel. Docking of polymer products is also made using a flanged method.

Sometimes it is required to connect communications from different materials. How is the transition from a cast iron pipe to a plastic pipe? Preliminarily clean the bell of metallic communication (if it is old). Funnel expansion is treated with a sealant and a transition is made from cast iron to plastic 110 mm (for riser), or another suitable diameter (50 mm for the lapel line). This cuff is rubber, polymer. The gaps between the elements are sealed. Likewise, docking of non-defensive communications is performed.

SEE VIDEO

A strong and tight connection of cast-iron pipes with polyethylene will ensure the use of a self-rotating press-fitting. It will avoid leakage that occurs during water hammering, temperature drops in the system. The end of the cast-iron product is cut and cleaned, lubricated with a solidol and put on it thread. At this point, wrap the wrap (sealing tape), apply silicone sealant and manually tighten the press fitting. The connecting element You can at any time twist, preventing the formation of a leak.

Tip: plastic and cast iron sewer pipes have different expansion factors, so it's better to use quality fittings.

What pipes for outdoor sewage are modern industries? There are two main types:

- Cast-iron;

- Plastic.

Each of them has both advantages and disadvantages, so it makes sense to fully understand their characteristics and understand what kind of all the same is better.

Cast-iron

Usually this species is not used for outdoor sewerage. The fact is that they are softer and do not withstand the load from the soil layer poured on them. They crumble, change their shape, which can lead to the formation of clog due to the narrowing of the diameter. In addition, they do not disdain rodents. Although polypropylene pipes can be used in sandy soils.

But they have a high index of heat resistance, they can easily pass material with a temperature of + 800C. They practically do not burn. Still, experts recommend using them solely to create internal sewage networks.

Today, manufacturers offer a corrugated version of polypropylene pipes. This worthy alternative has been recognized by industrial enterprises, where there is a need to run high-temperature materials or hot sewage through pipelines.

Polyethylene corrugated

Polyethylene corrugated double-layer

This is an ideal outdoor sewage pipe. Corrugated polyethylene is very widely used for erection of sewerage of various capacities, sizes and schemes.

The peculiarity of such pipes is, first, the fact that polyethylene has increased strength. And, secondly, the corrugated structure increases the initial strength a few times.

This all gives a guarantee that this type of pipe will withstand a fairly large load. Therefore, you can lay them down to a depth of 15 meters. Traditionally, manufacturers produce two dimensional species. This is 200 mm and 800 mm. The corrugated structure is located outside, but inside it is an ordinary smooth pipe, through which the drains pass unhindered towards their collection.

Conclusion

So, let's summarize. Cast iron pipes are discarded immediately, because this is the last century. From plastic pipes we choose either polyvinyl chloride or polyethylene. But the latter are more expensive, and you will have to take into account the allocated amount of money. Although, according to experts, PVC pipess - is an ideal option for creating a suburban area of external sewage.

Related Posts

Owners of private housing have to think over not only internal communications, but also a system of diversion outside the house. For this purpose sewer pipes for external sewerage are designed, for which different materials are used.

External sewage networks have to function in difficult conditions. Earth-filled pipes are forced to carry the weight of the ground, which people can move around, and often cars. Also they are affected by soil water, capable of provoking displacement of the docking assemblies, which can lead to depressurization of the sewerage network.

Systems have to constantly resist the static / dynamic effects of sewage, which are transported through pipes.

External sewer pipes, used for the installation of sewage disposal systems, have to be underground in difficult conditions

That is why special requirements are imposed on elements of external sewage networks. Pipes should have the following qualities:

- strength and rigidity;

- ability to withstand temperature fluctuations, without losing working qualities;

- frost resistance;

- wear resistance, long service life;

- resistance to the influence of aggressive chemical environments.

For the manufacture of external sewage systems, various materials (polymers, steel, cast iron) can be used, but all of them must correspond to the above factors. It should also be taken into account that the quality of the pipeline is affected not only by the specific properties of the pipes, but also by the quality of installation and installation of the system.

Differences between external and internal sewerage

The pipes used for laying out external systems differ significantly from the analogues used for intra-house communications.

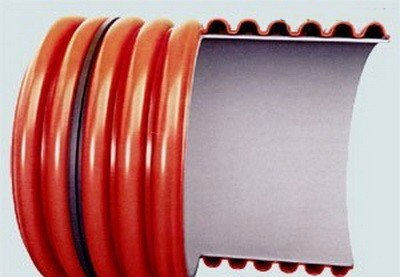

External sewage systems differ from internal pipes in bright orange color, as well as increased density and wall thicknesses

Characteristic features include:

- Orange (red) color, which facilitates easy detection of the pipe, therefore, helps to avoid unintentional damage to the network during the earthworks.

- The wall thickness of the part for external sewerage is always higher than for internal sewerage (when using PVC systems, these figures are 3.2-3.4 mm vs. 2 mm), since the pipeline laid under the ground has to bear heavy loads.

- Red pipes are usually made of materials of increased resistance (for example, unplasticized PVC, which is particularly strong).

- Due to the increased thickness and reliability of the walls, as well as the addition of specially selected components, the heat resistance of outdoor systems is higher than internal.

- Products of orange color, as a rule, serve a longer period than gray.

- The cost of elements for external sewerage is about 20% higher than for internal sewerage.

Experts warn about the inadmissibility of using gray pipes for laying external sewerage. It is difficult for them to withstand the increased load (especially for a long time), which can lead to breakthroughs and accidents.

Let us consider in more detail which materials can be used for the manufacture of external sewage systems.

Varieties of plastic products

Sewer polymer pipes appeared not too long ago, but they became widespread, having pressed traditional analogues in the profile market. Such components have a number of undeniable advantages:

- light weight, facilitating transportation, storage, laying;

- smooth internal surface, facilitating unhindered passage of waste water and not allowing subsidence of salts and other deposits. Thanks to this feature, proper installation and exploitation in plastic pipes there is practically no clogging;

- plastic pipes do not rot, do not undergo corrosion;

- similar products have sufficient life, although less than their cast-iron counterparts (maximum 50 years).

The most frequently used components for making external sewage systems are made of the following materials.

Option # 1: pipes made of polyvinyl chloride (PVC)

Polyvinyl chloride (PVC) is an affordable popular plastic, widely used for the manufacture of various products, including pipes for internal / external networks. Such components are particularly recommended for sewage systems that require a large throughput (collector, culvert, stormwater).

PVC pipes are widely used for laying external sewerage networks, however they are sensitive to aggressive chemicals and liquids having a temperature above 60 degrees

Pipes made of polyvinyl chloride have the following positive properties:

- good resistance to mechanical influences;

- high strength;

- resistant to ultraviolet, so that such products are suitable for open areas.

Among the most significant shortcomings of PVC pipes are:

- Sensitivity to aggressive materials. If it is planned to remove acids and oils through such components, it is better to purchase special NPVC pipes, which have special properties.

- Temperature elongation of the material. Because of this property, such parts are inexpedient to install for transportation of hot liquids (over 60 degrees C).

There are two types of PVC pipes:

- Pressurized to withstand high pressure (<10 атмосфер). Они применяются в системах, испытывающих постоянное повышенное воздействие различных сред.

- Non-pressure. Recommended for systems with unintended high pressure (the liquid in the pipe moves by gravity at a moderate speed).

Most often, the second version of products is used in external pipelines.

Polyvinyl chloride pipes can consist of one or two layers. In the latter case, the unplasticized material is used for the outer layer, and for the internal processed foam polymer.

The connection of polyvinylchloride pipes is usually made by means of funnels. In some cases, cold welding and glueing

In terms of stiffness, PVC components differ in the following categories:

- Rigid pipes (class S) with a maximum wall thickness, designed for installation at a depth of up to 8 meters. This kind can be used for any work, however it is most often used in industry.

- Medium-weight products (class N) are used at a depth of 2-6 meters. They are suitable for mounting the pipeline under not too busy roads.

- Light components (class L), sufficient to create systems that are laid at a shallow depth (0.8-2 m). Not suitable for laying under the carriageway.

The most common pipe for external sewage is a product with a diameter of 10-11 cm. In this case sewage from a country house is easily transported through the network.

Option # 2: polypropylene products

Pipes of this type are not too often used for laying external sewer networks because of insufficient rigidity of polypropylene parts. However, they can be used for laying a pressureless storm sewage system or for installing systems in sandy soils.

Among the advantages of this type of products:

- High heat resistance. Padded systems withstand the transport of hot liquids (up to 80, and occasionally up to 95 degrees Celsius).

- Chemical inertness. The plastic does not corrode, does not emit harmful substances.

In addition to the already mentioned insufficient density, the disadvantages of polypropylene include its sensitivity to ultraviolet. When storing and laying pipes made of such material, it is important to avoid direct sun rays.

Option # 3: polyethylene pipes

Such material is widely used for the installation of external pressure pipelines. The advantages of PE pipes include:

- ability to withstand hydrostatic shock;

- resistance to active substances;

- long life (50 years or more).

Among the shortcomings of such products are:

- insufficient thermal resistance (polyethylene pipes can be used in the temperature range from -40 to +40 degrees Celsius);

- susceptibility to ultraviolet.

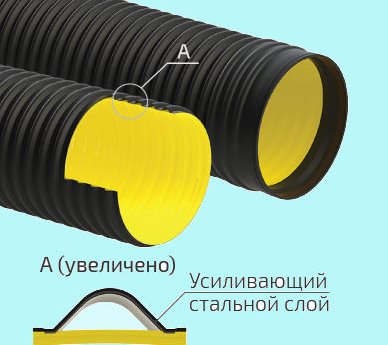

Option # 4: corrugated products

The common minus of plastic sewage elements is their insufficient strength. To correct this flaw, a special design was invented-a corrugated pipe with more mechanical stiffness.

Due to the folded outer surface of similar products, their area increases. This makes it possible to redistribute the pressure exerted by the ground, as a result of which the pipelines withstand increased loads.

Corrugated structures are very popular. They allow to improve the stiffness and density of plastic pipes, while maintaining a light weight of products

There are two types of corrugated pipes:

- Single-ply, with a unique ribbed surface inside and out. Such material is relatively cheap, but draining is much worse.

- Two-layer pipes having a folded outer surface and a smooth inner. Thanks to this, the flow freely passes through the pipe, without forming deposits and clogs.

Similar products can be made from different types of polymers. The most commonly used is low pressure polyethylene, polyvinyl chloride.

The diagram shows the arrangement of a double-ply corrugated pipe used for the installation of external sewerage. The part consists of an outer folded layer and a smooth inner surface

Pipes with a corrugated surface are connected by the socket method using special rubber cuffs. When installing pipelines, it is also possible to apply the method of cold welding.

Sewerage products of other materials

In addition to plastic, external pipes for sewerage can be made from other materials.

To produce similar products, a mixture of Portland cement with mineral asbestos fiber is used. Such systems have a number of important advantages:

- Durability: the service life can reach half a century and even a hundred years.

- Relative ease, greatly facilitating installation.

- Resistant to aggressive environments. Pipes made of asbestos cement can withstand almost all chemicals.

- Non-disposition to the overgrowth of the socket.

The disadvantage of this material is its fragility and sensitivity to mechanical damage.

When buying asbestos-cement products, you need to carefully inspect them to reveal chips and cracks - an already fragile material with the marriage will not endure the necessary load

When making a purchase, it is important to carefully inspect the ends of the pipes, where the most frequent damage is observed. When transporting and storing products from asbestos cement, it is important to observe special care.

Ceramic products

Even in ancient times, ceramics were used to make parts of the sewage system. This material is popular in our days, thanks to such advantages as:

- Chemical inertness. Ceramic systems allow transportation of almost any liquid media.

- A special structure of the inner surface, which prevents the formation of deposits and deposits of salts and other substances.

- Resistance to ambient temperatures and liquids passing through the pipe.

- Easy laying.

Among the shortcomings can be noted:

- Friability. Pipes made of ceramics are easily destroyed under mechanical influences; therefore, special precautions must be taken when transporting, storing and installing them.

- The small length of the pipes, because of which when laying the system it is necessary to increase the number of joints.

On sale there are ceramic elements in diameter of 100-600 mm, which can have two variants of connection: with a socket and with cutting.

Before installing the pipes, you should check the quality, inspecting the appearance of the parts and rattling them. The rattling sound that appeared when it strikes testifies to the presence of a hidden crack.

Cast iron systems

For a long time the most popular solution for outfitting sewerage systems was considered to be cast iron pipe fittings. As a rule, for private construction there are enough elements with a diameter of 16 cm.

The main disadvantage of traditional cast-iron pipes is a large weight, because of which for the laying of communication networks requires the use of special equipment

Systems of this material have many positive qualities:

- High strength, allowing the pipeline to withstand heavy loads.

- Durability. The service life of cast iron systems is at least several decades.

- Resistance to temperature changes.

- A simple installation is sufficient, which involves the use of the belling method.

At the same time, we can not fail to mention some of the shortcomings of such products:

- Great weight. Because of the gravity of the elements, it is impossible to lay a cast iron pipeline without the use of special equipment.

- The tendency to build up deposits on the surface: over time this can lead to the formation of blockages.

- Inability to use on a number of soils, especially in salt marshes.

- A fairly high price for traditional cast iron products.

At present, cast-iron pipes are used for building industrial communications, whereas in individual construction they were almost everywhere replaced by cheaper and lighter plastic analogues.

Sewer pipe manufacturers

The release of pipes of various materials used for laying external sewerage is handled by many foreign and domestic firms.

Companies specializing in plastic products

Among the companies that produce plastic products, we can note the following.

Wavin. The company, founded in Holland in 1955, specializes in the production of sewer and water pipe plastic pipes. The company's products are extremely demanded throughout Europe.

The Dutch company Wavin is well known in European countries. The company offers a wide range of pipes and fittings for external sewerage

For outdoor works, the manufacturer produces corrugated polypropylene pipes "Pragma", which have double walls, as well as other production options.

The components of Pragma are 6 meters long; they are easily connected to the system, because they have a bell in one end and a rubber seal on the other. The manufacturer recommends the use of these products to create a network of external gravity sewers.

POLYPLASTIC. An international company, whose divisions are located on the territory of the CIS countries (Russia, Kazakhstan, Belarus).

Among the assortment of branded products, various kinds of sewer elements occupy a large place, including external pipes made of different types of polymers (polyethylene, PAH, polypropylene, fiberglass).

For the products produced by the company, an optimal combination of a small weight with increased ring stiffness is characteristic, so that plastic pipes successfully resist even considerable loads.

Armored products "Corsis Arm", included in the range of the company POLYPLASTIC, have a steel layer, reinforcing the rigidity of external sewer pipes

The brand-name line of this manufacturer is the "Corsis" series, which includes:

- double-layer corrugated products;

- spiral-shaped parts;

- multilayered reinforced pipes.

All these elements are perfect for laying external sewage networks, other systems of water disposal. The company produces products with a length of 600 or 1200 mm, with a diameter of 110-600 mm. Unlike the products of other companies, the components of "Corse" have a corrugated black outer layer and the inner surface of light-blue, yellow or orange colors.

Ostendorf. The famous German company Ostendorf Kunststoffe, specializing in polymer pipes and other parts, was founded by the brothers Ostendorf in 1973. Now the company is considered the leading manufacturer of elements of similar systems in the profile market. Deliveries of products are made in many countries of the world, but Germany is the main consumer.

Pipes KG (manufactured by the German company Ostendorf) have high consumer qualities. Such systems are durable, reliable, durable, easy to operate

In 2011, Ostendorf started operating in Russia. At the enterprise, where the latest technological equipment manufactured in Germany is installed, imported raw materials and components are used. At the factory, strict quality control is organized, which is carried out in accordance with German and Russian regulations.

Because of the highest quality of products, it enjoys an increased demand of consumers, despite the relatively high cost.

The KG line, designed for outdoor sewage, is made of solid polyvinyl chloride without impurities, which has increased strength, water resistance, durability, and thermal conductivity. The convenient shape of the ends allows quick and easy installation of various systems.

POLITECH. The Russian company "Politec", founded in 1999, is the leader in the production of polymer products used for drainage, water supply, sewerage.

The products of the domestic company Politek became popular due to the optimal ratio of quality and price. Even budgetary products have decent characteristics

At the company's factories, the latest foreign special equipment is installed, which allows the production of European-class products.

Companies manufacturing cast iron pipes

Although metal products are now less common than plastic products, the demand for cast-iron pipes can be called stable. Such products are produced by several European companies, among which the following can be noted.

Duker. Founded in 1913 in Karlstadt (Franconia, Germany), the company initially produced products with socket systems. In 1968, innovative no-trumpet pipes were developed, allowing shortening of parts, as well as mounting the remaining trims, using a combination method.

Now the company is the only producer of sewage systems made of cast iron in Germany, while the factory has a completely completed production cycle: from casting to application of external coating.

The company offers the widest range of different systems having different lengths, diameters and connections. All of them have excellent consumer qualities: durability, resistance to aggressive substances, strength.

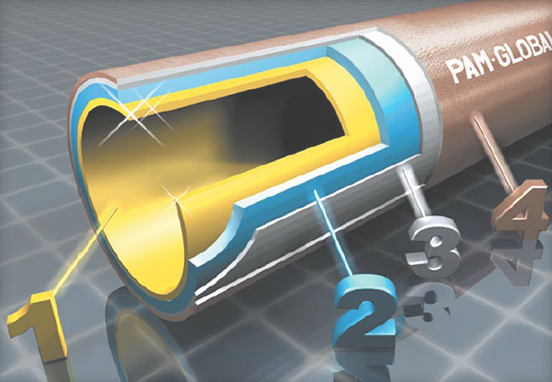

Pam Global. The large concern Saint-Gobain (France) specializes in the production of modern cast-iron products. To produce them, De Lavo technology (centrifugal casting) is used, followed by deep cooling of the structures.

Cast iron Pam Global pipes are produced in the factories of a large French concern. In the manufacture of products, the metal is coated with epoxy resin, zinc powder and acrylic lacquer

Pam Global C systems are specially designed for ground works, as well as the installation of quality long-term drainage systems. External sewer pipes have a diameter of 100-200 mm.

It is impossible to say unambiguously which type of pipe is the best. When considering product variants, it is important to know for what purpose they are intended and under what conditions they will be used. Only taking into account all the individual features of the site, the owner can choose which option is best for the arrangement of the sewage system.