Exhaust pipes for gas boilers. Purpose and construction of the chimney. Selection of a suitable option

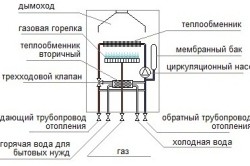

A gas heating boiler requires increased attention to the chimney device, despite the fact that the temperature of the waste gases is relatively low. The combustion product of the gas is water in the vapor state and carbon dioxide, but in the main gas there are sulfur impurities that are oxidized, react with water and form a solution of sulfuric acid in the vapor state. This mixture is able to dissolve the walls of a conventional brick chimney and a chimney made of steel, so that the lifetime of such structures under such conditions is only a few years. That is why, when choosing chimneys for heating boilers running on gas, it is necessary to take into account a number of features characteristic of such equipment.

Smoke pipes for gas heating boiler: highlights

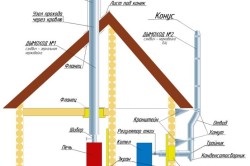

In already constructed buildings, it is allowed to connect to one chimney no more than 2 water heaters or heating boilers installed on one or different floors of the house, provided combustion products are introduced into chimneys at different levels not closer than 50 cm from each other or on a level with the device in The design of the chimney cut to a height of at least 50 cm.

A very important point in designing a chimney for a gas heating boiler is the observance of the channel cross-section.

The fact is that the sectional area of the chimney must be no less than the sectional area of the branch pipe of the gas heating boiler connected to the chimney. If the chimneys are connected to 2 water heaters, boilers, etc., the section of the chimney is determined taking into account their simultaneous operation.

Brick chimneys should be made of heat-resistant concrete, clay brick, frost-resistant brick for multi-storey buildings and asbestos-cement pipes for single-story buildings. However, modern columns and gas boilers heating have a high enough efficiency (up to 95%). In the conditions of such operation of the gas equipment, the temperature of the outgoing gases is sufficiently low, as a result of which a large amount of condensate is formed. It is because of the condensate formed, or rather its chemical composition, that the chimney constructed of bricks is destroyed. In view of this, a brick chimney must necessarily be used or lined.

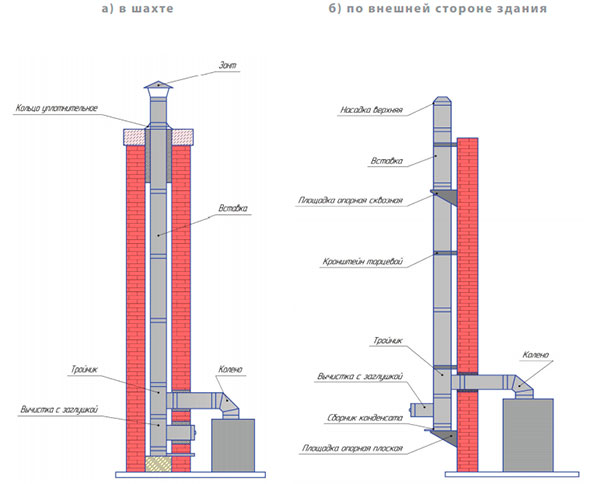

The liner of the chimney is the installation of a single-walled pipe made of stainless acid-resistant steel inside a brick chimney. A similar variant of the chimney design for a gas heating boiler provides a sufficiently rapid heating of the channel to a temperature exceeding the dew point and provides protection of the material against the destructive effect of the acidic medium formed during the combustion of gas.

The lining of the chimney duct is the installation of a so-called flexible chimney. Excellent solution for chimneys of non-standard sizes or having a curve channel.

The ideal shape for the chimney is the shape of the cylinder, it is followed by an oval one, and the rating of the square tube is closed. Why is the cylindrical shape best? The thing is that the exhaust gases of any heating boiler in the chimney rise upwards in a spiral. In a square-shaped pipe, small eddies will be created at the corners, which generally reduces the thrust power.

Requirements for chimneys for a gas heating boiler

The chimney for a gas-fired boiler must be vertical and not have ledges. Allowable slope of the chimney from the vertical - no more than 30 degrees with a deviation to the side not more than 1 m, provided that the cross-sectional area of the sloping sections of the structure is not less than the section of the vertical sections. The chimney that connects the heating boiler to the chimney structure must have a vertical section, the length of which, if counted from the bottom of the smoke outlet of the gas unit to the axis of the horizontal section of the chimney, should be at least 50 cm.

If the ceiling height in the room does not exceed 2.7 m, for equipment with traction stabilizers, the length of the vertical section is reduced to 25 cm, and for equipment without traction stabilizers, up to 15 cm. The total length of the horizontal sections of the connecting flues in new buildings should not be more than 3 m, and in existing houses - no more than 6 m.

The slope of the pipe must be at least 0.01 degree in the direction of the heating boiler. It is allowed to provide not more than 3 turns with a radius of curvature of not less than the diameter of the pipe. Below the installation site of the smoke exhaust pipe from the boiler to the chimney, it is necessary to provide a condensate collector and a revision.

The distance between the connecting pipe and the wall or ceiling of non-combustible materials is not less than 50 mm, and from the non-combustible and combustible materials - not less than 250 mm. It is allowed to reduce this distance from 250 to 100 mm, provided that the device protects difficult-to-burn and combustible structures with roofing steel on an asbestos sheet with a thickness of 3 mm. The thermal insulation must protrude beyond the connecting pipe by 150 mm from each side.

Mounting and suspension of connecting pipes are required to exclude the possibility of their deflection. Their links should be tight and without gaps to move in each other along the way flue gases not less than half the diameter of the chimney. The connecting pipe is tightly connected to the flue gas duct. Its end should not protrude beyond the wall of the smoke channel, for which the limiting devices (corrugation or washer) are used. If several instruments are connected to the common chimney at the same time without stabilizers of the draft on the chimneys, it is necessary to provide from these devices dampers (gates) having a hole with a diameter of not less than 15 mm. In the flaps installed on the chimneys from gas heating boilers, openings with a diameter of 50 mm should be provided.

Chimneys: installation features

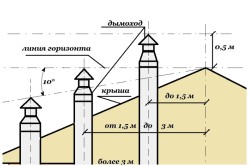

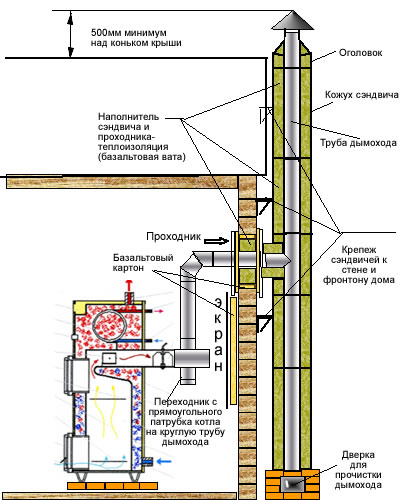

The height of the chimney of the heating equipment in relation to the roof ridge should be:

- not less than 50 cm above the parapet or the roof ridge - if the pipe is placed at a distance of up to 150 cm from the parapet or ridge;

- not lower than the level of the parapet or the roof ridge when placing the chimney at a distance of 150 to 300 cm from the parapet or ridge;

- not lower than the line drawn from the ridge down at an angle of 10 degrees to the horizon - when placing a chimney from the parapet or the roof ridge at a distance of more than 300 cm;

- not less than 120 cm above the flat roof.

In any case, the height of the pipe above the adjacent part of the roof must be at least 50 cm, and for buildings with a combined roof (flat roof) - not less than 200 cm. The zone of the wind channel of the chimney is considered to be a space below the line laid at an angle of 45 degrees to horizon from the highest points near the trees and structures located. Installation on chimneys for gas columns and boilers, umbrellas and other attachments are not allowed (the only exception is the cone, since it is used in the form of a transition from a thermo tube to a single-walled one).

Joint execution of chimneys in walls and ventilating channels is supposed. They should be separated by sealed partitions along the whole height of the structure. Partitions are made of wall material with a thickness of not less than 120 mm. The height of the exhaust ventilation ducts located near the chimneys is assumed to be equal to the height of the chimneys.

Combustion products from gasified installations may be provided for chimneys, made of steel. It is allowed to divert combustion products into the atmosphere through the external wall of the gasified room without the organization of a vertical channel from a gas heating boiler with a sealed combustion chamber. Output of combustion products can be carried out through the roof of the house in a vertical channel. The length of the horizontal section of the chimney when exiting through the outer wall should not exceed 3 m.

What is forbidden to do with the chimney device for a gas heating boiler

Do not use channels made of slag-concrete and other porous and loose materials. It is forbidden to lay chimney-drain pipes from stoves and appliances through living quarters. In addition, when installing the chimney, it is forbidden to install slats when connecting to the chimney of appliances with traction stabilizers.

It is impossible to provide an exit of a smoke channel through an external wall:

- in covered passages, entrances (arches), in closed loggias, balconies, bay windows;

- in buildings that are architectural or historical monuments, without obtaining permission from the relevant department, under whose protection the building is located;

- through the walls of the facades of buildings that overlap the streets and squares, which have a town-planning and historical-architectural value, as well as those located in close proximity to public health institutions, preschool institutions and schools.

- in homes in which the installation of gas appliances is prohibited.

Holes smoke channels must be placed in accordance with the instructions for installing the boiler.

The chimney for a gas boiler in a private house must be arranged according to certain rules. The part that rises above the roof surface is just a small visible element of a rather complex mechanism. The pipe is responsible for the removal of gas and smoke. Homeowners must necessarily be familiar with the device of the chimney in their own house. This will allow to properly operate the heating system. If you are only going to make the arrangement of gas heating, it is first necessary to determine the type of chimney and to become acquainted with the weak and strong sides of each solution.

Which chimney to choose

If you will be equipped with a chimney for a gas boiler in a private house, then first you should decide on a choice. Experts and private homeowners have long ago abandoned the classic brick options. This design is complex, high cost, and the erection takes quite an impressive amount of time. In addition, the performance characteristics of the brick chimney inferior to modern designs.

Using a stainless steel pipe

The chimney for a gas boiler in a private house can be made of stainless steel. In the building materials store you can see a wide range of models. Among the advantages can be identified resistance to mechanical damage, as well as exposure to corrosive substances. Such designs are made in the form of sandwich-systems, which assume the presence of two pipes of different diameter. The full space is filled with basalt heat-resistant cotton wool. Such products are characterized by reliability, and they look very presentable. To date, a stainless steel chimney made as a sandwich acts as one of the most successful solutions.

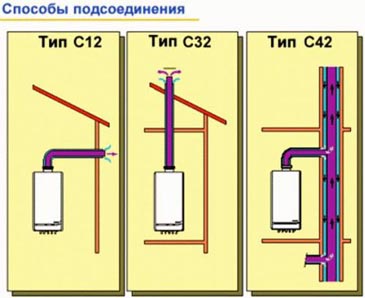

Using a coaxial chimney

A chimney for a gas boiler in a private house can also be coaxial. It can not be confused with any other construction. As a distinctive feature is an attractive appearance. It is necessary to recognize that the working parameters are at a high level. Such products have a specific shape, and condensation can not form on internal surfaces. This circumstance is most important for systems that operate on gas fuel.

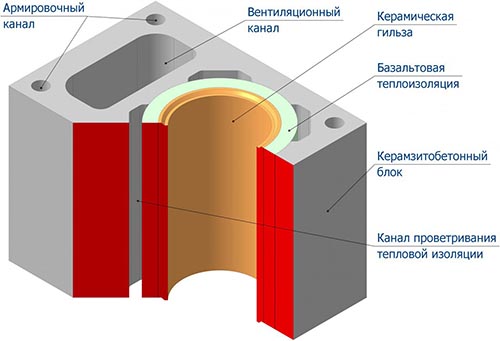

Using a ceramic chimney

Installation of a chimney for a gas boiler can also be done using a ceramic structure. Such solutions today do not enjoy much attention from buyers who are in the segment of elite construction. However, if you are aiming to establish a reliable, fire-safe and affordable chimney, then there is no other alternative to the ceramic construction today. Among other things, such products are easy to install.

Requirements for the flue gas device of a gas boiler

Installation of a chimney for a gas boiler requires maximum attention to the work. Particular emphasis should be placed on the tightness of the structural elements in the areas where the connection was made. You should try to achieve maximum tightness. This prevents the penetration of hot gases beyond the chimney. If the heating system has several units, common connecting flue pipes can be used.

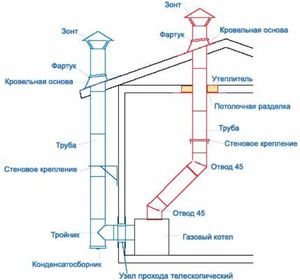

Chimney installation inside the building

Chimneys for boilers are installed both outside and inside the building. In order to understand the difference, it is necessary to make a comparative analysis. Thus, the internal chimney does not assume the presence of thermal insulation, if all rooms are to be heated. Through them the chimney will pass, and only the outer part of the pipe will need to be insulated.

As for the external chimney, the thermal insulation must be fully equipped. Internal chimneys have a high risk of getting carbon monoxide inside the room. This indicates an increased fire hazard.

If we talk about external structures, they are distinguished by a high level of safety in operation. Internal pipes have many different composite elements, which differ from each other in constructive features. This certainly leads to certain difficulties in the installation. The opponent's components are very similar, which ensures ease of installation. Internal chimneys are difficult to repair. The external chimney can be easily repaired, whatever problems arise.

Features of the device of the internal chimney

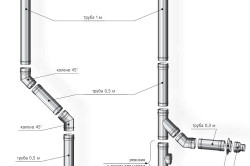

When internal chimneys for boilers are equipped, then the layout in the roofing cake and floors should be made first, which will allow making holes. The correctness of these works should be analyzed several times. Only then you can proceed to cut out the opening. The branch pipe, which extends from the heating equipment, should be connected to the adapter adapter. Next, the revision and the tee are connected, a metal sheet is fixed, and the main bracket is mounted. When building a pipe, it may be necessary to use the knee.

It should be stocked with a special branch pipe, if it is supposed to make the installation through the overlap. On the pipe it is necessary to put on a sheet of galvanizing, in which in advance it is necessary to make a hole of more impressive diameter in comparison with the chimney pipe. The zinc should be fixed to the ceiling. In order to make the docking more reliable, it is necessary to use clamps that are tightened with a good wire or bolts.

Final works

The rules for installing a gas boiler in a private house involve fixing the chimney with wall clamps. They are installed at a distance of 2 meters from each other. Among other things, it is recommended to use brackets in steps of 4 meters. To complete the design, a special tip should be used, which has a conical shape. At the last stage, insulation work is carried out in the chimney area.

Additional requirements for the chimney

The rules for installing a gas boiler in a private house provide for compliance with all the requirements that are imposed on the chimney. To remove gases and supply air to the boiler, you need to use special equipment. Outwardly it looks like a mine, in the inner space of which a pipe is installed. Installation of the chimney must be strictly vertical. The presence of constrictions and extensions within the channel is absolutely not allowed.

The device assumes the use of exclusively non-flammable and non-melting materials. The structure should not have cracks and any mechanical damage through which combustion products can leak into the room. When installing, only quality sealants should be used that are resistant to high temperatures. The height of the pipe its diameter must correspond to the output parameters of the boiler. Otherwise, it will not be possible to achieve sufficient traction.

As mentioned, the chimney can be both internal and external. There are standard schemes for connecting. If you have to choose an option that is not considered standard, it must comply with the regulations. Any connection system provides a slope towards the boiler of the horizontal chimney section within 3 degrees and above by one meter.

Connecting the chimney to the gas boiler

Chimneys for gas boilers, the price of which can vary from 700 rubles per 1 meter, are not connected according to a scheme that involves the connection of several heating appliances by combining the pipe with one chimney. In this case, the combustion products can get inside the room. It is forbidden to connect elements that consist of asbestos, galvanizing, bricks and aluminum. The optimum height of the chimney is a parameter within 5 meters and more. If it is a flat roof, the chimney device assumes an elevation of the element above the surface by 1, 5 meters.

With regard to the height of the pipe, whose axis is located 3 meters from the roof, this parameter should be determined by the level of the ridge. If the pipe rises above the last element by more than 2 meters, then additional fixation with the help of building stretches should be made.

Flue outlet outside

The diameter of the chimney for the gas boiler must correspond to the output parameters of the heating equipment. In order to bring the element out, it is necessary to mark out the area, and after verifying the dimensions of the pipe, comparing them with the marking. Only then you can start making holes. To the nozzle of the boiler it is necessary to connect the passage element, removing the pipe to the street. For the transition, use a branch pipe. The hole in the wall and the piece of pipe that passes through it should be well insulated.

When chimneys for floor gas boilers are removed, the tee should be installed with a revision, and then put on the plug. The master must build up the pipe, gradually adding to it the links. The construction should be attached to the wall in 2-meter steps. Mounting should be strengthened with clamps.

After the desired height has been typed, you should install a cone-shaped tip. If the outflow channel was formed from a sandwich material, the insulation is not performed, if it is not, then such manipulations should be carried out. First of all, the flue gas for a wall gas boiler must be safe, as well as efficient. Only after it is necessary to think about the aesthetic appearance of the product. If you are not sure about your abilities and powers, then it is better to entrust the connection to professionals in your business, this will give you a security guarantee.

One of the most important aspects is the definition of requirements that are relevant to a particular situation. This depends on the safety of operation of the gas boiler and its maximum performance.

It is necessary to divide all the indicators into two categories. The first concern directly the characteristics of the chimney itself, the properties of the material used and similar nuances. In the second category, construction norms are considered, which are able to narrow the assortment available for selection. Correlation between the two groups of indicators on the basis of the optimal result.

Signs of a quality chimney

First of all, let's look at the attributes of a quality product. A good chimney for a gas boiler must meet the following criteria:

- to withstand high temperatures;

- do not be afraid of moisture;

- resist chemical attack;

- provide traction;

- do not allow the accumulation of soot, especially in hard-to-reach areas.

How to make a brick chimney with your own hands? This question is asked by many owners furnace heating. This process is not very easy and time-consuming, but it allows you to save money. Let's consider in detail.

The high temperature is the result of heating the air and releasing the glowing gases after the combustion of the fuel. With the removal of smoke and gases, the surface of the pipe is heated. If it is not designed for high temperature, cracks may appear in the chimney, which leads to the ingress of combustion products into the room.

When a temperature drop is formed, condensate can settle on the pipes. For some materials the accumulation of moisture leads to their destruction. In addition, for metallic parts, this is fraught with the development of corrosion.

Important: In some cases, special catchers and separators are provided for the collection of condensate.

In addition, it is necessary to take into account the formation of aggressive chemical compounds, which also have a destructive effect. First of all, this concerns sulfur, which is released when fuel is burned. For gas boilers, this problem does not have a strong effect.

Building codes

Other requirements are more related to building concepts. The presence of good traction is due to the presence of a natural or forced boost. Only some chimneys are calculated for both ways of working.

As for the accumulation of soot, this problem is also relevant for gas equipment. It is important not to allow its ignition and excessive accumulation, otherwise the carbon monoxide will go into the room.

When designing a chimney, it is important to take into account a number of other points:

- it is not recommended to make a meandering channel, the number of knees should not exceed three;

- the diameter of the pipe can not be less than the cross-section of the boiler connection;

- the inside of the pipe should be as smooth as possible;

- the channel must be completely sealed.

Video: installation and installation of a chimney for a gas boiler

It is recommended to install an automatic traction limiter in advance in order to not manually control the position of the dampers. Also equipped with a hatch for cleaning the system from burning. The optimum shape of the channel is cylindrical, as it provides the best removal of surplus combustion, and also does not allow to accumulate a large amount of soot, as happens with the corners of the rectangular branches.

Important: As the pipe heats up during the operation of the system, care should be taken to limit it from flammable and easily flammable objects.

Types of structures

Based on the above-described indicators, you should also choose the most suitable type of construction. Varieties of chimneys are many. They differ in the materials used and the methods of arrangement, location and other structural nuances.

For gas boilers in general, almost any option, but some features of the equipment impose their limitations.

Brick chimney

Let us consider the most popular types of systems for the removal of combustion products. A traditional type is a brick chimney. They are used in a private house when equipping all types of boilers, fireplaces and stoves.

In order for the construction to withstand the load, it is necessary to think over the foundation for the chimney. That's why the entire system should be provided even during the design of the house itself.

Today such systems are used mainly for solid fuel boilers, and gas systems are equipped with lighter and more practical models. There is a rational explanation for this:

- refractory bricks are worth a lot and require skills for its high-quality styling;

- on the load-bearing elements of the building there is a significant load;

- inside a brick channel, soot easily accumulates;

- the brick is more vulnerable to condensate and sulfuric acid.

There is a way to solve this problem, which is to supplement the brick channel with other materials: steel and ceramics.

Ceramic pipes are the best option for any type of equipment. This material has a lot of advantages:

- heat-resistant;

- do not be afraid of moisture;

- resistant to chemical attack;

- durable;

- a smooth surface prevents the soot from settling.

Ceramic gas chimney It is selected for the operating mode at a temperature of 400-450 degrees and is supplemented by steam traps.

The ceramic pipe is supplemented with a layer of insulation. To ensure that this whole "pie" does not accumulate moisture, channels should be provided along its sides for airing. That's why for the installation of the system are ideal special concrete or expanded clay unit blocks. They may also have openings for communication, reinforcement and purging.

Tip: If you plan to install outside the mine, then it is better to consider the option of combining the ceramic sleeve and the steel case. Such a product has an attractive appearance and does not spoil the design of the home.

Of course, the cost of such products is rather large, but these costs quite justify themselves in the future.

Steel

Also a popular option for modern homes is a steel chimney. It is used alone or in combination with other materials. For the ceramic model, the steel pipe serves as a protective and at the same time decorative shell. For a brick variant, this is the way to reconstruct a damaged channel. The metal pipe is simply inserted into the shaft and fixed in it in the desired position.

It is also an ideal chimney for a wall gas boiler. The metal channel is much easier to remove from the equipment to the street, as it can be assembled from separate modules. It can also be laid outside walls, both indoors and outside the house. Glossy metallic shine will complement the modern interior, especially if you talk about a style like hi-tech.

The steel used for the production of such products must be of sufficient thickness and withstand the negative effects of condensation, heat and gases. In this regard, the cost of good models exceeds the price of previous samples. Cheap models will not last longer than 5 years, so you should not save on it.

Structural features

Separately it is necessary to highlight the principles of design of different types chimneys. There are three types of connection and removal of the pipe:

- Horizontal. It is used mainly for boilers with a closed combustion chamber. The pipe goes out through the wall. By this principle, coaxial models are arranged in the apartment and private houses.

- Vertical. This is a traditional option, when the pipe directly goes up through the roof.

- Combined. Mostly we are talking about general ventilation, which is relevant for apartment buildings. In this case, the chimney consists of two parts: horizontal from the boiler to the shaft and vertical in the form of a general terminal.

Also separately it is necessary to allocate sandwich-pipes. Mostly these are steel samples. They consist of an inner and an outer tube, and the space between them is filled with a layer of insulation. They produce such models in the form of modules. This is the best option for assembling the tap outside the wall. In addition, the insulation partially protects the pipe from condensation.

To ensure good draft in the boiler and uniform combustion, it is necessary to provide fresh air. For this, a special type of chimney with additional ventilation ducts. To this type is, above all, a coaxial type of construction.

Its peculiarity is that it consists of two main parts: a branch for smoke and gases, and an inlet channel. The inner steel pipe emits smoke, and the outside of the system starts air. This is the so-called pipe-in-pipe system. Due to this, air from the street enters the boiler and supports its combustion. This is an excellent compact version, suitable for an in-apartment installation. However, with temperature changes, there is a risk of condensation and its build-up in the cold. As a result, the tap is blocked and the boiler automatically turns off. Otherwise, the carbon monoxide will go into the room.

Selection of a suitable option

So, what chimneys for a gas boiler in a frequent house or apartment are best suited? To choose the optimal type of product, you should focus on such factors:

- Type and power of the boiler. For gas equipment, the brick look is not entirely suitable, so the choice should be made between ceramic and steel bends, and thin steel at high load will quickly become unusable. When the combustion chamber is closed, coaxial systems are used.

- Type of construction. The private house is accessible via a roof or along the outer wall of the building. It is better to use coaxial models in an apartment. If the boiler is located at the top of the house, try to reduce the load on the floors and use light materials, that is, steel.

- Presence of old systems and communications. If the house had a solid fuel boiler, the brick bend can be adapted for gas. For this use liners made of ceramic or steel.

- Affordable budget. The best option there will be ceramics, since it costs less steel and lasts much longer.

A coaxial chimney is one of the safest, eco-friendly ways to remove smoke from a room while heating a gas boiler. It can be of several kinds. Let's look at the installation system of each of them, as well as the features of the smoke ducts baxi.

Installation starts in a direction from below upwards. It is necessary to provide for the presence of a window for cleaning the pipe from soot, and install condensate catchers. The pipe, if it is not ready sandwich modules, is additionally wrapped with a heater.

You can not use more than three knees. Each connection uses clamps and clamps, which prevents the leakage of gases. When the external fixture must be mounted brackets, and at least one for every 2 meters of the pipe.

Previously, we already wrote and advised to add material to the bookmarks.

Important: If a horizontal or combined flue is installed, to prevent stagnation of gases, you can not make it longer than 1 meter.

Another important point is the neighborhood with other communications. If there are gas or water pipes, electrical wiring, you need to observe the distance. Do not allow the chimney and all these elements to come into contact with each other.

Steel pipes are equipped with flexible adapters to compensate for the thermal deformation of the material. Also, care must be taken to ensure that the brackets do not bend when the system is pulled together.

The right choice and competent installation of the chimney will ensure the maximum production of the gas boiler. In addition, this is a guarantee of your safety, since certain risks are always associated with heating equipment.

Properly arranged chimney is the most important part heating system. That is why gas specialists have justified requirements for this device. Properly arranged system allows not only to efficiently operate the gas boiler, but also ensures the safety of the tenants of the private house. The operation of such gas appliances takes place without visible smoke, but this is not at all a guarantee that carbon monoxide will not accumulate. It is very dangerous, because it affects the human body in a negative way.

Residents of private houses need to understand the device of the chimney for a gas boiler in order to properly operate it. And those who are just going to install a gas heater, should be aware of what kinds of chimneys exist, and what requirements they impose.

Types of chimneys for gas boiler

Brick construction

Brick pipes for gas boilers began to be installed at a time when there were no other materials. Currently, some homeowners are building them, although such a pipe in its construction is complex and time-consuming to install. In addition, it is quite expensive to erect such a brick system and it is expensive.

Brick pipes for gas boilers began to be installed at a time when there were no other materials. Currently, some homeowners are building them, although such a pipe in its construction is complex and time-consuming to install. In addition, it is quite expensive to erect such a brick system and it is expensive.

Such a brick chimney in its technical specifications considerably less than modern systems, because its internal surface is often overgrown with soot, which results in slowing the withdrawal of combustion waste.

Ceramic construction

Such a system already has many more positive qualities. Especially noticeable they are manifested in cases where the installation is carried out by hand. Ceramic chimney is very reliable and fairly simple, it is easy to install, has a high degree of fire safety and is affordable. However, despite such a number of positive moments, this design is not in high demand.

Such a system already has many more positive qualities. Especially noticeable they are manifested in cases where the installation is carried out by hand. Ceramic chimney is very reliable and fairly simple, it is easy to install, has a high degree of fire safety and is affordable. However, despite such a number of positive moments, this design is not in high demand.

Coaxial construction

Such a system has significant differences from other designs in all parameters. It has a neat appearance, and the shape of the pipe differs favorably from all other pipes and is withdrawn through the wall.

Such a system has significant differences from other designs in all parameters. It has a neat appearance, and the shape of the pipe differs favorably from all other pipes and is withdrawn through the wall.

Although this chimney has a small size, it works very efficiently because of its structure and special coating on the inner walls. Inside it, there is never condensation, which is very important for heating systems that operate on gas fuel.

Stainless steel sandwich construction

Such a system is considered the most popular, because it has a number of significant advantages over other designs. Such chimneys are of different modifications, and this is important. They have a large number of tees, a variety of transitions and other parts that are performed at different angles. Thanks to this you can assemble a design of any complexity.

Such a system is considered the most popular, because it has a number of significant advantages over other designs. Such chimneys are of different modifications, and this is important. They have a large number of tees, a variety of transitions and other parts that are performed at different angles. Thanks to this you can assemble a design of any complexity.

The stainless steel chimney-sandwich consists of three layers. The middle layer is a heat-insulating layer, made of mineral wool. The thickness of the layer of insulation is 5-10 cm and it depends on the place where the chimney will pass, and the average temperature in winter. Correctly selected pipe will not contain condensate, on which depends the serviceability of the whole system.

The stainless steel construction has a perfectly flat internal surface, which makes it easy to remove combustion products. And thanks to the mirror outer surface the system looks very presentable.

Elements of gas chimney

Regardless of which chimney is installed (except brick), additional elements will necessarily be needed. These include:

- an adapter that connects the boiler branch pipe and the chimney;

- telescopic pipes;

- revision tee, which has in the lower part a special fitting, used to remove condensate;

- bends;

- a through branch pipe;

- main wall fasteners - clamp and bracket;

- a tip having a conical shape.

Chimneys for gas boilers, the photos of which you see below, consist of the listed elements without fail.

Chimney for a gas boiler, photo

Requirements for a chimney for a gas boiler

The device of any chimney must meet the requirements SNiP 2.04.05-91 and DBN B.2.5 - 20-2001. Otherwise, it will be done incorrectly, and it will depend not only on the effective operation of the gas boiler, but also on the health and life of the tenants.

The device of any chimney must meet the requirements SNiP 2.04.05-91 and DBN B.2.5 - 20-2001. Otherwise, it will be done incorrectly, and it will depend not only on the effective operation of the gas boiler, but also on the health and life of the tenants.

To such rules it is necessary to approach with all responsibility, as their ignoring entails trouble with the gas service, and even the imposition of a fine. Any violation will still need to be remade in accordance with established standards.

For the proper operation of the chimney for a gas boiler, the following requirements apply:

- Condensate should be drained with a special moisture collector, installed at the bottom of the pipe.

- Chimneys for a gas boiler must have a good draft, this allows the system to work more efficiently.

- In order to have good traction, in the process of assembling the structure very it is important to achieve the maximum tightness of the connection of parts.

- The chimney must be of a vertical shape without any ledges. In accordance with the rules, a slope of 30 degrees is allowed.

- The length of the pipe, by means of which the gas boiler is connected to the chimney system, always have a vertical section.

- When the height of the room is three meters The total length of the horizontal connecting sections should not exceed this height.

- Particular attention is paid to the tightness of the fitting of the structural parts in the joints, achieving maximum tightness. This is necessary in order that the glowing gases do not penetrate the chimney.

- Chimney pipe head that passes through the roof, should be above it no less than half a meter. If the roof is flat, then the headpiece should be higher by one meter.

The size of the chimney for the gas boiler should correspond to the following formula: P * L\u003e S, where P is the perimeter of the pipe section, L is the length of the chimney, and S is the area of the internal surface of the boiler.

A traditional brick chimney for a gas boiler is quite in demand, despite the many shortcomings and low thermal characteristics. Despite the apparent simplicity of the construction, it is extremely important to adhere to the existing norms laid down in the SNiP during the erection of the canal from the brick. From compliance with requirements, safety of operation and efficiency of gas equipment depend.

Whether or not a brick chimney is allowed with a gas boiler

Existing standards allow the use of brick chimneys for gas boilers. At the same time, the conditions to which the smoke removal system must comply must be specified separately. If violations are detected, the gas service inspector may refuse to put the heating equipment into operation.The laying of the channel must be performed by a qualified specialist-mason. From the device of a chimney for a gas boiler made of brick by one's own hands, without the presence of special building skills, it is better to refuse. As practice shows, only the experienced stove can take into account all the nuances associated with the calculation and subsequent installation of the structure.

Requirements for a chimney for a gas boiler made of bricks

The main purpose of the chimney is the safe removal of combustion products from the boiler. The essence of all the requirements is reduced to preventing possible fires, as well as carbon monoxide poisoning during the operation of heating devices. In particular, in SNiP and PB it is indicated:From time to time, there are new requirements for a brick chimney for a gas boiler. Even before the construction starts, find out about the existing norms in the Gas Service. Current information will avoid unnecessary costs and will facilitate the commissioning of the structure.

Mono-brick chimneys for boilers on gas

There are several options for brick chimneys, among which, mono-construction has the worst thermal performance. Under the constant influence of an aggressive environment, the brick is destroyed, the seams crack and lose their tightness. For this reason, after 5-6 years of operation, you will need to repair the pipe and replace the damaged areas.During construction, the following conditions are met:

The disadvantage of the brick chimney system is a short service life and high requirements for the quality of masonry. It is difficult to lay the flue correctly, therefore it is better to use the services of a qualified mason.

Combined brick smoke exhaust systems for gas boilers

Combined systems are distinguished by better thermal performance than a conventional brick chimney. The main feature of the design is the presence of a core of steel, ceramics or asbestos cement. Due to the combined scheme of the installation, the drawbacks inherent in the brick channels are almost completely eliminated.When choosing combined systems, it is necessary to pay attention to the technical parameters of the core, ultimately determining the operational characteristics of the chimney.

Chimneys made of bricks and stainless steel

Existing schemes for the construction and restoration of existing chimneys, provide for the possibility of applying three basic modifications, differing in the material of the internal contour. The consumer is offered one of three options:

Before commissioning, it is mandatory to use old brick chimneys for use with gas boiler equipment.

Combination of bricks and ceramic pipes

This design is one of the best in its characteristics. The ceramics are resistant to acids and can withstand heating up to 1000 ° C. Pipe made of ceramics has good traction, quickly warms up and goes to the operating mode.

This design is one of the best in its characteristics. The ceramics are resistant to acids and can withstand heating up to 1000 ° C. Pipe made of ceramics has good traction, quickly warms up and goes to the operating mode. A separate standing brick chimney with an internal ceramic pipe for connecting a gas boiler is used as an alternative.

Problems with a brick chimney with a core of ceramics, are extremely rare. The design is characterized by a long service life and the resistance of the ceramic pipe walls to burn-out. On condition correct installation, the chimney will last at least 50 years.

The chimney is made of asbestos-cement pipes lined with bricks

Chimney pipe made of asbestos pipes lined with bricks can not compete in its characteristics with stainless steel and ceramics. The popularity of asbestos cement systems was achieved due to its low cost and availability of the material. At the same time, the pipes have several significant drawbacks:- Abundant production of condensate - the asbestos-cement pipe, even inside the brick, cools rapidly, which leads to condensation in a large volume. As a result, the chimney is often damped and the structure is destroyed.

- Low aerodynamic characteristics - the asbestos can not be used for condensing boilers and gas equipment with a closed combustion chamber.

According to its thermal and aerodynamic properties, as well as the ratio of cost and durability, the leading position is taken by a brick chimney shaft with a stainless steel pipe inside.

How to make a chimney for a gas boiler made of bricks

If the existing SNiP and GOST are not complied with, the danger of a chimney from brick gas heating. Particular attention should be given to the choice of building material, masonry mortar, thermal insulation.It is important not to allow the accelerated formation of condensate and to provide an opportunity for regular service smoke removal systems.

From which brick put a chimney for a boiler on gas

To use the chimney from gas appliances, a ceramic brick is used, made from baked clay. The material retains heat well and is able to withstand temperature changes. It is strictly forbidden to make a chimney from sand-lime bricks.For a smoke removal system, any ceramic brick, but only a certain brand, will not work. Moreover, for the manufacture of the outer and inner parts, a material with different markings is used.

- Fire resistance - the material is assigned a class "A" or "B". The first is designed for heating up to 1400 ° C, the second is 1350 ° C.

- Strength - brick M 250 or M 200 is needed for brickwork. The high density leads to an increase in the heating time, therefore, it is not recommended to use a building material marked M300 or higher.

- Frost resistance - chimney made of solid ceramic bricks with a coefficient of resistance F300.

The chimney can be made of facing bricks, but the material that withstands frosts does not tolerate heating / cooling. After a few heating seasons, the surface begins to crack and crumble. In the event of condensation, the lining material loses strength.

It is correct to make a brick chimney for a gas boiler in a private house, full-bricks, class "A" or "B", with a strength of M 250 and frost-resistance F300.

Which masonry mixture is used for the erection

The composition of the mixture for laying a chimney of brick is selected depending on which part of the construction is being erected. As practice shows, the use of ready-made refractory and heat-resistant masonry mixtures is optimal. The resulting solution is characterized by acid resistance and ability to withstand negative atmospheric phenomena.If there is no financial opportunity to buy a ready-made adhesive composition, the mixture is made independently.

- Clay mortar is heat-resistant, it is used for constructing a structure in the house. Clay soaks under the action of water, so the mixture is not suitable for the outer parts of the chimney.

- Cement composition - the use of cement mortar is necessary for parts of the chimney located outside the building. To increase the strength and give the solution acid-fast characteristics, special additives are added to the prepared mixture. The same solution is used in the manufacture of the chimney base.

The ready-made solutions contain all the necessary additives and plasticizers, which makes it possible to make a perfectly smooth seam without leaving any voids. The only drawback is the high cost of masonry.

How to insulate a brick chimney

The necessity of thermal insulation of a brick pipe is connected, first of all, with the need to reduce the amount of condensate produced. Warming the walls above the dew point is faster, which leads to a decrease in the volume of moisture that is lost.The technology of insulation of the external brick chimney is as follows:

- First you need to repair the brick pipe. Damaged areas are replaced. Are removed from the masonry mortar, the pipe is primed.

- To level the pipe, and remove the cracks and chips, it will be necessary to plaster the brick surface. Works are carried out by lighthouses. The solution is allowed to dry. It is forbidden to heat the chimney during this period.

- The thermal insulation of the brick pipe is carried out - the thickness of the insulation is 5-10 cm for the external cladding, it is fixed to a special glue composition, after which the plates are fixed with the help of anchors. The reinforcing mesh is stretched from above, placing it in a layer of glue.

- Finishing is in progress.

To insulate a brick pipe in an unheated attic, use mineral wool. The material is cheaper approximately twice, and in the absence of precipitation, it performs well heat insulation functions.

The device of a chimney above a roof

Most often violated rules associated with the passage of roofing, installation and cladding the overhead section. The rules for the passage of a brick chimney through a wooden ceiling during heating with a gas boiler are as follows:- When passing through slabs or roofing, observe fire breaks. In SNIP 41.01.2003 it is indicated that from insulated flue to combustible structures should be not less than 38 cm. For insulated pipes, the gaps are reduced to 5 cm. The space is filled with a basalt heater.

- For drilling a special box is installed, installed under the roofing.

- The chimney head is insulated with basalt slabs, ceramic tiles or faced with facade plaster.

- The height of the pipe is calculated depending on the distance from the ridge. There is a general recommendation that the brickwork in the private house is higher than the top level of the roof. In some cases, in accordance with this instruction, it will be necessary to rebuild the existing brick chimney for the installation of a modern gas boiler.

- The tube head is covered with a deflector to increase the traction force.

Connection of the gas boiler to the existing brick chimney is carried out only under the condition of sufficient pipe height and after the mandatory use of the system.

How to prevent condensation and methods of moisture removal

The main factors for the formation of condensate are the following:

Elimination of moisture condensate is carried out using a special steam trap, which seals the chimney.

Repair of a brick chimney pipe from a gas boiler

Reconstruction of the old chimney may be required in several cases:- The detected malfunction during regular inspection of the masonry.

- Re-equipment of the smoke removal system, which allows the use of conventional stove brick chimneys for modern gas boilers.

Why is the brick on the gas chimney destroyed?

The frequency of inspection of brick chimneys at least once a year, before the onset of the heating season. Inspection shows the presence or absence of a solution from the joints, cracking of bricks and other disturbances. The cause of the destruction are:

Do I need to use a brick chimney and what?

Chimney stamping is required in the following cases:

To avoid the destruction of the construction of the brick chimney system in the future (average service life of 6 years), the usage is carried out. A stainless steel pipe or corrugation is installed in the chimney.

Additional sealing of chimneys in brick walls for individual gas boilers is required only if ducts designed for ventilation are used.

How to clean a brick pipe with gas heating

You can clean pipes yourself, which, as practice shows, often leads to the destruction of brickwork. Without a certain qualification, it is not recommended to clean chimneys, because during the execution of work the internal walls of the canal are destroyed.Alternatively, you can call a specialist for cleaning. Works on average will cost from 600 to 3000 rubles. The time taken is from 3 to 6 hours, depending on the degree of pollution.

Advantages and disadvantages of connecting the boiler on gas to the brick chimney

Brick chimney channels have certain pros and cons. As advantages it is possible to allocate:- Low cost when using an existing pipe.

- The possibility of connecting a gas boiler with an open combustion chamber to a brick chimney.

- Accessibility of building and finishing materials.

- Short service life.

- High requirements to the quality of masonry and the qualifications of the worker who carries out construction work.

- The need for insulation.

- Many restrictions - to make a gas chimney in an external brick wall, use the old channel without using it, connect the system to condensing boilers and equipment with a closed combustion chamber, it is forbidden.