Good deep pump. Choice of design features. Criteria for choosing a pump for a well

The pump is the main component of the independent water supply of a private house. This equipment is the heart of the system, through which the supply of well water to the consumer. That is why in the process of arranging a domestic waterpipe, the owners of the plots concentrate particular attention on what kind of pump to choose for the well. Given the huge variety of types and models, it is not easy to make a choice that meets all the criteria. For the purpose of systematization and simplification of some concepts, in this article we will consider all types of well pumps, their pros and cons, and also make independent calculation of technical characteristics for equipment operation in specific conditions.

The depth of the water-carrier from which water is extracted for domestic needs can vary - from 5 m and above. For example, artesian waters usually located at a depth of 70-100 m. In this case, it is impossible to organize the supply of water without the use of powerful pumping equipment.

The choice of a pump for a well depends on several indicators, one of which is the placement method. On this basis, all downhole vehicles are divided into two groups:

- superficial;

- submersible.

It is impossible to say unambiguously which type is better, because each has its own characteristics, which can ideally be suitable for certain conditions and be completely useless in another situation. In any case, the correct choice of a downhole pump must be made taking into account specific criteria.

Surface and submersible pumping equipment for a well

Surface Pumps

This type is very popular among summer residents and owners of small suburban areas. Surface models are easy to install and operate. In addition, they allow pumping water not only from the well, but from any other reservoir. Since the electric motor does not have reliable protection from moisture penetration, such a device must be installed on a dry surface or have a special platform for placement on water.

Note. The choice of surface pump is usually applicable for wells of shallow depth (up to 9 meters), which is due to the physics of the process. For working at great depths, an additional ejector is used, which is placed directly in the aquatic environment.

According to the principle of action, surface aggregates are divided into:

- vortical;

- centrifugal;

- ejector.

Vortex

The most compact and affordable in the price plan devices. Such equipment carries out the lifting of water by means of a rotating shaft, which is equipped with blades. Due to this, vortex devices are capable of creating a pressure that is 3-5 times higher than that of centrifugal devices. The low cost is explained by a rather low efficiency (about 45%). In addition, before choosing a downhole pump of this type, it should be ensured that there are no impurities in the water, since it is capable of pumping only clean liquid.

The principle of the vortex pump

Centrifugal

Pump equipment operating on a centrifugal basis is capable of pumping out water with a small amount of impurities. In addition, it successfully copes with the air bubbles formed in the system and bubbles. Therefore, despite the higher price compared to the vortex pumps, surface centrifugal type appliances are more popular with private homeowners in the organization of autonomous water supply from a well or well.

The design of the centrifugal pump

Ejector

Application remote ejector, which connects to a pipeline section that is immersed in water, allows to significantly reduce the point of water intake. For example, such a pump can be chosen for a well depth of 20-30 meters. However, along with the increase in the depth of the water intake, the efficiency of the device falls (up to 30-35%). In addition, ejector units require the placement of two pipes in the well at once, which imposes certain restrictions on the minimum diameter of the hole in the hole.

Diagram of ejector immersion into the well

Submersible pumps

If the water mirror is at a depth of more than 9 m, then the optimal solution is to choose borehole pump for the well. Such equipment is characterized by high performance and a relatively small body diameter.

Interesting to know. The diametrical size of some models of submersible devices is 3 inches (76.2 mm), which makes it possible to install them inside narrow casing pipes.

Today the market offers a wide variety of modifications of deep aggregates, which differ in overall dimensions, technical characteristics and cost. Regarding the principle of operation, submersible pumps are divided into several types:

- screw;

- vibratory;

- centrifugal.

Screw

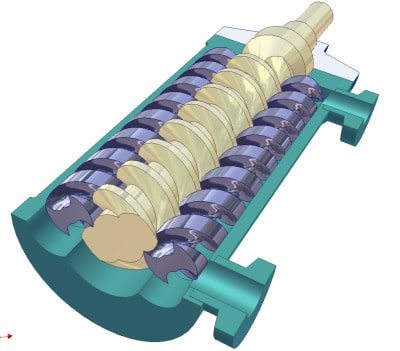

The design of screw devices consists of a rotor with a certain number of turns and a stator with an internal thread. During the rotation of the rotor, water rises along the spiral of the stator part, due to which pressure is created. This kind of deep well pump has one undoubted advantage - the ability to pump water with a lot of impurities. Pollution tolerance is up to 20 kg per 1 m³. Therefore, it can be said that the submersible type screw pump equipment is primarily intended for dirty water.

Screw (spiral) pump in section

Vibration

The main element of this device is a coil with a core, which is connected to the rubber diaphragm. As a result of the passage of alternating current through the coil, the diaphragm begins to vibrate at a high frequency, creating an excess pressure in the inlet pipe. Such devices are reliable enough and unpretentious in maintenance, besides have low cost. However, due to the creation of vibration in the water, they can help raise the sand from the bottom, so vibrating pumps are not recommended for sandy wells.

The device of the vibrating apparatus

Centrifugal

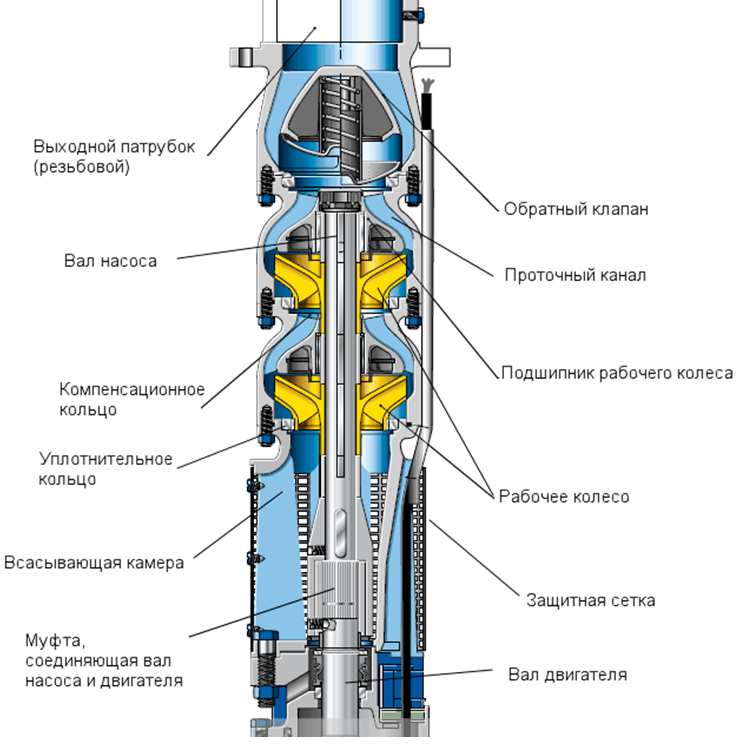

The principle of operation of such equipment is based on the creation of a centrifugal force during the rotation of the impeller located on the shaft. During the rotation of the shaft the liquid rises along the walls of the spiral housing and is pushed outwards. The centrifugal unit has good performance and very high efficiency (up to 85%) with relatively small dimensions (from 3 inches), which made it the most popular device for use in deep wells small diameter.

Scheme of a centrifugal borehole pump

Surface or submersible: what type is best for a well

To determine which pump to choose for the well - surface or submersible - we list the main advantages and disadvantages of each type.

Surface equipment:

- + Affordable cost for the average consumer.

- + Simple installation and convenient maintenance.

- + Ability to install in a dry indoor environment, which increases the service life.

- - Rigid depth restriction (up to 9 m).

- - High noise level during operation.

- - Low productivity in comparison with deep aggregates.

Submersible equipment:

- + Ability to operate at any depth.

- + No noise.

- + High performance.

- - Arrangement of local water supply on the basis of a deep pump will cost 2 times more than the organization of the surface system.

- - The complexity of mounting / dismantling.

- - The wedge of the device in the borehole is possible.

In most cases, the question of which well pump to choose is reduced to the depth of the source. For wells or shallow wells the best choice is the arrangement of pumping equipment on the surface or in a separate room, for example in the basement. When the water mirror is located below 9 m, submersible devices are used. Of course, in such a situation it is possible to apply an ejector for surface pump, but this does not make much sense. Firstly, it's extra costs, and secondly, the performance of the deep instruments is much higher.

Each type of pumping equipment is optimal for specific conditions

Selection of a downhole pump according to technical parameters

In order to choose the right pump for the well, only knowing about the types of devices is not enough. When selecting a particular model, attention should be paid to certain technical parameters.

- Water level. This characteristic can be considered a key characteristic, since all instruments are designed for a certain depth. If the real water level is below the passport data of the pump, then it either fails to provide water abstraction, or it will quickly fail.

Important. You need to be guided by the dynamic level of water in the well, determined during the operation of the pumping equipment.

- The diameter of the casing. This parameter is important when choosing a deep well pump, which is lowered directly into the structure. It is necessary to choose such dimensions that the device freely moved inside the pipe without the risk of a wedge.

- Water consumption. Depending on this indicator, the productivity of pumping equipment is calculated. The calculation is carried out based on the number of people living and points of consumption.

- The production rate of the well. Choosing productivity, you should consider the amount of water in the source itself, and how quickly it resumes. Too powerful the unit can quickly empty the well and leave it for a while without water supply.

Example of performance calculation

The choice of pump output for the well is based on the calculation of total water consumption. The following table is used for this:

Table of consumption of sanitary water consumers

To find out the total consumption, it is necessary to sum up the indices of all the points of the draw-off. For example, if there are two wash basins with a water tap in the house, a bath with a mixer, a toilet with a flushing cistern, a washing machine and a watering tap is used on the site, then the calculations are as follows:

0.1 + 0.1 + 0.25 + 0.1 + 0.25 + 0.3 = 1.1 l / s

However, that's not all. The likelihood that all points of water-disposal will be involved at the same time is small. Therefore, the result should be multiplied by the correction factor, which depends on the number of people living and on average (for 2-3 people) is 0.5. In this way,

1,1 x 0,5 = 0,55 l / s (or 1,98 m³ / h) - the pump to ensure the normal water supply of the house.

Browse popular models

When buying equipment for household needs, the buyer very often faces the dilemma of which brand / firm to choose a downhole pump. Below is a list of the most popular models, which successfully proved themselves during operation in systems of autonomous water supply.

The choice of pumping units is quite wide and varied

- BELAMOSTF3. A budget model with a flow rate of 3.3 m³ / h and a maximum immersion depth of 30 m. A single-phase motor is well insulated from water, and impellers made of technopolymer allow pumping out liquid with a sand content of 150 g / m³.

Important. When installing a submersible pump, make sure that the inlet pipe is at least half a meter from the bottom, and the housing must be completely immersed in water.

- GRUNDFOSSQE. High quality of the equipment of this manufacturer is known to many. Among the main advantages: built-in protection against dry running, surges and overheating, good pressure (up to 100 m), high efficiency, wear resistance.

- UNIPUMPMINI. One of the main advantages of the models of this series is compactness, which allows to equip wells with a barrel diameter from 85 mm. The floating design of the impellers prevents the wedging of the pump in case of ingress of coarse-grained sand.

- AQUARIUS. The dimensions of this device contribute to its placement in downhole structures with a diameter of 100 mm. Productivity 1,8 m³ / h will provide water vacation home If you need to choose a pump for a well 40-50 m deep, this is a good option.

- JILEKS WATCHES. Pumping equipment of this series is noiseless, has a minimum level of vibration and is made of reliable materials. At the entrance there is a strainer with cells 1.5 x 1.5 mm, which prevents sand from entering the system. "Water meter" is characterized by high efficiency and a long period of operation.

The pump "Dzheleks Vodomet" is often used to organize independent water supply in suburban areas

So, we have considered the basic nuances of the correct choice of a pump for a well. You can only take advantage of the advice provided and get the best in terms of its characteristics for its own conditions. Do not forget that in the event of any difficulties during the installation of equipment - you can always use the services of specialists.

In houses outside the city to have a central water supply system is almost impossible. Usually this function takes on a well or a well drilled by the owners. In any case, you have to break your head, how to lift water from the mine. With a well of problems less: threw a bucket and pulled! But with a well this number will not work. In its construction, the bucket simply does not fit. The only option is to install a water pump. But they differ in the principle of action. It is desirable, before choosing a pump for a well, to study their range and features of operation, as well as the characteristics of the casing for which you select the equipment. About some nuances, like these, we'll talk today.

What is important to know when choosing a pump?

There are several parameters that affect the selection of a particular pump model for a well. And you need to analyze each of the parameters as accurately as possible.

Daily water flow

Before you start to pick up the pump, you need to calculate how much you have left per day of water. This will determine the capacity of the unit and its performance. If your family is small (3-4 people), and there are no large kitchen gardens, you can stop at the unit, which gives out 60-70 liters per minute. If a lot of flower beds and beds, where frequent watering is required, it is necessary to select a pump more efficiently.

When studying pump models in the store, pay attention to the product passport. It always indicates the depth to which this model is designed. Your task is to correlate this information with the data of your well. If you do not specifically remember the dimensions, you can do this:

- To hang a load on a rope or a thin twine (it is desirable iron);

- Lower it into the well shaft until it rests against the bottom;

- Take out and measure the wet and dry part of the twine. Wet will tell you what the height of the water column is in the well, and the dry one is the distance to the surface from the beginning of the water;

- Adding these two values, get the total size of the well.

The rate of filling the well with water (debit)

It is impossible to calculate the well debit in an ideal way, because in the spring the inflow of water will be faster, in the winter time - more slowly. But you can manage with approximate figures. To count them is easy: you need to ask friends or neighbors around the site to operate the pump and start it at work at its source.

- Distinguish the time for which the whole water is pumped out;

- Notice how many hours the well will be full;

- Divide time # 2 at time # 1 - you get an approximate debit.

There may be a question, how to know that the well has been completely filled. Elementary! Periodically dropping the same weight with which you measured the height of the column. As soon as the readings coincide with those that you received when determining the size of the mine - the well is full.

Casing diameter

If the well is only planned, it is better to make it a four-inch. For designs with a diameter of pumps sold a great variety, which can not be said about the three-inch. They are drilled less often, because they produce little equipment for them.

Measure the diameter of the casing with a building tape measure, and then convert centimeters to inches (1 inch is approximately equal to 2.54 cm)

The diameter of the finished borehole is easy to measure by yourself (in centimeters, and then converted to inches), or to contact the workers who have drilled your construction.

Quality of the drilled well

If you drilled the construction yourself or are not sure about the professionalism of the drillers, then look for pumps designed specifically for wells. Universal units, of course, will be cheaper, but they are less effective. The fact is that unprofessional or long-used sources are often washed with sand, and it will interfere with the operation of machinery. You will often have to clean the pump, and its service life will be shortened. If the unit was created specifically for wells, then blockages in the liquid are not so terrible.

If the well was drilled by non-professionals, then it can be washed with sand. Therefore, it is better to buy specialized pumps designed specifically for wells, rather than universal

We select the unit by the features of work

When all of the above is analyzed, you can begin to familiarize yourself with the types of pumps. Based on the features of the work, all systems are divided into 2 subgroups: surface and submerged (otherwise - deep). Consider their differences.

Surface Pumps

This type of equipment is installed on the ground, without immersion. The pump pumps the fluid through suction. The deeper the water column is, the harder it is to raise the liquid, the more powerfully the system is selected. Surface pumps are recommended to buy for wells in which the distance to the beginning of the water column does not exceed 8 meters. Do not buy a rubber hose for pumping water. He will turn on the walls when the equipment is turned on because of the rarefied air and will not let the water pass. It is better to replace it with a pipe with a small diameter. The most important plus surface pump: easy to install, dismantle.

The surface pump can be installed right near the well, and to reduce its growling, it is possible to make a wooden box and hide the equipment there

Submersible units

If you have a deep well, the option with a surface pump will not work. We'll have to look for submersible units.

The technics is immersed directly in a pipe, in a water column. Systems operate on the principle of liquid ejection. Determine what kind of pump you need for your well, according to the size of the well. More precisely - it is necessary to calculate, on what height the unit will have to push out the water jet. To do this, remember the measurements that you conducted earlier. The length of a dry rope with a weight is the height at which the pump will have to lift water. Add to it 3-4 m., Because the pump is immersed for a couple of meters deeper than the beginning of the water, and you will get the final figure. If it does not exceed 40 meters, then you can buy simple, low-power pumps. Look for information in the passport about the maximum depth at which the system can operate.

Finding more powerful submersible pumps is easy: their appearance is larger than that of low-power "brethren," and by weight they are heavier

By the way, if by your calculations the height of water lifting is 60 meters, and for the pump this depth is the maximum, then this model is better not to take. The technique will work at the limit of its strength, because with each meter in depth productivity decreases, and the load increases. Look for pumps that are 70 meters deep. This will help the equipment to work without unnecessary strain and better preserved.

Advice! Take models with automation. If the motor overheats (from a long running time or clogged water) or the entire fluid is deflated, the pump will shut itself down. Otherwise, the motor will simply burn until you find the problem.

Of the two types of deep-well pumps (centrifugal and vibrating), stop at the first. Vibrations are too sensitive to dirty water, and in the process of work destroy the walls of the well.

A centrifugal pump captures water with blades rather than a vibrating membrane, as it vibrates, so it hangs motionless and does not destroy the walls of the well

The pump is selected for a long time, so look for models produced by well-known, well-established manufacturers. Then it will be easier for you to find a service center for repair and maintenance of your system.

From the correct choice of pumping equipment for the well will depend on its productivity, durability, and sometimes the operational life of the hydraulic structure itself.

The main types of pumps and their features

- Vibratory - are more often used in wells, because as a result of vibrations they are able not only to raise the sediment from the bottom, but also damage well walls

- Centrifugal submersible - more than once convinced that this the best decision for wells. At work, a minimum of vibration is formed, the capacity is sufficiently high, as well as the water lifting height, and overheating is excluded due to engine design features

- Drainage or self-priming - their application is relevant for wells of shallow depths or as dehumidifiers for caissons

Basics of selecting a pump and equipment for a well, the criteria

- The height of the water rise is the total values of the depth of the well (from the point of immersion of the pump to the surface of the earth) and the height of the highest point of water intake from the ground level. Also, the horizontal water movement coefficient is taken into account if the hydraulic engineering structure is sufficiently far from the house (20-30 meters)

- The type of borehole (sand, artesian) and casing material - we have come across in practice with damages that are capable of applying PET vibratory pumps or downhole filters

- The volumes of water consumption and maximum total loads

- Production Rate

- The quality of water in the well and the presence in it of solid impurities

I advise you to rely in this matter on the experience and qualifications of professionals. We will not only help you choose a really suitable pump, but we will also offer it to you at a dealer price, we will carry out a professional installation.

Now I will answer the questions that our clients ask us most often.

Which pump is better for the well?

Based on personal experience, I can say that for wells, regardless of their depth, the material of the walls of the casing string and the type of bottomhole filter, it is better to use centrifugal (vortex) submersible pumps.

During operation, they do not vibrate, so do not pick up the sediment, and most importantly - not able to damage the casing walls and bottomhole filter. They also have high performance, and unlike vibratory pumps can last longer in continuous mode.

Important!

How to choose a pump Regardless of which type of pump will be preferred, the basis of choice is the productivity of the well in relation to the volumes of consumption (peak and average).Pros of centrifugal submersible pumps

Centrifugal pumps can not physically overheat, as water passes through an engine that consists of a rotor electromagnetically rotating electromagnetically, and a stator. Between them moves the flow cold water, providing natural cooling.

If the water surface is not more than 10-15 meters from the surface, you can use a self-priming pump, but there are a number of difficulties, including the need for additional maintenance and control. Below I will look at the characteristics of several centrifugal pumps in comparison with a vibrational analogue, so that you can better understand the difference in performance.

|

Pump model |

Power |

Lifting height |

Output l / h |

Depth of dive |

|

|

Vibration pump BELAMOS BV012, 25 m |

2800 rubles |

||||

|

Centrifugal submersible pump Caliber NPCS-1,5 / 50-550 |

5300 rubles |

||||

|

Centrifugal submersible pump QUATTRO ELEMENTI Deep 1500 Pro 772-531 |

19500 rubles |

||||

|

Submersible borehole pump BELAMOS TF-60 |

15000 rubles |

||||

|

GRUNDFOS SP 5A-25 3x400B 05001K25 with protection against dry running |

67,000 rubles |

||||

|

Gileks Vodomet PROF 55/75 House (kit for automatic autonomous water supply) |

26000 rubles |

As you can see, the characteristics of the pump directly affect its price, but in each price category there are pumps of different capacities. I have more than once convinced myself that only a professional can determine the priority criteria for selection.

Frequent errors in the selection and installation of the pump

In my practice, I periodically encounter a problem with the wrong pump, and this is fraught with far more serious consequences than you think. So, what not to do?

- "The neighbors have this - it means that it will suit me" - a classic mistake. Two wells, located at 20-50 meters from each other can vary very much in production rates. In addition, it is important to take into account factors such as material, casing diameter, type of bottomhole filter, consumption volumes

- "I'll buy more - in reserve" - another common misconception. First, why repay? Secondly, a too high-capacity pump can destroy a well with a low rate of volley pumping. We often had to repair the well, the quality of water in which was lost precisely because of the wrong choice of the pump

- "I will do all the calculations myself" - even many of my colleagues who switched to free bread do not always make calculations with high accuracy - too many factors and coefficients need to be taken into account. Better leave it to professionals

And here are some classic mistakes that many people admit, who decided to make installation of pumping equipment themselves:

- Incorrect depth selection

- Incorrect fixing of the pump on the supporting cable, as a result of which part of the load falls on the electric cord

- Incorrect connection to mains

IMPORTANT!

Self-assembly - is it necessary?Self-selection and installation of the pump can lead to serious waste afterwards. I strongly recommend that you do not spare one or two thousand rubles for the work of specialists who will make all the calculations and carry out the installation correctly.

Optimum depth of installation of the pump between the bottom and the mirror of water for a regular water intake

Here we completely disable imagination - the installation depth of the pump is a constant value recommended by the equipment manufacturer. Nuances occur only for high-performance models with a large installation depth. In this case, at least one meter of water should remain at the bottom of the well.

At what depth should the submerged pump be installed to pump the well?

At the stage of pumping the well, we always pursue the same goal - to pump out sand and muddy from the face. It is irrational to do this by a centrifugal pump, since they are very sensitive to the presence of solid fine fractions in the water. Therefore, for pumping (if possible) is used vibrating pump with a lifting height of up to 80-110 meters. They are not afraid of sand, and they can be installed almost at the bottom, in order to maximize the extraction of unnecessary dirt from the well. If the well is pumped by a centrifugal pump, then at least one meter should remain to the bottom of the well, as required by the instructions for the equipment.

Dry-running protection for downhole pump

I highly recommend choosing pumps with this optional option. Yes - they are more expensive, but they will last longer without replacement. Imagine this situation - you are not at home, the tap is running, and as a result, the pump pumped all the water out of the well and continued to work. The result is the replacement of expensive equipment, as the plastic impeller will not withstand high temperatures. If it is protected against dry running - a relay, special floats and automation, then such incidents are excluded.

Conduit for downhole pump - extension of submersible pump cable for well

I can assure you that you will not find such a pump, to which would be attached an electric cable of the same length as the height of the lift to which it is designed, because 120 meters of cable, this is a lot. The maximum that the manufacturer offers is 15-30 meters. How to be? Ramp up! Do it yourself I do not recommend categorically, but if you still decided, then here are some of my professional advice:

- Use a water-supply cable - yes, it's slightly more expensive, yes - there will not be a catastrophe if you take a conventional one, but if for some reason a simple cable will be damaged, the consequences can be serious. Vodopogruzhnoy designed for direct contact with water, it is better

- The connection must be at the maximum height from the water mirror - do not cut the cable directly before entering the pump - cut the plug

- Use special connectors and epoxy resin for sealed joint sealing or special shrink sleeves

- Use a cable of appropriate cross-section with a correction for the resistance along the length

In general, and here not all is simple, therefore I recommend also to leave this work to specialists.

Pump and automation for wells on sand

Wells in the sand in the Moscow region are used primarily for irrigation in garden areas. The production rate in such wells is generally low and unstable, and the quality of water is low, since there is a lot of sand in it. Therefore, the optimal solution in this case, I see a submersible vibrating pump. It is affordable, non-selective to the quality of water.

Thinness of vibration pump installationWhen installing the pump, it is important to fix it so that it does not touch the walls of the casing or the bottom filter, otherwise vibrations can lead to mechanical damage to the equipment or the structure itself.

We automate the system based on a vibro pump

The simplest option for automatic shutdown of such a pump is a switch with a timer. If you know the flow rate of a well, and it is, for example, 500 liters per hour, and your pump pumped this volume in half an hour, then simply set the timer for 20 minutes to select the correct amount of water, and leave your business. You can also use a float system.

Low-productivity pump for a well with a low production rate

A serious problem is represented by wells with a low production rate. I often came across the fact that people are looking for low-performance pumps as a solution, but you will not find them, because even the smallest pump has a minimum capacity of 450 liters per hour, and if the output of the well is 250 liters, then this is almost twice the discrepancy. What to do? I propose the following solution:

- We install in the basement or in the attic accumulating capacity of 500-1000 liters. If in the basement, then with a membrane to maintain pressure, if in the attic, then without

- We connect the automation to the tank to constantly support its full

- We install automation to protect against dry running in the well

What do we get as a result? Your summer cottage is provided with water, since even with a very large desire you will not make a volley drop of 500 liters. The volume of water in the bathroom is 200 liters, one washing machine is 60-80 liters, the toilet tank is 8-15 liters. The pump runs in intervals of 5-7 minutes, if necessary, adding capacity or stopping work if the water in the well goes below a certain level. The problem is solved!

Is the vibrating pump harmful for the well?

Harmful, and I'll tell you more, if not properly installed, it will destroy the well faster than you think. The fault of all vibration. Sometimes the use of a centrifugal pump is irrelevant, and in these cases it is important at least to observe the installation rules:

- Install the vibrating pump at least 1.5 meters above the bottom of the well

- The pump must not touch the walls of the casing - it must be free to hang in the water column

- Also, I recommend using models with an upper water intake - so it will less disturb the face

Hydropump when the pump is turned on and a strong impact when switching off

Hydraulic strike in the water supply system not only leads to the failure of sanitary equipment, but also the pumping equipment itself. This phenomenon occurs when the pump is wedged into the system directly. To avoid this simply - for this I advise you to use membrane hydraulic accumulators. They extinguish the sudden pressure jumps in the system, prolonging the life of your expensive plumbing equipment.

Peculiarities of maintenance of pumping equipment

During my professional career, I have faced this question many times. In fact, in the case of correct installation and the operation of the submersible pump does not require additional maintenance. Some models require pre-lubrication of individual elements just before installation - no more. When using centrifugal submersible pumps for pumping water with sand impurities, repairs may be required - replacement of blade blades. All these works should be done only by a professional - you can only do harm yourself.

Important!

Company "Kopanka" - professional selection and installation of pumping equipment

We offer our customers a full range of services for the calculation, selection, supply and installation of pumping equipment of all types for your specific needs. Turning to us, you get a guaranteed quality of the result by the most favorable prices, as well as consultations of competent, experienced professionals.

Private houses, remote from the city, are most often not connected to the water supply system. The only way out in this situation is to equip a well or well. But for water to enter the house, it is necessary to install a pump. By design, they can be submersible and shallow, but each of them has its advantages and disadvantages. It is therefore extremely important to know which pump is best for the well to be selected.

Surface devices are designed for wells and wells with a shallow depth. Up to the surface of the water should not be more than 8-9 m. For wells with greater depth, submersible pumps are installed, so they are called in another way deep.

Surface devices are placed outside the well. Due to what they are easy and convenient to maintain. Often they are installed together with the storage tank to stabilize the pressure in the system. But because the surface pump works outside the well, it makes a lot of noise, and also takes up space. As a result, it is necessary to equip the area for it and build a structure to absorb sounds. Since the pump is out of the water, its engine does not cool to it.

Arrangement of internal and external well pumps

Submersible devices are divided into several types:

- vortical;

- screw;

- vibratory;

- centrifugal.

Vortex pumps have one impeller. It draws water into the inner part and pushes it into the outer part, due to which a vortex appears. When the water passes through the wheel, its speed and pressure increase. The design of these pumps is simple, so they have a low price. But because of this they have low efficiency and they are unable to work with liquids in which there is sand or other similar impurities, as this leads to a rapid deterioration of the device.

Vortex pump arrangement

The main working element of the screw device is a screw (auger). Water, getting inside the pump, is gradually pumped by the auger, as a result, there is a head and liquid is forced out. Just like the vortex device, the screw device has a simple construction and a low price. Recommended for use in wells with low production rates. But in comparison with the vortex pump, the screw is more resistant to impurities in the water.

![]()

Screw pump arrangement

Vibrating or centrifugal

The vibrating device is capable of pumping water from wells with a depth of up to 40 m. They have a simple design and a relatively low price. The vibrating pump does not require constant maintenance, and has a small weight and dimensions. But he is unable to work for a long time, and can also give out an insufficiently strong pressure. The most important drawback is that due to vibration, the walls of the well are destroyed, and it gradually falls asleep.

![]()

Scheme of vibration pump device

The centrifugal pump, in contrast to the vibratory pump, works without damage to the walls of the well and does not make noise. There is also a large selection of devices of this type with different characteristics.

The impeller of the centrifugal pump consists of the front and rear discs, and between them are blades directed to the opposite side of its movement. It is on the number of these wheels and the height of the head depends, the more they are, the higher it is. therefore centrifugal pumps have different heights.

Note! Unlike all previous devices, centrifugal pumps are able to work for a long time, as well as they are more energy efficient.

Principle of operation of a centrifugal pump

Best Submersible Pumps

Aquarius BCPE 0.5-32U

Characteristics of the device:

- weight - 11 kg;

- head - 47 m;

- the nominal power is 820 W.

The pump can only work with clean water and a temperature of up to + 35 ° C. It is installed vertically, the diameter of the outlet 1 ". In addition, the device is equipped with protection against overheating and smooth start-up. Submersible pump Aquarius BTPE 0,5-32U works silently and has a long cable. The top cover is made of metal, not plastic like many other devices. The starting capacitor is remote and is in the box. In case of breakage, it can be replaced.

The disadvantages of the pump include the dependence on the voltage in the network, so it is recommended to additionally install a voltage regulator. As in case of its reduction, the head decreases.

Based on user feedback, Aquarius submersible BCPE 0,5-32U is a reliable device and can work for a long time.

Grundfos SQ 2-55

Pump specifications:

- weight - 5,2 kg;

- head - 68 m;

- the nominal power is 1020 W.

The device is recommended to be used for pumping clean water without impurities. The diameter of the outlet 1 ". The length of the cable is 1.5 m. The pump can be installed both horizontally and vertically. In addition to the soft start and protection against overheating, there is a function of monitoring the water level. The engine works just like the previous device, noiselessly.

The Grundfos SQ 2-55 pump is manufactured in Denmark, therefore it has a high quality of all parts and is reliable in operation. The only drawback is a very short cable.

Dzhelex Vodomet PROF 55/75 House

Device Settings:

- depth of immersion - 30 m;

- head - 75 m;

- power consumption - 880 W;

- there is protection against overheating.

The outlet diameter is 1 ", the length of the cable is 30 m. The pump can only be installed in an upright position. In the complete set with the pump there is a stop armature, the control panel and a hydroaccumulator.

Pump Gileks Vodomet PROF 55/75 The house runs quietly and perfectly keeps the pressure. The control panel is simple and intuitive.

Belamos TF3-150

Device Settings:

- immersion depth - 80 m;

- head - 150 m;

- the power consumption is 1600 watts.

The diameter of the outlet 1 ". The length of the cable is 80 m. The device is mounted only in an upright position.

The Belamos TF 3-150 pump can pump water containing no more than 180 grams per m 3 of sand. Provides a constant and stable head.

Best surface pumps

Marina CAM 80 / PA

Technical characteristics of the surface pump:

- suction depth 8 m;

- head - 42 m;

- weight - 7,2 kg.

The Marina CAM 80 / PA works silently and is additionally equipped with a water sensor. Installation is only in the horizontal position. The diameter of the hole is 1 ".

Pump Marina CAM 80 / PA gives a stable head.

Note! Among users, it is often used to pump the original water out of a well with a high content of impurities.

Grundfos MQ3-35

The maximum head of the device is 33.8 m, the suction depth is not more than 8 m. The pump is installed horizontally and weighs about 13 kg. Equipped with a sensor that controls the water level, protection against overheating, and an additional function to increase the pressure.

Most users are pretty satisfied with this model, since it does not require maintenance for a long time and gives a constant and stable head.

The main disadvantages are a short cord with a length of 2 m and a large weight. The device produces more noise than indicated by the manufacturer. It is recommended for pumping only clean water, without impurities, as otherwise the parts will wear out within one or two years, which leads to a breakdown of the pump.

Gilex Jumbo

Model 70/50 Ч-24 is installed in a horizontal position. The maximum head is 45 m. The length of the cord is 1.5 m. The device is equipped with a 24-liter tank and fully automated. The body is made of cast iron and has small dimensions. Pressure adjustment is possible. All parts and connections are executed qualitatively and without backlashes.

The main drawback of the model 70/50 Ch-24 Jilex Jumbo - the pump does not have dry run protection, and also a short cable.

Vortex PN-1100N

The centrifugal pump of this model is designed for installation in a horizontal position. The maximum discharge is 50 m, the suction depth is 9 m. The engine is quiet, the body is made of stainless steel and has a light weight. The pump is recommended for use only with clean water.

During pump operation, care must be taken to ensure that it does not run dry, as the unit is not equipped with a water monitoring sensor.

![]()

Wilo PW-175EA

The maximum discharge head with this pump is 35 m with a suction depth of 8 m. Just like the previous model of a surface device, it is installed horizontally. The Wilo PW-175EA pump is equipped with overheating sensors and has compact dimensions. Power consumption 125 watts. The device is assembled reliably and qualitatively, it works silently.

The only drawback identified by users - after a long downtime, it may be necessary to push the impeller for the first run (screwdriver).

NeoClima GP 600/20 N

The pump can operate with a suction depth of up to 8 m. The maximum output is 35 m. The power consumption is 600 W. The device is equipped with a function of overheating. It is equipped with a hydraulic tank with a volume of 20 liters. It is recommended for pumping only clean water.

The pump body is made of stainless steel. The engine runs noiselessly.

Note! Although the device is manufactured in China, all the parts are made and connected qualitatively.

Based on user feedback, it may be necessary to adjust the pressure switch, otherwise the pump will not shut down.

Choosing a pump, you should give preference to devices with a steel or cast iron body, since they are more durable. To prevent the device from breaking off electrical network, it is recommended to install protection against drops. To ensure that the work items do not wear out too quickly, filters should be installed.

To protect the pump from overheating and dry running, it is better to install sensors if they are not pre-assembled in advance. Counting the power, you should choose the device 20% more powerful, so that it does not work at maximum loads, as this will quickly lead to its failure.

If the water from the well can be extracted by a bucket, then it is difficult to perform this operation with a borehole. To get water, you need to use a special technique - a pump. But which one? Submersible or superficial? Vibrating or centrifugal?

Before choosing a pump for a well, its main characteristics should be determined. In addition, it is necessary to study the features of the device and the operation of various types of pumping equipment in order to select the most suitable unit for a particular well.

Before acquiring a suitable pump for a well, it is necessary to clarify a number of indicators of its construction:

- static level;

- dynamic level;

- flow rate;

- the bottom of the bottom;

- diameter of the pipe.

If the drilling of the well was done by professionals, then in accordance with the contract the owner had to provide her technical passport. All the above mentioned characteristics must be indicated in it. However, in cases where a well is used (or not used) for a long time, this information will not be prevented from clarifying.

Owners of wells that were created by own forces or with the help of hired "shabashnikov", of course, there is no such document. They will have to explore their own wells and establish its characteristics with simple measurements.

The static level is the distance that a constant mirror of water and the surface of the earth share. To establish this distance, you will need a string with a weight attached to it in the form of a cylinder or a cone without a bottom. Instead, you can use a plastic tube. You will also need a tape measure or ruler. The length of the string should be comparable to the depth of the well.

To measure the depth of the well, its dynamic and statistical level, you need to use a rope or twine with a load at the end

Before the start of measurements, one should refrain from taking water from the well for at least an hour. During this time, the water level should be maximized. Now the string with the weight is lowered into the well until the load "slams" on the surface of the water. A characteristic sound is usually clearly heard.

It remains to make a mark on the string, take it out of the shaft and measure it with a suitable tool. The first indicator of the characteristics of the well is defined. The dynamic level is considered the distance from the surface of the earth to the minimum water level in the wellbore.

To determine the dynamic level, the well must first be prepared. The water is pumped out with a submersible pump with high capacity (it can be bought or borrowed), lowering it downward as the water decreases.

The static water level shows its maximum amount in the well, and the dynamic level indicates the minimum amount of water with the pump running

When the water stops falling, we can assume that the minimum water level in the mine is reached. Now we need to again perform operations with twine, cargo and tape measure. Measurements will give a new indicator of the well - its dynamic level.

Comparison of these data - static and dynamic levels - allows us to make a preliminary conclusion about the productivity of the well. The smaller the difference between these indicators, the faster the water column is replenished, and the more powerful the pump can be used with such a structure.

It should be noted that at a good artesian well, the dynamic and static levels may well coincide, which indicates the exceptionally high productivity of such a structure. This happens because water arrives as quickly as it is pumped out.

The difference in levels for a high-performance well is usually less than one meter. Dynamic level information will be useful when installing a submersible pump selected for the well. The depth of its immersion should be two meters above the dynamic level, so that the device is always in the water.

The flow rate of a well is the amount of water that can be obtained from it during a unit of time. It is measured in the following units: l / min, cc. m / hour, cu. m / day and the like. If the pumping of water by a high-power pump changes the water level insignificantly, then water comes quickly.

To determine the flow rate of a well, it is necessary to pump water out of it, measure its volume, and also to find out for what time the well will be filled again with water

We can assume that the production rate of the well is large and choose a pump with high capacity for it. When calculating the production rate of a well, it should be remembered that this is not a constant value. In the spring, the water arrives well faster than in the summer, and in the winter this process is slower.

To understand that the well was filled with water, and the tributary stopped, you just need to measure the depth of the water level. If it coincides with the previously obtained static level, then the well is full. Those. After pumping out water such measurements will have to be performed several times.

If the water rapidly decreases, but arrives slowly, it will be necessary to establish the exact volumes of water that can be obtained from this well. It is necessary to take the capacity of a significant and at the same time known volume. Most often use a barrel, but it can be any tank, bath, etc. The main thing is to know the volume of liquid that is placed in this container.

First you need to lower the pump closer to the bottom of the well and completely pump out water from it. This will be reported by the characteristic "sobbing" sound of the running pump. Then, time is detected and waiting until the static level in the well is restored. After that, the water is pumped again, measuring its volume. By simply dividing cubic meters into hours or liters per minute, you can determine the debit of your well.

This indicator will allow you to select a pump, the performance of which will correspond to the volume of water arriving in the well. If the equipment is too powerful, the well will become empty, which may cause the pump to run dry, i. E. without water. And this leads to a quick damage to the equipment.

To determine the mark of the bottom of the well, i.e. its depth, again use a twine with a heavy weight without cavities inside. Now it is lowered to the very bottom, until the twine weakens. After that, it is removed and measured. Usually only the wet part of the string is measured. Its dry part corresponds to the statistical level of water in the well. The total depth of the well is equal to the sum of two values: the static level and the depth to the water mirror.

The diameter of the well is the diameter of its casing. To select a submerged pump, the inner diameter must be taken into account, since the dimensions of the pump should allow it to be freely lowered and, if necessary, taken back.

Minor nuances that need to be considered

The quality of the drilling work is another point to consider when choosing a pump for a well. If drilling is carried out with the help of professional equipment and by a specialized brigade, such a well is considered more reliable. If the drilling was performed by the shabashniki or the owners of the site with the help of friends-amators, the quality of the well would hardly be ideal.

If the well is drilled professionally, it will be less often silted up and seared, which will favorably affect the operation of pumping equipment

"Amateur" wells, as shown by practice, are more susceptible to the processes of flooding and filling. Therefore, for such wells it is recommended to use special pumps designed for work in difficult conditions. Equipment of this type is more expensive.

But it better tolerates situations when they receive water with a lot of pollution. Under the same loads, conventional pumps break more often. Owners of "professional" wells have more options when choosing equipment, since they can choose both a universal and a special pump.

It is not always convenient to use a rubber hose to lift water from the depth of the well to a height. During the operation of the pumping equipment, the air inside the hose becomes rare, from this wall of the hose collapse and the flow of water ceases. To prevent this phenomenon is simple: instead of a rubber hose should be used plastic constructions suitable diameter.

A special water-lifting pipe is more effective when used in a well than a rubber hose that can collapse, creating an obstacle to water supply

An important indicator when choosing a pump is the approximate water discharge for one day. This is an average value, since in summer the water consumption usually increases, and in winter, on the contrary, it decreases. It is believed that the daily consumption rate for a family of three or four people is approximately 60-70 liters.

These figures do not take into account the water discharge for irrigation and other household needs. The daily rate should be increased depending on the number of plants on the site, the availability of pets, etc.

Prudent owners choose four-inch casing for the well, although designs with a diameter of three inches are also used in this capacity. The fact is that a significant part of the pumping equipment is designed specifically for a more spacious four-inch pipe. To convert centimeters to inches, you should divide the result of measurements by a tape measure by 2.54, since that's how many centimeters are equal to one inch.

Surface or submersible unit?

All domestic pumps in the place of installation are divided into two types: submersible and surface. The first drop down almost to the bottom of the well. The second work on the surface. They are usually installed near the water source or directly on the water surface with a special float.

In the surface models, the suction principle is used. The efficiency of such a pump is significantly affected by the distance to which it is necessary to lift water. Usually they are used only if the depth to the mirror of water is from eight meters or less.

Surface pumps are successfully used, but only for small depths, because these devices can not cope with the rise of water to a height of more than 8 meters

If we are talking about an Abyssinian well, of course, the surface pump will become an ideal choice, since it is a very specific well - narrow and shallow. But when using a filtration or artesian well, the surface pump can simply not cope with the load. In this case, choose the submersible model.

Choosing between a submersible pump and a surface pump, one should take into account the much higher noise level during operation of the latter. To eliminate this trouble, it is enough to close the pump with a wooden box or install it in a separate room.

Image Gallery

If surface pumps draw water in, the submersible pushes it upward. When choosing such a pump, first of all, take into account the height, which will have to be supplied with water, or rather, the distance from the surface to the pump.

Therefore, the data on the dynamic level of water should be added a couple more meters. The height is 40 meters. If the data exceeds this figure, it is necessary to select a pump of increased power. The technical passport of each product indicates the maximum height at which it can supply water.

That the noise from the surface pump does not interfere with others, and also for its protection, the device is placed in a special box that can be bought or manufactured independently

Visually pumping technology of high and low power varies considerably. More powerful pumps have a large body and weigh significantly more models that cope with a depth of immersion up to 40 meters.

Focusing on the depth of immersion, it is better to give preference to units with a certain margin of performance. If the pump is designed to work at a depth of 60 meters, it is more suitable for a 50-meter well.

For a deep well, a submersible pump should be selected, since surface models are not designed to pump water from a depth of more than 10 m

If it is lowered to the maximum depth, the unit will have to work continuously with the maximum load, which will increase its wear rate and shorten the service life. For a well with a depth of immersion of 60 meters it is better to take a pump designed to work at a depth of 70 meters. The presence of automatic protection against "dry running" is an important time when choosing a pump.

For various reasons, water can stop flowing to the device. If the pump continues to work, it can overheat, break down, burn, etc. If there is adequate automation, the device will be disconnected from the power supply as soon as it starts to work at idle speed, which will prevent the occurrence of malfunctions.

Image Gallery

What you need to know about submersible pumps

The type of device distinguishes between centrifugal and vibrating pumps. The first for water supply uses a rotating blade with blades, and secondly - a special membrane that transmits water with the help of numerous vibrations. These structural features are important, since they affect the integrity of the well differently.

Vibration pump + well: yes or no?

Is it possible to install a vibrating pump in the well? These models are relatively inexpensive, easy to operate and have a performance that is suitable for a significant number of wells.

A lot of experts categorically object to the use of any vibration technology in the well. However, the owners' feedback reports that pumps of this type are successfully used without any damage to the structure. So, which pump - vibrating or centrifugal - is better for the well?

The objections of experts are justified. Long-term vibration effects almost always have a negative effect on the state of the surrounding objects. A well is no exception.

Image Gallery

Vibrations from the pump located next to the filter affect the state of the casing and the surrounding soil, which are gradually destroyed. Vibration can cause a significant acceleration of the silting and dressing processes.

But this does not happen immediately. Usually wells for some time successfully resist vibration. Therefore, with the help of such a pump, it is possible to swing the well, and to clean it, and to successfully operate without visible damage.

But the destruction from vibration still occurs, although not too fast. Continuous use of the vibrating pump can significantly shorten the life of the structure. If necessary, the use of vibration models is quite acceptable, but only as a temporary option. But at the first opportunity, it is necessary to replace such a pump with a safer centrifugal device.

How to choose a centrifugal pump

For this, it is necessary to carefully study the technical passport of the device and find out several important points:

- what is the pump capacity;

- whether its dimensions are suitable for a well;

- from what depth it can raise water;

- what are the features of its installation and operation;

- how, and under what conditions, warranty service is provided, etc.

Usually consultants give quite professional recommendations when choosing such equipment. It should be remembered that many manufacturers indicate marginal, rather than average, characteristics for pumps, so some reserve of service life must be taken into account.

A few words about popular models

If the decision is made to use a vibrating pump, it is likely that "Malysh" or "Brook" will be purchased. These models are characterized by good performance, resistance to breakage and quite a democratic price.

They are easy to clean or repair by hand. But for the constant use of vibration technology is not suitable, it must be replaced as soon as possible.

Vibrating pump "Kid" is a popular but not very suitable choice for a well, as vibration of the device can cause its destruction

Among the popular brands of submersible centrifugal pumps is worth mentioning "Aquarius" and "Watermelon". They are very similar, but according to user feedback, "Aquarius" appreciably wins in quality and durability, although it costs more.

However, and "Vodka" has its adherents. If you are lucky enough to get a well-assembled model, it will show quite decent results.

Submersible centrifugal pumps of the brand "Aquarius" have proved to be reliable and durable equipment for the well, able to cope with high loads

Specials downhole pumps will cost a substantial amount, but such costs eventually fully justify themselves. As an example of such equipment it is worth noting the 3STM2 and 4STM2 models produced by TAIFU.

Useful video materials about pumping equipment

Visual information about the calculation of well production and selection of a suitable pump is contained in the following video:

Here you can find interesting information about household pumps in general and well equipment in particular:

Before acquiring a pump it is useful to study the recommendations of specialists in the arrangement of wells:

So, in order to choose a suitable pump, it is necessary to accurately study the characteristics of a particular well. It should also take into account the general need of the family for clean water and deal with the features of the functioning of technology of different types.