The fontanel pump weakly pumps water. Pump "trickle" for a well: purpose and technical characteristics

For many decades, a popular unit for pumping water has been the Rucheek submersible pump, which is manufactured by Livgidromash OJSC, located in Belarus.

Due to low cost and good quality pumps, until now they cannot be forced out of the market by foreign brands. In order to know all the possibilities, as well as the nuances of operation, we will consider the main characteristics of the Brook pump.

Submersible pump "Brook"

The Rucheek brand pump is a submersible device, as it is capable of pumping water from great depths. Having a relatively small weight - 4 kg, it pumps out water up to 450 liters per hour. The unit is intended only for clean, cold water without salt content. Thus, it cannot be used for pumping sewage or contaminated water from reservoirs.

This pump consists of inexpensive and easily replaceable parts, which makes it possible to quickly repair it. It is quite easy to operate and requires only pressing the "on" and "off" button. The unit is able to work up to 12 hours a day, while it is desirable to take breaks between work to increase its productivity and service life.

The high strength of the body of the unit, made of metal, creates its complete tightness, and the built-in rubber ring, prevents the pump from coming into contact with the walls of the well or well. For fixation submersible pump use a cable or twine, which is attached to the apparatus.

A special sensor built into the pump detects its overheating and automatically turns off the unit. Overheating can occur due to a sharp drop in the water level in a well or pond.

Vibration pump "Brook"

The pump of this brand belongs to vibration-type devices, since its operation is carried out by an oscillating diaphragm, which is subjected to pressure drops in the device itself.

Pressure drops occur when electricity passes through the entire pumping system. The current creates a magnetic field, which subsequently makes all the working parts of the vibration pump move.

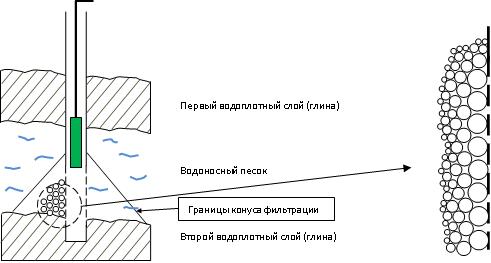

The design of the unit does not have rotating elements, so that the parts do not wear out and are not erased. The water intake is located at the top of the pump. Thus, the Brook pumping apparatus does not overheat and does not suck in solid particles of sand or silt from the bottom of the well.

The pump can be used in many areas, from irrigating the garden to summer cottages and ending with providing country house autonomous plumbing system. In addition, the pump can pump water from various tanks or pools.

For a better idea of the pumps of the "Rucheyek" brand, consider one of the popular models of submersible pumps - "Rucheyek-1"

Technical characteristics of the pump "Brook-1"

Model "Stream -1", like all other submersible pumps of this company, is intended only for drinking fresh water with a temperature not exceeding 35 degrees C. The absorbed power is 225 W, and the water pressure reaches 40 meters. The pump is equipped electric cable at 10 meters. The device weighs 4 kg. This series has an upper water intake that prevents water turbidity.

There is also a model "Brook -1M", which has similar specifications, as in the pump "Brook -1", but is equipped with a lower water intake for the possibility of complete pumping out of water from tanks or containers. Redirection of water in a horizontal position can be carried out at 100 meters. When the water rises to a height of no higher than 1 meter, 1500 liters can be pumped out per hour. The deeper the pump sinks, the less water it pumps out.

Video about the features of using the Brook pump

Belorussian vibration pump The brook has been sold for over 40 years. During this period, consumers have appreciated the capabilities of this, at first glance, a modest unit.

Behind the small dimensions and weight, there are excellent opportunities for providing autonomous water supply to a summer house or a country house (a backup unit that can be powered even from a low-power generator). Of course, you should not entrust the pumps of this series with solving global problems, but it will cope with ensuring the flow of water at one point at the same time.

Water pumps Brook traditionally different high quality, you can’t say “Made in China” about products manufactured under this brand. Completely domestic development, characterized by efficiency with good performance.

The advantages of the equipment experts include the following qualities:

- Excellent maintainability. It is possible to replace all rubber elements and assemblies.

- No need for expensive maintenance. The pump works on the principle - turned on and forgot, can be operated in long-term mode (up to 12 hours a day). True, manufacturers recommend taking technical breaks every 2 hours of operation (10-15 minutes), this will significantly increase the working life of the unit.

- The upper water intake ensures good cooling of the electrical part of the pump. This eliminates the possibility of clogging the unit with bottom silt or other debris that can accumulate at the bottom of the well.

- It can be used for pumping water from wells, wells, tanks, artificial and natural reservoirs.

|

|

The truth is to remember that submersible pump Brookdesigned to work with drinking water, do not use it to pump fecal effluents or other contaminated liquids.

- The metal case is characterized by increased strength, depressurization of the product practically does not happen. A protective rubber ring is used as protection against contact with the walls of the well or the casing.

- The pump does not need to be attached to the walls of the well, it is suspended on an ordinary string or cable.

- The pump is equipped with a thermal protection device, which ensures that the unit is turned off at critical heating values, which can occur if the water level in the water supply source drops.

The water pump Creek is recommended for installation in wells and wells with low water debit. Its small capacity will provide water supply for a long time without complete drainage of the hydraulic structure.

Unit Specifications

Depending on the modification of the pump, it may have slightly different characteristics, so we will give averaged data:

- Power consumption from 225 to 300 W.

- Supply voltage - 220 V ( household network alternating current).

- The maximum head is 40-60 m (depending on the model).

- Productivity at a depth is more than 430 liters per hour, and at 1 meter it can reach 1.5 cubic meters.

Such technical characteristics of the Brook pump make it advisable to use it for various domestic purposes.

Scope of the pump

Most often, this type of pump is used for the following purposes:

- Watering the garden and vegetable garden.

- Filling heating systems before starting work.

- Pumping water from pools, basements, tanks.

- Ensuring autonomous water supply, subject to the simultaneous use of one water distribution point. Such a pump is very effective in meeting the needs of a bath, washing machine or dishwasher. The flow of water will be quite enough for a shower or washbasin.

To meet production needs submersible pump The streamlet is not used, but it is quite possible to try to restore the well's performance with its help. This is made possible by the vibration principle of operation. When the well filter becomes silted, it is necessary to lower the pump to the water intake level (the upper suction will prevent the possible ingress of silt from the bottom of the well).

The vibrations created during the operation of the pump have a high-frequency effect on the downhole filter. This leads to increased leaching of sand and silt particles from the mesh structure.

Literally a few hours of work at such a depth can restore water inflow by 30-40%.

Features of pumping drainage water

During the spring flood, situations often arise related to the flooding of basements, inspection pits and other structures below the surface. Usually such ground water practically do not have impurities, so their pumping by vibration pumps is quite possible.

If it is necessary to work with contaminated water, it is necessary to use an additional filter, which will prevent possible damage to the pump. Such a filter has the form of a cap, which is put on the receiving part of the device, and the installation must be carried out after the filter has been preheated, this will greatly simplify the installation process.

Repair of pumping units of the Rucheek type

Despite the fact that the unit of this brand is highly reliable, there is no one hundred percent guarantee against possible damage. During long-term operation, various breakdowns are quite possible and repair of the Brook pump becomes a necessity. Although in most cases a faulty pump is simply sent to a landfill and a new one is purchased, which is facilitated by the low price of products in this class.

The main problem, due to which the repair stops at the initial stage, is the inability to unscrew the fixing bolts. As a result of long-term operation without periodic lifting from the well, these bolts are covered with a layer of rust. In this case, it is impossible not only to unscrew the bolt, but even to determine the type of screwdriver required. According to statistics in best case it is possible to unscrew only 1-2 bolts, dismantling the rest becomes a significant problem. In some cases, the use of a rust remover helps, but most often you have to cut off the heads of these bolts with a grinder. Therefore, experts recommend not to suffer in search of a solution, but to immediately pick up a cutting tool.

If the pump does not turn on when voltage is applied, then the reason most often lies in the failure of the electromagnet winding. It is quite possible to rewind and reanimate the unit. Such a repair of a submersible pump Brook should be trusted to an electrical specialist who can pick up desired wire and restore the winding with all recommended parameters.

Quite often, another type of breakdown occurs, in which the pump buzzes, but does not pump water. In this case, the reason lies in the wear of the valves or the membrane. In case of failure of rubber parts, the pump is easily repaired, for which it is necessary to purchase a repair kit, which includes all the main elements of the pump. We recommend changing all parts at once, even if only one valve fails, this will eliminate the need to disassemble the pump in just a week, when another worn part fails.

Restore the exfoliated fill of the electromagnet using auto-sealant, which is used when installing the windshield on the car. Before applying it to the surface of the magnet, it is necessary to apply a number of chaotic grooves (no more than 2 mm deep) using a grinder. Such bands provide more reliable connection sealants and products.

The probability of breakdowns in the first 2-3 years of operation is negligible (subject to the rules of operation). Therefore, you can safely purchase a pump of this type, you can be sure that it will not let you down.

Household vibration pumps appeared on sale in the 50s of the last century. Over time, their range has expanded significantly, pumping equipment from foreign manufacturers has been added, but all the needs of the consumer market have not yet been filled. And all because not all vibration pumps are equally popular. Among the equipment that does not lie on store shelves for a long time is the Belarusian-made pump "Rucheyok". This became possible due to the many positive properties and stable quality of this unit.

There are two types of pumps - vibrating and submersible. Further about the features of each type.

Electricity, passing through the system of the unit, creates pressure drops, which in turn creates oscillations of the diaphragm - this is the principle on which the operation of vibration pumps is based.

What is very important - there are no rotating elements in the design of the unit, so not a single part is subject to abrasion or wear. In addition, since there is no friction, there are no products that appear as a result of this process (for example, metal dust), so the mechanism does not get dirty. This, in turn, prolongs its service life.

The water intake hole is located in the upper part of the body, due to which the vibration-type device not only does not overheat, but also does not suck in silt and debris from the bottom of the well.

Vibrating models can be used for a variety of household purposes.

All about submersible models

Submersible models differ from vibration models in that they are designed to work at depth. But they can only be used in cases where the water in the well is clean and not saturated with salts. Therefore, submersible units cannot be used to work in tanks with dirty water or in open reservoirs.

Submersible models differ from vibration models in that they are designed to work at depth. But they can only be used in cases where the water in the well is clean and not saturated with salts. Therefore, submersible units cannot be used to work in tanks with dirty water or in open reservoirs.

Submersible products can work 10-12 hours a day, but do not be too zealous - the mechanism must be turned off periodically. This will extend its service life and increase productivity.

Submersible models weigh 4 kg and can pump out about 450 liters of liquid in one hour. Parts are inexpensive and easily replaceable, so in the event of a breakdown, it is possible to repair the product at low cost.

The metal case is durable and sealed. Moreover, it is so high quality that there are practically no cases of depressurization.

To prevent the equipment from coming into contact with the walls of the well, a safety ring made of rubber material is built in. To fix the unit, you do not need to attach it to the walls of the well, but you just need to tie it to a cable or twine, so installing the device is quite simple.

The submersible unit also has a built-in sensor. It detects when the Brook pump overheats and automatically turns it off.

Specifications

Each modification has its own technical characteristics. But there is General characteristics common to all models. These include:

- Power consumption. Each device needs from 220 to 300 watts to work.

- In order for the Brook pump to work smoothly, it needs a voltage of 220 V. In other words, it needs a regular household electrical network.

- The maximum head pressure, depending on the model, is from 40 to 60 m.

- Performance depends on depth. For example, if the liquid needs to be raised to a height of 1 m, then the pump can supply 1.5 cubic meters of water per hour. From a depth of 40 m during the same time, the device will pump about 430 liters of liquid.

Based on the technical characteristics listed above, the Brook pump - ideal aggregate to meet the needs of any country house.

Below are also the technical characteristics of the vibration type equipment:

- The pump housing contains two working chambers. One of them is motorized, the other is pumping with an anchor and a pump.

- The chambers are separated by a round diaphragm, for the manufacture of which thick elastic rubber is used. An anchor is attached to the rod, which is equipped with a rubber shock absorber.

- A magnetic coil is located in the motor chamber. It causes the armature to vibrate, which drives the pump that pumps liquid.

- To ensure the drainage of water, the pumps have a valve. When the unit is turned on, it closes the hole, and when the device is turned off, the valve moves back and the liquid leaves the working area of the pump compartment without obstacles.

Advantages and disadvantages

The most important indicator is the stable quality of pumping equipment of this brand, good performance, efficiency. In addition, domestically developed products have the following advantages:

- Simple and reliable design.

- Relative unpretentiousness in work.

- Reliability, low cost.

- High maintainability - it is possible to replace all rubber components and elements.

- Ease of operation.

- Does not require expensive maintenance.

- It can be used for pumping water from any artificial or natural reservoir, tank, well, well.

- The electrical part of vibration pumps is perfectly cooled in cold water. Since the pump is located in the upper layers of the water, it cannot become clogged with debris or silt that usually accumulates at the bottom.

- The pump kit includes a thermal protection device, so if the unit heats up to critical levels, it automatically turns off. This usually happens if the water level in the source is greatly reduced.

There are disadvantages in the devices of this brand. This:

- Insufficient performance, therefore, the Rucheek pump is designed for operation in wells and wells with low level water - it can supply water for a long time, and at the same time it will not drain the hydraulic structure. Because of this, the disadvantage as such can not be considered.

- The thermoregulation sensor may not always work. This leads to overheating of the unit, which reduces its service life.

- Vibration patterns can destroy the well.

- Submersible pumps must not be used for pumping contaminated liquids and sewage.

Scope of application

Units of the "Rucheyok" brand are not intended to meet production needs, but they may well perform tasks in a small country building, whether it be a house or a summer cottage. They are used for:

- Watering the garden and orchard.

- filling heating systems to put them to work.

- Pumping fluid from tanks, basements, pools and other reservoirs.

- Water supply of a residential building.

Interesting! It is possible to provide a residential building with water only if one water distribution point is used at the same time. For example - washing machine, shower, washbasin.

Pumps are also used to restore well operation. Vibration models are used for this. The vibrations that the device creates during operation affect the well filter with high-frequency waves. Thanks to this, silt and sand are washed out of the mesh structure. Only 3-5 hours of work pumping device help restore the watercourse by 35-40%.

Repair Features

Many consumers do not repair pumping equipment, but prefer to purchase new products, because they believe that it is expensive and difficult to reanimate the device.

But in fact, just the opposite: pumping units have a very simple design.

Interesting! Parts for replacing failed elements are more than affordable, so equipment repairs will not be expensive at all.

But, if you do not know some of the features, the repair may not succeed at all. Problems may arise when:

- Removing the fixing bolts. During operation of the pump, the fasteners become rusty and cannot be unscrewed. The best way out is to cut off the bolt heads with a grinder. If you take a large disk on the grinder, you can damage the internal mechanisms, so you need a small disk element.

- If the filling of the electromagnet is damaged, it is necessary to eliminate this malfunction with an auto-sealant. Make it simple. Make shallow grooves on the electromagnet with a grinder - they will help to securely strengthen it. Then it remains only to apply the adhesive composition to the magnet itself.

- If the membrane is worn or damaged by foreign objects, it must be replaced with a new one.

Important! If the winding breaks, if there is no proper knowledge, it is best to contact a specialist.

Pumps "Rucheyok" are very similar to the model "Kid," both in terms of use and characteristics. Both were developed in the USSR 40 years ago, for the needs of summer residents. But they are still in high demand. The design of the pump is well thought out, there are enough opportunities to meet the needs of a small family and water a plot of up to 12 acres. The pump rarely breaks, the service life is 8 years.

Technical characteristics of the pump "Brook"

Power consumption does not exceed 300 W, which is comparable to a 500 liter aquarium filter pump. If necessary, it can be run on battery power. At a depth of 40 m, the productivity is 40 liters per hour, but with a surface intake (no more than 1.5 m) - 1500 liters per hour. Operating mode for 12 hours a day, the pump tolerates normally. This is due to the design features, excess heat is removed with the help of pumped water.

The scope of the pump is extensive - pumping water from wells, wells, ponds, pools, reservoirs and natural reservoirs.

Pump device

When installing the "brook" fastenings are optional, in most cases it is enough to hang vertically on the cable. But it is absolutely impossible to hang the pump by the wire. During operation, vibration occurs, which will damage the wire. The case is made of metal and is well protected from damage, but for additional shock absorption on top put on a rubber ring. All components of the device are easily replaceable.

Principle of operation

The magnetic field created by electromagnetic voltage leads to a change in pressure and due to the vibration of the diaphragm, the water rises. Long non-stop operation is possible due to the absence of breaking parts.

The magnetic field created by electromagnetic voltage leads to a change in pressure and due to the vibration of the diaphragm, the water rises. Long non-stop operation is possible due to the absence of breaking parts.

Application possibilities

Scope of "Brook" purely domestic. For industrial use, it will have enough power, the same applies to farms. If you have a large flow of water, then it is better to purchase a powerful pumping station. Pool with a volume of 100 cubic meters "Brook" will fill in a week. Its main convenience is the ability to use in shallow wells. Where a powerful pump will empty it very quickly and turn off, the "trickle" will work and pump up to 6 liters per minute. It is often possible to observe an increase in well capacity by 30% after using the device.

Scope of application:

- Delivery of water from wells, wells.

- Delivery of water for irrigation system.

- Pumping water from tanks, pools.

- Filling the heating system.

The "brook" is used for cleaning wells, due to vibration and liquid suction, this happens quickly.

Drainage water pumping

The pump was designed to pump drinking water. But the situations are different and the "Brook" was used as a drainage. There are special protective nozzles for working in dirty water. If the device is not used for its intended purpose, its service life is significantly reduced. And getting into the mechanism of small stones and sand is guaranteed to disable it. Do not use for pumping viscous liquids.

The designers have laid down enough power to calmly pump out melt water of medium pollution. But before such work, install an additional protective filter, it resembles a glass.

There are a large number of modifications to protective covers, but the most common is a rubber cover that is put on a heated pump.

Design features

The design of the pump is very simple and consists of the following elements:

A constituent parts just two:

- Vibrator or mechanical. Which includes a rod, an anchor and a shock absorber. The anchor is made of electrical steel and filled with a steel rod. After the anchor, a shock absorber is put on and fixed with M12 nuts. Further, there is an aluminum sleeve, on which a rubber diaphragm is attached, which is needed to separate the electrical and internal parts pump. On the top there is a rubber non-return valve that protects the suction part of the pump from water ingress when the pressure rises.

- Electric. It contains an electromagnet, which is made of U-shaped wire, and coils are put on it. copper wire with a diameter of 0.6 - 0.7 mm.

The core together with the coils is placed in an aluminum case and fastened with epoxy resin. Filling acts as a reliable means of fixing parts, and also effectively removes heat.

Connection sequence "Brook"

At the very beginning, a check valve is attached to the pipe. This will save you from the need to control the filling of the well. The pipe will prevent the water from draining when the pump is turned off. A bowl-shaped filter is attached to the suction pipe. This will protect the working chamber from flooding.

At the very beginning, a check valve is attached to the pipe. This will save you from the need to control the filling of the well. The pipe will prevent the water from draining when the pump is turned off. A bowl-shaped filter is attached to the suction pipe. This will protect the working chamber from flooding.

Discharge hose attached to the check valve. Water flows through the hose to the outlet valve. The other end of the hose is attached to the accumulator. For a more secure fit, attach them to the adapter.

The electric cable and the injection hose are fixed together with polymer clips or ties. Using wire will damage the hose. A polymer rope is attached to the hole located in the upper part of the housing, on which the pump will hang in the well.

After everything is collected, he slowly and carefully descends into the well. The entire weight of the device is supported by a rope. Do not use a hose for lowering.

Repair Features

Due to the low cost of the Brook, many people neglect repairs and immediately buy a new device. Repair is simple and the cost is low. Therefore, do not throw away a broken pump, but turn it in for repair and buy a new one. So you will have 2 devices, which will provide you with an uninterrupted supply of water. If you have free time, then you can do the repair yourself, the design is very simple.

Pump disassembly

The first thing you need to do is remove the mounting bolts. They are covered with rust and tightly sit in the body. If it was not possible to unscrew with a screwdriver, you need to cut off the heads with a grinder. Use a disc with a small diameter so as not to accidentally damage the motor. Don't forget to secure the pump in a vise.

Membrane replacement

A common cause of pump failures is the failure of the membrane as a result of the ingress of a foreign element. On sale there are special repair kits. If there are no spare valves and membranes on hand, they will be replaced by rubber caps from medicines. Such a artisanal solution does its job well.

A common cause of pump failures is the failure of the membrane as a result of the ingress of a foreign element. On sale there are special repair kits. If there are no spare valves and membranes on hand, they will be replaced by rubber caps from medicines. Such a artisanal solution does its job well.

Winding replacement

Special engineering knowledge is indispensable here, the best option- Send it to a specialist for repair.

Electromagnet Surface Repair

Such damage is easily repaired with auto-sealant. With the help of a grinder, apply shallow grooves, and then apply glue.

The price of the pump "Brook"

The price of the pump depends not only on the technical characteristics, but also on the country of manufacture:

- Power 225 W, capable of lifting water from 60 m - 2500 r.

- Power 280 W, capable of lifting water from 40 m -1600 r.

It is better to buy a more powerful model, the difference in price is not very big, but the gain is obvious in terms of characteristics.

Pros and cons of the Brook

Pros:

- The reliability of the design has been proven over the years.

- Simplicity, allowing you to carry out simple repairs yourself.

- Unpretentiousness to working conditions.

- No need for additional fasteners.

- Low price.

Minuses:

- Low power.

- The thermostat works with a delay.

- Put washing machine in one place, and the shower in another, it will not work.

When using a pump with a well, shock absorption must be used, which will not allow the walls of the casing and the well to come into contact. If this is not done, then the pump is guaranteed to fail. "Brook" works on vibration and without depreciation, it beats against the well.

Although more than 40 years have passed, the design has not undergone significant changes so far, and the quality has remained high. This pump, in terms of the ratio of technical characteristics, price and service life, has no equal so far.

The unit is designed to deliver water from wells, natural reservoirs, wells up to 40 m, more than 10 cm wide. It takes the liquid from the top, which prevents various contaminants from entering the systems. The feed power when working at a depth of 40 m is 430 l / h. If it is produced surface fence(not lower than 1.5 m), then this pumping will be about 1.5 m3 / h.

Power consumption is 220-300 W, which allows you to power the vibration pump "Brook" from the battery. Moreover, the equipment can work for quite a long time, up to 12 hours. But presented, reviews of which were provided in various sources by experts and ordinary users, indicate the need to turn off the unit every 2 hours for 15 minutes. As practice shows, few people do this, but such actions significantly increase its service life.

The advantages that the Brook has distinguish it from the mass of similar equipment and make it so in demand. These are the facts.

- Repairs are made quickly and inexpensively.

- There is no need to produce expensive .

- Good cooling of electrical components due to the top type of water pumping.

- Wide application possibilities.

- The high strength of the body, made of metal, prevents depressurization.

- Does not require fastening to the walls of the well.

- The presence of thermal protection, which turns off in case of overheating of the presented device.

Remember that such equipment is not intended for faecal effluents or dirty liquids!

Submersible vibration pumps "Rucheyek" are used in the following areas.

- Pumping water from basements, tanks or pools.

- Watering a small (private) plot of land.

- Filling the heating system before starting.

- while using one point of water distribution.

Installation of a vibratory submersible pump

The device of a submersible pump requires the implementation of a certain algorithm of actions during installation. First, a check valve is mounted on the nozzle. This element prevents unauthorized discharge of water from the system after shutdown.

The pump is not intended for pumping fecal effluents and other contaminated liquids.In this form, the vibration pump for the well is introduced into the well. A bowl-shaped filter is installed on the side of the inlet to the suction pipe, which prevents the filling of the working chamber with water.

Next, the injection hose is attached to check valve. Through it, water flows under pressure to the outlet valve. And the second side of the pipe is mounted to the hydraulic accumulator systems. If the vibration pump for the well is involved in arranging the output of the main communications from the well, the internal adapter is attached from the inside.

The electrical cable of the network is connected to the supply hose using polymer ties or special clips.

It is important not to use in the wire connection scheme! She crushes the hose, which will cause the Brook vibration pump to break.

In the upper part of the equipment body there are devices, into the holes of which a polymer rope should be inserted. It keeps the equipment inside the well.

Further assembled structure delivered to the well with a rope. Do not hold the Brook water pump by the cable and hose bundle at this moment. A rope is attached to them with the help of screeds, and then, in this form, it is lowered into the well. After immersion, the bundles are disconnected, and a test run of the pump is performed.

Possible malfunctions and repairs

In the event of a breakdown of the presented equipment, many users purchase a new copy. The cost of the presented equipment is low. But it will be cheaper to repair the Brook pump, which makes the resuscitation procedure of the device more than expedient. Moreover, it is quite possible to perform it on your own.

Common breakdowns are:

- membrane wear;

- damage to the filling of the electromagnet;

- failure of the electromagnet winding.

Vibration pump repair begins with disassembly. Some difficulties may arise here. The bolts on the body of the instrument are often covered in rust. This makes it impossible to unscrew the fasteners with a screwdriver. Trying to perform such a procedure would be impractical. In this case, you will have to resort to the help of a grinder. Use a tool to cut off the bolt heads. In order not to damage the motor inside the housing, use a small diameter disc, fixing the pump in a vise.

If it does not pump, the cause of the breakdown is the wear of the membrane. Using a special repair kit, you can quickly replace old valves or membranes with new ones.

Pump malfunctions in the area of filling the electromagnet are eliminated with auto-sealant. With the help of a grinder, small strips are cut on the surface of the electromagnet. Next, a sealant is applied to it. But if the pump does not turn on when connected to the network, the malfunction is most likely in the electromagnet winding. It is better to entrust repairs to an experienced specialist who will select the correct type of wire.

WATCH VIDEO

If the operating rules are followed, the possibility of a breakdown in the first 3 years of equipment service is negligible. This is a reliable, inexpensive and productive pump, the quality of which is confirmed by years of impeccable service.