Installation of a gas boiler. Installation of a gas meter. Connection to the gas main

An autonomous heating system is the dream of many homeowners. Most of them choose gas heating, a significant disadvantage of which is considered mandatory installation of equipment by certified specialists. However, this only applies to connecting devices. Installation of the floor gas boiler can be carried out independently. How to do it? We'll figure out.

Those who are sure that the installation of a gas heater starts with its purchase, are greatly mistaken.

Start with the collection of permits. To make it is necessary the following:

Step # 1: Obtaining Technical Conditions and Permission.

It is necessary to find out whether in principle a gas boiler can be installed in a particular apartment or house. For this purpose, a statement is submitted to the gas service with a request to conduct such a procedure. It necessarily indicates the estimated annual volume of gas consumption. The document will be reviewed and, as a result, the applicant will receive the installation authorization together with the Technical Conditions or a justified refusal.

Gas boilers are the most practical and economical option for heating premises. Can be used in both multi-apartment and private houses

Step # 2: Create a project for future installation.

To begin with it is desirable to be defined with a mark of the counter and a copper, but to buy them yet it is not necessary. Then the installation project is ordered. It is performed on the basis of the previously obtained permission for specific equipment. The document necessarily indicates the connection scheme of equipment, and the laying of the main inside the building from the point of connection of gas communications. Only a licensed company is eligible to engage in the project.

Step # 3: Getting approval from the gas service.

The new project should be coordinated with the gas service, which serves the site in which the house is located. The procedure usually takes a maximum of three months and a minimum of a week. At this stage it is already possible to purchase gas equipment, because in addition to the project, it is necessary to provide such documents:

- technical passport of the gas boiler;

- certificates of conformity and sanitary and hygienic;

- operating instructions for the heater;

- the conclusion of the examination of the conformity of the device to all technical requirements.

It is very easy to obtain these documents. The manufacturer obligatorily applies them to their products. At the end of the verification procedure, the applicant receives an agreed project, in which case a special seal will be placed in his hands. If the document is not agreed upon, a list of activities for adjusting the project must be compiled. After they are carried out, reconciliation is carried out.

For the installation of a floor boiler, a special furnace room, finished with incombustible materials

Rules for furnishing a furnace room

According to the existing SNiPs, the gas boiler is installed only in a specially equipped room, which is called a furnace room. Neglect this rule is impossible, because the gas boiler is classified as a potentially dangerous equipment, and it should be treated with extreme care. Otherwise, penalties will inevitably follow and there may be emergencies.

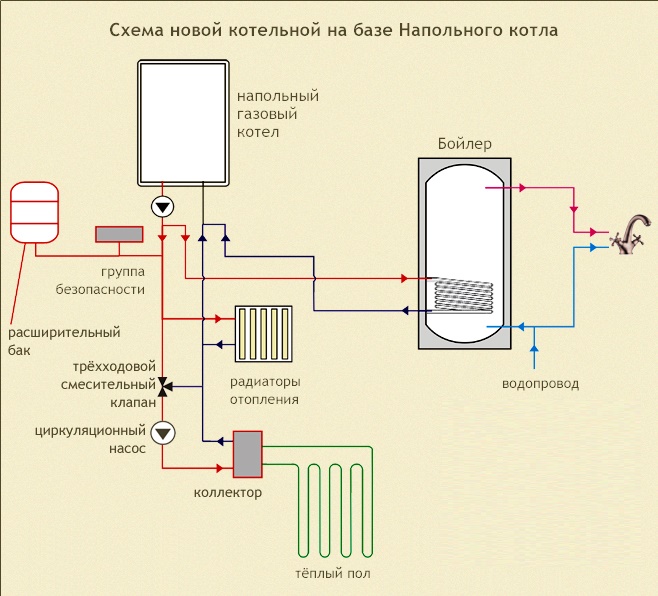

The optimal option for installing a floor gas boiler is the organization of a boiler house, isolated from residential premises, equipped with a system of combined extract and input ventilation

First you need to determine the location for the installation of the boiler. The instructions allow the installation of single-circuit heaters with a capacity not exceeding 60 kW in any room in the building. Most of the floor gas units are single-circuit, because They are intended for servicing only heating systems.

Two-circuit models of any power can not be installed in the kitchen. This is a miniature boiler house with a built-in security group and its own expansion tank. For them, the heating is arranged. If the total capacity of the equipment does not exceed 150 kW, it can be mounted on any floor.

More powerful installations or groups of devices can be installed only on the ground floor or in the basement. In any case, gas heating boilers It is forbidden to install in living rooms, bathrooms and in bathrooms. The room intended for the fire room must have certain dimensions. Its minimum volume can be calculated by the formula: 0.2 m³ multiplied by 1 kW of the device's power, but not less than 15 m³.

If the walls of the furnace room are made of combustible materials, they are closed with special refractory overlays

In addition, a number of requirements are placed on the premises:

- the minimum width of the doorway should be 80 cm;

- the minimum ceiling height is 2.5 m;

- the degree of fire resistance is not less than 0.75 hours;

- the presence of natural light, which is calculated as follows: 0.03 square meters. m of the window area for each 1 cubic meter of furnace volume;

- the presence of a gas analyzer associated with an automatic valve that will shut off the gas supply when leaking;

- arrangement of effective ventilation;

- the door or wall leading to the next room must be equipped with a ventilation grill whose area is determined by the formula: for each kilowatt of the capacity of the heater there are 8 square meters. cm construction;

- providing free access to the heating device and auxiliary equipment for repair and maintenance work.

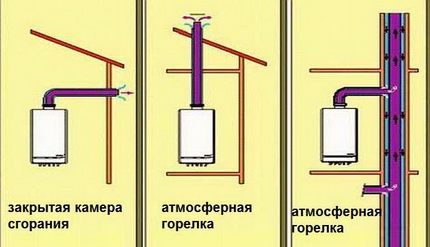

These requirements are strictly required for the implementation in the case of furnishing a furnace room for a boiler with an open combustion chamber. For units with a closed chamber, the area of the room is not important and the ventilation requirements are less strict, since for their work they do not use air from the room, but take it from the street. In flue gas duct is equipped. Its horizontal section within the premises should not exceed 3 m.

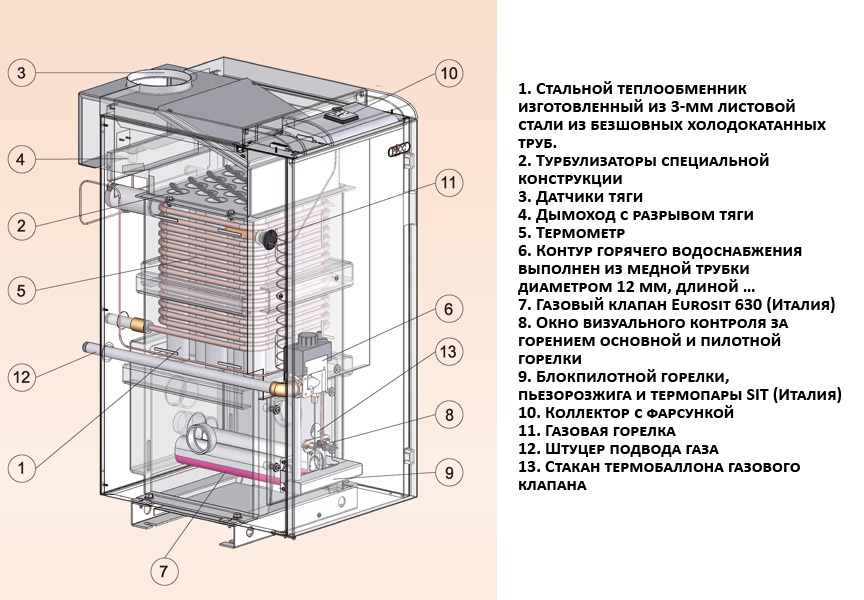

The process of installing a gas boiler largely depends on its device. The figure shows general scheme devices of such equipment (+)

The number of turns can not be more than three. The vertical outlet of the chimney is raised above the level of a flat roof or a skate-shaped skate not less than a meter. The materials from which the design is made must exhibit resistance to aggressive thermal and chemical influences. Multilayer materials, for example, asbestos-cement pipes, can only be used in areas that are more than 5 m away from the exhaust pipe.

In the combustion chamber there should be no cavities or niches formed by horizontal surfaces. Combustion products can accumulate here, which is very dangerous for humans. The space in front of the heater must be free. The floor in front of it is covered with a metal sheet, the minimum size of which is 1x1 m. It is forbidden to use asbestos cement for this purpose, as it quickly wears off and is harmful to human health.

The prevailing number of floor gas units is intended for heating the coolant in heating systems with a natural and artificial type of circulation

Preparing the room for installation

Before starting the installation of the heater, you must finish all work related to the arrangement of the heating system, the installation of radiators, the distribution of water supply and warm water floors, if they are present. In addition, the electrician and the sewage system must be fully installed. The boiler room should also be ready. Under the gas boiler, a strong floor is laid on the basis of a cement screed or a separate foundation is prepared.

The last option is considered not the best. Overlapping, floor and walls, if they are decorated with combustible coatings, must be additionally protected from possible ignition. For this, incombustible linings made of roofing sheet steel, laid on a refractory pad, for example, asbestos, are used. The thickness of the sheet of the latter can not be less than 3 mm.

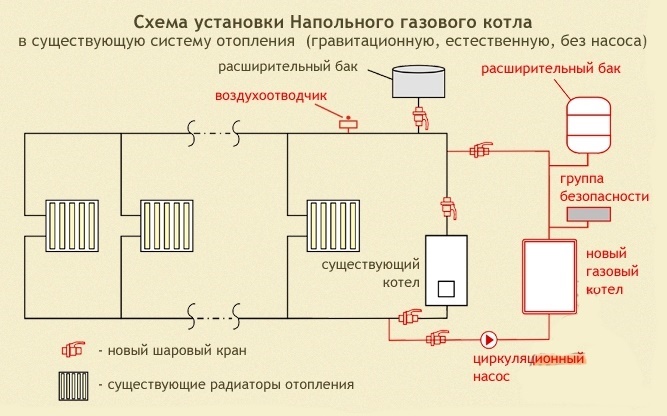

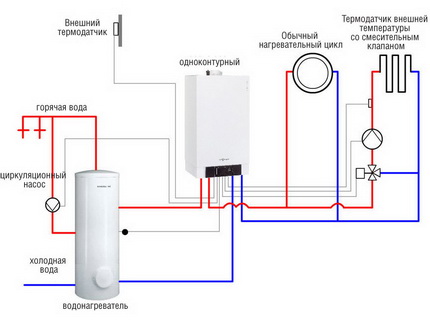

Depending on the type of floor boiler, the number and type of auxiliary equipment varies. The figure shows a possible scheme for installing the system in conjunction with a wall unit

In this case, the insulation should support the overall dimensions of the device body at least 100 mm along the entire perimeter. The minimum distance from the heater to the wall made of non-combustible materials, should be 100 mm. Regulated and the distance from the protruding fragments of fittings, burners and automatic control devices to the opposite wall. It should be at least 1 m.

If the floor is made of combustible material, it should be protected from possible ignition. To do this, use a platform, laid out of concrete blocks. Its height should be not less than 100 mm. Above, the elevation is covered with a steel sheet, the thickness of which is at least 0.8 mm. It is possible to equip a site for installing a device from special refractory plates.

In addition, it is desirable to install auxiliary equipment, otherwise the boiler will interfere with this. Optimal in advance to implement the layout of its placement, to think through all the nuances of the arrangement. According to this scheme, fixing holes are marked on the walls and floor, after which the necessary devices are installed. The heater is installed and connected last.

Chimney arrangements for gas boilers of different types

Chimney: requirements for accommodation

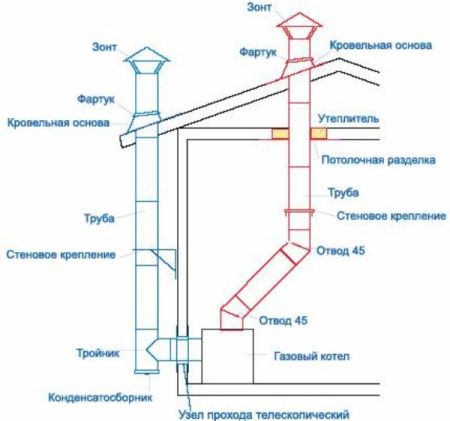

Before installing the floor gas boiler with your own hands, a chimney must be prepared. It is advisable to put the heater on the prepared base, so that the distance between its body and the wall is sufficient for inspection and maintenance of the device. After that, indicate the location of the chimney. It is possible not to put a boiler, and the layout should be based on calculations. In this case, you need to take into account a few nuances.

First of all, the chimney and the hole for it must match exactly the type of the floor boiler. So, for modifications with an open combustion chamber, a separate type of chimney is installed with a section corresponding to the power of the device. For example, for devices with a power below 30 kW, the diameter of the pipe should be at least 140 mm, for more powerful appliances from 40 kW, a chimney with a cross section of 160 mm is selected.

Apparatuses with a closed combustion chamber are equipped with special chimneys of coaxial type. In the technical documentation of the device, the manufacturer always indicates the required diameter of the chimney. In addition, it should be remembered that the pipe that will connect the boiler with the chimney should not be longer than 0.25 m. It is also necessary to equip the closing hole through which the structure will be cleaned.

When installing the chimney, strict observance of all fire safety standards

Smoke from the boiler installed in one of the apartments high-rise building, must necessarily be taken to the common chimney. If there is no such system, the gas service does not issue a permit to install the boiler. Everything is much simpler in a private house. There can be mounted a chimney of almost any configuration. It is important that it is safe and effective.

According to current regulations, the chimney pipe can not be mounted near the window opening. The minimum distance between them is 0,6 m. It is necessary to exclude the possibility of returning exhaust gases to the room. In practice, sometimes supervisory services allow the installation of equipment directly under the windows. In this case, it is necessary to ensure that the exhaust pipe is as far removed from the window or the opening window.

The technology of installation of a gas boiler of floor type

First of all, remove the device from its packaging and check its equipment again. To know what should be in the box, you need to take the operational instruction, which the manufacturer necessarily puts in the package, and check everything on it. If a shortage is found, you should immediately contact the seller. You also need to do this when there are traces of repair work, dents, etc. on the case of the device.

Another important point is the reconciliation of technical data. Those that are applied by the manufacturer to the body of the device must exactly match those that are inscribed in the technical passport. If a discrepancy is found, you should contact the seller. From the device all plugs are removed, if necessary, the pipes are washed. So you can just make sure that they do not have random garbage that could get inside when assembling.

The floor gas boiler is installed on a solid podium made of refractory material

The installation process of the floor equipment can seriously vary depending on the type and modification of the equipment. In general, it is the installation of the device in the place intended for it, the subsequent connection of communications and the arrangement of the chimney. Let us examine each stage in detail.

Work on the installation of the heater

To begin with, you need to put the equipment in the place prepared for it. This can be a concrete base, a small podium of a refractory plate, and the like. A strong wooden floor is covered with a metal sheet, which should extend beyond the body of the boiler by about 30 cm along the entire perimeter. For private houses, another option is used. Here for the heating devices a groove is prepared, which is below the floor level by 0.3 m.

The bottom of this pocket is poured with concrete, and the walls are finished with any non-combustible material. More often tile tiles. Gas boiler in the floor version is usually a fairly massive equipment. For its transportation use wheels, which the device most often supplies the manufacturer. The device is installed on a prepared base and carefully leveled.

The figure shows a diagram of one of the options for installing a floor gas boiler

It is necessary to understand that the uninterrupted operation of the device largely depends on the accuracy of its presentation. Therefore, the installation horizontal must be checked using the building level. The equipment is leveled in place with adjustable legs. If they do not exist, small pieces of any non-combustible material, for example, a metal sheet, are placed under the supports.

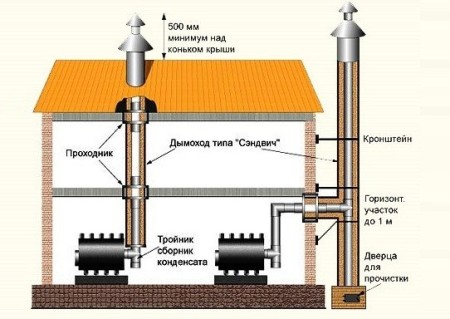

Chimney installation installation

First you need to make holes for the chimney. Once again we check the diameter of the planned details, it should be slightly larger than the section of the chimney pipe. We make holes in the ceiling and in the roof. Then on the boiler outlet we put on the adapter adapter, which will be connected to the chimney. Important nuance. Corrugated, as in the installation of wall-mounted devices, in this case it is strictly forbidden to use.

The adapter must be made of sheet metal only. After installing the parts, mount the tee and the so-called revision, through which the inspection and cleaning of the chimney will be carried out. Further the remaining elements are fastened: straight segments of the pipe and the knee. For the passage of the chimney through the ceiling and roof special parts are used. Particular attention should be paid to fire safety.

On the upper part of the chimney is installed a special nozzle, which protects the construction of sediments, debris and wind

Therefore, the sections of the passage through the floors must be equipped with non-combustible materials. The chimney must be mounted under a slight slope towards the street. The exact amount of slope can be found in the technical documentation for the boiler. This is necessary for the unimpeded withdrawal of condensate, which inevitably accumulates in the pipe due to the temperature difference.

The assembled structure is securely fixed to the wall or to the ceiling by clamps and brackets. The fastening of the first is 2 m, the second is 4 m. The connections of the elements are recommended to be strengthened, for this purpose they are tightened with clamps, tightened bolts or wire. The pipe raised to the roof surface or to the wall is lifted to the desired height, after which a tip must always be mounted, which will protect the chimney from rain, debris and wind.

Connection of heating system

At this stage, it is necessary to connect the boiler to the discharge and supply piping heating system. For a single-circuit instrument on this work and run out. For the two-circuit it is still necessary to connect to the water supply. First we connect the heating pipes. Depending on the existing heating system, which can be both two-pipe and one-pipe, the number of pipes for connection can be different.

All connections must be carried out in strict accordance with the rules and regulations, as well as with mandatory sealing

In any case, experts strongly recommend installing a strainer coarse cleaning to protect the boiler from the particles of scale and dirt that can get into it from the heat main. The heater is not very sensitive to the quality of the coolant, but if its parameters are very different from those recommended by the manufacturer, additional cleaning equipment should be installed.

This can be, for example, a polyphosphate dispenser or other similar system. On the return and the flow, it is desirable to install cut-off valves, which will help to prevent the radiators from radiating and make it more convenient to repair the heater. All joints of elements are carried out strictly according to the rules with mandatory sealing. To seal the thread, you can use the usual patches and paint or more modern tools.

The procedure for connecting the boiler to the water main is practically the same. It is also strongly recommended that the filter be installed in order to avoid unnecessary dirt entering the device. On water pipes it is also advisable to install and cut off the cranes. It is best to use so-called "Americans" with detachable connections, which allows you to quickly replace the worn out assembly if necessary and greatly facilitates installation.

To seal the gas pipe joints, only the tow can be used

Connection to the gas main

It is necessary to know that according to the norms for installing gas floor boilers, only a specialist with a tolerance can perform this operation. You can do the work yourself, but to check the assembly and make the first start will, after all, be a visiting professional. The connection works are carried out extremely carefully and carefully. Start with a connection gas pipe with the corresponding element of the boiler.

As a sealant, you can only use the patch. No other material will give the required tightness of the joint. It is mandatory to install a shut-off valve, which is additionally equipped with a filter. At the same time, experts strongly recommend installing a quality system here. An inadequately effective filter can cause damage to the boiler.

For connection it is recommended to use copper pipes, the diameter of which can vary from 1.5 to 3.2 cm, or special corrugated hoses. In any case, special attention should be given to the quality of sealing compounds. Since the gas has the property of seeping out of loose connections and accumulating in the room, which is fraught with the creation of an explosive situation.

A flexible connection must be placed behind the filter, which is performed only with a corrugated hose. Rubber parts are strictly prohibited, because over time, cracks appear on them, creating channels for gas leakage. Corrugated parts are fixed on the boiler pipe by means of a union nut. The obligatory element of such a connection is a paronite gasket.

After installation and connection of the gas heating unit, it is necessary to check the quality of the connections and assemblies. The simplest method control - application of a soap solution to the joint. If it bubbles, then there is a leak

Perform a trial run

This completes the basic work on the connection of the gas boiler. Exception - appliances with a closed firebox. For them it is necessary to connect to electrical network. It is better to do this through a stabilizer. After which the system can be filled with a coolant. This is done as slowly as possible to displace most of the air present in it. The liquid is pumped to a pressure of 2 atm.

All connections are carefully checked for possible leaks. After a representative of the gas service inspects the connection and allows the gas supply, you should also carefully inspect all connections on this pipeline. They need to be coated with a soap solution and make sure there are no bubbles. Now you can carry out the first start of the equipment.

Video materials about the installation of a gas boiler

How to install a floor boiler correctly:

How to avoid errors in the process of installing a floor-standing instrument:

Example of installation and connection of a gas boiler:

Independent installation and connection of a gas boiler of floor type is one of the most important operations, because the safety of all tenants directly depends on the correctness of its conduct. Do not get down to business, if there is no experience of carrying out such work. It is better to invite specialists. Self-confidence and levity can be too expensive.

The majority of the population in the household actively uses natural gas, it is used for heating the house, heating water, cooking food. Gas is a flammable product that is capable of creating an explosion hazard during storage, so the installation of gas appliances is carried out according to strictly defined rules, by qualified specialists. In order to install the gas equipment, it will also be necessary to obtain an appropriate permit from the gas office.

Gas appliances, basic connection rules

The connection of gas appliances must be carried out exactly in accordance with the project. According to the rules, the room intended for installation of gas equipment should be:

- is equipped with supply and exhaust ventilation,

- have a natural light source, i.e. window.

To install in private homes and apartments only manufactured in the factory heating devices, plates and columns that have factory passports are allowed. If institutions require the use of non-standard equipment, then it must be manufactured in accordance with a special project.

Installation of gas meter

Installation of measuring gas equipment is a very important moment, the gas meter allows you to monitor fuel costs, and analyze them and plan for more rational use.

The meter is installed at a height of 160 to 180 cm above the floor level, in addition, the distance to the nearest open fire source should not be less than 80 cm. The height of the shut-off valve installation in this case should be equal to one and a half meters.

If the modern apartment is connected central heating and hot water supply, installation of a meter is not mandatory. The height of the laying of the supply gas pipeline in this case should be equal to 170 cm, the installation of the crane is performed at a distance of 20 cm from the plate, from the side.

Rules for installing gas appliances - how to install a gas stove

A sufficient condition for installing a gas cooker is a window with a window (transom) to which there is free access. To the plate itself, an approach must be provided on both sides. The plate is not allowed to be placed in front of the window - the movement of air can lead to a flame displacement. Do not push the cooker to the wall for a distance of less than 5 cm.

![]()

If the gas stove is installed near a non-plastered wooden wall, it will be necessary to cover the area of the wall near the slab with a sheet of roofing iron or an asbestos plate. The width of the passage in front of the plate must be at least 1 m. It must necessarily be leveled in a horizontal position, and all its legs should be placed on the floor.

The distance from the installed gas stove to the rigid gas pipeline should not be more than 4 m. When connecting the gas valve and the hose, a dielectric insert must be installed.

As modern plates are equipped with electric ignition and oven lighting, they will need to be connected to the mains, the outlet installed in the kitchen must be grounded.

For flexible gas supply to the plates you can use three types of hoses:

- rubber-cloth,

- rubber with a metal braid on which there must be a yellow marking (for water marking blue and red),

- bellows metal hose, the most expensive, but also the most reliable.

The internal diameter of the hose should be at least 10 mm, too thin can not provide a normal gas supply for the oven and all the burners.

The rules for installing a gas cooker require that it be checked before installation. There are certain rules on which a specialist conducts a test. This mandatory procedure helps to detect the following problems:

- a loose use of burners to the nests,

- incorrect fixing of the handle of the cock,

- seizure of handles when turning,

- damage to the nozzle of a mechanical nature and the like.

In addition, the plate must pass a leak test. It can be carried out by applying a thick soap foam on the joint area. When the gas supply is switched on, bubbles on the surface of the foam should not appear.

Installation of the gas cooker is made according to the scheme attached to the document for this product. Installation of gas equipment is carried out according to the same rules, regardless of whether it is carried out in a private house, in a city apartment or in a cottage.

More details on the rules for installing a gas cooker look at the video:

Installation of flow-through gas water heaters

Gas water heaters, or columns, can be installed only on concrete or brick walls decorated with non-combustible materials. If the walls in the house are wooden, they must necessarily be plastered, in addition, the wall near the gas appliance should be covered with asbestos or metal sheet, the distance from the column to the wall should be at least 3 cm.

If as a decoration of a wooden wall serves ceramic tile, then the iron or asbestos upholstery is not required, but the distance from the wall to the heating device should be increased to 5 cm.

On non-plastered wooden surfaces, water heating columns must not be installed.

Columns are installed at such a height that from the burner to the floor was not less than 100-120 cm. If the water heater is installed above the bath, it is better to do this from the side of the bath outlet.

Installation of gas heaters is performed on special metal strips attached to the wall. To ensure complete removal of smoke equip chimneys from the gas burner. It is strictly forbidden to include gas columns without the presence of a smoke extraction system in a separate chimney - usually the cubic capacity of the bathrooms is small, the ingress of combustion products into the air can cause severe poisoning.

Since the amount of air necessary for combustion of the gas flows to the burner directly from the bathroom room, it is necessary to leave a specially provided clearance between the bathroom door and the floor for airflow into the room.

About connection features gas columns look at the video:

Requirements for the installation of a gas boiler

Gas boilers are the most common option for heating a private house today. But the installation and operation of such equipment should be treated with special attention, if improperly installed and operated, it can cause a fire or explosion. The installation of gas boilers should be carried out in accordance with applicable state standards. Guided by the regulations should be on the design process of the building and its construction, if the installation is made in the old house, then the choice of the room should be taken very seriously.

The requirements for the boiler room are as follows:

- the room must be separate, the installation of the boiler in the living room is prohibited,

- ceilings should have a height of at least 2.2 m,

- to install a single boiler will require a minimum of 4 square meters. m area,

- the walls of the utility room must be covered with non-flammable, better simply plastered,

- the flooring should be made of non-flammable material,

- the width of the doorway should be 0, 8 m,

- the area of the windows facing the street should be 0.3 sq.m. for every 10 cubic meters of room volume.

In the room assigned to the boiler room you need to sum up:

- gas, equip the shut-off unit for the installed boiler,

- sewerage, for the installation of emergency drains from the heating system and boiler,

- electricity, 220 V, with automatic network protection and grounding,

- water supply, with the possibility of connecting hot water and heating systems.

Each parameter of the installed communication structures must comply with the normatively established one.

An obligatory condition for safe operation of the boiler house is the creation of an effective ventilation system. Exit to the ventilation system must be on the ceiling of the boiler room, and the ventilation itself must have a message with the general ventilation system of the house.

It will be necessary to equip the two chimney channels, for the installation of the chimney and its cleaning. For air supply can be used installed in the door ventilation grill, while for each 1 kW power boiler will need at least 8 square meters. cm of the grid area when supplying air from the street or 30 square meters. cm when supplying air from inside the building.

Certain requirements are also imposed on the chimney:

- it should be airtight and not allow the possibility of smoke penetration into the room,

- the size of the exhaust opening should be equal to the area of the boiler flue,

- the height of the upper cut must be above the ridge of the roof, this will prevent the possibility of air sucking through the chimney.

Installation of the gas boiler can be carried out away from sources of open flame. The boiler must be accessible to the approach from either side. The rules for installing a gas boiler allow you to refuse the arrangement of natural draft, for boilers with forced removal of smoke, it will be sufficient to install a chimney above the roof and install a fan in the chimney. A rational solution is the arrangement coaxial chimney. He represents two pipes, one of which is enclosed in the other. Air from the outside is fed into the combustion chamber along the outer annular channel. Since inside the structure there is a pipe with hot smoky gases, the supplied fresh air will have time to warm up well, this significantly increases the efficiency of the boiler operation.

If a fan is included in the kit of the floor gas boiler, then during operation it creates considerable noise. Therefore, experts recommend installing floor gas heating appliances in basements or in the basement of the house. Select the place of envy from the type of unit (floor or wall).

On the rules for the installation of gas boilers and the arrangement of chimneys in wooden house look at the video:

It is necessary to warn owners of houses - the installation of such equipment as a gas heating boiler should be performed by professionals who have the appropriate license for the production of works of this complexity. Often, installation services are offered to companies engaged in the implementation of gas appliances, there is no point in abandoning the help of specialists.

Features of the arrangement of chimneys

Gas appliances used for domestic purposes must be connected to separate chimneys. In cases where the use of a separate chimney is not possible for some reason, the connection is made to a common chimney, but it involves the arrangement of a system with different levels of combustion products.

Usually chimneys are made inside the walls. The area of the pipes used should be at least 150 square meters. cm, for example - 13 x 13 cm. On the whole length of the chimney there should be no horizontal parts.

In those areas where chimneys are located near the wooden elements of the structure, they arrange cuttings made of non-combustible materials.

Top chimneys protected by an umbrella made of metal. It will exclude the possibility of penetration of atmospheric precipitation of various kinds inside the chimney. Umbrella is often made removable. This makes it easier to pipe clean.

The connection of gas appliances and chimneys is made of galvanized or roofing steel. Diameters of connecting pipes and nozzles of devices should correspond. For the production of bends use sheet steel.

The vertical part of the connection (from the bottom of the nozzle to the horizontal part of the pipe axis) must be at least 0.5 m.

The length of horizontal joints should not exceed:

- for buildings under construction - 3 m,

- for those built earlier - 6 m.

Turns are allowed in the connecting structure, but not more than 3. The radius of the turning curves should not be less than the diameter of the pipe.

The connecting pipe links must be as tight and free as possible during installation. The end of the pipe-joint is inserted into chimney, that is, in the masonry, at least 10 cm. Here it is worth using a limitation device (corrugation or washer), which will prevent the projection of the end of the joint beyond the channel wall.

Safety standards are strictly prohibited from laying pipe connections through living quarters. Pipes-connections located in unheated rooms are insulated.

On the construction of a coaxial chimney on video:

Gas heating boilers are an excellent way to create a heating system for rooms. They are quite economical and capable of demonstrating a decent coefficient of efficiency. However, such heating systems are sources of increased danger and, therefore, during the construction process, it is necessary to follow the rules for installing a gas boiler.

Specialist required

First of all, note that all equipment is designed for working with gas (be it a boiler, pipes, connecting fittings or other devices) must have a corresponding certificate. It is not possible to use equipment intended for the creation of gas communications, for example, for water supply systems. As a rule, for the installation of gas boilers and heating systems based on such devices, it is also required to employ workers who have the appropriate admission and trained. But in extreme cases, you can install a heating system based on a gas boiler and yourself.

Basic rules for the installation of gas heating equipment

To ensure trouble-free and safe operation of gas heating equipment, it is necessary to observe a number of strict, but simple enough, rules.

Requirements for the boiler room

First of all, remember that natural gas is extremely flammable and its use in unprepared and inappropriate premises can lead to very unpleasant consequences.

However, gas heating boilers with a capacity of up to 60 kilowatts can be installed in any, even unprepared rooms. But the boilers must be single-circuit. In the event that there is a second circuit in the heating boiler - its installation in the kitchen is prohibited.

To install gas heating boilers up to 150 kilowatts, you can choose any floor of your home. However, if you plan to install a more powerful heating system, it can be placed only in the basement or in the basement.

Please note that according to the existing standards for 1 kilowatt of the power of the gas boiler there should be 0.2 cubic meters of the room volume in which it is installed. Also, the installation of a gas boiler house in a private house should have a ceiling height of at least 2.5 meters and provide convenient access to any of the elements of the heating system. The walls of the gas boiler house must be fire-resistant with an indicator of at least ¾ hours. As with other accommodation options, there should be natural light in the room of a separate gas boiler house, that is, it should have a window in the outer wall of the house.

Requirements for chimneys of gas boilers

Chimneys of gas heating boilers also have their own installation rules. Their improper work can lead to the accumulation of combustion products and to tragic consequences.

The required minimum chimney diameter is specified in the specification for your gas boiler. At the same time, its inlet cross-section must coincide with the section of the outlet of the gas boiler.

To ensure the removal of combustion products, the upper edge of the flue must be placed at least half a meter from the roof ridge. As a rule, chimneys of circular cross-section are used for gas heating, the walls of which are made of black metal or stainless steel.

When creating a heating system project, it must be ensured that the flue gas duct of the gas boiler has no more than three bends or turns. The initial section of the chimney immediately adjacent to the gas boiler should be at least 25 centimeters.

Obtaining permits

Because of gas heating is a source of increased danger - before its installation it is necessary to obtain a number of permits.

At the initial stage, it is necessary to fix the connection to the gas supply pipe with the contract. Before the construction of the heating system, a gasification project is being developed and approved. Only after the approval of the project in the authorized organization can start to purchase equipment and directly to the installation.

Rules for installing a wall gas boiler

After approval of the project, at the stage of purchase, be sure to check the presence of the fastening devices in the delivery package. If the manufacturer has not enclosed them in the kit - they must be purchased separately. Be sure to require a certificate for the purchased gas boiler. Conduct a reconciliation of the boiler labeling and the information specified in the safety certificate.

At the preliminary stage of installation, carefully purge the internal piping system of the boiler. Remove all transport plugs. Pipes are cleaned with a low pressure water stream, water will remove small debris and dust.

Make sure that the wall material on which you plan to place the gas boiler is made of non-flammable material. Otherwise, it must be strengthened with fireproof coating thickness of more than 3 mm. The boiler itself should be placed at least 45 mm from the surface of the wall.

The height of the installation of the gas boiler is then 80 to 160 cm. At a distance of at least 20 cm there should be no other electrical or gas equipment, or any flammable materials.

When installing the mounting brackets, check the construction level with their horizontal and vertical position.

In the event that the design of the gas boiler requires traction in the chimney - we form and test the way out the combustion products. There are also so-called "non-flue" boilers in which combustion products are removed forced circulation air through the exhaust fan.

Gas connection to the boiler is carried out with the obligatory participation of a certified specialist. During installation, only metal pipes and special connecting devices are used.

If your gas boiler has electrical appliances - we connect it to the mains through a separate circuit breaker and overheating protection.

The first start-up of a gas heating boiler must be carried out in the presence of a specialist from a gas company, after a thorough check of compliance with all installation rules.

Rules for installing a floor gas boiler

Outdoor gas boilers have a greater power compared to the wall and require more stringent installation rules.

When installing a floor boiler, as a rule, a branched heating system is installed that distributes heat in several rooms or on several floors. Therefore, even before the purchase of the boiler, it is necessary to compile the design of the heating system and to understand the location of all its elements, including the correspondence of the location of the outlet pipes of the floor boiler to the inlet connections of the heating system.

The floor boiler can be installed on a solid wooden floor, however (unlike a concrete one) it must be protected with galvanized iron or clinker tiles. At the same time, the non-flammable substrate should extend beyond the front of the boiler by at least half a meter.

As well as the wall version - floor gas boilers during installation are carefully verified on the building level. When installing such boilers, a qualitative chimney system

Water heating systems based on gas boilers require the installation of a stiffness filter for incoming water flow.

Take into account that each branch pipe of the approach and intake of water must be equipped with devices that facilitate their dismantling. This is done in order to replace any of the elements of the system in case of repair. Also on all nozzles are installed valves.

The rules for installing a gas boiler in the floor version also require its connection and the first start only with the participation of a specialist from a gas company.