How to make heating without a circulation pump. How does this all work? General scheme of the system and its installation

One of the advantages of individual housing construction is the possibility of installing an autonomous heating system. It can be a gas, electric solid or liquid fuel boiler. Water is the most commonly used coolant. But it is quite realistic to arrange in a private house and steam heating.

What will it take for him?

The device of the steam system

Installation is not complicated, but, like any unfamiliar work, it is better to entrust it to professionals. First you need to buy necessary equipment - pipes, convectors, elbows and connectors.

Pipes are better to take waterproofing from plastic with a diameter of 25 mm, if this is allowed in the planned scheme for implementation. Metal products are cheaper, but they can become clogged due to the deposition of salts. In addition, the use of plastics simplifies installation, and this material has better thermal conductivity.

General scheme of the system and its installation

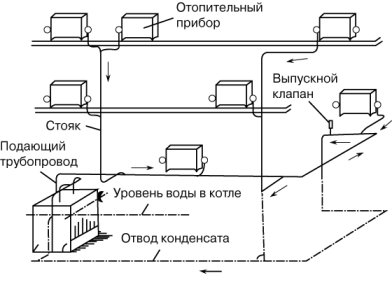

Steam heating of a private house consists of the following parts:

- heating boiler

- expansion tank

- pipeline system

- convectors

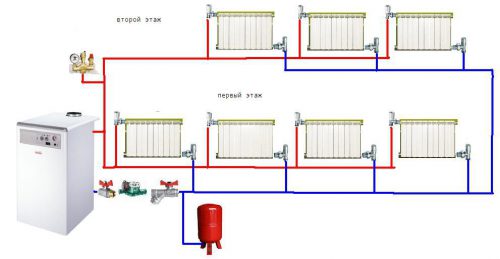

Installation starts from the pipeline. He is bred around the house in accordance with the scheme. Convectors are installed under each window so that they warm the cold air entering the room. As for the number of pipes, it is estimated that about 2 liters of pipeline volume per square meter of the house area. And the volume of the expansion tank should be from 20 to 40 liters.

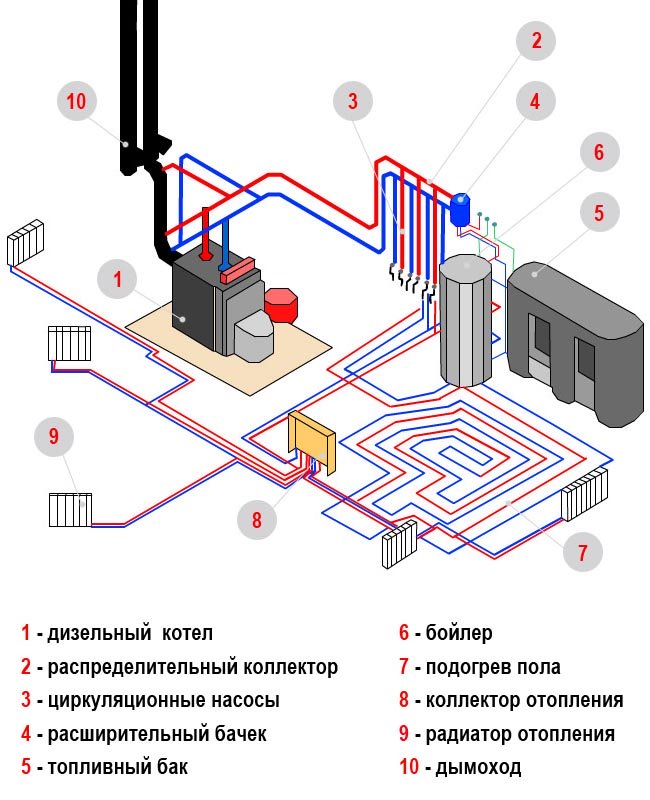

The boiler specialists recommend to put in the basement. But at the same time, if it is planned to install also a floor heating system, the boiler should be located above the floor level to ensure a normal circulation of the coolant. Specialists for this case recommend buying a dual-circuit boiler - so that one circuit would work to heat the entire house, and the other would provide floor heating.

Please note that regulatory requirements do not allow placing the boiler, wherever it is. Its installation must comply with existing regulations. If it is decided to use a gas unit, then it can only be installed by certified gas service employees.

Organization of steam heating from the furnace

Steam heating a country house can be arranged and from existing furnaces. In this case, use a single-circuit heating circuit. Laying it out is done so that from the furnace the pipeline goes higher than the one that returns to the boiler.

It is also necessary to consider what kind of fuel the room will be heated. If planned wood heating, the pipes should be put only metal. The fact is that wood can heat the coolant to a temperature that the plastic simply can not stand.

Organization furnace heating is more expensive than gas, so at the first opportunity you need to abandon it and switch to more advanced schemes.

An exception is the use of a solid-fueled long-life boiler. But such units are not so common in our regions as gas ones. This type of heating equipment can work on solid and liquid fuels and can reduce the cost of providing a comfortable microclimate in the winter. However, this method is usually considered only when there is not even a theoretical possibility of conducting more popular gas heating.

One of the most effective and inexpensive ways to heat a private home is to include a kind of steam heating. The effectiveness of this method consists in the direct possibility of self-equipping the heating system (of course, the desirable presence of a specialist) along with the maximum functionality of rapid heating of both small and large rooms. However, for this project you will need a scheme of steam heating, which is best ordered from professionals.

For installation of steam heating in the house the following elementary components are necessary:

- Boiler;

- Exhaust valve;

- Radiator;

- Pipes (metal);

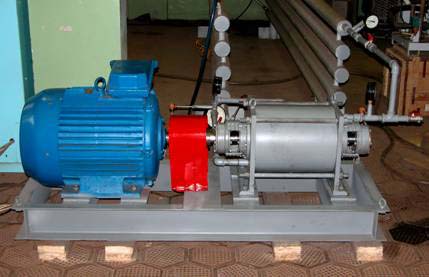

- Pump (when the system is open);

- The furnace.

Steam heating scheme: description and operation principle

Heating in a steam way is simple enough in its principle. The steam boiler, which heats the water to the boiling point, forms steam, which appropriately penetrates the radiators and pipes. Condensation, the water again gets back into the boiler. Here, the difference in the heating system is the choice of the method for draining the condensate. A steam turbine or a reduction-cooling plant takes steam out, the condensate formed comes through a certain technological tilt of the pipe back into the boiler or into the pump that pumps the condensate. Heating devices can be convectors, radiators or pipes (ribbed or smooth), depending on the choice. Typically, often use either pipes, as the most economical option, or radiators.

Steam pressure systems:

- High pressure (pressure 0.18 - 0.47 MPa);

- Low pressure (from 0.15 to 0.17 MPa).

Condensate return:

- Closed type (return of condensate occurs immediately immediately into the boiler under a certain fixed angle of pipes);

- Open type (the tank collects condensate, from where it is subsequently pumped into the boiler by a pump).

Way of laying:

- Upper wiring (the location of the steam pipe is above the heating devices, the condenser is below);

- Lower wiring (Steam line and condenser are located below the heating devices).

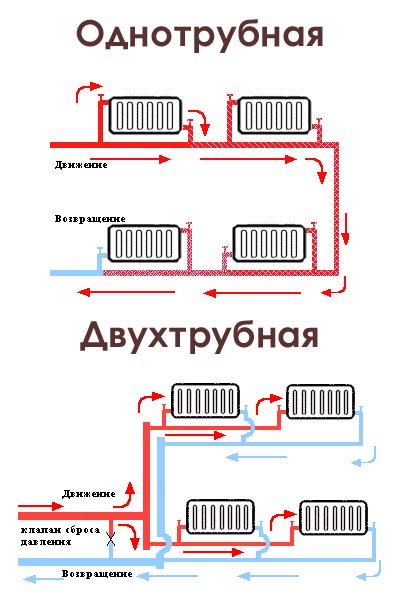

Installation diagram:

- Single-tube;

- Two-tube.

The choice of a single-pipe or two-pipe system primarily depends on the room in which it will be installed. In a private house, a more compact single-tube system is desirable, combining less occupied space and the possibility of warming up a small room, in contrast to a two-pipe system, which is used in large, often uninhabited premises.

Types of steam boilers:

- Gas tube;

- Water tube;

Also, boilers differ in the type of fuel burned:

- Solid fuel;

- Liquid;

- Combined (the choice of fuel is both solid and liquid);

- Gas.

Stages of the system installation:

- Plan. In the preparation of the plan there is a necessary alignment of the installation site for batteries, a boiler, an intake valve. An appropriate heating drawing is drawn up, in advance coordinated with the state control bodies authorizing the installation of the heating system;

- After the plan is drawn up, the next item is to prepare the premises for the safe installation of the boiler house. At this stage, the foundation is poured under the boiler and important measures to protect the premises, such as wall sheathing with fire resistant materials (asbestos, for example) This measure is mandatory, as possible unforeseen situations during installation (breakage, steam skipping) can lead to damage to your premises ;

- It is important to note that the boiler is mounted at the bottom of the radiator and pipes, as this will create conditions for steam to pass up the heating system. And also allow condensate to merge back into the boiler (if you chose a closed type of steam heating system);

- Mounting of radiators - either by welding or threading; Important! Observe tightness during installation, avoiding passing steam under high pressure pipes. There is a risk of getting burns, and therefore it is worth paying close attention to these parameters.

- Installation of the boiler and its subsequent testing. In this case, it is necessary to help the relevant specialists who will conduct a full-fledged start-up of the heating system in your home, taking into account all the indicators and norms. This stage is very important, because if you ignore it, there is a risk of explosion of the system, the passage of steam from the pipes, which can lead to injuries, burns and damage to your home and loved ones.

The positive aspects of choosing this type of heating system:

- High efficiency. Uncomplicated in the installation and in principle the operation of the unit has sufficient efficiency for a long time. The steam system, by its very principle of circulation of water and condensate, is very productive;

- Good heat-accumulating characteristics of steam, which allow the transfer of heat through the radiators without significant costs;

- Low installation costs and a wide range of choices for both your budget and any type of room in which to install.

- Possibility of rather fast and regulated heating of a private house.

In general, it is worth noting that the steam heating system is quite an advantageous option for those who want to equip themselves practically independently, cheaply and according to their own budget, a reliable and ergonomic system. The range of selection of boilers, pipe types, radiators and other incoming elements is quite wide and varied. Plots of land, large rooms and private houses with safe and proper installation (see the steps and general advice) can be sufficiently provided with this type of heating system.

- Do not use at all plastic pipes!! The high temperature of water and steam creates a huge load, which can lead to an explosion of the system if the material is incorrectly selected. It is necessary to use metal pipes (preferably galvanized or stainless pipes). In this case, savings can be unsafe and risky;

- The installation of the system should be done exclusively by professionals, or under the supervision of appropriate specialists, who can find a defect in the installation on time and eliminate it. Control, the first start of the system is made only with the availability of professional skills;

- When choosing a boiler, account should be taken of the amount of steam produced (indicated in kilograms) produced by the boiler. This directly determines the heating rate of your house, which will allow you to choose the best option for a certain room.

The scheme of steam heating in a private house updated: November 2, 2016 by the author: kranch0

Steam heating according to the principle of operation is similar to water heating. Only in it, as is obvious from the name, steam serves as the carrier of thermal energy along the contours. Calculation and installation of such a heating scheme was first carried out in the 18th century, which became possible with the beginning of the use of steam installations in the industry. And the first domestic systems of steam heating earned in the beginning of the XIX century.

Principle of operation and features

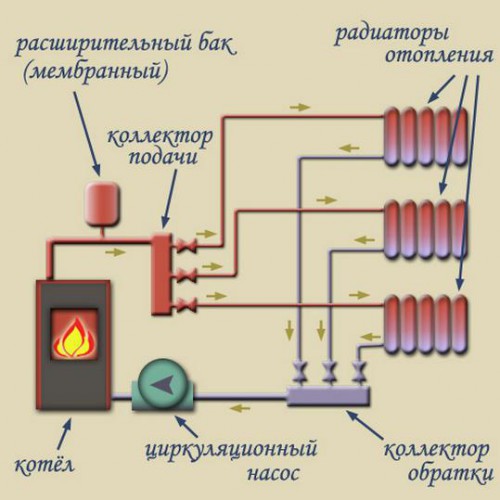

After two centuries, there were many qualitative changes in the technology and technology of production, which contributed to the improvement of materials and equipment used, including in these heating schemes. There were several different ways of constructing and calculating them. Nevertheless, structurally all the variants of the system are similar. The principle of operation differs only in details. Steam heating is based on such a composition of devices and elements:

- a boiler or other product serving as a heat source and capable of converting the energy of combustible raw materials (or electricity) into steam energy;

- radiators that transfer heat from the steam to the atmosphere of the premises;

- the collector serving as the accumulator of water formed after cooling;

- connecting elements that form a complete contour, through which the movement of steam through the system;

- additional products (pump, various fittings, etc.).

The principle of operation is simple: heat is transferred by steam from the boiler to the radiators, and then the water condensed in them is returned through the collector back by means of a pump (or gravity flow). Steam heating, despite the presence of many other systems today, can still be found both in industrial buildings and in residential buildings. It is often used so that the heating of the premises is practical and effective. Advantages of the system of steam heating are manifested in such things:

- The efficiency of the boiler or other heat source is close to unity due to the almost complete absence of losses in heat exchangers;

- small overall dimensions connecting elements, since large diameters are not required for normal operation, while the contour can cover structures of almost any height;

- the radiators become "fiery" for a short time after the boiler starts working;

- radiators and connectors are not destroyed in case of freezing;

- there are no environmentally dirty by-products of operation (for most types of boilers);

- the use of steam as a circulating coolant does not entail unnecessary costs.

Steam heating is used where its shortcomings can be neglected. They are few, and all of them are conditioned by the nature of the coolant, which deprives the system of flexibility in management. The list is as follows:

- there is no way to smoothly adjust the temperature of the radiators;

- the temperature of the radiators and connectors is so high that it will cause a burn on contact with their surfaces;

- the above drawbacks contribute to one more thing - shortening the service life of the system.

Schematic solutions

The scheme of steam heating for a particular building is designed with the expectation that, with the greatest efficiency, the least costs will be incurred, both for installation and subsequent operation. For example, the plant can already have steam generating equipment involved in the process chain. It is more appropriate to additionally attach heating radiators, rather than equip the premises with some other system. Of course, the possibility of such a connection must be supported by calculations. For a private structure in which there is an oven, on its basis, by some refinement, it is also possible to arrange the operation of such a scheme. Alternatively, after completing the calculations and selecting the appropriate equipment and materials from the boiler to the pump, build the system from scratch.

Steam heating can function, being implemented different ways. If we take such a parameter as the vapor pressure in the system (absolute), then we can select the following options:

- vacuum-steam (up to 0.10 MPa);

- with low pressure (from 0.10 to 0.12 MPa);

- with increased pressure (from 0.12 to 0.17 MPa);

- with high pressure (over 0.17 MPa).

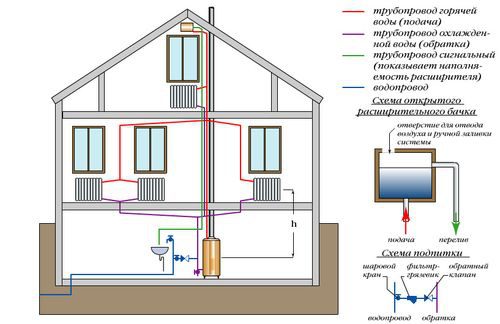

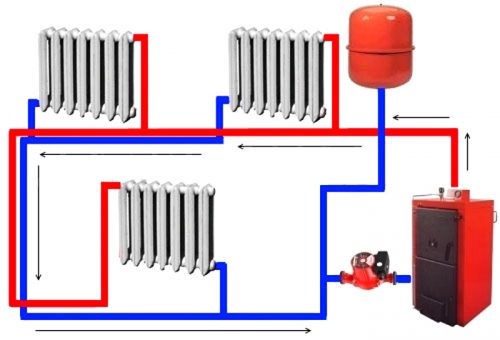

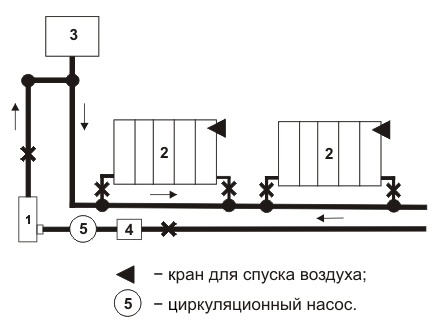

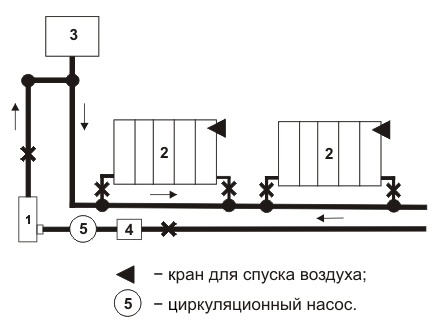

To ensure a long trouble-free operation, it is necessary to perform a calculation so that, after mounting the pipe, etc., the connecting elements, boiler, pump, radiators, etc., do not fail because of their inability to withstand pressure in the system. Steam heating, depending on how the water enters the steam generator after the completion of the previous cycle, falls into two types: closed and open. In the first version there is no pump.

The fluid flows under the influence of the same formed column, that is, by gravity. This option is typical for a low-pressure steam heating system in which the radiators are located at a sufficiently high level relative to the boiler. In an open circuit there is a collector and a pump that pumps water into the boiler. This option is used where the installation of a system with gravity-based water return is impossible or impractical.

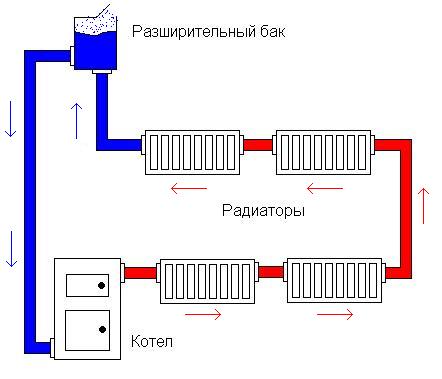

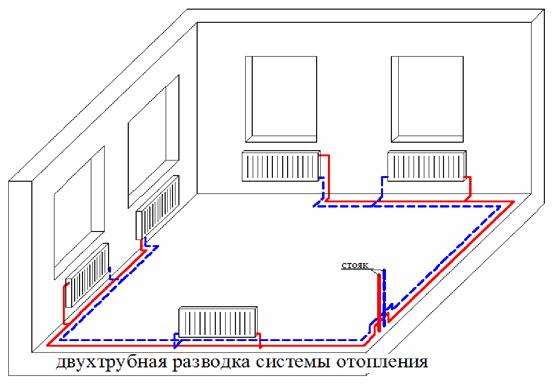

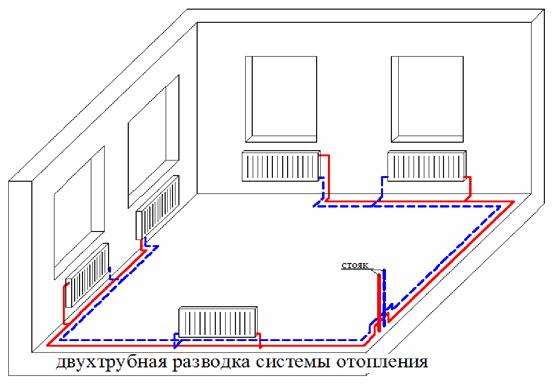

Structurally, steam heating in the part of the connecting elements can be realized in one of two ways:

- two-pipe;

- single-tube.

In the first case, the steam heating system is laid from two channels - steam and condensate. Radiators are connected to them in parallel vertical bends. In the second case, steam and water formed during the condensation process are moved sequentially through the devices and circuit elements. The openness or closeness of the latter is determined by the presence or absence of direct communication with the air of the external environment.

Openness is characteristic of systems with low pressure. In this case, the closed circuit has contact with air through a pipe of a "dry" condensate pipeline, and an open type (with a pump) - by means of a collector. Steam heating with high and high pressure is equipped on a closed basis.

Calculation and installation

Steam heating, like almost any other, requires attention to the stage of its design. The fulfillment of the thermohydraulic calculation is aimed at completing the circuit with the equipment with the optimal set of parameters. It combines:

- hydraulic calculation, which clarifies the characteristics of steam and condensate-conducting pipes;

- thermal calculation of steam heating batteries, following which results their geometric and other indicators become known;

- selection of functional equipment (boiler, pump, etc.) and other components of the circuit.

The installation of the steam heating system is similar to the installation of a water heating system. The difference is determined by the fact that the components are exposed to a higher temperature. Therefore, insulation of radiators and pipes for steam heating is a common thing. Before starting operation, the circuit is subjected to tests, the main purpose of which are:

- Check the uniformity of steam supply to the heater and the absence of its passage into the condensate-conducting pipe.

- Evaluation of the tightness of the circuit and verification of its working pressure.

The considered type of heating is a somewhat outdated, but proven and reliable version of the heating system. Most of all, it is acceptable and beneficial for enterprises that have appropriate equipment. But the owners of individual buildings are quite capable of taking it into service, provided they have a competent approach to the calculation and installation of the scheme.

We make a self-heating system

The owner of the house sometimes finds it difficult to determine the choice for him of life-supporting communications. Depending on the remoteness of the dwelling from the industrial civilization, it is hardly possible to centrally conduct some of them. In such cases it is necessary to install autonomous systems. It is important to strike a balance between resource costs and a useful result. With regard to heating rooms in the cold season, one of the surest ways to achieve a good climate at home is to design and install steam heating with your own hands.

What is this system

Such a system has relatively few positions. The main parts are:

- The device of vaporization, in which quality in a private house can serve as a suitable type of boiler or stove.

- Radiators, similar to those used in water systems;

- Pipes, fittings, etc. Elements for connecting the first device with the second.

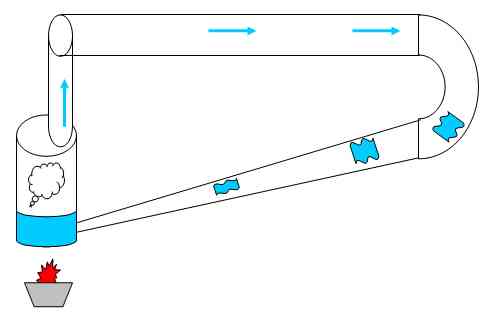

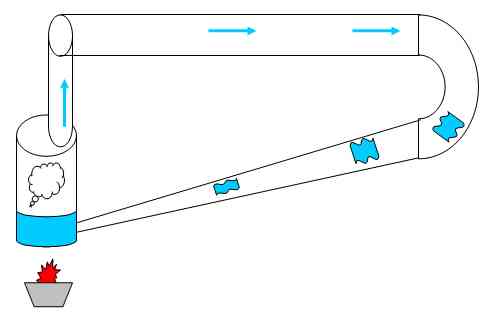

Additionally, in a number of embodiments of this heating circuit, a pump may also be present. It is established when the circulation of the heat-transferring substance in the system is not possible in a natural way. The general principle of the operation of this heating is described as follows:

- in the heat exchange circuit of the furnace (boiler), in which the firewood (or other energy carrier) is burned, the water becomes steam;

- steam moves through pipes to radiators;

- in the radiators there is a process of condensation of moisture, accompanied by an increase in the temperature of their surfaces;

- moisture drains into the collection tank, and from it - back to the furnace (boiler), while at the last stage it can "help" the pump.

In the scheme without a pump, the self-discharge of moisture is provided provided that the component parts and the connecting elements are correctly positioned and tilted relative to each other. Advantages and disadvantages of this heating system result from the properties inherent in the heat-transfer material circulating in it. Positively here is what:

- the operating speed is high - the radiators will quickly become hot soon after the boiler starts;

- almost 100% of the efficiency of the vaporization device is work without heat losses and with a maximum heat transfer in the heaters;

- the system is economical, which is ensured by the above item and the modest dimensions of the component parts and connecting parts;

- the system is not afraid of "supercooling" - it will most likely not be during defrosting.

An inconvenient side of such a system are:

- hot surface of radiators and connecting parts to a temperature capable of causing burns of living creatures in contact with them;

- the impossibility of changing the temperature of individual radiators;

- shortening the life of equipment and fittings due to the harsh conditions of their operation.

How and from what to collect

In order to properly select the equipment and materials for heating the house, and then properly install them, you should first conduct a small project survey. Their task is:

- Find out which scheme in this house will be optimal.

- Determine the position and extent of the contours of the connecting parts, including all necessary turns, forks, etc., as well as the location of equipment, primarily the boiler and radiators.

The first item involves an analysis of the existing options for the implementation of steam heating and their applicability to the characteristics of this house. First, the system can operate at a certain level of vapor pressure. There are four categories: from ultra-low (vacuum-steam) to high. The last (up to 6 atm.) Is advisable to apply if the house is large enough. Secondly, the system variants are selected according to the way in which the moisture returns to the boiler. It can be carried through a collection tank, from which to pump by a pump - this will be an open method. And it is possible - in a gravity way, due to the pressure provided by a water column of sufficient height - this is a closed method.

Thirdly, the contour formed by the connecting parts can be single or double. The latter is used more often, since the first, perhaps, is not always constructed. For this, it is necessary that the pipes and equipment form a sequence that provides movement, both steam and condensate, in one direction, due to slopes and angles. So, the boiler should be located much lower than the heaters. In a double variant for the supply of steam and diversion of moisture serve different pipes. At the same time, along with heating, the same system can also provide hot water supply.

The second item implies a thermohydraulic calculation of the future heating scheme of the house. Here you need to determine the specific parameters of the equipment, which will be the best in this building. First, it is necessary to find out the capacity of the boiler.

Depending on the total heating area, approximate ratios are as follows:

- up to 200 square meters. m - up to 25 kW;

- up to 300 square meters. m - up to 30 kW;

- up to 600 square meters. m - up to 60 kW;

- up to 1200 square meters. m - up to 100 kW.

On a working fuel, the device should be selected from those elementary considerations, so that the type of energy used is affordable and cheap in the area. Secondly, the geometric characteristics and material of the pipes must ensure that they withstand the effects of steam and pressure in the system throughout the estimated (estimated) service life. The most suitable for this purpose is rolled from alloy steel or copper. However, this is not the cheapest option. Thirdly, the dimensions and material of the radiators should also contribute to the durability and efficiency of the heating system.

The installation features depend on the chosen variant of the scheme implementation. It is also necessary to carefully study the recommendations given by manufacturers of equipment and materials. And, of course, follow them, paying attention to such things as the distance from the boiler to the walls and ceiling of the room, the requirements for fire resistance of insulation and finishing materials, the availability and performance of ventilation systems, etc. In general, you can install the steam system by sequential execution of such stages:

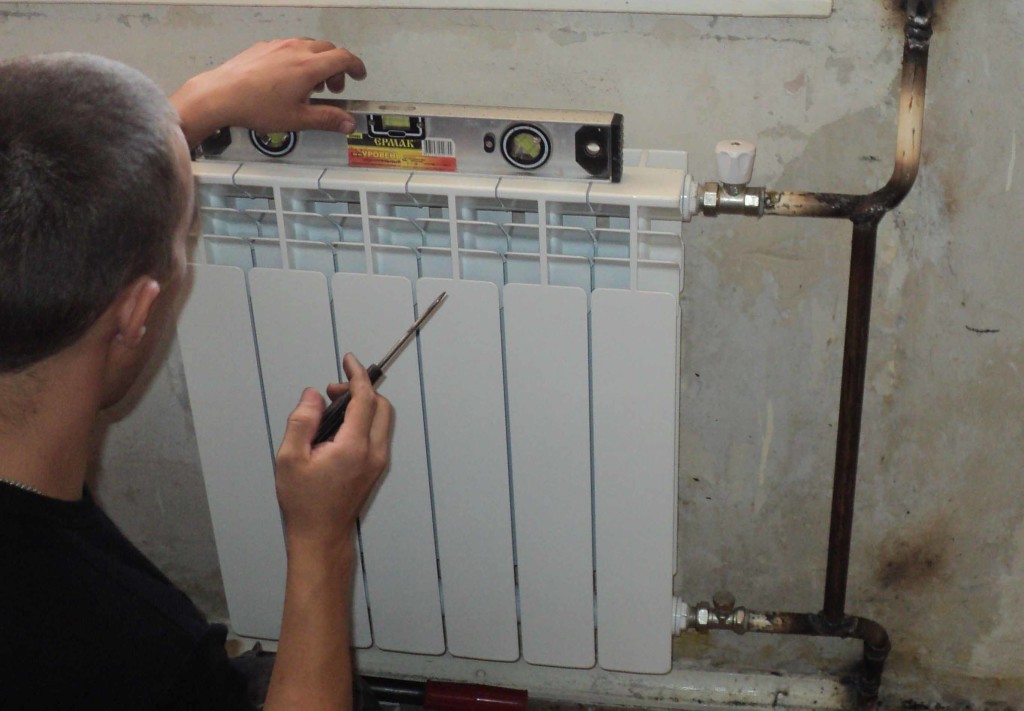

- preparation of places for the installation of equipment and fittings;

- installation of the boiler and radiators in the prepared places;

- installation of pipes and additional equipment attached to them (control devices, various fittings, safety valves, etc.);

- control the working capacity of the circuit and all its devices and elements.

Having learned more about how to make steam heating, it is not difficult to translate this idea into reality. Of course, this requires a certain level of qualification. But this business is acquired, and most importantly - the desire and perseverance in achieving the goal.

- ABOUT steam boilers and their strapping

- The scheme of steam heating

- Water heating from the oven

- Conclusion

Today, steam heating of residential buildings is considered a relic of the past. In principle, steam is never heating systems apartments and not served, but only from boiler rooms to thermal points. This expression has long been common and in the common people means just the usual water heating. Nevertheless, on the Internet it is often possible to meet recommendations on how to install steam systems in private homes. This article will explain why it is unacceptable to heat your home with a ferry.

Features of steam heating

In Soviet times, many industrial enterprises, whose boiler houses produced steam for technological needs, organized heating, where it served as a coolant. Registers or steel convectors were used as batteries, and a boiler for steam heating provided a pressure in the system of 3 bar and above at a coolant temperature of more than 130 ° C. At the same time, the surface of the registers represented a danger of burns for the employees of the enterprise.

Since then, the overwhelming majority of enterprises have undergone reconstruction and carried out a transition to water or air heating. But, as we have already noted, a lot of Internet resources give recommendations for installing steam heating in private houses, which in itself is nonsense. This is motivated by the fact that the system of steam heating in a private house:

- does not require large radiators, because the temperature of the coolant is much higher;

- provides very fast warm-up of premises;

- needs pipelines of smaller diameter than water pipelines;

- it will cost less in equipment and installation.

In order to dispel all myths and to save homeowners from irreparable mistakes or waste of time studying all aspects, we will consider the principle of the operation of steam heating and list all its features. So, in the beginning the boiler plant produces steam of a certain temperature and pressure, these parameters are directly interconnected. For example, at a temperature of 133 ° C, the steam pressure is 3 Bar, at 140 ° C - 3.5 Bar, and at 144 ° C - 4 Bar.

Steam under pressure moves through a pipeline whose diameter should be greater than for the same mass of water. By giving up heat in the radiators, it condenses, but only partially, resulting in a steam-water mixture. Moving back along the condensate line, it passes the process of secondary effervescence, which is fraught with water hammers. For steam heating on wood or other fuels to function normally, the following requirements must be fulfilled:

- to get rid of steam-water mixture, on each branch it is necessary to put a special separator - a steam trap;

- the system can be assembled only from steel seamless pipes (for example, according to GOST 8732-78). Pipes for water and gas, copper, and especially for polymeric use for steam is unacceptable;

- all heating of a private house should be mounted on flanges or welding, conventional couplings will flow in half a year;

- shutoff and control valves also need a special one, designed to work with steam.

About steam boilers and their piping

The thermal plant for steam production is not more complicated than a hot water boiler. She has to work with high pressure and temperature, so the quality of the metal used is higher, and the thickness is higher. In addition, the unit is equipped with expensive automation and safety equipment. The following diagram shows the scheme of a steam boiler:

Note. In vertical versions of steam units, the burner is installed from above, and in horizontal versions - from the side.

Due to extreme operating conditions, the installation of the boiler includes the provision of water treatment. Yes, simple water from the tap does not fit here, it must be desalted, cleaned and removed dissolved oxygen. Otherwise, the coil, where the evaporation of water occurs, will fail very quickly. On the supply line of the heat generator a separator is installed, which does not allow the water to evaporate.

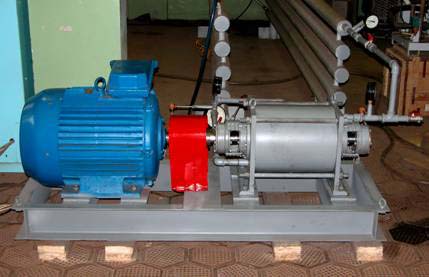

As for the circulation, the steam heating pump works differently here. Steam moves through the pipes on its own, as does the condensate. The latter enters the storage tank installed in the boiler room, from where the make-up pump pumps it into the boiler as necessary to repeat the cycle.

From the above, the conclusion suggests that the steam generator is more complicated, more expensive and much more demanding than hot water. There can be no question of making a steam boiler with one's own hands, this is a very dangerous experiment.

The scheme of steam heating

By and large, the schemes of heating systems for steam and water are almost identical. Only in the case of steam, the connection to the boiler becomes more complicated, there is an additional storage tank for condensate (receiver) and water treatment units, which is demonstrated in the diagram:

Regardless of whether you are going to install heating yourself, or hire specialists, we will present 5 arguments why it should not be steam:

- steam heating is injurious: heated up to 130 ºС radiators and pipes - a source of burns for you and your children;

- no savings: it is almost impossible to regulate the temperature in rooms heated by steam;

- purchase and installation of steam boilers, as well as special fittings is much more expensive than traditional water systems;

- commissioning of equipment that produces steam requires approval from the relevant control authorities;

- equipment for generating steam is a source of increased danger. Its sphere of application is industrial production.

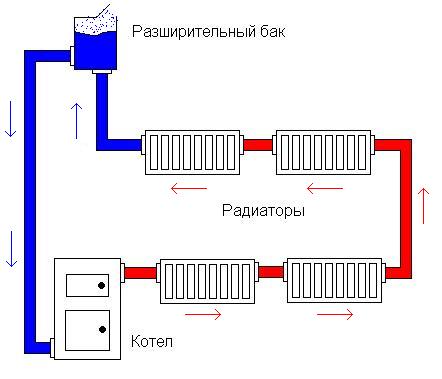

Water heating from the oven

There is such a thing as stove heating, introduced by our grandfathers. But there is no steam in the pipelines here, this is water system with radiators, operating from a heat exchanger installed in the furnace or flue duct of the furnace. Heat exchangers for these purposes are of two types: in the form of a coil or a container with nozzles. The tank is usually cooked from stainless steel, and the coil is made of thick-walled steel pipes.

Council. When it is planned to make heating in the dacha or in another building with a periodic heating method, in order to prevent the batteries and the heat exchanger from defrosting in the oven, it is necessary to pour antifreeze liquid into the system.

To make steam heating from the stove, you need to make a pipe wiring and install radiators. As a rule, the capacity of the heat exchanger is sufficient for a good heating of 2-4 batteries, this number should be oriented. The system can be made gravity, but it will clutter your house with large diameter pipes. If there is no urgent need, it is better to install a circulation pump and lay the trunk above the floor.

As in the case of boilers burning solid fuel, a safety group should be installed on the supply pipeline. The combustion process in the firebox does not always manage to be checked or stopped in time, so the presence safety valve with a manometer will not hurt. The best option, in which the overheating of the furnace tank is practically impossible - this is the presence of a heat accumulator.

Conclusion

It is expensive, inefficient and just dangerous to use water vapor when heating a private house as a coolant. For these reasons, even industrial enterprises refuse such heating, which produces steam for technological needs.

Steam heating refers to a system in which heated water vapor acts as a heat carrier. Such heating was widely used in the 19th century in residential buildings. Soon, steam was replaced with water, but the name of the system (in our case - erroneous) remained the same.

Water vapor efficiently transports and transfers heat, but this heating was abandoned due to the strong heating of the heating equipment (its temperature exceeded 100 ° C). Any contact with the surface of the device caused a burn, and the rupture of the main line led to serious injuries and even death.

Note! In view of all this, to date, steam heating (in its original form) is prohibited for use in public housing.

However, the ban does not apply to private homes, so anyone can do as they wish. But before taking such a serious decision, you should weigh the pros and cons.

- The price of such a system is quite low.

- Steam heating does not unfreeze, so it is possible to use it year-round without risk of freezing of the coolant.

- The heat losses in the heat exchangers are practically reduced to zero.

- In such a system, energy is transmitted by radiation and convection. For comparison: the convection component predominates in the water one, while the heat transfer at the radiators is rather low.

- During installation, radiators and pipes of smaller size / diameter may be used.

disadvantages

But there are also disadvantages that you need to know about before installing.

- Circulating through the system of steam creates noise.

- The temperature of the heating equipment can exceed 100 ° C.

- When a break occurs, there is an increased emergency danger.

- Exposure to corrosion.

Principle of operation

The heat generator in steam heating is a boiler operating at low pressure - it forms hot steam and passes it through the mains. When moving, the steam condenses and settles on the walls of the instruments, giving off a lot of heat - this is the secret of high system performance.

Note! When condensing 1 kg of steam, more than 2,400 kJ of energy is released, while cooling of the same amount of steam at 50 ° C produces only 110 kJ. Condensate itself settles down and settles down into the heat generator in a natural way or with the aid of circulating pump.

The vapor pressure depends on the type of system:

- in ordinary steam heating it is higher than atmospheric, but does not exceed 6 atm .;

- in vacuum systems it is lower than atmospheric.

Adjustment of heat supply is carried out by changing the intensity of vaporization. If there is a need, the supply is simply shut off, which creates conditions for the cooling of the house.

Heating equipment here are traditional radiators made of cast iron or steel, as well as finned tubes.

According to another classification, steam heating can be:

- closed - in this case the condensate returns naturally, for which pipes of a larger diameter are used;

- open - here water accumulates in a special container and is pumped through a pump.

Steam heating by one's own hands

The arrangement of steam heating consists of two stages - design and installation itself.

Stage 1. System Design

Once again, we recall the features of the use of steam as a coolant - this is the high temperature of the pipeline and radiators, as well as an increased accident rate. When all the pros and cons are weighed, you can start work. First, a project of the future system is created.

First, the required power of the heat generator is determined. This takes into account the area of the house - if it does not exceed 200 m², then a 25 kW device is enough, but if it fluctuates between 200 m² and 300 m², a minimum of 30 kW will be required. Based on this information, a cauldron is selected. When buying, consider the following factors:

- type of fuel to be used;

- the possibility of heating water for domestic needs.

Note! Selecting a boiler is one of the critical stages arrangement of steam heating.

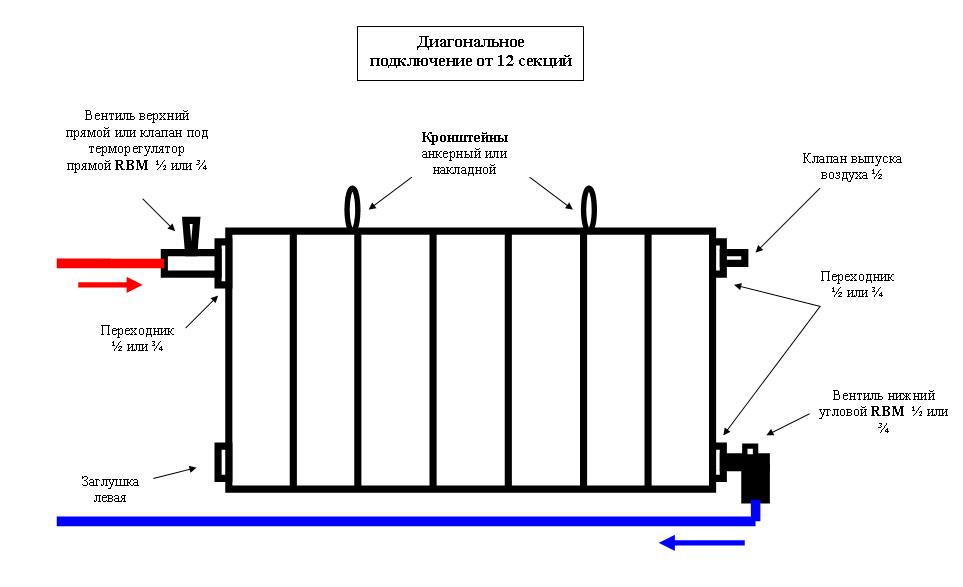

Heating circuit

![]()

![]()

With the scheme also need to decide in advance. The choice of this or that option depends on:

- the location of the boiler;

- the area of the heated space;

- conditions for the installation of heating appliances;

- necessary number of these devices.

In a word, this is a rather difficult choice, in which the video below will help.

Video - Features of work with steel pipes

Pipes

For steam heating, the use of conventional plumbing pipes is unacceptable due to the high temperature of the entire system. For this reason, the selection of pipes should be given great attention, let it be small.

In order to facilitate the installation work at the design stage, it is necessary to determine:

- the location of the radiators;

- length of the pipeline;

- places of installation of distributors, branches of the main line, adapters and so on.

Note! All this data is transferred to paper. An approximate sketch of steam heating is drawn up, where all the necessary details are indicated.

Question price

After the project is drawn up, future costs are determined. It is difficult to say how much the equipment of such a system will cost, without reference to heating appliances, work volumes and specific conditions. We only note that, according to experts, steam heating in any case will be cheaper than conventional water heating.

Stage 2. Installation work

Step 1. First, the exact layout is drawn on the basis of the sketch.

Step 3. The expansion tank is attached. It must be connected to the pipeline leading from the heat generator to the radiators. Another important point: the tank needs to be installed at the highest point of the heating system.

It can be closed and open, with overflow and without it.

Note! Professionals advise installing an open tank, moreover in the closest proximity to the boiler. Although this scheme may well be suitable for a closed type device.

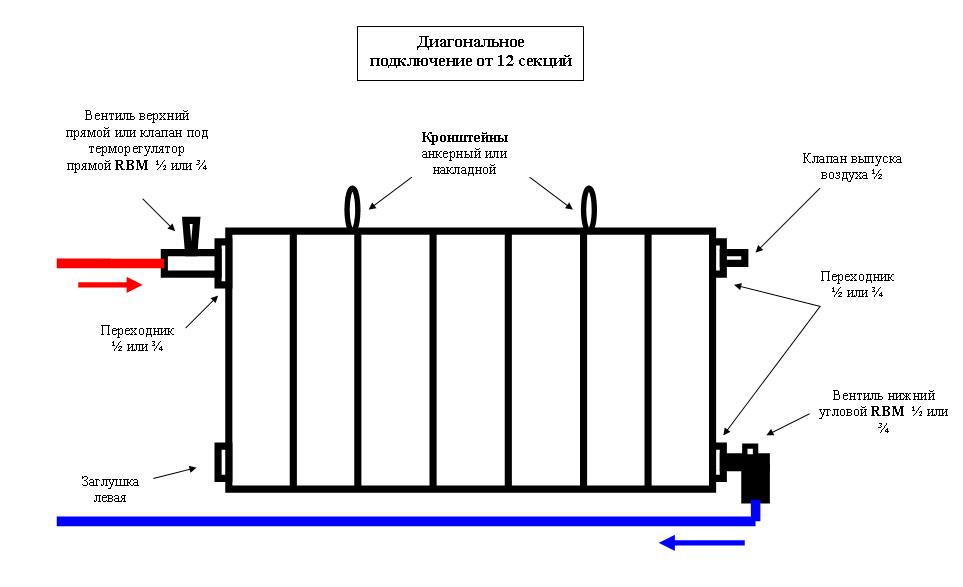

Step 4. Installation of pipelines. This occurs as follows: the pipe is fed to the radiator, cut off when necessary, and then connect the leads and inputs. Then the pipe is similarly supplied from the first radiator to the second radiator, then from the second to the third, and so on.

Note! It is recommended that each radiator be equipped with a Mayevsky crane to remove the formed air congestion.

Step 5. The circuit closes, that is, it is fed to the beginning - the heat generator. It is important that the boiler is equipped with a filter and (if necessary) a circulation pump.

Note! Hot water vapor can go from the boiler, mounted in any convenient place - in the garage, in the summer kitchen or in the house itself. The quality of heating will not affect this, and the financial side of the issue depends entirely on the required length of the pipeline.

In this case, the installation of a heat generator is no different from a similar procedure in a residential building. In this case, the bay / drain assembly can be equipped on any section of the highway. This node is necessary for draining the coolant after the end of the heating season or before repairing the system.

Video - Installing the boiler

Step 7. All heaters are tested. If they are new, it is advisable to invite a specialist for trial launch.

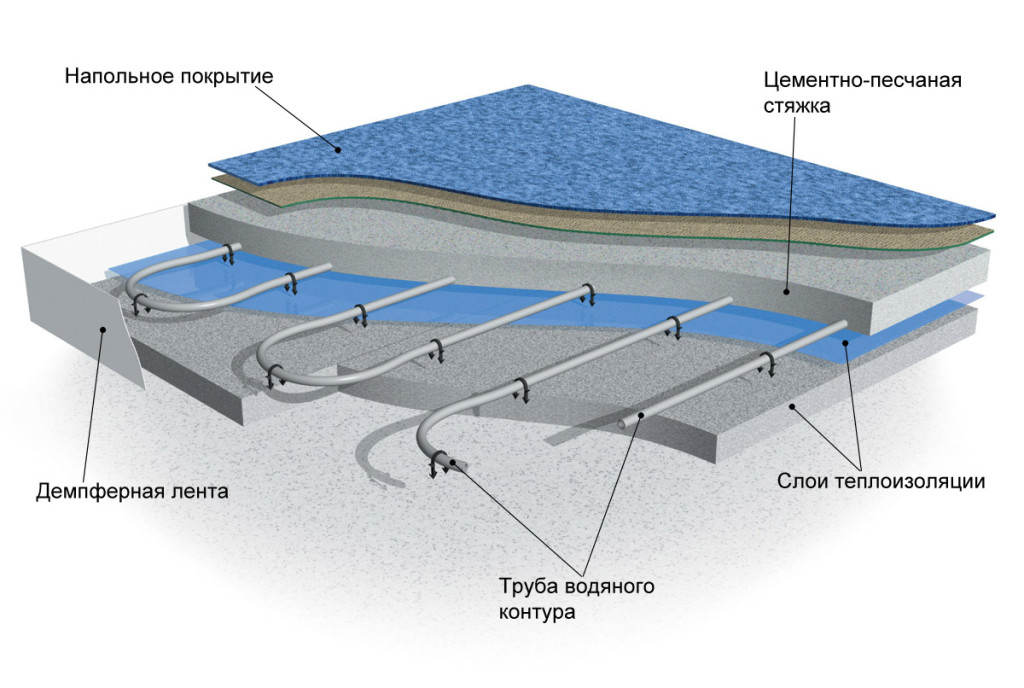

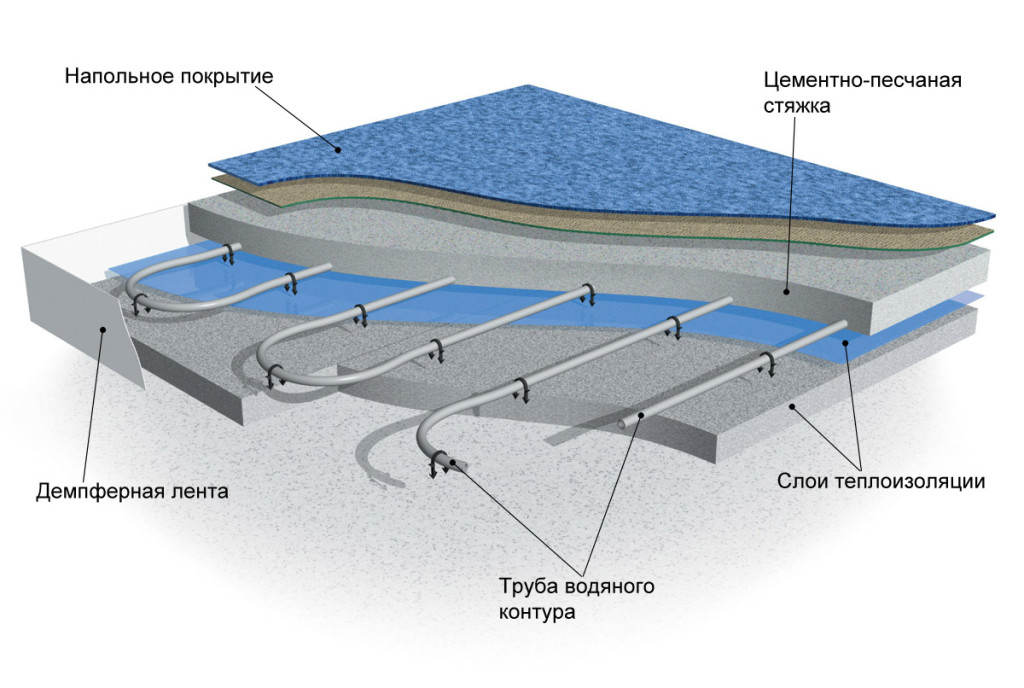

The "warm floor" system

"The warm floor" has been gaining popularity in recent times. Often it is created on the basis of electric heating, but if desired, you can use water. Installation of such a system is a complex and time consuming procedure. Under the floor covering are laid polypropylene pipes (it is also possible to use metal-plastic), through which a hot heat carrier will circulate.

Scheme of wiring and installation of the regulator

Such a variation of the "warm floor" system has a lot of advantages compared to electric, the main of which are low cost and low energy intensity.

conclusions

The use of hot steam can hardly be attributed to popular types of heating, in addition, according to current legislation, it is prohibited to use it in residential and public buildings. But sometimes, for the sake of economy, it is still installed in garages, outbuildings and even in private houses.