Ventilating armature plastic. Connecting elements and fittings. The main advantages of plastic ventilation

The lightness, strength and durability of plastic materials for ventilation helps consumers to move away from metal analogues.

But, at the same time, skeptical people put forward doubts: is it true that the plastic is as durable as metal?

Plastic pipes for ventilation, the dimensions and features of which must be studied before installation, will be amazed by a vast spectrum of excellent characteristics. Due to these properties, these products enjoy the highest popularity.

Ventilation network from of this material can last more than 50 years. For rapid air circulation - this is the most the best option.

Purchase and installation costs plastic pipes will be much lower than on metal ones. It is also worth highlighting their aesthetic appearance and ease of maintenance.

Pipes in such systems:

- not prone to discoloration;

- do not undergo corrosion;

- easy to install;

- durable;

- acceptable price;

- flexible.

The ventilation system is a complex process of exchanging air in the room. It operates in this way: the air in the room (whether it is a living room, office or production hall) is replaced by clean air - from the outside (outside).

Only now to the ventilation system can be attributed not only the process of air exchange, but also thanks to modern systems Added also conditioning, ionization, cooling and heating, humidification and dehumidification and other useful functions.

Under the ventilation system, all the so-called "material part" is understood: ventilation devices, exhausts, fans, as well as pipes (which in turn are divided into a round or square / rectangular section), which are also an element of this system.

We will get acquainted with the widespread sizes and the prices for them. Dimensions of the rectangular duct: 11 x 5.5 cm; 12 x 6 cm; 20.4 x 6 cm. The diameter of the round: 10 cm; 12.5 cm; 15 cm.

Accordingly to GOST, air ducting is produced with the size of the internal section from 10 to 200 cm. The traditional size of ventilation for the kitchen hood is similar to the dimensions of a rectangular.

The price of rectangular and circular air ducts will average from 400 rubles and lower, and you can buy them in any building supermarket.

On construction companies, you can make an order for a round and flexible duct. System flat PVC channel will cost from 100 rubles.

The price for a flexible and plastic option is about 320 rubles.

Ventilation system with a diameter of 12.5 cm

The main task of ventilation is to provide outflow or inflow air. High strength of these products is not required, but the small weight for this task is ideal.

This is very important when you have to install not on the main wall, but on a decorative partition, or over a suspended ceiling.

Pipes with a diameter of 125 mm are used in a standard length of 5 meters. Longer billets are difficult to pack and transport. Pipes for 125 are most often used for ventilation in a residential area.

Tubing materials are very easy to join - they are simply inserted into the socket of another workpiece.

The throughput in this case is 400 m / h. These are the most optimal indicators for domestic needs, in which the necessary air circulation is created and no unnecessary noise is generated during operation.

How to calculate the size and section

For laying produce different fittings, which makes it possible to connect several sites in a single whole.

Sealants help seal the joints, which do not allow air to escape outwards at the junction points.

Fastening of such a construction is performed by fasteners. On sale they are in a wide range.

Select plastic pipes for ventilation and their dimensions are recommended for the type, purpose and extent of the structure itself. Type, exponent, length and location are determined at the design stage.

At the design stage, the performance of all components of the system is calculated. If this is not done, there may be problems in the form of insufficient air circulation or strong noise during operation.

The cross-sectional area of the channel for an air speed of three meters per second is calculated by the formula: S = 0.9 x L. In it, the designation S is the cross-sectional area and L is the air speed index.

Incorrectly selected diameter will cause components to quickly fail. A repair and connected to the system will cost a decent amount.

Section

Mounting plastic ducts for ventilation, the dimensions of the section must be selected exactly. They are an important characteristic in this case. This selection is carried out depending on the location of the network.

For example, if the main overlap and ceiling separates a small distance, then a flat-oval view of the duct is recommended. Its design is not much different from the system of circular cross-section.

Purification of air passes with the same intensity. But, it should be noted that plastic constructions the oval section does not create the proper resistance to the air flow, as a result it easily passes and the engine does not work with a high load.

The truth is the only drawback will be this is a high cost. But, this is justified by the need to use just such a form based on constructive features premises.

Ventilation channels

Plastic ventilation ducts harmoniously fit into the interior decoration of the room.

And the presence of a visor gives elegance and sophistication. This element allows you to hide not only flat, but also round channels.

They are used not only in everyday life. Such a box is often constructed by the exhaust line in offices and small commercial premises.

TO virtues can be attributed.

- Smooth surface outside and inside.

- High index of strength.

- High connection rate.

- Simplicity and ease of cleaning the surface.

- Presentable appearance.

TO shortcomings Such construction is its high cost, if we compare with galvanized and flexible options. This also applies to the limitation of the PVC pipe diameters being manufactured.

Flat ducts

Rectangular plastic pipes are used for laying flat plastic systems.

Their appointment is as follows.

- Creation of supply and extraction networks for small and medium-sized premises.

- To construct a flat output channel.

- For the supply of exhaust and ventilation equipment.

Design features.

- Made from environmentally-friendly material of high quality, which is not subject to burning.

- A wide range of use temperature (from -30 to +70 degrees).

- Minor resistance to the passing air flow.

- Long service life.

- A little noise when working.

- Economical use of space between the ceiling.

- A wide range of options when looking for a standard size and the nominal value of flat tube materials.

Couplings and fittings

Plastic ventilation is easy, this is facilitated by fittings, which greatly simplify this process.

The airway network is constructed in a single modular construction by means of connecting parts according to the scheme for working with the children's designer.

These modules are divided into the following types:

- Connectors. They are intended for direct fastening of parts of the same type and size. For example - this is a rectangular duct of plastic 6x12 cm with a similar 6x12 cm (UPC 612). Also knee for fastening of networks of one kind and dimensions under an inclination (ККП 12,5 or КРП 612).

- Reducer. Set for a network of one type, but of different sizes.

- Adapter. This part serves to fasten different parts of different sizes.

- Splitter (tee). It is installed to divide the system into separate branches.

- Flange and overlay. Such elements are placed when attaching the system to the vent hole.

- Holder. Mounted for fastening to the wall and other surfaces.

Fittings of the modular network are perfectly adjusted to each other and do not cause any difficulties during the installation.

Fittings do not spoil the appearance of the structure in its visible areas. The connecting elements help to hide the air duct in the niches or to pass unnoticed, for example, over the suite in the kitchen.

Fittings in the ventilation network made of rectangular pipe materials allow it to be located inside a partition of plasterboard or behind suspended ceilings without any difficulties.

Correctly selected pipes allow creating a beautiful and reliable modern ventilation system. Thanks to a large number of positive characteristics of plastic, it will last a long time effectively and smoothly.

Choose the material from which the pipes will consist

So, let's imagine the situation. You moved to a new house. Ventilation in the dwelling is an important issue.

There are several types of ducts: plastic and metal (including galvanized metal and others).

Metal pipe owners of living quarters prefer to give less.

It's understandable: the material is less wear-resistant than plastic, heavy in processing, it weighs a lot and with unreliable fastening even creates a danger for others.

So metal ducts are mainly used in non-residential premises and in various industries. Pipes for ventilation from plastic - the most "running" material for the "home" system.

And the plastic for the ducts is also different. The most common materials are PVC (polyvinyl chloride), polypropylene, polyethylene, polyurethane and some other materials of this type and composition.

The advantages of plastic ventilation systems

Do not worry about the internal state of your ventilation systems - many are afraid that plastic pipes retain a static charge, and as a result, dust, dirt, fluff, debris, insects, light household waste are electrified and settle on the inside surface of the ventilation duct.

Only in reality there is no dense layer of dirt and dust, because manufacturers take care of those who will use their products in advance. How, you ask?

Everything is extremely simple - one of the most important processes of production processing is the so-called "antistatic" treatment.

Simply put, pipes made of plastic both from the outside and from the inside are treated with an antistatic to prevent any particles from sticking to the inner surface. Safety for the health of the customer is the most important aspect for air duct manufacturers!

And another "myth": the owners of living quarters are afraid that the plastic can melt under the influence of high temperatures and even will "drip" in your kitchen, creating a threat to health for those who live in the apartment.

Well, such an option seems quite fantastic, and that's why: first of all, the minimum temperature threshold that the plastic pipes for ventilation can withstand is not less than 80 degrees Celsius.

With all diligence, you can not create such high temperatures in the kitchen unless, of course, you create a threat to your health and the health of your loved ones, for example, lighting a small fire in the kitchen.

And yet - all manufacturers also take care of your safety, therefore, in addition to antistatic treatment, the processing of products with a layer of special refractory compounds is used.

Moreover, the modern production of plastic products has already reached the point where special refractory compounds are used not only in the processing of finished plastic, but also in its direct creation!

That is, a refractory layer of the substance is already embedded in the plastic product, which will create safety for you and your ventilation!

Where ventilation and exhaust ventilation is required

Now we will discuss directly where it is necessary to install ventilation systems and hoods in a dwelling. Without fail, exhaust ventilation is installed in the kitchen (in the dining room) and in the bathroom (and also in the toilet, if the bathroom is separate).

The logic is clear: it is necessary to remove hot air from the kitchen (which will always be there, because there is a cooker, as well as many electrical appliances), food smells, fumes, soot, unpleasant smells and others.

In the kitchen, you can use air cleaners with various filters (including coal filters, etc.), as well as an extractor, which is installed directly above the plate (gas / electric) and piped to the main ventilation.

In the bathroom and toilet there should be no humid air and foreign unpleasant odors, so here it is also necessary. Additional devices for ventilation in the bathroom are not required, but the output for ventilation should be mandatory.

Combined air ducts

Once every two weeks, the grille of the air intake should be gently washed and cleaned of the settling dust.

By the way, when installing ventilation you can use not only plastic or metal ducts only.

First, it can be combined variants - with metal knots such as couplings, clamps or directly the grilles of the air intake.

And secondly, there is another common type of pipe for ventilation - corrugations. Gofra is used not as a single pipeline, but rather as another element of the type of adapter node.

Simply put, if the ventilation hole due to circumstances and the location of the appliances in your kitchen is not above the cooker and hood, but away from them, then it is just the corrugation that will help you.

A distinctive feature of the corrugation is its versatility and the principle of "spring", which allows you to smoothly connect pieces of pipe corrugation, turning them as you like and without making angles more than 90 degrees.

After all, if you create a too straight angle during installation, this will be a serious loss in the process of air exchange.

Each angle of 90 degrees does not just "slow down" the flow of air, but at the same time it significantly reduces the productivity of the ventilation process itself - by 10-15% or more!

Your task is to simplify as much as possible the installation of your ventilation and create ideal conditions for the air exchange process. So corrugation is an excellent "helper" for joining plastic elements.

In the duct system, plastic pipes for ventilation are the basic design element. Are made with a thermal insulation and there are various profiles. The most optimal option is PVC vent pipes, which have round or rectangular cross sections. They have found wide application not only in production, but also in residential premises or public buildings.

This is an alternative to metal ventilation systems and is the leader in sales in the building materials market.

Quality and general use characteristics

The plastic ventilation pipes have a lot of positive characteristics and therefore are in high demand. Of the positive qualities can be identified:

- Strength;

- Durability (resource more than 50 years);

- Resistance to corrosion - 100%;

- Increased tightness of joints;

- Ecological compatibility;

- Easy to transport and install (important for high-altitude work);

- Low noise;

- Relatively low cost.

Also they can be characterized as follows:

- Meet all standards of hygienic requirements;

- Resistant to chemical reagents;

- Well mounted in hard-to-reach places;

- Do not resist air flow;

- Do not require labor-intensive maintenance;

- Easily processed;

- Unprecedented form factor in production and color palette;

- Aesthetic visually and easily integrated into the design.

Features and features in the application

When designing a ventilation project, you can make it any shape for the features of the building. The tightness of the joints does not allow air to leak, and the use of suitable sealants strengthens the tightness of the joints. The smoothness of the inner surface relieves the air flow from turbulence and resilience. The inside has a high class of purity. The roughness of 10 hundredths of a millimeter is already critical. This can be seen from the ventilation made of other materials, since they often have to be cleaned. You can use antistatics, this eliminates the attraction of dust. Treated the entire system with such a preparation, get rid of cleaning works in the future. Thanks to these qualities of plastic, you can install ventilation equipment less power. This will significantly reduce the cost of construction and make the ventilation system as quiet as possible.

In domestic and residential premises, plastic ventilation pipes usually provide the output of carbon dioxide, cooking fumes and fresh air. In public areas, you can install an effective channel conditioning system. With the help of pipes, the cooled air from the air conditioner is evenly distributed throughout the building. This makes it possible to reduce the number of cooling units.

Due to different sections, plastic ventilation pipes can be installed indoors, without fear of spoiling the external aesthetic appearance. For example, use flat-oval, rectangular or other necessary sections in a small space between the ceiling and the suspended ceiling. Thus increase the volume of low rooms.

The beautiful appearance of the surface and profile allows you to make a ventilation structure without subsequent lining to hide it. When designing, you can also rely on a design with non-standard curly bends, notches and thickenings. Rectangular, square, oval elements of a design, it is possible to make under the order. This is not difficult to do in production conditions and with the help of special equipment.

Material for the manufacture of plastic pipes

For the manufacture of ventilation pipes use plastic of three types: polyurethane, polypropylene, polyvinyl chloride. There are also various small additives for coloring and resistance of the product to temperatures and chemicals. For example, PVC pipe resistant to ultraviolet light. Polyurethane is extremely durable and elastic material. Its abrasion resistance exceeds other plastics and even metal. Stability to deformation makes it possible to use a polyurethane pipe in places with high temperature. And the use of additives saves the material from destruction at several dozens of frosts.

Installation. What to consider

To ensure the most optimal functioning of the ventilation, first of all you need to determine the purpose of all parts of the system. Pipes, fittings, fasteners, material for each specific hood or duct, round, rectangular or combined sections, it is necessary to select individually. Purchase of materials and installation should always start only with the project. All the features of the location, installation, functioning of the system (room area, temperature conditions, humidity, performance of the elements, acoustic discomfort) should be considered. Everything must be taken into account to ensure normal life.

Round and rectangular pipes of small diameter can make more noise than wide-profile pipes.

The optimal cross-sectional area of the air duct at a flow rate of 3 m / s is determined by the formula a = 25s. The cross-sectional area in square centimeters (a) and the air flow rate (s) are related to the constant (25). Thus, the optimum cross-sectional area is equal to 75 square meters. see A and knowing the school geometry (a = π * r²), you can now easily determine the required dimensions. The diameter of the plastic pipe is 2.8 cm. And according to the diameter, a certain length is made. Rectangular tubes are calculated by a similar method.

For those who do not want to communicate with such nuances and have enough other concerns, they can entrust such work to several installers. And in order not to alter or what is worse, it is better, of course, to provide the specialists with knowledge of all such nuances and having experience. After all, ignoring all the features can lead to premature breakdowns and failure of almost the entire structure. And also entail additional unforeseen expenses.

Features during installation and disadvantages

There are practically no fire resistance properties for polymers. In this case, combined installation and additional blowing fans are used to force the air flow to be forced. Specialists in the installation of ventilation systems usually combine plastic and galvanized metal, round, rectangular or other sections. Such combinations are used for the installation of extended systems from technical rooms through places of large crowds (fitness centers, clubs, restaurants, etc.).

The most popular plastic pipes with a cross section of 55-110 millimeters and a length of 0.5 to 1.5 meters. When installing connections and fastening, use a variety of special fittings:

- Reducers-adapters;

- Couplings for connection;

- Check valves in connectors;

- Adapters for changing the circular section to rectangular;

- Tees and splitters;

- Elbow bends;

- Lattices.

Ventilation is always more effective if it passes as close as possible to a straight line. And the cost of all the turns and the necessary hardware for this will significantly increase the total amount of repairs. The ventilation of a certain size has its own interchangeable installed shapes, diameters and all component parts. When choosing the shape of plastic pipes, it should also be taken into account that rectangular pipes are more resistant to the flow of air than round ones. And the technological process of fastening and docking, requires more trouble.

Before starting the design, you need to know all the shortcomings of plastic pipes:

- Low fire resistance (main drawback) limits the scope of use. The ventilation system may not be accepted according to the inspection certificate by the fire service. This is the main reason for the unpopularity of production facilities;

- Not used to transport very hot air or steam;

- Labor-intensive installation. The installation technique requires the necessary knowledge and skills, as well as a huge number of varieties of fittings and special fittings.

Ventilation from plastic pipes has excellent characteristics and fully corresponds to the budget variant of the entire ventilation system. This will significantly reduce the overall cost of construction and beautify the exterior and interior view of the building.

In rooms with standard household safety requirements, plastic ventilation ducts for ventilation do not have equal comfort for installation, low price of the system (materials, components, installation costs), durability of use.

Ventilation products made of plastic are seamless round or rectangular cast sleeves.

The integrity of casting determines the high quality and reliability of each individual part.

The smooth inner surface is ideal for free air circulation, the material of the products is resistant to contamination, corrosion, and exposure to aggressive media.

The products have an aesthetic appearance, can be located in the exterior design, without disrupting the overall design of the room.

The variety of connecting or transition parts (couplings, corners, fittings, ventilation grids) makes the installation of the system simple, affordable even for the layman. Various components allow you to assemble a scheme of any complexity without using a special tool.

The only restriction that does not allow the use of plastic pipes for ventilation is high air temperature!

Purpose and application

For free circulation of air in the premises, ventilation, equalization of the temperature regime in the premises, air duct systems are arranged.

Ducts made of plastic are designed to connect individual ventilation points of the room with the main exhaust duct of the walls of multi-storey buildings. In low-rise private construction for cases where there is no heavy mechanical load on the main channel, the entire system can be entirely mounted from plastic.

This is a justified, reliable option for ventilation of granaries, garages, industrial buildings and premises with high humidity.

Use ventilation ducts made of plastic for drawing is adopted in residential and low-rise office buildings, private households and apartments of multi-storey buildings for the device natural circulation air, passive or active exhaust systems. For example, in order to save energy consumption of the premises, the system can be equipped with a recuperator (heat exchanger). As a result, incoming air is heated or cooled due to a temperature exchange with the exhaust flow and is supplied to the rooms by plastic vent channels.

As a rule, the recovery system is passive and does not require additional energy inputs.

Plastic ventilation ducts are used for:

- Passive ventilation (natural exhaust, from the ventilation grill).

- Active drawing (with the use of electric fans).

- Hoods gas stove or boiler (with mandatory compliance with T. B).

- Airing basement and storage space.

- The wiring of warm air from the heater.

- Supply and distribution of fresh air

Description

Air ducts differ in the materials from which they are made. The main materials of plastic products are:

- PVC (polyvinyl chloride)

- Polyurethane

- Polypropylene

PVC

PVC - the most common and affordable, durable and lightweight material, mounted without the use of special tools, it is possible to assemble the entire structure at home on its own.

It is not permissible to heat above 120 ° C, this will result in the evaporation of the chlorine contained in the material!

For ventilation systems that do not include heating devices, PVC plastic products are the cheapest and most convenient to install. On them, you can lay the entire ventilation load of the room, except for baths, kitchens, boiler rooms.

PVC ducting is used in the vast majority of ventilation systems, which has a large branching and total length. You can buy products of this type in any sanitary ware shop or a building supermarket.

Polyurethane

Polyurethane is distinguished by a higher price, but it outperforms PVC by its characteristics, it is stronger, more plastic. The relatively high melting point allows the use of polyurethane products in kitchen hoods and other nodes with increased air temperature.

When using a cooker hood or connecting to a heater, you must first use a section of steel corrugation to reduce the temperature, otherwise polyurethane ventilation deserves full confidence. The material has the best value for money.

Polypropylene

Ventilation from polypropylene can be mounted using heating elements for bending, for example - a construction hair dryer.

When heated to plastic softness, the material does not emit harmful fumes.

The average price is justified by the versatility and safety of plastic products based on polypropylene.

This material allows you to do welding connections, having hermetic strength up to 80% of the whole structure.

The main types of plastic products

- Round ducts (pipes, ducts).

- Rectangular ducts (ducts - ducts).

- The knees are round.

- The knees are rectangular (horizontal, vertical).

- Tees round.

- Couplings (round, rectangular).

Round ducts have an optimum internal design for free air circulation.

Smooth bends do not interfere with the flow of air, do not accumulate contaminants. The disadvantage is the need to hide the pipes on the walls with the device of decorative boxes.

Rectangular channels are more compactly adjacent to walls and ceiling, easily hide in small niches, and can even be used as decor elements.

A flat duct is very convenient in transportation due to the tight packing of packages. With large volumes, this significantly reduces transportation costs and the final cost of the systems. In addition, they allow you to maximize the ceiling height during installation.

The knees serve for the angular joints of the duct, and the tees for the branches and tie-in.

How to calculate and choose the size

For calculations it is necessary to know the volume of air that will pass through the ventilation duct per hour. It depends on the volume of the room and the required multiplicity of air exchange.

At least 3 m³ / h for 1 m ² of the room area is required for qualitative circulation. For example, for a room of 16 m², the minimum air flow is: P = 3 m³ / h * 16 (m²) = 48 m³ / h.

P = P / (3600 * C), where:

П - cross-sectional area of duct, m²

P - air flow m³ / hour

C is the velocity of the air flow in the channel m / sec (usually from 1.5 to 8 m / s)

3600 - the number of seconds in one hour

In our example, the air flow rate is 48 m³ / h, the flow velocity is assumed to be an average of 4 m / s (a compromise between noise and air channel sizes), then the cross section is obtained from the calculation:

Section P = 48 m³ / h / (3600 * 4 m / s) = 0,0033 m ² (3300 mm ²)

Now for a circular duct you can calculate its diameter:

Substituting our data, we obtain a circular duct diameter of at least 64.83 mm. Of the common, the closest normalized size is 100 mm.

Common dimensions

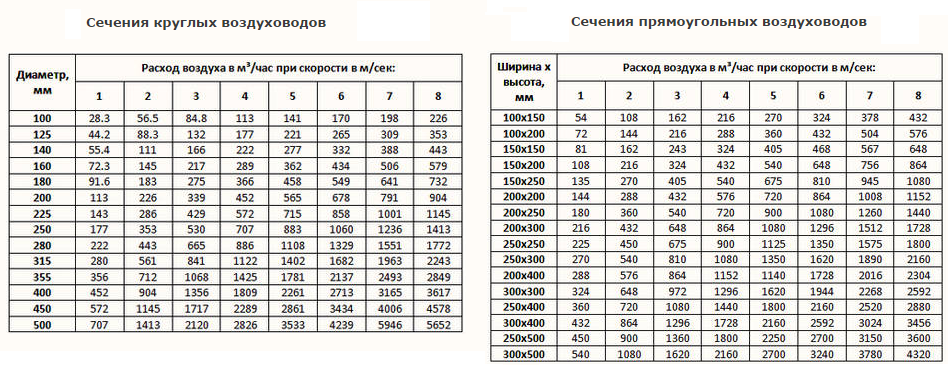

All sizes produced are standardized. The most common sizes are shown in the table. Here you can also see the dependence of the diameter on the speed of the air flow and air flow.

In rooms up to 50 m², round air ducts ∅100 mm and rectangular 60 mm × 120 mm are used. If the area is up to 100 m², use ∅150 mm round and 60 mm × 240 mm rectangular ducts, respectively. With more complex schemes it is more expedient to address to experts for correct selection of elements.

A wide range of models allows you to assemble systems of different performance and complexity.

Characteristics

Plastic ventilation boxes are made of synthetic plastics on high-tech equipment. Products made of plastic are chemically inert, do not destroy under the influence of ultraviolet rays, are resistant to corrosive environments, are not susceptible to corrosion, under standard conditions, the life of plastic canals reaches 50 years.

The solid cast construction of such boxes eliminates air leakage throughout the entire length of the system. When using special silicone grease for installation, the tightness of the joints is comparable to welding.

Products made of plastic meet the requirements of environmental safety, complies with GOST and SNiP.

Due to the simplicity and low cost of carrying out emergency works, plastic channels have no analogues. If necessary, only the damaged ventilation area can be replaced without dismantling the entire system. The replacement speed eliminates the long-term inefficiency of ventilation, minimizes production losses.

A wide range of component sizes allows to make preliminary calculations for the consumption of materials with an accuracy of up to 90% of the actual.

The material is easily cut and processed by household electrical tools.

Installation of ventilation systems does not require additional strengthening of the attachment points, because plastic has a small specific weight and optimally rigid construction. Fixing clamps and flanges reliably fix the ventilation systems of the most complex configuration.

Example of installation under the ceiling

The produced couplings allow making tight transitions of different diameters and profile geometry.

The disadvantages include the fragility of the material in comparison with the metal analogues, low frost resistance.

conclusions

The versatility of applications and the high performance characteristics of the elements put the material at the top of recognition as giants of the construction industry, so small units and individuals.

We also offer to watch the video