The diameter of the exhaust hood of the kitchen hood. Advantages and disadvantages. Kitchen hood: features of the device

The main task of the ventilation system is to feed, transport or remove air mass from the room. Among other things, due to the duct, you can avoid the settling of fat, impurities, remove odors, and regulate air circulation. In case of inefficient operation of ventilation, staying in the kitchen can be uncomfortable and even harmful. That's why you need the right choice and installation of this equipment.

Kitchen extractor - a useful element

Today it is difficult to imagine a modern kitchen that does not have the banal household appliances needed for cooking: a refrigerator, a stove, a microwave oven ... This basic set should be for everyone. Similarly, there should be no doubt about the hoods, or, to be more precise, the hoods. Thanks to these simple designs, it is possible to get rid of excessive moisture or combustion products.

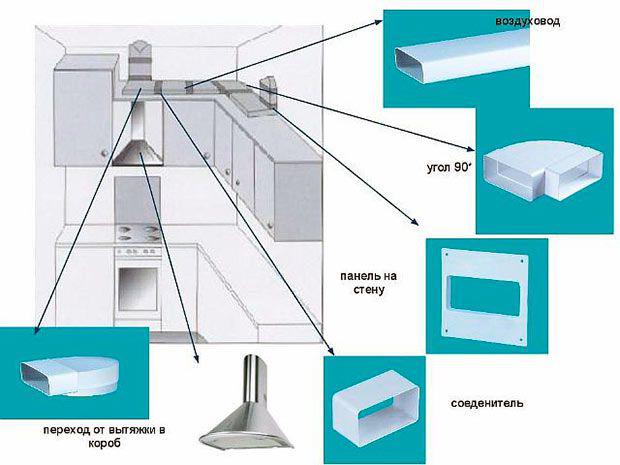

What elements are required to install the hood

The remnant of the Soviet system is the equipment of the apartment by a single ventilation duct. For the sake of justice it is necessary to note that with the exhausting work the polluted air is ideally removed from the kitchen.

A similar situation occurs with a violation of natural system circulation of air in the dwelling, which immediately leads to its stagnation.

Features

Plastic ducts significantly outperform in the technical plan of metal analogs, which affects the gradual abandonment of the latter, and entirely:

- from plastic are perfectly amenable to processing. At the same time, the smoothness of the surface from the inside is maintained. Air ducts made of metal in a similar situation become rough, and this is a minus for their further functioning. With the growth of static resistance, the advance in the metal structure of air reduces the mass of the output.

- Considering that this is a chemical alloy, a plastic version of air ducts has in the composition of antiseptic components, which allow to reduce the dustiness of the surface. As a result, cleaning is simplified. What is not saving on maintenance?

- The plastic lends itself to grinding and cutting (in comparison with metal). Therefore, it is much easier to adjust the plastic version to the required format, while it's definitely necessary to tinker with the metal.

How to properly install the hood

Plastic ventilation ducts are environmentally friendly due to the pure materials from which they are made. This allows us to talk about confidence in their safety and reliability. Therefore, plastic is more hygienic than metal, due to its anti-corrosion and antiseptic surface.

Current technical features can be called basic, since they are initial since the moment of creation, and in any way this will not change. The choice will depend exclusively on the buyer.

How to choose a hood take into account all the pros and cons:

Advantages and disadvantages

Click to enlarge

However, for home use, say in the kitchen, the plastic version is clearly more practical and in no way inferior in reliability. Therefore, this is a reasonable solution for ventilation in the house.

How to choose

Click to enlarge

What to look for

When choosing a duct from plastic, you will have to pay attention to a couple of small things. First, it is worth taking care of the awareness of the appropriate for your room performance and. Its calculation is made by the formula: the area of the kitchen is multiplied by 12. The resulting figure will become an indicator of the required performance of the device.

Extractor for air duct

If the area of the kitchen is large, it is better to stop on devices with the possibility of connecting to the ventilation system, as this does not fit here. Since in this case, the latter have a sufficient supply of power. A certain circle complains about design limitations. If the appearance is important for the buyer criterion, it is better to turn to diversity exhaust hoods with connection to the duct. Literally all variants of systems without connection are different only for noisy work. And if for you this indicator is invaluable, then refer to the plug-in version.

Click to enlarge

When choosing a device, resort to a fat filter of 5 or more layers of the aluminum network.

Additional Items

The duct can be hidden behind the false panels

As a rule, speaking of additional elements, rectangular plastic ducts immediately come to mind, the choice of which falls when space saving is needed. This unit is quite noisy, so it may require additional elements that allow the indicator to be reduced to none. Here you can note:

- fans;

- noise insulation materials;

- supply and exhaust grilles.

Installation process

The more carefully you approach this issue, the more reliable the design will be

This is probably the first question to be solved before the installation. Here everything is corny - connection kitchen hoods without special requirements. The only thing that needs to be considered. We start with the cable feeder in 1.5 square sections, it is possible and the third one with grounding or the standard 2nd one. Personal protection in the form of an RCD or an auto-switch is not required.

Regarding the connection of the hood to the power grid in the same way, there will be no difficulties. You can solve the problem in 2 ways:

- special connector for connecting cables;

- isolated and twisted wires.

The latter will require high quality wiring (so they are not heated), and good propayki.

Connectivity

occurs according to the following algorithm:

- Duct connection.

- We hang the wardrobe with the corrugation on the wall.

- We fix the homemade box on the cabinet.

- We fix the hood into the cupboard.

- We firmly fix the corrugation on the hood and fix it with a yoke.

- If you connect the hood directly - you need to connect the duct to the mine.

- In the case of installing PVC ducts, the situation is identical.

During installation, minimize the number of pipe bends for greater traction. Each repetition reduces the power by about 10%.

Care and operating instructions

The main advantage of plastic ducts is simple: easy installation, unpretentious care, availability of service support.

How to properly mount the ductwork:

How to decorate or hide

How to hide the air duct

There are several ways to harmoniously hide the air duct:

- The most popular - to hold them behind hinged cases or inside them as miracles will be created.

- Also enough an interesting option may be painting the pipes in accordance with the general atmosphere of the room.

How to hide the pipes in the kitchen:

As a result, we can say about the almost ideal version of the air duct for the kitchen. Although, in principle, there are no alternatives. The plastic version is available, easy to install and maintain, environmentally friendly, safe, reliable, perfectly fit into the ambient atmosphere of any kitchen design. It remains only to enjoy all its advantages.

Comments:

- Why an extractor is needed

- How to choose an airway pipe?

- How do I have a cooker hood?

- Which ducts are better - plastic or corrugated?

- Tips for installing a hood

- Types of exhaust devices

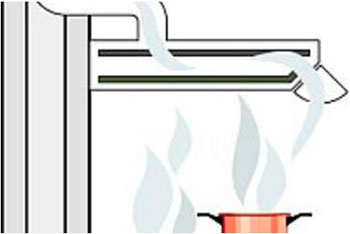

For each room, where gas, thermal electrical appliances for cooking are used, exhaust is necessary. This device connects to the air duct and provides the removal of steam, fumes and unpleasant odors. Hoods are necessary both in living quarters and in professional kitchens. Even if a small family lives in the house and the process of cooking does not take much time, without stretching the microclimate in the dwelling will not be favorable for living. The exhaust device can not be replaced by conventional ventilation, since the ventilation system has a completely different operating principle and ensures air exchange in an enclosed space, but in no way a withdrawal of combustion products and steam. The exhaust devices are connected by an air duct with a ventilation shaft. The duct diameter and length are calculated according to certain rules.

The most popular and practical are circular ducts.

Why an extractor is needed

Extraction is an important equipment for any kitchen. Its main function is to remove polluted air. Smoke with products of combustion, cooking fumes, odors that do not affect well-being are all derived from the room with this equipment. This device, cleaning the air, takes care of people who are directly in the kitchen or in the neighboring rooms.

The hood provides comfortable conditions in industrial kitchens to working personnel and favorable living conditions, if it is installed in the kitchen in a dwelling.

The exhaust device solves the following tasks:

- removal of odors from the kitchen;

- output of combustion products;

- cooling of air;

- decrease in humidity.

The hood prevents the appearance of mold, the reproduction of bacteria, for which the warm and humid environment is optimal. With the exhaust device, dirt, grease, soot do not settle on the finish and interior items.

The diverse design of modern hoods allows you to choose this equipment in accordance with the style of the kitchen. Now on sale there are such devices of different types: decorative, domed, modern and with ethnic motives. You can also buy a built-in hood, which will be almost invisible in the interior of the kitchen.

Back to contents

How to choose an airway pipe?

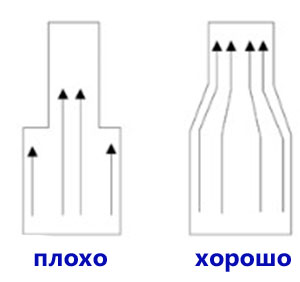

The correct choice of the diameter of the airway pipe is of great importance for the effective operation of the extractor. In order for the system to work efficiently, without malfunctioning or noise, the diameter of the duct must be the same or larger than the diameter of the exhaust hood. When using the duct, the smaller diameter hood reduces the efficiency of operation as a result of increasing air resistance and reduces the drawing power. However, not only the diameter of the duct is important for the proper operation of the hood, attention should be paid to the configuration of the duct, how it is located along the wall and what is its length. When you need to ensure that there are no sharp and right angles of the fold. When the pipe is bent by 90 °, 10% of the productivity of the hood is lost.

The air pipe must have only obtuse angles of bending.

To avoid reverse air movement, it is necessary to supply the air duct with a check valve.

Back to contents

How do I have a cooker hood?

The exhaust devices must be located above the thermal equipment fixed to the ceiling, or on the side, fixed to the wall. The cooker should not be located a long distance from the ventilation shaft, where the duct will be removed, since the airway pipe should not exceed 3 m. Exceeding this length will lead to a decrease in the efficiency of the equipment. Plate should not be installed against the wall opposite the vent of the ventilation shaft, otherwise, laying the duct, will have to do a lot of bends, which also adversely affect the operation of the exhaust system.

Back to contents

Which ducts are better - plastic or corrugated?

Now, two types of air pipes are used: plastic and aluminum corrugated pipes. The cross-section of plastic products can be round or rectangular. Round plastic ducts have less air resistance than with a rectangular cross section, so they work more efficiently. But rectangular air ducts in the interior look more natural, they merge with furniture and other kitchen equipment.

Much attention when assembling the elements of the airway pipe should be given to the quality of the connections. Therefore, it is better to buy all components for the system together with plastic pipes, so that when the elements are joined, there are no problems. Corrugated pipes do not need connecting elements, they easily bend at any angle, and also stretch and contract. Their installation is reduced to fixing one edge of the pipe to the hole ventilation duct, and the opposite - to the outlet of the exhaust device. In addition to the ease of installation, one more advantage of corrugated pipes in front of plastic pipes is their light weight. And the drawbacks include noise during the operation of the exhaust system, the accumulation of fat and soot on the inner walls of the pipe.

Plastic ducts have a lot of advantages:

- quiet operation;

- insignificant resistance to air due to smooth internal walls;

- do not clog up the mud, all waste is discharged into the ventilation shaft.

The disadvantages of plastic pipes include more complex installation and the need for connecting components, as well as a higher cost in comparison with corrugated pipes.

Back to contents

When installing the exhaust system, the height and location of the hood should be correctly calculated with respect to the working surface of the cooker. If it is placed too high above the cooker, the cooker hood will not work, steam, unpleasant smells will remain in the room. And if set low over the stove, it will interfere with the work. The optimum distance from the hood to the plate is 75 cm.

When connecting the air duct to the ventilation duct, care should be taken to ensure that fresh air to the kitchen is not completely blocked. To do this, you need to install a special grille with an attachment for the air tube and a special valve. During the operation of the hood, the valve closes, and when the equipment is not in use, check valve opens and circulates air.

When installing corrugated airway pipes, gratings with fittings and clamps are used. Corrugated pipe is advised to stretch so that there is no wrinkling left on it, otherwise dirt will accumulate in them, and the work of the exhaust device will be accompanied by noise.

Plastic airway systems are installed using adapters for connection to the hood and ventilation duct.

In order for the exhaust system to work effectively and with a minimum noise level, the diameter of the duct must be greater than the outlet opening of the device. If this condition is not observed, the load on the motor of the device will increase, the efficiency of its operation will decrease and noise will appear.

When choosing the location of the hood, its type must be taken into account. Flat devices are mounted to the wall, island exhaust devices are fixed to the ceiling. Instruments with a corner mounting bracket are installed inside the suspended furniture. For the duct in the furniture make a hole of a suitable diameter. Hoods decorative, domes are mounted on the wall. To mask the duct, install a decorative box.

It's time to figure out how the air withdrawn from the kitchen is removed from the room. This is done with the help of an air duct.

Types of air ducts

Air ducts are flexible and rigid.

Flexible duct for kitchen hoods

Flexible - aluminum corrugated. Rigid is plastic air ducts for kitchen hoods. But tough can be and air ducts for cooker hoods, metal. For example, in a variety of workshops often welded to order boxed tin ducts from the strips of tin.

Air ducts are of circular section and rectangular. Rectangular ducts for kitchen hoods attractive because they are not as conspicuous as round. After all, the furniture in the kitchen is entirely in the shape of a rectangle. Therefore, a tube of rectangular section among such a headset is easier to disguise.

Rigid duct for kitchen hoods

Rigid duct for kitchen hoods But the round corrugated hose-boa constrictor with the thickness of 100-150 millimeters, and even brilliant in its aluminum nature, immediately flashes into the eyes!

How to buy air ducts for kitchen hoods

First of all, we must determine dimensions of the duct for cooker hoods. In length, preferably, it should not exceed 3 m - every meter above this value weakens the draft in the duct by 10%.

Plastic duct and accessories to it

Plastic duct and accessories to it The diameter of the duct of the cooker hood should not be less than the diameter of the exhaust outlet of the hood.

With regard to ducts of rectangular cross-section, for extractors with a capacity of 300 m 3 / h. It is necessary to buy air ducts cross-section 55х110 mm;

For extractors with a capacity of 350 m 3 / hour - 60х120 mm;

For powerful extracts, air ducts of 60x204 mm are used.

It is also advisable to plan the route of the airway ducting and mark, where and at what angle it will bend, before buying. This is necessary to buy corner adapters (if you, of course, buy rigid pipes, but not corrugated).

Flexible duct and accessories to it

Flexible duct and accessories to it Remember that one turn of the pipe by 90º reduces its throughput by 10%. It is not possible to unfold the pipe over an angle of more than 90 °: countercurrent air will be created in it and the working conditions of the exhaust fan will deteriorate.

Calculate the total length of the duct. If you decide to use a corrugated air line, then it should be maximally stretched so that the corrugations do not create an additional obstacle to the passage of air.

The price of PVC air ducts for kitchen hoods - about 200 rubles. for a running meter (with a diameter of 100 mm).

Grid for venting the duct to the ventilation duct

Grid for venting the duct to the ventilation duct Flat vent pipes for kitchen hoods is more expensive. For example, with a cross section of 55x110 mm, about 300 rubles per cubic meter. m

Corrugated aluminum costs about 100 rubles. / Пгн. m at a diameter of 100 mm and 185 rubles per square meter. m at a diameter of 200 mm.

It is necessary not to forget to buy another adapter from the hood to the duct and a valve that prevents the air from entering the air duct from being pushed back into the ventilation system.

Installation of air duct for kitchen hoods

The corrugated hose is attached to the wall using clamps. Pipes made of plastic for kitchen hoods in themselves have a good load-bearing capacity. Enough support brackets - one for each meter of pipe. Moreover, many householders prefer to hide air ducts in decorative boxes or lay them on top of cabinets or mezzanines.

Mounting the duct to the kitchen hood

Mounting the duct to the kitchen hood Joints should be coated with a sealant.

When installing the exhaust valve on the end of the duct, pay attention to the fact that its axis is located vertically. If you place it horizontally, the valve flap will clap under its own weight.

Welded ducts, metal

Welded ducts, metal In ventilation ducts high-rise building The air ducts are removed by means of a special grate. In the upper part of it there is an opening for the air duct, the rest is taken up by an ordinary grating to ensure natural ventilation premises.

Ducts for kitchen hoods: Photo

Plastic duct

Plastic duct  The air duct is hidden behind the stretch ceiling

The air duct is hidden behind the stretch ceiling  Routing the duct through the mezzanine

Routing the duct through the mezzanine  Placing an air duct behind a false wall

Placing an air duct behind a false wall  Hiding the air duct in a gypsum board box

Hiding the air duct in a gypsum board box  Wiring ducts over hanging cabinets

Wiring ducts over hanging cabinets

Each mistress dreams of equipping her kitchen with the latest technology. Naturally, the hood to the kitchen with the duct will be an obligatory component, ensuring the timely outflow of the smells of the prepared food.

Kitchen hoods consist of several structural elements. One of them is an air duct, the main function of which is to ensure the removal of air from the kitchen area. This is a special channel or pipe that delivers air from the intake hood to the place of its withdrawal (for example, the ventilation shaft).

It can be confidently asserted that without a duct the entire ventilation system will not be able to function. However, in the modern market there are already devices that do not require air ducts. The air is cleaned directly in the hood using special charcoal filters. This system is not very popular yet due to the need for frequent replacement of cleaning cartridges.

Differences of the kitchen exhaust system from ventilation

For residential premises, special health standards, which determine the air exchange in the room. To meet these requirements, ventilation is installed in all apartments, which can circulate air. However, for the localization of strong smells, fumes and smoke, this system is unsuitable, because it works at the expense of natural air exchange.

It is the presence of a kitchen hood, which provides a local intensive air discharge. It is installed in places of increased accumulation of unpleasant odors.

Types of ducts for kitchen hoods

There are several types of classification of ducts for drawing.

They are subdivided:

- in form;

- on the material from which they are made;

- by configuration.

When choosing an air duct in the kitchen, it is necessary to take into account the whole set of parameters of this device.

Form of air ducts

According to the shape of the section, they are divided into the following types:

- rectangular. Such air ducts are conveniently located behind the cabinets. On sale, they exist as separate sections and adapters between them. This allows you to lay any trajectory from the hood to the ventilation shaft. Suitable for kitchens with any ceiling height. They have a very aesthetic appearance. However, they have less performance than ducts of other shapes;

- round. Not suitable for kitchens with low ceilings, as very cumbersome. If the outlet is rectangular, special adapters are required from rectangular to round;

- oval. Possesses pluses and minuses of round air ducts.

One of the types of rectangular ducts are flat structures. They are compact and easy to hide from the eyes. Available in three standard sizes:

- 110x55 mm. Used for hoods with a capacity of no more than 300 m3 / h;

- 120x60 mm. Such air ducts are able to pass through a larger volume of air, but not more than 350 m3 / h;

- 206x60 mm. The largest air ducts. They are installed to high-performance hoods, when a high degree of air purification from odors is required.

Material for air ducting

For the manufacture of air ducts in our time it is customary to use the following materials.

Plastic (polyethylene, PVC and fiberglass)

The most popular material. Usually available with a round or rectangular section.

And if the rectangular look more beautiful, then the ease of installation is a hallmark of round systems (they usually do not require special adapters for connection to the hood and ventilation grilles).

The advantages of plastic ducts:

- smooth internal surface prevents the accumulation of dirt and grease inside the system;

- plastic pipes are not capable of rusting;

- low weight;

- ease of assembly. A wide variety of parts allows the collection of air ducts of any configuration and extension;

- at work there is no strong vibration and noise;

- a small price.

- for installation, a variety of adapters and fittings are required;

- unstable to increase in temperature. At high temperature, they can release toxic compounds into the kitchen space.

Aluminum

Quite popular material. Corrugated pipes for air ducts are made of it. Its pluses include:

- ease of installation. Universal material for almost all cases;

- well tolerates heating;

- low price.

Disadvantages:

- not an aesthetic appearance. To give presentability, a pipe of this type is hidden in a special box or paved inside the cabinet;

- mechanically unstable material, unstable to external influences and deformations;

- since aluminum conducts heat well, then in a room where air ducts are installed from of this material, it is possible to accumulate condensate.

Steel

They are made of galvanized or stainless steel. But in the domestic application in the kitchen they found themselves just galvanized models. However, this type of air ducts is gradually becoming obsolete and every year it becomes less and less in demand.

The merits of air ducts from this material include:

- smooth surface. The speed of air flow does not decrease when passing through pipes of this type. They do not get stuck with carbon deposits, dust and other pollution;

- easily maintain a high temperature, without any consequences for themselves and the environment;

- belong to the budget price category.

Disadvantages:

- in comparison with the same plastic pipes, have a significant weight. Accordingly, additional fasteners are required for wall mounting;

- to seal channels, additional mixtures or formulations are required;

- if it is required to assemble an air duct of complex shape, it may be necessary to cut metal pipes;

- at work they produce a loud enough sound.

Air duct configurations

In this classification, ducts are divided into:

- flexible. These include corrugated channels, most often made of aluminum, but now there are models made of plastic. They can be placed at any angle. The possibility of stretching or squeezing is an added plus. However, it is important to consider that a poorly stretched box strongly hinders the free movement of air, which greatly reduces system performance. Another disadvantage is that the corrugated box is not recommended to do more than three meters long. As each additional meter reduces productivity by 5-10%;

- hard. They are made of all three materials. Convenience in assembly and smooth internal surface, preventing accumulation of dirt - the main advantages. The price is slightly higher than that of flexible ducts, but the convenience of use compensates for this disadvantage.

Basic installation rules for ductwork

Before the assembly of the air duct, it is first necessary to determine its dimensions. For optimal selection It is necessary that the following requirements are met:

- the duct section size must coincide with the exhaust outlet of the hood. A smaller pipe diameter will cause unnecessary noise when the system is running and cause the motor to overload;

- if the outlet hole differs in shape from the shape of the duct section, you need to purchase a special adapter.

Nuances of installation

When installing the duct for extraction, the following points should be considered:

- The number of duct rotations should be made as small as possible, since each bend reduces the efficiency of the exhaust system by 10%. Recommended installation of no more than three knees.

- Since the air duct should be periodically cleaned, it is recommended to make it dismountable.

- When mounting a corrugated aluminum box, it can be attached to the hood by conventional clamps.

- It is inadmissible to attach the air duct to the ventilation grille of the kitchen blindly. With the tight fit of the box, at a time when the ventilation system is not working, is violated natural circulation air. In order to avoid this, a special ventilation grille with apertures and an integrated check valve is required.

- It is undesirable to use channels of different sizes. This will require the use of special adapters, which greatly reduces the efficiency of the entire system.

- The most aesthetic appearance is a flat rectangular box.

Ways to hide the airway

- are cleaned for a false ceiling. With its presence, all horizontal pipes are easily removed there. For vertical sections special casings are made, covered with the same material as the ceiling;

- decorative box. There are many modifications of such a casing, differing in shape, color and method of execution. It is even possible to integrate spotlights into it;

- at simultaneous purchase of furniture the air ducting is possible inside of cabinets or on their "cover";

- possibly independent manufacture boxes of plasterboard. Further, in accordance with the design of the kitchen itself, the design either is painted in a certain color or is pasted with wallpaper.

Currently, a huge number of air duct models are available on the market to create a kitchen exhaust system. And the choice of this or that type is determined not only by its design characteristics, but also by personal preference, ease of installation, appearance. A proper installation of the selected system will ensure a good outflow of air in the required area and will save the kitchen from unpleasant smells.

When planning the repair or renovation of the kitchen, in addition to the furniture set, refrigerator, sink and dishwasher should be provided space for drawing. The hood performs an important task and should not only be properly selected, but installed. We will advise how not to get lost in the jungle of offers and choose a model that will suit your needs, how to properly plan the ventilation, what duct to draw.

What is a cooker hood?

More and more kitchens are equipped with hoods. In some houses, it is also necessary, like a stove. With it, you can quickly get rid of the smell of fried fish, burnt porridge or vinegar marinade. Without it, particles of fat accumulate on the kitchen cabinets, which fly around the kitchen together with the steam from cooking. An effective hood removes excess moisture from the apartment and is an integral part of the modern kitchen, in addition, if it is coordinated with the interior, it also decorates the room.

Types of kitchen hoods

The market is flooded with various kinds of kitchen hoods, among which it is not difficult to get lost. When buying, we advise you to follow certain rules. First of all, two questions should be answered:

- What do we expect from the hood?

- What can we afford, given the technical and financial capabilities?

Answering these questions, you will be able to outline the range of products that you should pay attention to.

The hood is most often connected to a ventilation duct. Then she works in open system. If it is not connected to ventilation, it works in closed system, as an absorber of contaminants from the air with a filter.

According to the design, the hoods can be:

- wall - installed between kitchen cabinets directly on the wall;

- angular - located in the corner of the kitchen, fastened directly to the wall;

- island (sometimes called pendant) - fastened to the ceiling above the stove, are located far from the walls of the kitchen above;

- inclined - designed for installation between cabinets;

- built-in - mounted under a hanging cupboard;

- the sliding - also mounted under the hinged cabinet, equipped with a retractable absorbent plate.

Most of the hoods are connected to the ventilation ducts with the help of duct-ducts, which are practically in every kitchen and are placed above the kitchen stove.

Typically, the hoods are placed on the wall above the stove and can be located separately, or be built into the kitchen hanging cupboard. There are also modern solutions, such as those used in rooms with high ceilings and in other special cases. However, this option is very expensive.

Extraction to the kitchen without a duct

Each house must be equipped with a ventilation system. However, it is not always possible to connect this device to it, for example, in apartment house (usually high-rise), equipped with a collective duct. In addition, it is not connected to natural ventilation if there is a wood fireplace, coal boiler or other devices connected to the chimney (for example, a gas stove, a gas boiler) in the house. There are models of hoods that do not require an air duct and work in a closed loop, using special filters.

The extractor is connected to the ventilation duct by means of a duct. She collects air around the stove and blows it into the ventilation. An air duct is connected to the ventilation, which usually has a circular cross-section and a diameter of 125 or 150 mm. Some manufacturers offer pipes with a rectangular cross-section.

A cooker hood with a duct works properly only if the right amount of fresh air enters the room and optimal conditions for its flow are created. Sometimes it's just enough to open the window or window. It is also possible, as it is sometimes practiced, to make small holes in the balcony door of the kitchen to allow fresh air to enter the room. Instruments can be equipped with valves that prevent the return of vapors into the room, and partitions that protect against the return of condensed steam.

The device can be equipped with one or two motors. Their power ranges from 18 to 200 watts.

The engine-powered fan sucks air over the plate and feeds it through the duct to the vent. The fan can suck air in the bottom, on both sides (bottom and front).

There are also versions that are equipped with two engines, sucking in air even on four sides, thereby increasing the efficiency of the work.

Noisiness

The device will not deliver discomfort if the sound level it produces during operation is low, especially if the device does not work at full speed. The loudest models, when working at maximum power, produce sounds up to 72 dB, which is certainly not very comfortable for hearing. For comparison, the conversation between two people creates a noise of 50 dB, the sound of the sewing machine is 70 dB, the traditional vacuum cleaner is 72 dB. Some companies use silencers in their products, which significantly reduces the noise of work.

Drawing capacity

Performance can vary greatly. It is higher than more air can change per unit time. The simplest model replaces slightly more than 200 m3 of air per hour, and for large kitchens it is possible to choose models with an air exchange capacity of up to 800 m³ per hour.

The model should be chosen so that within an hour, it could replace the air in the room six times. On the other hand, the wrong opinion is that the more performance the better. For example, in kitchens where food is cooked on gas stoves, models with excessively high power should not be used, which replace air in the room by more than 12 times per hour, since such an exhaust can degrade the conditions of gas combustion.

What affects the output of the kitchen hood with ductwork

Performance should be consistent with the size of the room in which the device will be installed. Only properly adjusted performance will ensure effective removal of odors and moisture from the kitchen.

Performance should be consistent with the size of the room in which the device will be installed. Only properly adjusted performance will ensure effective removal of odors and moisture from the kitchen.

Thus, the easiest way to choose the optimum output of the hood (measured in m³ / h) is a very simple calculation:

cubic capacity of kitchen (m³) * 6

For example, if your kitchen has an area of 12 m² and a ceiling height of 3 m, then the minimum output of the hood is calculated as follows:

12 x 3 x 6 = 216 m³ / h

It should be noted that the value of productivity and efficiency of the hood can vary under certain conditions. As a rule, the hood is connected to a duct-duct of length up to 2 meters with one bend of 90 degrees.

The exhaust and the ventilation system to which it is attached create resistance to the air flowing through them. The larger the path the air must overcome, and the more obstacles in the form of bends, the lower will be the real productivity of the device. Therefore, we must strive to make this "path" as short and as simple as possible.

The exhaust and the ventilation system to which it is attached create resistance to the air flowing through them. The larger the path the air must overcome, and the more obstacles in the form of bends, the lower will be the real productivity of the device. Therefore, we must strive to make this "path" as short and as simple as possible.

Duct hood diameter for kitchen

A large room or open kitchen requires a ventilation duct with a minimum diameter of 150 mm (most hoods have an outlet of this diameter), and if you want to install an additional engine, then 180 mm or more.

Air ducts to the kitchen hood with a diameter of less than 150 mm reduce the efficiency of the device and raise the noise level of the air flow.

When installing the device, conditions should be created to reduce the loss of productivity that may be caused by improper connection or a reduction in the cross-section of the duct.

When installing the device, conditions should be created to reduce the loss of productivity that may be caused by improper connection or a reduction in the cross-section of the duct.

Each bend of the duct of a duct by 90 degrees and each additional meter of pipe significantly reduces the productivity of the device. Installation of a carbon filter reduces the efficiency by about 25-30 percent.

Metal Filters

Metal filters affect the efficiency and productivity of the hood, but without them you can not operate the device, since the ingressing fat particles settle on the inside of the device, on the engine and the duct. Over time, this can lead to a deterioration in engine performance, increased noise and, ultimately, engine failure. The efficiency of standard metal filters: from 40 to 80%. 12-layer structure and sealing tapes can increase the efficiency up to 95%.

By connecting the hood to the air duct, make sure that the right amount of fresh air enters the room.

Also important is the direction in which air is fed. Avoid creating drafts, in which air moves diagonally across the room.