Tank membrane for water supply design. Membrane tank for water supply - selection of the optimal model and installation example

Often, water supply systems in the private sector are unstable: significant pressure drops are possible, which becomes a real problem for modern household appliances. To compensate for pressure fluctuations in water pipes use, most often, a membrane tank for water supply.

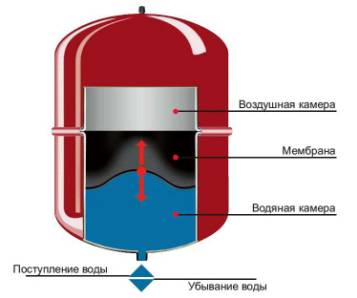

Membrane tanks are tanks of various capacities, made of metal and equipped with a rubber membrane. There are two types of membrane expansion tanks on the market: a fixed (non-replaceable) rubber partition and a replaceable one. Their task is to accumulate a certain amount of water and deliver it at the right time under the required pressure, preventing unnecessary load in the circuit of the system and reducing the risk of emergencies.

Installation of a membrane tank with a fixed rubber partition

Principle of operation of the membrane tank: after switching on, the pump pumps water into the water chamber, the volume of the air chamber decreases, and the pressure in the tank, respectively, increases. When the pressure exceeds the permissible mark, the pump will shut off until it again decreases as a result of the water intake (water to the consumer comes directly from the tank). Pressure monitoring and adjustment of the operating range relay are carried out by a manometer.

What to look for when choosing a tank

When choosing a membrane tank for water supply, it is necessary to take into account the number of users of the system, the intensity of the flow of water, its total quantity. All this affects the basic parameters.

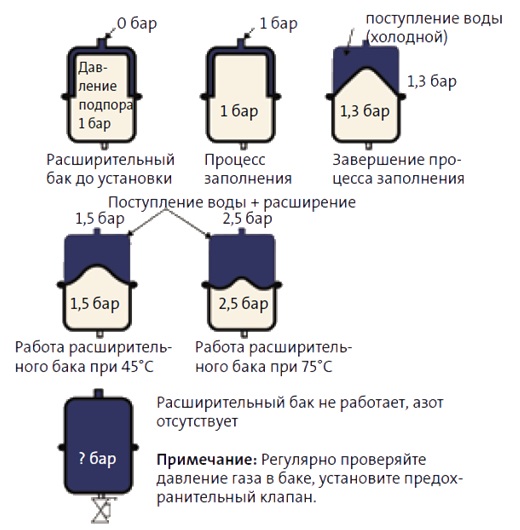

Preliminary pressure in the membrane tank is an important parameter. Usually the manufacturer sets it no more than 4 bar, and on the spot there is an adjustment. The proper setting depends on the life of the membrane and the reliability of the entire system. The pre-pressure must be measured before installation with the emptied tank, it must be lower than the pump start-up pressure.

The maximum and actual volume of the membrane tank do not match. The maximum is not more than 75% of the total volume, and the actual is much less. So, if the pressure difference between switching-off and switching on of pumping equipment is in the most acceptable for autonomous heating range 2-2,5 bar, then the actual volume of water will be about 30-35% of the total capacity. It should be noted that the greater the difference between the pump on and off pressure, the actual volume of the membrane tank is greater.

The minimum allowable volume of the membrane tank depends on the intensity of the intake, on the maximum permissible number of switch-on / switch-offs of the pump per hour and on what pressure values they will be used for. Determine it (approximately) can be from the following formula: V = 2Q / N, in which V - volume, m3; Q - estimated water intake, m3 / h;

N is the permissible number of pump inclusions per hour. It is important to know that a tank, whose volume is somewhat larger than the minimum allowable, will help prolong the life of the engine of the pumping equipment.

Short installation instructions

Want to install a membrane tank for water supply - the instruction should be contained in the technical documentation. Let's consider only some moments.

It is most convenient to install a membrane tank before the branching of the water supply system

- It is most convenient to install a membrane tank before the branching of the water supply. The room should provide for the possibility of draining the water and make up the system. The air temperature in the room must be above zero, freezing of water is not permissible.

- The attachment point must have sufficient load-bearing capacity. Membrane tank It should not experience an additional static load from the impact of other aggregates, pipes, etc.

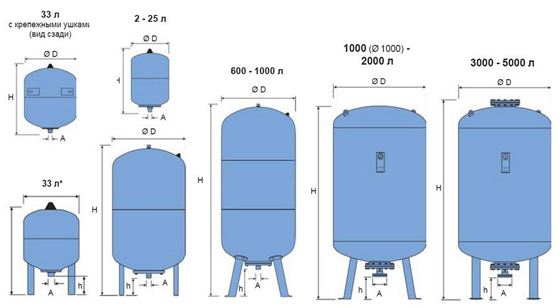

- To install tanks with a volume of 8 to 30 liters, you need a special wall mount, which is more robust. A large tank is better to install on the legs.

- Before installation it is necessary to make sure that the technical calculation is done correctly. It is necessary to get acquainted with technical characteristics equipment, which is on its housing, and not to exceed the maximum permissible pressure in both the air and in the water chamber when setting the pre-pressure and during operation.

- The tank must be grounded to avoid electrolytic corrosion.

- At the entrance to the tank, check valve, if it is not provided for in the pump design, and at the outlet - a pressure gauge for pressure monitoring and an automatic valve for air release.

- In the event that the tank is not initially equipped with a shut-off valve, which is required during technical inspection, for example, it must be installed at the place of installation.

Membrane tanks have a lot of advantages. For example, when using them, water pollution is excluded, they have a larger useful volume, compared to others, are easy to install and practical. But their installation and operation will require compliance with safety regulations. Trust the installation of the membrane tank better specialist.

Tank closed type

The expansion tank is an auxiliary equipment, but without this device, it is not possible to operate the heating system efficiently. In order for the network to function properly, it is necessary to correctly select and configure the parameters of all its elements. One of the most important indicators in this case is the pressure in the expansion tank.

Why this design?

Before talking about the functions and tuning of the expansion tank, you need to understand the types and operation of this equipment. Why do we need such a design in the heating system? The main task of the device is to compensate for thermal expansion in the network. After all, during heating and cooling, the coolant changes its density and volume.

Note! If this device is not installed in the utility network, as the water warms up, the water will increase in volume and influence the walls of pipes and radiators. With a strong increase in water pressure, the system can simply break. Installing the expander allows you to save not only the pipeline, but also the boiler. After all, his work is initially calculated for a certain pressure of water in the system.

Expansion devices can vary in volume. When choosing a model that is suitable for a particular network in terms of technical parameters, it must be taken into account that the volume of this element must be at least 10% of the volume of the coolant circulating in the system. To perform this calculation, the volume in the radiators, pipes and boiler is summed. The easiest way to determine the volume is at the time of system injection. It should be remembered that a volume of 10% is a minimum, but it is better to take a model with a small margin.

About expansion tanks for wall-mounted gas boilers is worth mentioning separately. Most modern models with wall mounting have a built-in device mounted on the back or side wall and equipped with a nipple. With the help of a nipple, the pressure is inflated.

The device and the principle of operation

All kinds of expansion tanks have the same device. Inside the metal case there are two sealed compartments. On one side there is a nipple, and on the other - a neck for connection to the pipeline. Inside the case there is a diaphragm. In an empty container, it will occupy most of the volume, while the rest of the space is filled with air.

During the operation of the system, the coolant heats up, increases in volume, and its excess enters the cavity between the body and the diaphragm. When the temperature of the water in the system decreases, its volume decreases, and the injected air squeezes it back into the pipeline.

Installing the Expansion Element

Boiler equipment is designed to work at a certain head of water. This means that in the expansion tank for its normal operation, too, there must be a certain pressure. It is supported by air or nitrogen, which is filled with the body. The air is pumped into the tank at the factory. During installation, make sure that air is not released. Otherwise the device will not be able to function.

The pressure is monitored using a manometer. The running arrow indicates that the air has come out of the expander. In general, this situation is not a serious problem, since air can be pumped through the nipple. The average pressure of water in the tank is 1.5 atm. However, they may not be suitable for a particular system. In this case, the pressure must be adjusted independently.

Normal indices are at 0.2 atm. less than in the system. Strictly do not exceed the pressure in the expansion tank in comparison with this indicator in the network. In such situations, the increased heat carrier can not enter the reservoir. The tank is connected to the pipeline through the connection size.

It is important not only to properly connect the expansion tank, but also to choose the right place for its installation. Despite the fact that modern models can be mounted anywhere, experts advise installing this element of the system on the return between the boiler and the pump.

To ensure maintainability of the structure, a ball valve is installed on the pipe through which the expander capacity is connected. In the event of equipment failure, the shut-off valve will remove it without pumping the coolant out of the system. During operation of the system, the crane must be open. Otherwise, it will sharply increase pressure, and it will flow at its weakest point.

Installation in the boiler room

AT open systemsoh with natural circulation coolant tanks are installed of other types. Such a tank is an open tank, usually welded from sheet steel. Install it at the highest point of the engineering network.

The principle of operation of such an element is very simple. As the volume increases, fluid is displaced from the pipes, rising along them along with the air. Cooling, the coolant returns to the pipeline under the influence of gravitational forces and natural air pressure.

Why does the pressure drop?

The pressure in the expansion vessel must be constant, but the situation when it falls during the operation of the system is not uncommon.

There are several reasons why pressure can decrease:

- Leakage of coolant. Most often, a similar problem occurs in systems where the coolant is not water, but antifreeze. Such liquids can penetrate into the smallest cracks, causing leakage. In this case, it is necessary to eliminate leaks and fill the tank with air.

- Pressure drop in the boiler. If the indicators are significantly reduced, you need to contact a specialist. If the pressure decreases slightly and is equalized after the start-up of the system, it can be operated, since such failures do not cause harm.

Pressure adjustment

The water pressure in the expansion element of the heating system is a configurable parameter. The setup is simple enough, and all the actions can be done independently.

To configure the necessary settings, you need the following:

Principle of connection

- Make the calculation and determine the required indicators - by 0.2 atm. less than in the system.

- Set these indicators before installing the tank into the system, dropping air or pumping it through the nipple.

- Connect the tank to the pipeline and fill the system with water. This should be done slowly, monitoring the pressure indicators in the pipes and the tank. To pump the coolant should be until the pressure indicators are not equal.

- After this, it is necessary to connect the pumping equipment and continue to pump the coolant. It is necessary to pump the water until the operational pressure calculated before the installation of the network is reached in the tank. This will ensure that there is a reserve volume of water in the body.

- The first activation of the system must be carried out in the maximum temperature mode. Under this condition, the volume of the heat carrier increases by the value of the specific increment. This ensures that a quantity of water equal to its capacity enters the tank. The pressure in the tank rises to the maximum.

Conclusion

The expansion tank is the most important additional element in any heating system. If for open systems with gravitational circulation it is sufficient to install a simple open reservoir at the top point, then for complex systems closed systems The installation of industrial models is required.

These tanks are leakproof. In the production process, air is pumped into the body, maintaining the pressure necessary for the normal operation of the systems with forced circulation. You can adjust the required pressure indices yourself using a pressure gauge and a conventional automotive compressor.

Related Posts

A detailed consideration expansion tank for water supply, operating principle and device, types and features. The criteria for the selection of the expansion tank are presented, the shortcomings and the main purpose are considered.

Figure 1: Types of expansion tanks

The most important condition in the water supply system is optimal support of water pressure. To ensure correct pressure in the expansion tanks, expansion joints are used to equalize loads on pipes and equipment. Water is used not only in technical, but also for food purposes, so the tank and the membrane on the inside are made of a special material that does not change the taste and smell of water. This material must meet sanitary and hygienic requirements and there must be a certificate of quality. The expansion tank for water supply systems compensates for hydraulic shocks, which greatly extends the life of the pumps and the pipeline.

Expansion tank unit

Inside the expansion tank there is a rubber membrane that divides the tank into two chambers: air is pumped into one chamber and the other chamber remains empty. After the installation and start-up of the heating, the coolant starts flowing into the empty chamber. In the other chamber, where the air is inflated, the required volume will be restored. When the liquid cools, it is displaced back into the water supply system. Thus, the pipes keep a constant, necessary pressure, which is why the system always works stably, there are no overloads and pressure jumps.

Figure 2: Dimensions of the expansion tanks

The water from the well is under pressure, and the membrane at this time increases, the air volume decreases, and some pressure is created. The pump switches off when the pressure reaches the required level. Water is consumed, accordingly, the pressure drops, and the pump is turned on to maintain the pressure. The drawback of the expansion tank is the irrational method of temporary storage of water. The Dutch were the first to suggest the use of expansion tanks with a membrane. To date, closed expansion tanks are very aesthetic and have a different design.

Figure 3: Expansion tank in operation

The membrane expansion tank for water supply also has a drawback, which is that it can not replace a membrane. If the heating system is working normally, the liquid expands when water is started, and otherwise the pressure fluctuations go smoothly. The membrane of this tank is made of high-quality material and serves a very long time.

Figure 4: Membrane Expansion Tank for Water Supply

Advice! Do not forget to check the air pressure before each heating season. For systems that have large volumes, it is best to use a stationary manometer. (See also: )

With the help of a membrane expansion tank, the hydrodynamic shock is compensated, which greatly reduces the frequency of the pumps. This design extends the service life and saves electricity. When the heating medium is heated or cooled, the system remains intact. This compensates for the volume of changes and it is for this purpose that the membrane expansion tank is installed. Even during a power outage, the backup tanks have a fire extinguishing function. Use of membrane tanks is possible not only in household systems, but also in industrial, as the working pressure is calculated to 16 bar. Hydroaccumulators can be horizontal and vertical, open and closed. In addition, they differ in the volume of water and working pressure.

Volume of the tank

In order to know the volume of the tank, it is necessary to calculate the initial air pressure in the tank and the working pressure, at maximum load, according to the formulas. But the buyer will know enough that the volume of the tank is 1 to 10 of the volume of the coolant, which is located in the system.

Figure 5: Calculation of the volume of the expansion vessel

Important! If the volume of the tank is not correctly chosen, the heating system will not last long. Even at the highest heating temperature, the pressure in the heating system must in no case exceed the permissible. (See also: )

Expansion tank for water supply, installation instructions are attached to each tank. There also it is necessary to look at the features of the choice of the expansion tank, depending on the needs and characteristics of the heating system.

Expansion tanks of open type

They are installed at the highest points of the heating system: on the roofs of buildings or attics. Thermal expansion of the coolant does not allow boiling water and if a leak occurs, the heating system replenishes with water. To date, the tanks open type there are few where they are installed, because they have some disadvantages:- too large a design;

- is installed on a high point of the heating system, and for this it is necessary to purchase an additional pipe (there will be heat loss); (See also: )

- in the heating system, air enters through the tank, corrosion occurs on heating appliances and on heating systems of some parts;

- can not work stably under high pressure.

Figure 6: Scheme of the expansion vessel

- Housing;

- Water level;

- Pipe of cold water;

- The drain pipe;

- Safety valve;

- Shut-off valve;

- The upper point in the pipeline riser.

Expansion tanks of closed type are used:

- in the heating system, which works with autonomous sources heat;

- in the heating system, which is connected to centralized networks, compiled according to independent schemes;

- in the system that is connected to the solar collector and pumps;

- in a system connected to cold and hot water supply.

Selecting the expansion tank

Choosing an expansion tank is necessary taking into account all the features of the system. First you need to select the required volume, choose the design, determine the membrane material. Just pay attention to the weight of the product, which is why the indicator can determine the quality of reliability and durability of the expansion tank. The best is to acquire well-known brands, since they will be able to provide the heating system with a long operation and prevent breakage in the system. Installation of an expansion tank for water supply and the price for it will please everyone who needs to install such a tank.Use of materials is allowed only if there is an indexed link to the page with the material.

Tips for choosing

Membrane tank is made in the form of a vessel with two chambers, one of which is pumped with air, and the other receives water. Expansive membrane tanks They are used in heating systems to drain additional water when heating the boiler and expanding the liquid and to prevent a hydraulic shock. In water supply systems membrane tanksserve to accumulate a certain amount of water for its supply under certain pressure at the right moment.

Calculation of the minimum volume of the membrane tank

In the first approximation, the volume of the expansion a membrane tank should be equal to 10% of the water volume in the system.

To calculate the minimum allowable volume a membrane tank, you need to know the maximum allowable number of pump starts per hour, the intensity of the water set and at what pressure values the pump will turn off and on.

An approximate formula for calculating the minimum volume a membrane tank looks like that:

V = 2Q / N, where V denotes the volume of the membrane tank in cubic meters, Q is the expected water intake in cubic meters per hour, N is the maximum allowable number of pump starts / stops per hour.

If you want the pump motor to last as long as possible, you need to choose membrane tank, the volume of which slightly exceeds the minimum allowed, calculated by the above formula. In one system, you can install two or more membrane tanks, but you need to make sure that the pressure in the air chambers is the same.

Before installation a membrane tank it is necessary to make sure that during the technical calculation the parameters were chosen correctly. Do not install membrane tank with unchecked parameters, because it can damage people, the system and the tank itself. Membrane tank mass of more than 30 kg is fixed with a special device.

Calculation of the pre-pressure in the membrane tank

Manufacturers membrane tanks set the value of the preliminary pressure no more than 4 bar. However, it must be adjusted on site in accordance with the operating conditions. The pre-pressure setting provides long service membrane and reliable operation of the entire system.

The pre-pressure is measured when the tank is emptied. To accurately expose it, use the matching table:

Calculation of the maximum and actual volume of the membrane tank

The maximum volume of water in a membrane tank is ¾ of its volume, and the actual volume is much noticeably smaller. If the pressure drop before switching on and off the pump is about 2 bar, then the actual volume of water in the a membrane tank will be about 30% of the total volume. Actual volume a membrane tank directly depends on the difference between the pressures when the pump is turned on and off, the larger it is, the greater the actual volume.

Remember the safety precautions: the pre-pressure should not exceed the level indicated in the a membrane tank nameplate.