How the piping is piped with polypropylene. What can be the strapping of a solid fuel heating boiler - the scheme is simple and complex

Polypropylene pipes, which are made with modern technology, have many advantages. The most important are cheapness, resistance to aggressive influences and ease of processing. At the same time, the durability of such products is very high. They have smooth walls, which do not settle plaque, often leading to a clogging of pipes.

The creation of connections from such pipes does not require complicated equipment. They are mainly produced by soldering, which makes it possible to achieve reliability and tightness. In soldered pipes, there is practically no leakage. Nevertheless, in work even with such malleable material, there are several nuances that should be borne in mind by the owners of buildings, important in the performance of communications using polypropylene products.

An important advantage polypropylene pipes is the possibility of creating from them a contour of almost any complexity, although it is rarely required to perform complex systems in domestic conditions. You can even say, the simpler the piping of the heating boiler will be made with polypropylene, the better - it will be easier to assemble it qualitatively. When creating complex systems, the probability of improper or insufficiently effective work of the elements is great, so it is best to leave this work to professionals.

|

|

To assemble the heating system at home, it is possible to weld the joints and using fittings. The first method requires a specialized soldering iron with a set of nozzles for different pipe diameters. The price of such a device is low. Assembly using fittings can be done with conventional tools, but over time connections can leak.

Regardless of the method of assembly, it is recommended that you consider how the heating boiler will be piped by yourself. The system should have the least number of connections, otherwise the time of its use decreases and the efficiency of the heating device decreases. Smooth transitions are also preferable to sharp ones.

The service life of the polypropylene pipeline is 40 years on average. It can withstand pressures of up to 25 atmospheres. The permissible temperature of the coolant circulating through the pipes is 95 ° C.

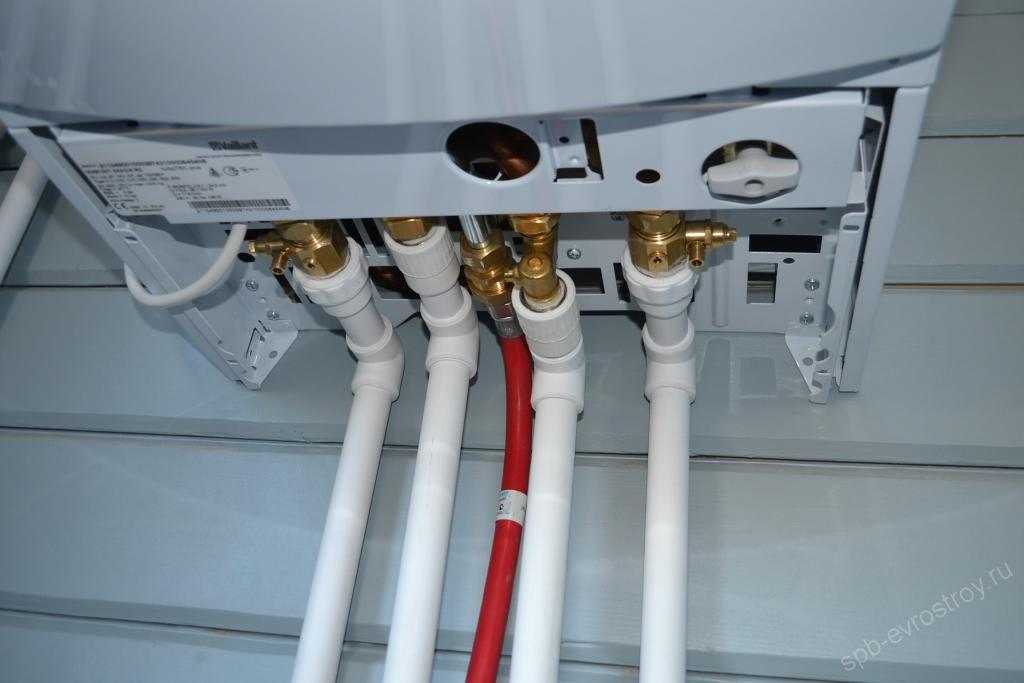

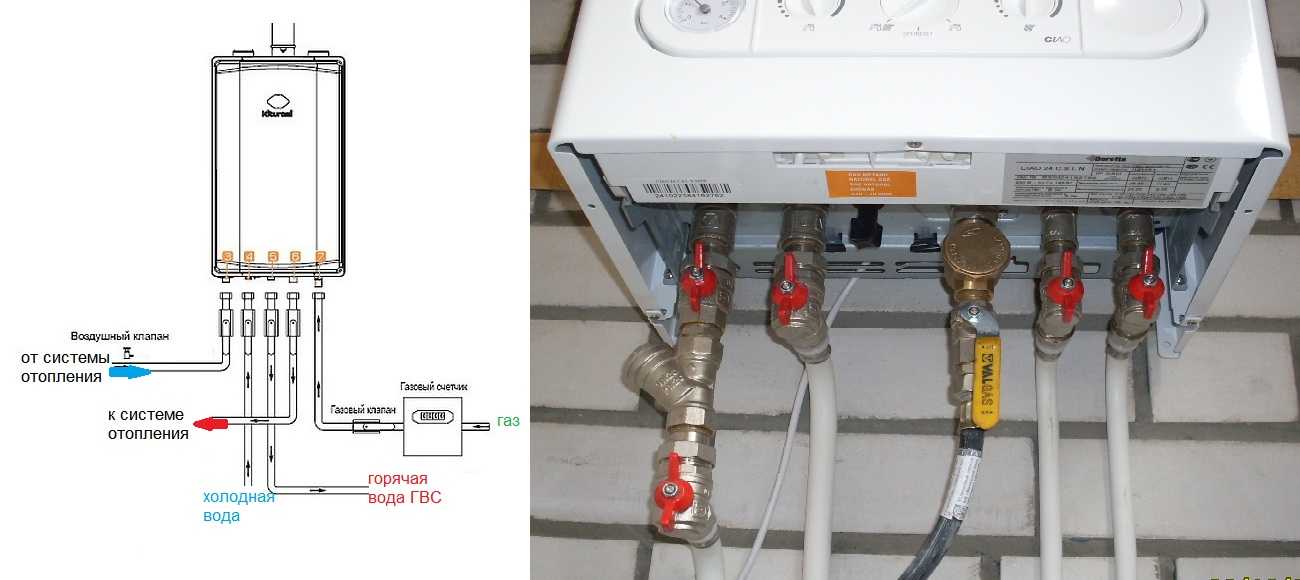

Connection of the gas boiler has some features. According to building codes, the gas supply to the device must be carried out using metal pipes. And the connection of the pipe with the generator must be carried out with a metal hose or "American". It is allowed to use gaskets only from paronite, the use of rubber materials, pakli or fum-tape is unacceptable. This material is made from a non-combustible mixture of mineral and asbestos fibers and rubber, it keeps the shape well and ensures the tightness of the joints.

Hard connection is required, based on safety requirements when using gas appliances. Pipes and cushioning materials must be resistant to fire. The use of rubber as a cushioning material is also bad in that it can reduce the cross-section of the gas passage.

Placement of the system and its individual elements

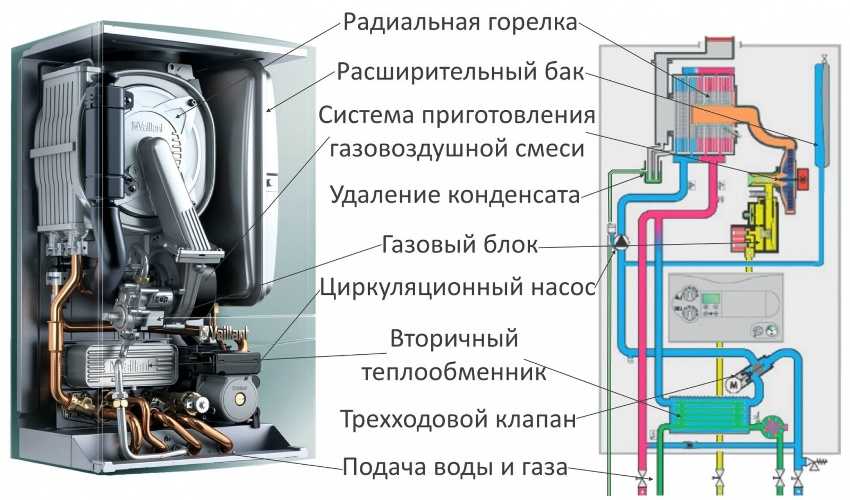

The boiler is the main element of the heating system. Its design has a significant effect on the strapping device.

The piping of the floor gas boiler should be designed so that the heat generator is installed on the floor or at a low altitude, but not at the highest point of the piping. Otherwise, air plugs will accumulate inside the boiler.

When using a boiler in which there is no air outlet, the supply line should be positioned strictly vertically. The presence of an air outlet can be determined from the nozzles that are located at the bottom of the unit. They are connected to the supply line and return pipe. Typically, such nipples are available for gas and electric equipment operation principle, placed on the wall. This feature of the structure should be taken into account when creating a scheme for tying the wall-mounted boiler - the possibility of independent removal of accumulated air greatly simplifies the operation of the device.

In some cases, the boiler is sold without additional tools. In this version, the necessary devices are purchased separately. When buying, you should pay attention to the compatibility of devices and purchase the necessary adapters. Optional devices are often not required when the system has a natural circulation.

Ways to bundle heating boilers

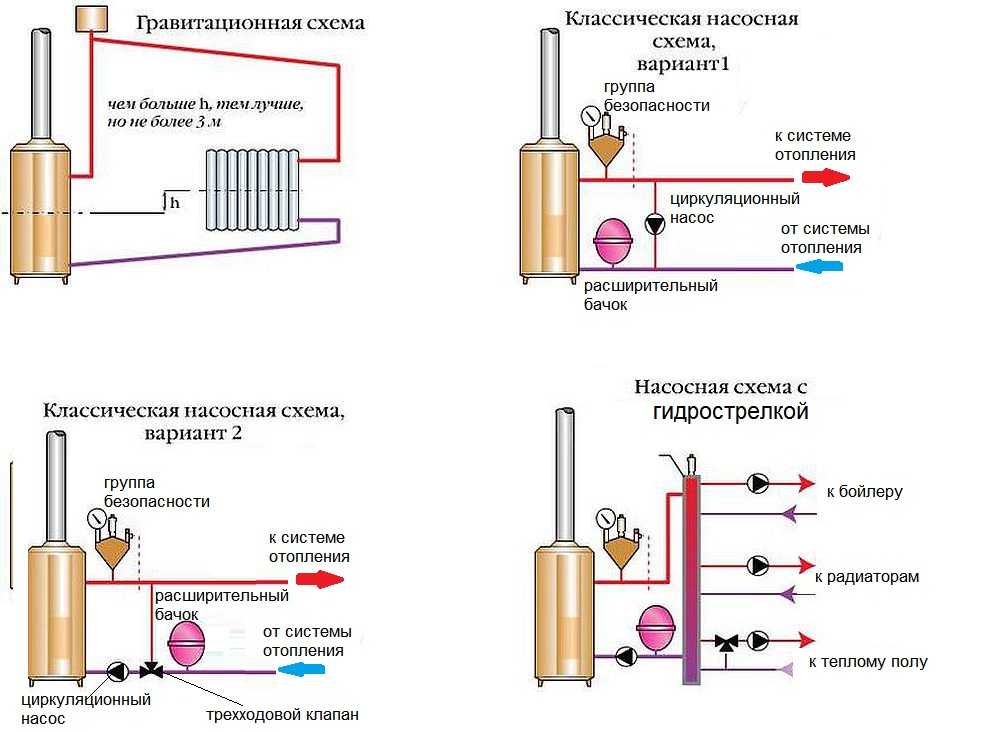

All ways of tying the heating equipment can be divided into two categories, depending on the principle of coolant circulation along the contour: with natural and artificial circulation. The second category consists of several subcategories, determined by the type of wiring.

Systems with natural circulation

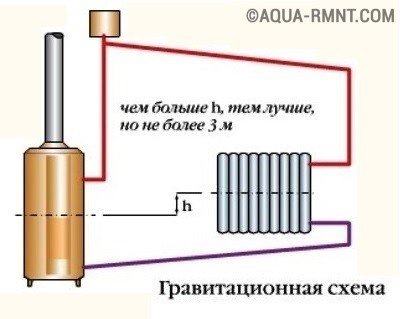

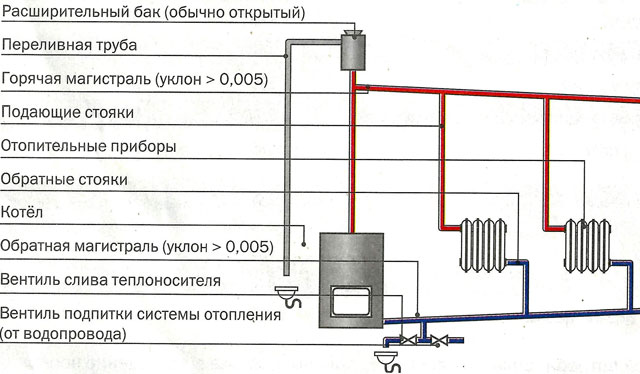

The piping of the heating boiler is a system with natural circulation

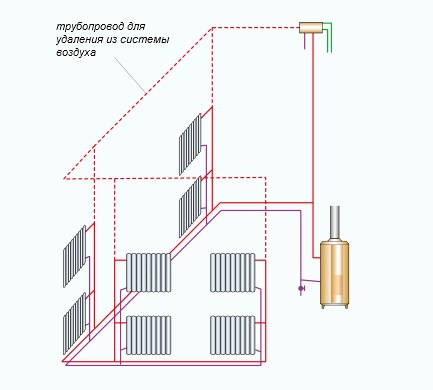

This category includes the simplest and cheapest contours, which are mounted with the least problems. A feature of these heating systems is the absence of a pump. The heating medium is driven solely by gravity, without the aid of additional devices. For this reason, the size of such a heating system is very limited - it can be used in small cottages and country houses, but in no way in multi-storey buildings or buildings with a large area.

The piping of the floor heating boiler with polypropylene is made easier than other methods of creating a heating system, therefore, for self-installation, it fits best. The composition of such a system includes only three elements - a boiler, expansion tankand and radiators.

Advantage of the system with gravitational circulation are:

- Ease of installation.

- Independence of work from external sources of energy, both electricity and fuel.

- Availability of equipment.

- Easy to create and maintain the system.

- Compact size.

- High reliability - almost no device can fail.

- Possibility of self-repair.

However, there are a lot of disadvantages to such a system. When the system is created on its own, there is often a difficulty in determining the required pipe diameter. To find products of the desired cross-section, certain calculations must be made. Sometimes pipes of considerable diameter may be needed to create the system. The drawback of gravity circulation is also the inability to regulate the operation of the system. The strapping scheme can be improved by integrating a circulation pump into it, which can be used to control the operation of the heating system.

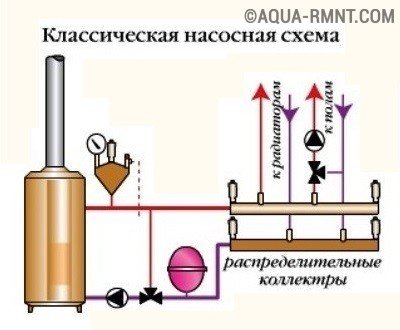

The circuit in which the coolant moves forcibly is more convenient to operate. Its operation can be controlled by choosing the optimum heating mode for each room. The equipment will automatically maintain the set operating mode. For such a system to function, it needs electricity. In the event of a power outage, which often happens in suburban homes, the efficiency of the circuit drops dramatically.

This heating system has such disadvantages:

- A complex scheme, which includes a number of devices that take into account the flow and pressure, performing the distribution of the energy carrier, which is especially typical when creating circuits for tying wall-mounted double-circuit boilers.

- The need for balancing devices.

- The need for regular maintenance.

- The complexity of installation and repair work.

- The high price of the elements of the system.

The scheme for tying the wall gas boiler and other types of devices can be simplified by using primary-secondary rings. A variety of devices that control the operation of the system and protect it will be less if several rings of the system are created, each of which will have its own circulation pump. This ensures a uniform supply of coolant to the consumer.

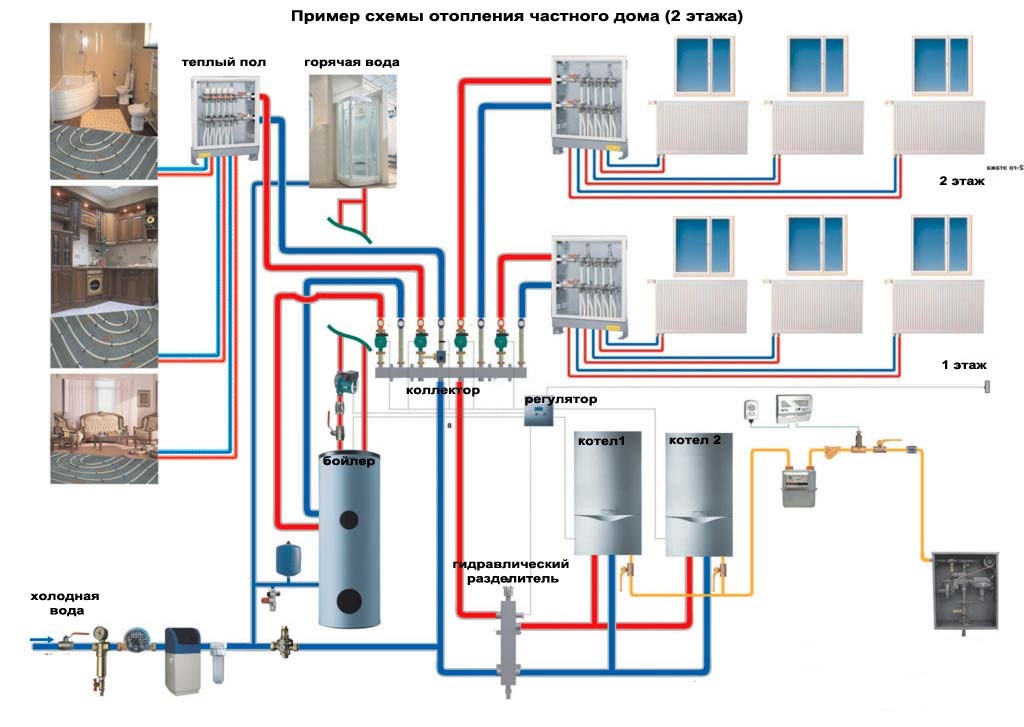

In large houses, heating systems with hydraulic equalizers are created. Hydraulic elements are placed in heating systems, where the boiler's output exceeds 50 kW. They ensure a uniform supply of coolant to all circuits. With the help of hydraulic leveling, all devices receive heat in the right size. In this case, the pressure in various elements of the system is compensated. In simpler systems, similar work is done by collectors-combs.

Pipes made from polypropylene using innovative technologies have a lot of priorities, among them cheapness and resistance to aggressive factors occupy leading positions. The affordable products serve owners no less than expensive counterparts. On the walls they do not settle the contraction diameter of the pipeline plaque. The connections are made by soldering, so that the piping of the boiler with polypropylene becomes "monolithic", that is, there are not exactly leakages typical for pipelines with poorly installed leakage fittings. However, there are some nuances about which it is necessary to know the owners of houses, choosing polypropylene for the communication device.

Specificity of piping with polypropylene

A significant advantage of polypropylene pipelines is recognized as the possibility to create a contour of any complexity, which in principle is not very interesting for those who use the piping for their own hands for the first time. The simpler the scheme of the future system, the easier it will be to implement the idea. And the heating output is inversely proportional to the degree of complexity: the simpler, the more efficient. To make connections home master can use, as welding technology, and selected strictly in the size of pipes fittings. However, at the slightest "shifts" in the places of installation of fittings, the system may start to flow slightly.

With the help of polypropylene pipes, it is possible to create heating circuits of any complexity, but it should be remembered that the complexity complicates the installation and reduces the efficiency of the heating system

It is desirable that the created heating system has the least number of connections. If you can make a smooth transition, you need to use it.

The polypropylene pipeline will operate without problems for 40 years, guaranteed by the manufacturer, it will withstand pressure, the values of which exceed 25 bar. Without damage to the structure of the material, a coolant with a temperature of 95º can circulate through the pipes. However, there is a limit, which should be taken into account if the gas boiler is bundled.

The gas connection to the boiler must be rigid, the building requirements dictate the use of metal elements for the connection and the use of a paronite gasket

The gas connection to the boiler must have a rigid connection. Building requirements require a metal pipe and docking with a heat generator through a metal overhead or an "American". Use only a gasket of paronite. Rubber materials, tapes, towels are prohibited. Paronite, obtained by vulcanizing a mixture of asbestos fibers, mineral fillers and rubber, perfectly holds the shape, ensures tightness and does not burn. Other cushioning materials tend to ignite, and rubber sandwiched between the elements can reduce the size of the gas passage. If the diameter of the passage is reduced, the gas supply will be reduced and the boiler will not supply the required amount of heat.

Determination of the location of the boiler in the common system

The boiler is the main "organ" of the heating circuit, the choice of the binding scheme depends to a large extent on its type. The floor heat generator can not be located at the highest point of the pipeline layout. This is the main rule of its installation. In the event of non-compliance with this condition, air plugs will accumulate in the boiler, which does not have an air vent. The pipe of the supply line leaving the boiler without an air vent should be strictly vertical.

The presence of an automatic air vent installed in an electric or gas boiler can be determined by the nozzles located in the lower part of the unit, a supply line and a return line

On the presence of an automatic air vent installed in the boiler, "tell" the pipes located at the bottom of the unit, intended for connection to the heating network. They usually have a wall-mounted electrical or gas equipment. This feature of the scheme of the walling of the wall heating boiler must be taken into account, since most monoblock boilers mounted on the wall can independently be freed from the accumulated air.

If the boiler was purchased without an expansion tank, a pump, a pressure adjustment device, all the missing components can be purchased separately, the safety group can be installed both at the inlet and outlet of the coolant

Boilers can now be purchased, as with the expansion tank, and the security team, and without the entire list of additional devices. If the purchased unit does not have the listed devices, they can be purchased separately and included in the circuit. People who build, they mostly do not need, and those who arrange the outline with forced heating, be sure to be necessary.

Ways to bundle heating boilers

By the principle of circulation of the coolant through the heating circuit, all types of strapping are divided into systems with natural and forced movement. In the latter of these groups there are subgroups, the division into which is made by the type of wiring.

Option # 1 - circuits with natural circulation

This group includes the simplest and most accessible self-assembly system. A characteristic feature of this heating, also called gravity, is the absence of a pump that stimulates the movement of the coolant. That is, the movement of heated water to heating appliances and cold outflow is accomplished on the basis of physical laws without human intervention and mechanisms. The simplest scheme for tying the heating boiler is suitable for small country houses. It will not cope with the maintenance of multi-storey buildings and large-area buildings.

Tying the heating boiler with natural circulation - the best option for self-installation, the structure includes only a boiler, radiators and expansion tank

Advantages of gravitational heating:

- the easiest installation;

- work that does not depend on the availability of electricity and is associated with the supply of this energy carrier interruptions;

- budgetary size, both construction and maintenance;

- almost uninterrupted functionality, because in their composition there are no devices capable of failing at the wrong time;

- the ability to repair the system on its own, if, of course, it will not be necessary to repair the boiler.

There are some disadvantages too. Precise calculations of the diameter of the pipes are necessary in order for the circuit to perform its functions fully. The diameter will be considerable, which does not always suit the owners of compact cottages. The interior looks natural circulation system is not too presentable. It is impossible to regulate its functionality. However, the scheme of tying the floor gas boiler or wall-mounted unit can be modernized by inserting circulating pump, which can be used if necessary.

Option # 2 - forced type heating

The circuit with forced movement of the coolant is more comfortable, its owner can control its operation. It will be possible to choose the optimal temperature for each room, and the mode specified by the host will be automatically maintained. It is only necessary to take into account that such a strapping of a floor boiler and a wall heat generator requires power supply. In case of interruptions, which are not uncommon for domestic networks, the circuit will not work. If electricity is not supplied, this type of heating will have to be abandoned.

The classical version of the piping of a heating boiler requires balancing and compulsory maintenance of appliances

- a complex scheme of strapping, including a mass of flowmeters, devices for venting air, distribution manifolds, valves, etc .;

- mandatory balancing of devices;

- the need for regular, expensive service;

- professional installation and repair, which takes a lot of money;

- high cost of appliances and services installers.

The number of devices built into the network can be reduced by applying the principle of primary secondary rings. The protection and control devices will be smaller, but each of the arranged heating rings will need to be equipped with its circulation pump. The systems consisting of several rings with a floor boiler with a power of less than 50 kW are equipped with comb collectors, which guarantee a uniform supply of coolant to the devices.

The creation of a heating system involves the connection of the boiler and radiators (radiators, convectors and a warm water floor). Also, there must be security devices in the system. The procedure for connecting all this farm is called "tying the boiler."

What is the strapping and what is it made of?

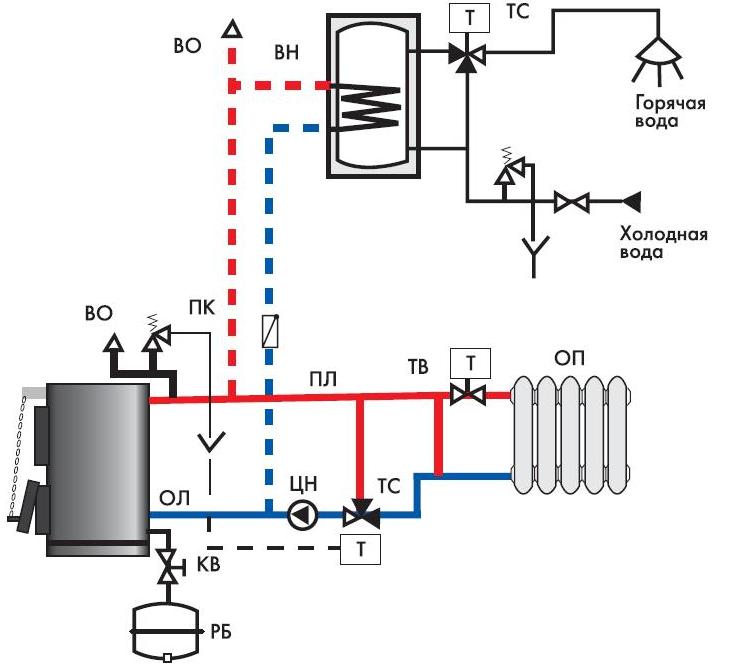

In the heating system, two main parts - a boiler and radiators or warm floor. The fact that they are connected and provides security - this is the harness. Depending on the type of installed boiler, different elements are used, therefore, they usually consider the binding of solid fuel assemblies without automatics and automated (more often - gas) boilers. They have different operating algorithms, the main ones are the possibility of heating the boiler's TTs in the active combustion phase to high temperatures and the presence / absence of automation. This imposes a number of limitations and additional requirements that must be met when tying a solid fuel boiler.

An example of piping the boiler - first comes copper, then - polymer pipes

What should be in the harness

To ensure the safe operation of heating, the piping of the boiler must contain a number of devices. Must be:

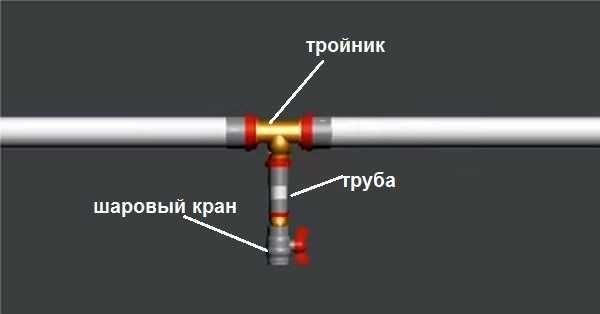

Some of these devices are already installed under the casing of a gas wall-mounted boiler. The strapping of such an assembly is very simple. In order not to complicate the system with a large number of taps, a manometer, air vent and emergency valve are assembled into one group. There is a special case with three outlets. The appropriate devices are screwed onto it.

So the security group looks like

Establish a safety group on the supply line immediately at the outlet of the boiler. Set so that it is easy to control the pressure and you could manually relieve pressure if necessary.

What pipes to make

Today, metal pipes are rarely used in the heating system. They are increasingly replaced with polypropylene or plastic. The piping of a gas boiler or any other automated (pellet, on liquid fuel, electric) is possible with these types of pipes.

When connecting a solid fuel boiler, at least one meter of pipe on the pitch is impenetrable to make a metal pipe and, best of all, a copper pipe. Next, you can put the transition to metal plastic or polypropylene. But this is not a guarantee that polypropylene will not collapse. It is best to make additional protection against overheating (boiling) of the boiler's TT.

Which polymer pipe is better? Polypropylene or metal-plastic? There is no unequivocal answer. Piping with polypropylene is good in the reliability of joints - properly welded pipes are a monolith. (). But the maximum permissible temperature of the coolant in the system is not higher than 80-90 ° C (depending on the type of pipe). And then, the prolonged exposure to high temperatures leads to the rapid destruction of polypropylene - it becomes brittle. Therefore, the piping of the boiler with polypropylene is done only in low-temperature systems based on automated boilers.

If there is protection against overheating, the piping can be made with polypropylene pipes

Metalloplastik has a higher operating temperature - up to 95 ° C, which is enough for most systems. You can also make them the binding of a solid fuel boiler, but only if one of the systems protects against coolant overheating (described below). But metal plastic pipes have two significant drawbacks: narrowing at the junction (fittings construction) and the need for regular testing of the connections, as they eventually flow. So the piping of the boiler is made of metal plastic, provided that water is used as a coolant. Non-freezing liquids are more fluid, because in such systems, it is better not to use compression fittings - they will still flow. Even if you replace the gaskets with chemically resistant ones.

Tying of gas boilers

Modern gas boilers have good automation, which controls all parameters of the equipment operation: gas pressure, presence of a flame on the burner, pressure level and temperature of the heating medium in the heating system. There is even automation, which can adjust the work to weather data. In addition, wall-mounted gas boilers in most cases contain also such necessary devices as:

The parameters of all these devices are indicated in the technical data of gas cats. When choosing a model, one should pay attention to them and choose a model not only in terms of capacity, but also in terms of the volume of the expansion vessel and the maximum volume of the coolant.

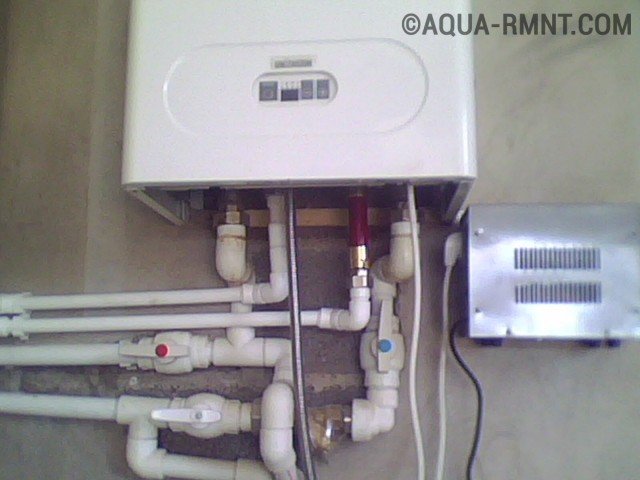

Scheme of the walling of a wall gas boiler

In the simplest case, the piping of the boiler contains only shut-off valves at the entrance to the boiler - so that, if necessary, repairs can be carried out. Even on the return pipeline, coming from the heating system, put a mud filter - to remove possible contaminants. That's the whole strapping.

Example of piping of a wall gas boiler (two-circuit)

In the photo above there are angular ball Valves, but this, as you know, is not necessary - it is possible to put conventional models, and the pipes to be deployed closer to the wall with the help of corners. Also note that on both sides of the sump there are taps - this is for the possibility of removing it and cleaning it without draining the system.

In the case of connection of a single-wall wall gas boiler, it is still simpler - only the gas is supplied (gasmakers are connected), the supply hot water to radiators or water warm floor and a return from them.

Circuit diagrams for floor gas boilers

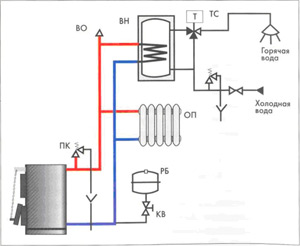

Floor models of gas heating boilers are also equipped with automation, but have neither a safety group, nor an expansion tank, nor a circulation pump. All these devices have to be installed additionally. The strapping scheme because of this looks a little more complicated.

On two schemes of classical piping of the boiler an additional jumper is installed. This is the so-called "anticondensation" loop. It is needed in large systems, if the water temperature in the return line is too low, it can cause condensation. To eliminate this phenomenon and arrange this jumper. With her help to return line Hot water from the feed is mixed, raising the temperature above the dew point (usually 40 ° C). There are two main ways to implement:

- with the installation of a circulating pump in the jumper with an external temperature sensor (and the photo above at the right);

- using a three-way valve (pictured below at the left).

In the circuit with the circulator on the jumper (condensation pump) it is made by the pipe at a step of smaller diameter than the mains. The sensor is attached to the return pipe. If the temperature drops below the set temperature, the pump supply circuit is switched on, hot water is added. When the temperature becomes higher than the threshold, the pump switches off. The second pump - the actual heating system, it works all the time while the boiler is running.

In the second scheme with a three-way valve, it opens a hot water slurry when the temperature drops (it is set on the valve). The pump is in this case on the return pipeline.

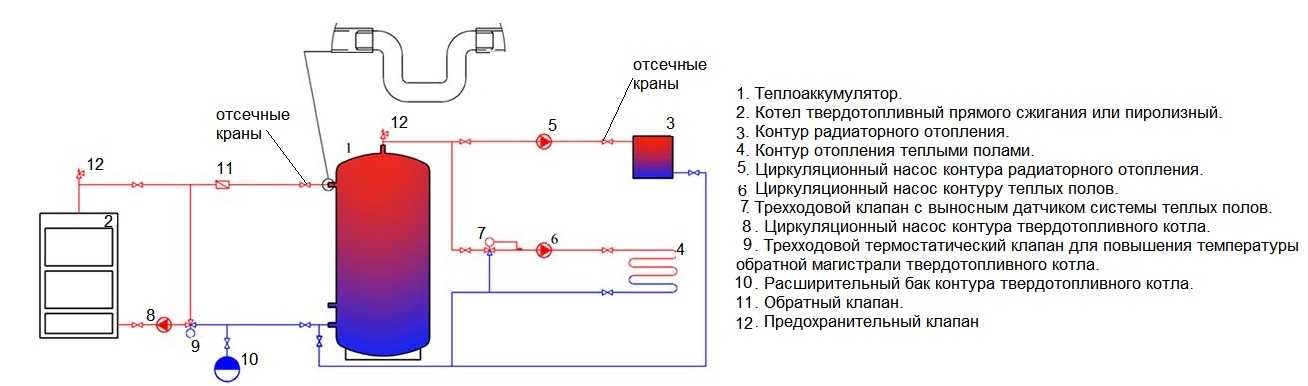

Tying the solid fuel boiler

Any owner of the boiler's TT knows that during the active combustion phase a lot of heat is released. Since time comes experience - when and how to cover the damper, for what period of time, etc. But it's worth a little distraction, and the water in the system overheats and can even boil. To prevent such a phenomenon, the piping of a boiler without automatics should contain several devices preventing the boiling of the system. Only in this case it is possible to make a house wiring with polymer pipes. Otherwise, sooner or later, the superheated coolant will soften the material, the pipes will break with all the ensuing consequences. Therefore, the binding of a solid fuel boiler, in addition to the traditional elements - the safety group, the expansion tank and the circulation pump - contains a substantial number of additional devices and usually requires quite substantial means.

The cyclical nature of the operation of solid fuel boilers leads not only to the boiling of the system, but also to the fact that the house is very hot (when the fuel is actively burning), it is cold - when everything is burned out. To eliminate these phenomena, there is a solution: install a boiler indirect heating or heat accumulator. Both are containers with water, they simply perform different functions and, accordingly, connect differently.

Tying with an indirect heater

With this construction, there is no sharp increase in temperature for the time of active burning that is usual for a solid fuel boiler. All because the volume of the tank is added, because there is almost no overheating of the water. Then, when the fuel burned out and in the usual system the house begins to cool down, the heat stored in the heating system continues to be consumed in the system with the TA. In this way, the temperature background is equalized and the time between the furnaces increases.

Such binding of the boiler on solid fuel is more reliable and the distribution from the TA can be done with polypropylene pipes, but the contour from the boiler to the vessel must be made with metal pipes. In this case, you can use steel, but better still copper.

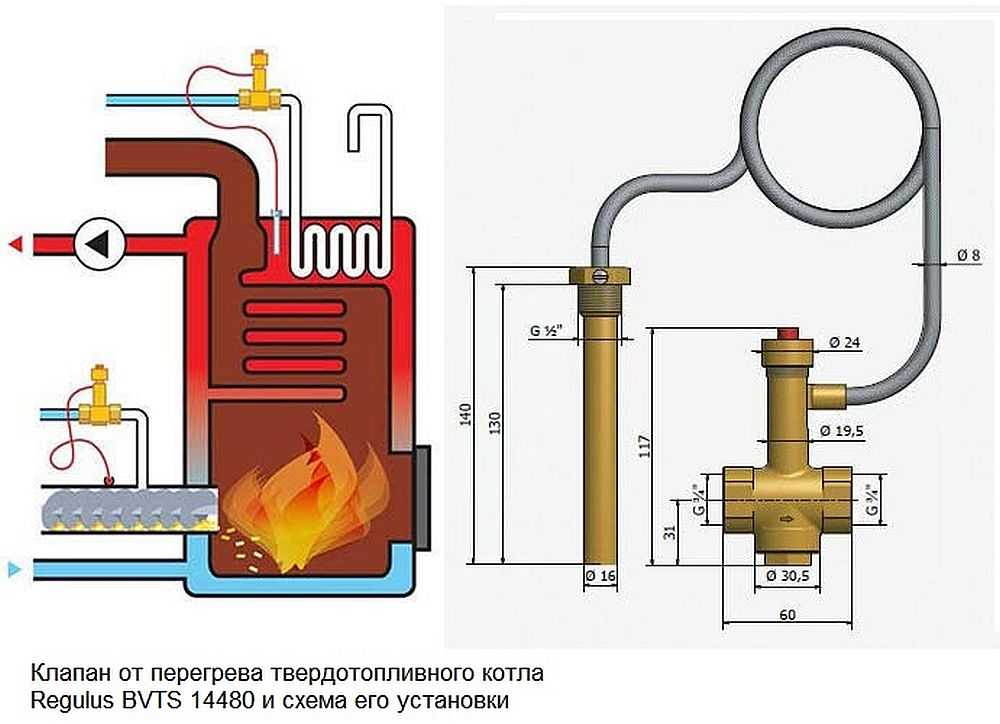

Staging the boiler's CTs with a valve against overheating

The third way to make protection against overheating of a solid fuel boiler is to install automatic device protection against overheating. This is a special valve with a temperature sensor. The principle of operation is simple: if a certain temperature is exceeded (usually 95-97 ° C), the valve opens the inlet cold water from the water pipe, and overheated excess will release into the sewer. So, for example, REGULUS DBV 1-02, Regulus BVTS 14480 works.

Protecting the solid fuel boiler from overheating with the REGULUS DBV valve

Valves, though produced by the same firm, have a different structure and installation scheme. So REGULUS DBV is installed at the output from the boiler, has a built-in temperature sensor (the installation scheme is above). The Regulus BVTS 14480 overheating protection valve has a remote sensor, can be mounted both at the inlet and outlet (installation diagram at the bottom). What is good about this option? The fact that it can work in systems with natural circulation - it does not need pressure for work.

Tying the heating boiler with the coolant boil-off valve

Their approximate cost - 40-60 € - is much less than the cost of installing a heat accumulator or an indirect heating boiler, but the problem of temperature fluctuation does not solve this problem. By the way, these valves can be used to improve the reliability of the circuit with an installed indirection and thus to precisely eliminate the possibility of boiling the system.

What else is needed in the system

The piping of the boiler will be incomplete if it does not have a tap for draining and filling the system. And it is better if they are separate. The exact location of the installation depends on the structure of the system, but there are certain rules:

In some systems, drain and fill systems are made from one tap. This is possible if there is a pump that is pumped in and there is a pressure gauge to control it created pressure. If there is a separate tap for filling the system at a high point, you can fill it with gravity.

What is the strapping?

What is included in the binding system?

Tying Options

Strapping Elements

Other Strapping Elements

The boiler can be called the heart of the heating system. However, in order for the heating system to work effectively, it is not enough just to select the boiler correctly and connect it correctly. It will be necessary to select correct scheme heating. If at least one device is incorrectly connected, this will severely affect the entire system. Therefore it is important to consider what the piping of the boiler means and what is the sequence of its installation.

What is the strapping?

In fact, this is all equipment intended for efficient operation of the boiler and the successful delivery of coolant to the radiators. The harness provides several advantages:- provides the optimum temperature in the heating main,

- controls the amount of coolant in the system,

- removes air from the main line,

- guarantees the safety of the boiler against overpressure,

- does not allow devices to clog with slag, squeaks and other debris,

- controls the heating time of the heating devices,

- allows you to connect different heating circuits and adjust them to the desired temperature,

- effectively distributes heat through radiators.

What is included in the binding system?

This includes different instruments. Here is a list of the main elements:- expansion tank,

- pump,

- distributive valve,

- balancing crane,

- manometer,

- drain and ball valves,

- valves (air, through, return, safety),

- filter.

Sequence of installation works

Regardless of the wiring options, it is assembled in one sequence.- First, you are advised to carefully read the instructions for all equipment and its characteristics. It is important that during the installation of the heating system did not have to run to the store and change the device.

- Boiler installation.

- Installing the expansion tank.

- Selection of the place for the collector. Here you need to be careful not to confuse the supply line with the return. This information is on the case of the device.

- Safety devices are installed on the supply line.

- Then the pump is mounted.

- To the trunk, devices are installed to improve the operation of the system: a filter, an air vent, cranes, valves, control devices and so on.

copper piping

copper piping Adhering to this order, you can make a successful binding of the boiler.

Tying Options

There are 4 main and most common ways:- with the circulation of natural,

- with forced,

- collection classical,

- on primary-secondary rings.

1. Stroke with natural circulation. This option is the easiest. Here, as the name implies, there is no pump, and the coolant moves along the main due to physical laws. All settings are set manually, and also it is necessary to observe the operation of the system. In order for this heating to work properly, you need to consider some tips:

- the pipe should be of a large internal diameter (from 32 mm),

- the boiler is installed below the radiators,

- the slope of the pipes should be at least 5 mm along the course of the coolant,

- the minimum number of rotations of the pipes, so as not to interfere with the natural course of the liquid in the pipeline.

2. Forced circulation. This type of strapping is the most common. It has many advantages. One of the most important is the temperature adjustment of each battery. Principle forced circulation consists in the fact that the heat carrier can flow along the main line at high speed, thanks to the pump. The only drawback of this option is the dependence of the pump on electricity. When it is turned off, the pump stops working. However, there are 2 ways to solve this problem:

- installation of a bypass pipeline (bypass), which will enable the system to switch to natural circulation;

- arrange a high-quality emergency scheme, through which it will be possible to lose excess heat;

- to establish a system of autonomous power supply (uninterruptible power supply).

3. Collector wiring. Although this version of heating is the most expensive and complicated in terms of installation, but it is the most efficient, convenient and energy-saving. Its essence is that all the pipes from the boiler pass through a special device called a collector. In this node there are various valves, cranes, air taps, measuring devices and so on. From the collector there is a separate wiring to other devices. There are a number of advantages that appear due to this method:

- Each heating element is controlled separately from the collector box, which makes it possible to disconnect any without disturbing the operation of the entire highway.

- Throughout the highway the temperature is the same.

4. Strapping on primary secondary rings. This method is often used in buildings where there are many consumers. More than one circulating pump is used here. The essence of this wiring is the following: to a small circuit where the heated coolant is located, pumps are connected, which, if necessary, take this water to the consumer. There are 2 types of circuits connected to the boiler:

- Mixing. Here, the temperature of the coolant is affected by how open the damper is.

- Straight lines. In this case, the liquid is heated from the burner.

There are also 2 ways to connect the circuits:

- Two-way connection, when the coolant is supplied by pumps.

- In the three-way connection, each circuit has a separate tap, and is connected to a boiler in which the coolant is heated.

- Cold water is supplied from the water supply.

- The pump switches to an additional power source (for example, a battery). Using this option, it is important not to forget to monitor the charging of this source.

- Installation of an additional circuit with natural circulation. This small circuit removes heat after the pump is turned off.

- Simultaneous use of two circuits. When the power-dependent branch stops working, the loop with natural circulation continues to heat the room.

Strapping Elements

Now it is worth paying attention to the main elements that are used when tying the boiler. You should consider the features of mounting each of them.Boiler

It is very important to connect the boiler correctly. On this depends not only the effective operation of the entire heating system, but also the safety of people in the room. cascade connection of boilers

cascade connection of boilersTo begin with, a little about installing gas boilers. Since the connection occurs to a pipe in which gas is under high pressure, it is forbidden to connect this equipment independently. Therefore, acquiring a gas boiler, the next step will be the call of specialists.

The electric boiler is not difficult to install. Basically, the complexity is related to the adjustment of automation.

Now about the installation of a boiler, running on liquid fuel. It's better that experts do it. However, there are basic principles that must be taken into account for the successful operation of this unit:

- Correctly install containers for waste oil or diesel.

- Provide the necessary conditions for safety requirements. Neither the fuel nor the boiler should be close to flammable materials.

- The burner is connected using a duct with a filter.

- A pump can be connected to the system, which will give a uniform fuel supply.

- First you need to build a foundation. It can be made of clay or concrete. Above him lay a sheet of iron or asbestos.

- Place the boiler below the radiators. This is especially important if natural circulation.

- Then connect it to the chimney through chimney. The connection must be sealed to prevent the release of carbon monoxide.

- For better ventilation of the room, it is advisable to install a fume hood.

Pipes

Pipes are an important component of the boiler's piping. But it is not easy to decide which pipes to use, due to the fact that the popular versions are metal-plastic and polypropylene. Therefore, it is worth paying attention to everyone.Metal-plastic consists of 5 layers, which includes 2 layers of plastic, 2 glues and 1 aluminum. The diameter of such pipes is from 16 to 63 mm. They have such advantages:

- increased plasticity, which simplifies installation,

- low thermal conductivity,

- not subject to corrosion,

- easily repaired,

- do not need an expensive tool for installation,

- good noise absorption.

- at a mechanical pressure there is a dent,

- it is necessary to carefully check the connections for leakage during installation.

- if the water freezes in them, they do not collapse,

- resistant to both acids and alkalis,

- are not afraid of mechanical damage,

- are connected by a method of soldering, which eliminates leakage over time.

If you pay attention to the shortcomings, you will see the following:

- difficult to repair if damaged,

- for installation, expensive equipment is required,

- at a high temperature, pipes are elongated.

piping of the boiler plant with the use of polypropylene pipes

piping of the boiler plant with the use of polypropylene pipesSo, choosing pipes for tying, you need to consider your needs. If important indicators such as diameter, frost resistance, endurance to damage, reliability of connections, polypropylene pipes are suitable. However, if it is preferable to endurance to high temperature, ease of repair and installation, then the metal plastic wins.

Other Strapping Elements

The expansion tank plays an important role in the system. It does not allow the water to expand from the heating, create pressure on the components of the heating main. Tank open type is installed at the highest point of the system, into the outflow pipe. Installing the tank closed type with a membrane, should adhere to several principles:- choose a free place for access, near the highway,

- mounting is made on brackets and at plus temperature,

- connect first measuring counter, and then the pressure reducer,

- on the flow pipe is mounted safety valve.

- it is placed near the cauldron,

- on the highway it is necessary to organize a bypass that will allow to disconnect the pump, not breaking system work,

- installation of shut-off valves, filter and check valve.

- this group is mounted on a pipe that exits the boiler,

- the boiler must be below the safety valve,

- put first a pressure gauge, then a safety valve, and then an air vent.

Engineering systems from affordable polypropylene pipes can last up to half a century. Pipe products from the polymer are extremely simple to install, to connect them you need only one soldering iron. But is this material suitable for heating systems? Will the piping of the boiler be polypropylene durable and reliable? If everything is done by technology, the plastic pipelines deliver the coolant safely to the batteries.

Strapping is a set of heat engineering equipment that provides transportation of heated water to radiators and trouble-free operation of the heater itself. On the one hand, it helps to distribute heat evenly throughout the premises of the house, and on the other hand it increases the reliability of the whole heating system, protecting the boiler from overheating and over-consumption of fuel.

In the device for tying the boiler equipment there are certain nuances associated with different types of water heaters.

Image Gallery

Also, under the strapping of the heating apparatus, it is meant to calculate the parameters of all the elements of the indoor heating network and to install them. The heating system should work not only reliably, but also correctly. A large number of additional devices and complex wiring can seriously reduce its efficiency. Everything must be done competently.

Proper piping increases the efficiency of the water heater and the reliability of its operation

Optimal and ready for all buildings without options of heating systems simply does not exist. In order to maximize the impact of a particular boiler, it is necessary for each house to prepare an internal heat network project individually. But there is a certain set of standard rules and a list of standard equipment.

![]()

In the simplest scheme of tying the boiler heating with the gravitational motion of the coolant, the minimum shut-off devices (+)

Depending on the type of fuel used, the quadrature of the house, the heater model and its location, the strapping with polypropylene is done according to various schemes. But in all of them there are:

- Boiler (single-circuit or dual-circuit).

- Expansion tank. Hydraulic with diaphragm or usual capacity, depending on the type of heating system.

- Polypropylene pipes and fittings.

- Batteries (cast iron, steel, aluminum, bimetallic).

- Bypasses (sections of the pipeline, allowing to disconnect individual devices from the circuit). Recommended for all types of networks, but not always used in simple flow charts.

According to the principle of the coolant flow, the heating circuits are divided into systems with natural (gravitational) and pump (forced) circulation.

![]()

The circulation pump is a mandatory compulsory heating component. It is needed to stimulate the movement of the coolant (+)

In the forced-type heating network, the above set is complemented:

- Crane of Majewski.

- Circulation pump.

In the scheme with the supply of coolant to each device for the flow and return lines intended for it, the collector-distribution device is necessarily included. In heating circuits that require mandatory adjustment of the qualitative and quantitative characteristics of the circulating liquid or steam, control devices are built in:

- The manometer.

- Thermostat.

- Hydraulic arrow, if there is a need for pressure equalization.

In the system with forced circulation of the coolant to maintain the preset pressure in it, an expansion tank with a membrane is placed. And in its gravitational analog it will be enough to have a conventional open tank without any inserts inside.

The expansion tank of systems with natural movement of water contact with the external environment, because of what they can be saturated with air. To prevent this phenomenon, the systems are supplemented by an air circuit that collects and discharges air

The expansion tank of the simplest heating system with the natural principle of motion is a conventional container with a screwed or welded pair of pipes. One of them is the feed pipe, the second is the signal pipe, telling about the filling of the container with water that has expanded with heating. In a more sophisticated version of the tank, four pipes are already screwed.

With an increase in the volume of the heat carrier above the norm, excess is simply diverted through the signal pipe. In the future, the coolant will also expand and take the same volume in the same way, but there will be no more overflows to the signal branch pipe. Air by analogy is taken away spontaneously, therefore it is not necessary to install Mayevsky cranes.

Between the boiler and pipes from polypropylene a group of control and safety from various sensors, regulators and emergency valves

Circulating pumps in circuits based on natural principle coolant movements are not applied. In such a system, water moves under the influence of gravity. Her additional pressure boosters are not required. On the one hand, this increases the reliability of heating (there is simply nothing to break down), and on the other hand it reduces the quality of heating of the distant rooms in the house (to the extreme of them the coolant is already cooled down).

Polypropylene pipes in heating systems

Fittings and pipes made of polypropylene (PPR) are popular due to their cheapness and ease of installation. They are not susceptible to corrosion, have smooth inner walls and serve no less than 50 years declared by the manufacturer.

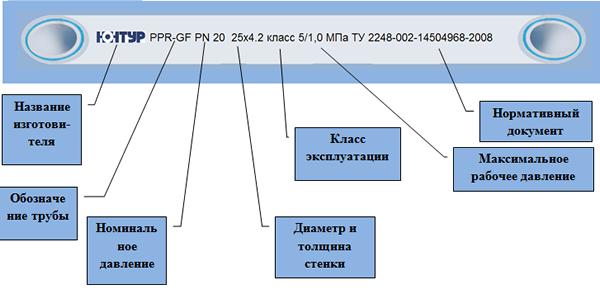

There are several types of these pipe products that differ technical characteristics and purpose. In the construction of heating systems, as well as in the device close to them for operational parameters, the DHW circuits are used:

- Pipes marked PN 25. Products with reinforcement, made of aluminum foil. They are used in systems with nominal pressure up to 2.5 mPa. Limit of operating temperatures + 95º С.

- Pipes marked PN 20. Enhanced version, used in the DHW branch of dual-circuit heating boilers. The period declared by the manufacturer will be fulfilled if the temperature of the coolant is not higher than +80 ° C, and the pressure is up to 2 mPa.

- Pipes marked PN 10. Thin-walled polymer products. Used if the boiler supplies the heating medium to the system of the water-heated floor. The operating temperature is not above + 45 ° C, the nominal pressure is up to 1 mPa.

Polymer pipes are suitable for all known ways of laying: open and hidden. But this material has a large coefficient of thermal expansion. When heated, these products begin to increase slightly in length. This effect is called thermal linear expansion, it must be taken into account when constructing pipelines.

The boiler is to be tied with polypropylene pipes, which have an operating class of 5 in marking, a working pressure of 4-6 atmospheres and a nominal pressure PN of 25 and above

To prevent the destruction of polypropylene heating pipes, it is possible to install compensating loops. But it is easier to take multilayer pipes, the reinforcement in which is specially designed to compensate for this stretching. The layer of foil inside the polypropylene tubes PN 25 reduces their thermal elongation by half, and the glass fibers in all five times.

Image Gallery

PPR piping installation features

Fittings with polypropylene pipes in a single heating system When tying the boiler, they are connected by a threaded method, and also by cold or hot welding. Screwing is much more convenient, but because of them the assembly of the system will cost significantly more. True, if desired, attach a polypropylene pipeline to a metal colleague without threaded fittings not enough.

For the formation of linear and nodal connections of polypropylene pipes, an extensive line of fittings (+)

"Hot" is welded with a special apparatus (a soldering iron, an "iron"). Pipes are heated with a suitable nozzle to a melting point of 260 degrees, and then the parts with softened edges are pressed against each other. The result is a reliable and solid connection.

Before welding, foil must be cleaned without fail. Otherwise, it will prevent the connection of polymer products, making the seam fragile. With fiberglass these unnecessary actions will not be required. He calmly melts together with the plastic.

PPR soldering technology is extremely simple, you can do all your work yourself (+)

Cold welding involves the use of a specialized adhesive composition. In recent years, this method is rarely used, because the result is not reliable enough.

In heating systems, threaded joints should be sealed by paronite or high-temperature sealant. Do not forget about the sufficiently high operating temperature of the coolant.

There is one more nuance of the use of polypropylene for tying the boiler heating. Antifreeze with plastic is a bad combination. It is recommended to use water as a coolant for a system of plastic pipes.

Choice of the layout of the heating system

There are several options for tying the boiler with polypropylene. For each house this scheme is selected individually. What is optimal in one building, in another can be ineffective.

In addition, heating systems based on the principle of water flow are divided into: forced with a hydraulic pump and gravitational (gravity, natural), there is also a classification for the construction of pipelines. According to their structure, they are one- and two-tube, collector beam or analogues with closed rings.

Which is better: drift or pump?

In the gravitational circuit, the heated water to the radiators from the boiler flows by gravity. A hot heat carrier, having a high temperature, always tends to replace a cooler liquid.

This system of tying the heating boiler is the easiest to assemble. In addition to the heater there are pipes made of polypropylene, radiators and an expansion tank. In version c top wiring water after heating rises to the highest point - in the expander, and from there it descends to the batteries. After recuperating the heat, it returns to the cauldron, where it is again heated, then starting a new cycle.

According to this scheme, heating is arranged in many houses in the country villages. Only there is a stove on solid fuel. This is the easiest and cheapest way to organize the heating of a small cottage. However, it has limitations both in terms of the number of radiators being connected and the remoteness of the outermost of them from the water heater.

The scheme of tying with natural movement of water is the simplest of all possible options, in it the minimum of nodes and points of connection of pipes made of polypropylene

More complex and expensive forced system. However, it greatly simplifies the creation of comfortable rooms in separate rooms. In it, the coolant moves already by stimulating its movement by a pump.

The choice of the layout scheme for pipes made of polypropylene and the boiler itself is closely related. A system with natural circulation is non-volatile. If the water heater does not require power from the mains, even if there is a power failure, the house will be heated.

AT compulsory scheme The pump needs constant power supply to work. Therefore, it is best for her to choose a boiler that is dependent on electricity, which has additional capabilities. But to hedge against stress problems, you'll have to buy them a backup generator or an uninterrupted power supply.

What to choose: single-tube, two-pipe or collector

There are many ways to build pipelines from polypropylene from the boiler to the radiators. But all these schemes are divided into:

- single-tube;

- two-tube;

- collector.

The first two options can be used both for gravity flow and for forced circulation. And the latter will only work if there is a circulation pump.

The single-tube scheme is certainly cheaper than a two-pipe, but the radiator in the chain from the boiler receives a minimum of heat energy (+)

One-pipe method means laying one looped line and serial connection to her batteries. In the two-pipe scheme, two independent pipelines from the boiler hot water and a return flow. And already they are connected to the radiators.

With the collector strapping, one or two collectors are built into the system, from which separate pipes are poured to each battery. Also, such a distributor allows connecting to the boiler a "warm floor" made of all of the same PPR.

Collector wiring makes it possible to create effective systems Heating for large areas and different number of storeys (+)

The use of collectors and separate risers for each battery leads to a significant rise in the cost of both design and installation. At the stage of project preparation, more complex calculations have to be made. And when assembling a much larger volume of polypropylene is consumed. But it turns out the system, each part of which can be adjusted to specific conditions and requirements.

Contour made of polypropylene for different boilers

Most water heater manufacturers recommend the first meter of the pipeline from metal. This is especially true for solid fuel devices with a higher outlet water temperature. Polypropylene with strapping should be connected already to this tap, otherwise in case of failures in the boiler it will receive a heat stroke and may burst.

Option # 1: Gas Water Heater

It is recommended that the polypropylene strapping of the gas boiler be performed using a hydro-gun and a collector. Often, gas models are already equipped with built-in pumps for pumping water. Almost all of them were originally intended for compulsory systems.

The most reliable in terms of safety will be a circuit with circulating equipment for each circuit behind the collector. In this case, the built-in pump will pump pressure on a small section of the pipeline from the boiler to the distributor, and then additional pumps will be used. It is on them will be the main load on the transfer of coolant.

Bonded polypropylene gas boiler can be without long metal pipes, water in such a heater rarely when heated to 75-80 degrees

If the gas boiler has a cast-iron heat exchanger, then when it is strapped into the system, an additional heat accumulator should be installed. It will smooth the sharp changes in water temperature, which have a negative effect on cast iron. With a sudden heating or cooling of the coolant, it may even burst.

When tying a two-circuit device with parallel heating of water for DHW, this filter will also have to install fine and coarse cleaning. They should also be mounted at the entrance to the water heater, where cold water is supplied.

Option # 2: Solid fuel model

The main feature of the solid fuel boiler is that it is inert when the fuel supply stops. While everything in the furnace is not completely burned, it will continue to heat the coolant. And this can be detrimental to polypropylene.

When strapping a solid fuel boiler, only metal pipes should be connected directly to it, but only through a meter and a half it is possible to cut polypropylene. In addition to this, it is necessary to provide a reserve supply of cold water for emergency cooling of the heat exchanger, as well as its diversion to the sewage system.

The section of the pipeline from the solid fuel boiler to the collector should be made of metal, and it is already possible to carry out the strapping with polypropylene - only this protects the plastic pipes from overheating

If the system is built on forced circulation, then it will be necessary to install an uninterruptible power supply for the pump. Water must constantly remove heat from the furnace, where solid fuel burns, even in the event of a power failure.

In addition to it, a small gravitational circuit can be made, or all batteries can be equipped with bypasses to disconnect individual parts of the system. In case of accidents, this will allow repairing the damaged section when the heating is in progress.

The solid fuel boiler must be covered with a protective casing, which limits the spread of heat from the furnace walls to the boiler room. But even with its presence, the collector and plastic pipes should be removed away from the stove.

Option # 3: Heaters for liquid fuel and electricity

The boiler on the working or diesel is tied with polypropylene in an identical scheme with a solid-fuel analog. The polymer must be removed from it as far as possible.

When tying the electric boiler PPR, you do not have to worry about the gusts of the pipes, there is a protective automatic system that does not allow the water to reach the boiling point

Heating of the coolant in the water heater by electricity to critical temperatures for polypropylene is virtually eliminated. With the loss of voltage, it simply stops working. From hydraulic shocks the pipes in this case are protected by a hydraulic accumulator and valves to relieve excess pressure.

Video about pipes PP and ways of tying them with boilers

How to choose pipes from PPR:

Solid fuel boiler piping technology:

How should I tie a heater in a two-story cottage:

Choosing the scheme of piping the boiler with polypropylene pipes, it is necessary to take into account all the features of a particular building. The process of installing pipelines and connecting equipment is not complicated, even a novice master can cope with it. With a soldering iron for polypropylene fittings and pipes it is easy to work. But here it is better to entrust the preparation of the heating system project to a specialist, errors are unacceptable here.