Principle of operation of the coarse filter. Rating of the best rough water filters for the house. The use of a woven filter

Passing through complex communication systems from the water station to the consumer, water very often stops responding health standards. First of all, this is due to the imperfection of water mains, most of which have long been in need of replacement. Perhaps the simplest and most accessible filtering means is a coarse water filter. And although it does not help remove absolutely all impurities, the largest suspended particles will be eliminated, which will significantly improve the quality of water in the house.

Facilities mechanical cleaning water

Tap water filtration: prejudice or need

Using water from the tap without pre-cleaning, many do not think how harmful it is to the body. The fact is that water is an excellent solvent for various chemical components that have a negative effect on human organs. Of course, there are special treatment facilities, but they usually remove only the most dangerous contaminants at the entrance to the water main. In addition, municipal pipelines do not always meet hygiene requirements, therefore, often water reaches a consumer with a different quality composition.

Important! Excessive water hardness can be the cause of increased deposition of salts in the body. The content of manganese and iron exceeding the norm negatively affects the bone system, promotes liver diseases and increases the risk of cardiovascular diseases.

The need for a coarse filter for tap water is also caused by the detrimental effect of large suspended particles on household appliances and plumbing. Various deposits can lead to a rapid breakdown of expensive equipment, forming plaque and clogging small through holes.

Impact of raw water on household appliances

The principle of mechanical cleaning

Rough water treatment is the mechanical removal of suspended components (sand, rust, etc.). Usually the particles to be removed have a size of 15 microns and in some cases are easily discernible to the naked eye. That's why this sort of filtering is considered rude.

The principle of the filter for mechanical water treatment is similar to sifting grain or cereals through a fine sieve (mesh). Filtering is subject only to large particles, the size of which does not allow to overcome the filter zone. In this case, there is no sense in sequentially installing several coarse filters, since the first element in the line will fully cope with its task, while the others will only create additional hydraulic resistance in the pipeline.

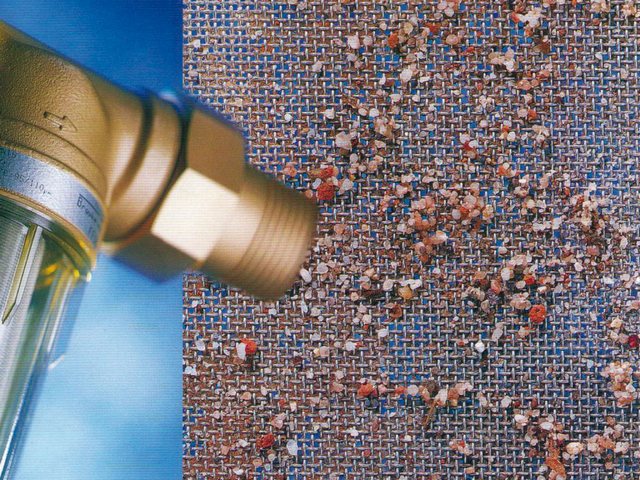

Sieving the suspended particles with a grid

To increase the efficiency of filtration, after the coarse, fine water purification is performed, the difference of which lies in the lower capacity (< 5 мкм). В этом случае в роли фильтрующего элемента выступает сорбционный материал (например, уголь), ионообменная смола или мембрана reverse osmosis.

Types of coarse filters

Structurally, the filters for coarse water purification for houses and apartments are not very complicated and are quite easy to maintain. Their advantages include:

- low cost;

- simple installation;

- convenient operation;

- wide temperature range of application;

- durability.

Depending on the device and the filtration method, the mechanical filters for rough cleaning are divided into mesh and cartridge filters.

Mesh

The mesh filter has small dimensions and a simple device. As the name implies, in this case the filter element is a metal grid that is capable of screening out large suspended particles of sand, clay or rust, often found in tap water.

For your information. Mesh devices belong to the class of trunk devices, since they are installed directly in the water pipe. Due to their resistance to temperature, they are widely used in cold, hot water supply lines, as well as heating systems.

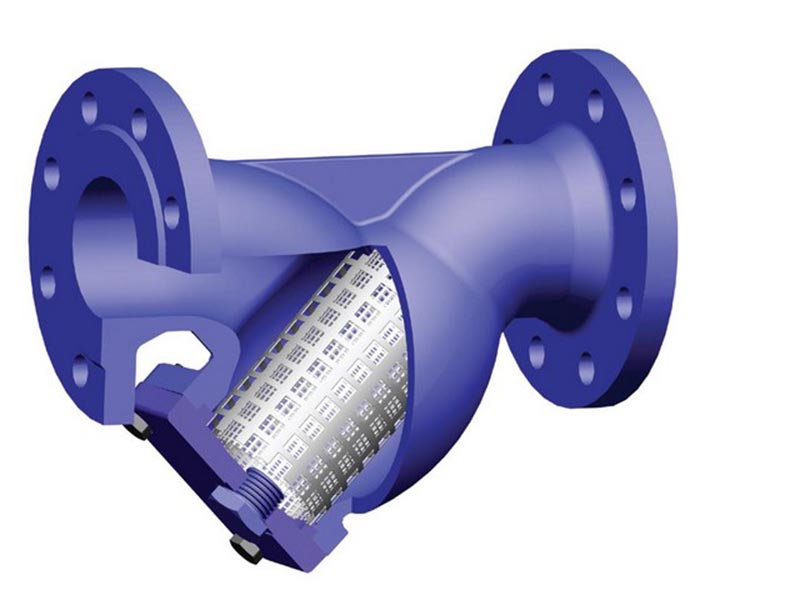

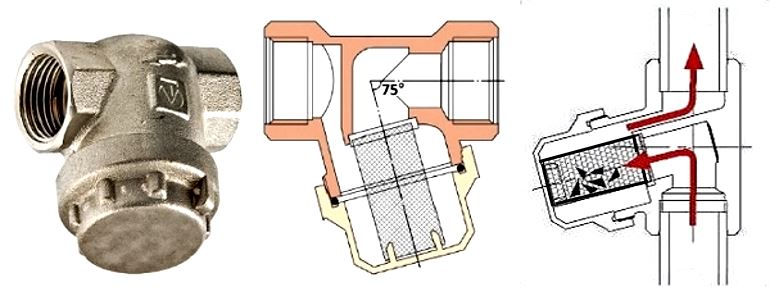

The pre-filter pre-filter consists of an inlet and outlet branch pipe, as well as a special reservoir (sump), in which, in fact, filtration is carried out. The settler can be located both perpendicular to the main line, and be executed in the form of an oblique element.

Strainer in section

The direct design of the clarifier means an exceptionally horizontal arrangement. In addition, such filters often have larger dimensions, so the installation requires sufficient space under the pipe.

Unlike the placement of direct devices, the installation of a coarse coarse filter can be carried out not only horizontally, but also vertically. Since the oblique filters are less dimensional, they can be mounted on a pipeline that passes in the immediate vicinity of the floor or wall.

Cartridge

The use of a cartridge contributes to more effective filtration. Externally, the cartridge devices look like a vessel with a double wall - outside is a transparent or opaque housing, and inside the filter element.

Interesting to know. The shape of the cartridge resembles a cartridge. Hence the alternative name - cartridge filter.

The principle of operation is as follows: water enters the body cavity, passes through the cartridge, which detains large inclusions, and returns back to the main line. Since the filter zone and settler are more voluminous than those of simple mesh devices, cleaning or replacement of the filter element is much less frequent.

Cartridge filter (cartridge) filter for rough water treatment

The body can be made of metal or plastic. In this case, for cold water Usually a transparent glass is used, which makes it possible to visually observe the level of contamination of the cartridge. Whereas for hot water supply, filters of opaque material are used.

Installing and maintaining the filter

To understand how to properly install a coarse water filter, you need to know some installation rules. In addition, such devices involve the periodic performance of treatment activities, without which the filter will quickly be blocked with debris, which will significantly reduce the quality of the water flow.

Installation rules

- The water pre-treatment element is best installed in front of the meter to protect its parts from the effects of large insoluble particles.

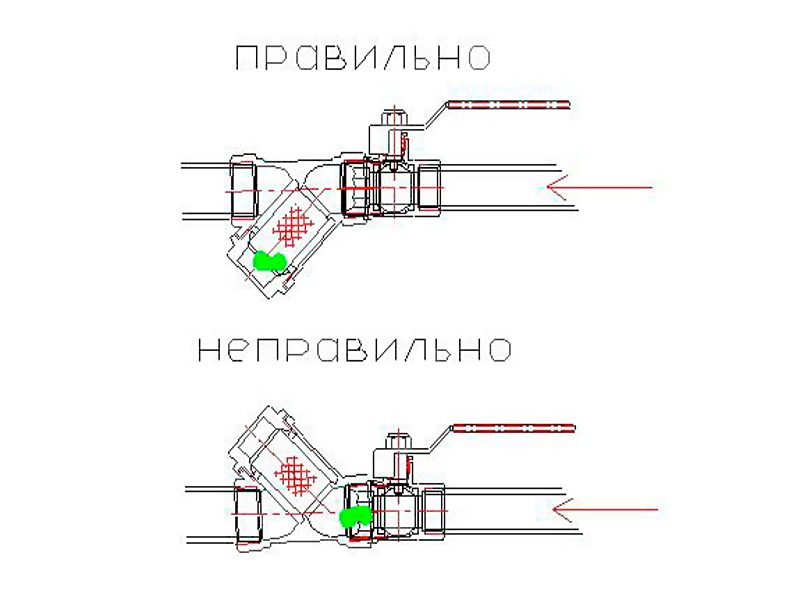

- When installing, be sure to take into account the direction of the flow of water and make the installation according to the arrow indicated on the body of the product.

- The installation of a strainer of coarse water purification in a vertical pipeline is allowed only in the case of an oblique settler and only when the water flow moves from top to bottom.

- Installation of the product with a direct settler is carried out only in a horizontal pipeline. In this case, it is necessary to provide a place for the possibility of carrying out treatment measures.

- Do not install the filter cover on top. Both the straight and the oblique settler must be pointed downwards after installation.

Filter layout

Cleaning the filter element

Since the principle of the coarse mechanical cleaning filter is based on the delay of suspended particles in the water, the filter element must be cleaned or replaced over time. To do this, it is necessary to unscrew the so-called mud collector, in which the filtered elements accumulate, then rinse the mesh, cartridge or replace them in case of large wear.

Note. Some filters are additionally equipped with a washing system. In this case, it is sufficient to periodically open a bottom-mounted faucet and remove dirt under the pressure of water into the sewage system or a separate container.

If the washing system is not available, all garbage must be removed manually. To do this, pre-close the pressure line, unscrew the sump or flask, carefully remove the filter element, rinse it underwater or replace it.

Treatment measures should be carried out at least once every 3-4 months

Since it is a question of a pressure main, all works on installation, cleaning and replacement should be carried out extremely accurately. If you do not know what type of coarse water filter is installed in the apartment, or if you doubt your own strengths before carrying out routine maintenance, then it is much safer to turn to specialists to prevent emergencies.

The first level in a competently organized system of quality water filtration is a coarse filter. This is a small device designed to collect mechanical impurities and dirt particles contained in the consumed liquid. One of the types of such devices is a strainer of coarse water purification with a different level of contamination. The equipment is very in demand, because it differs:

- simple installation and easy maintenance;

- the available cost at a sufficiently high efficiency;

- wide model range of devices - are made for the purification of water containing insoluble suspensions of various sizes. The grid is capable of retaining particles with a diameter of 50 to 500 μm.

Mesh devices can be used as independent filters, and be an integral part of the scheme of a quality filtration system. They effectively remove rust and sand from the water, foreign particles that enter it as the substance passes through rusty, overgrown and not repaired pipes. After cleaning the liquid of impurities and particles of dirt, it does not become 100% suitable for drinking, but the use of such water (without mechanical suspensions) has a special consumer value. A properly selected and installed water strainer increases the quality of the substance, which means:

- protects the water-heating and water-consuming equipment from premature failure;

- reduces the intensity of clogging of fine filters;

- reduces the cost of purchasing consumable filter elements;

- increases the performance of ultrafine cleaning and mineralization filters.

The advantage of the device for coarse filtration of water is its versatility. Manufacturers produce various types of mesh devices, the installation of which is performed directly on the pipes of the water supply system. What types of grid filters are there? How to choose a device?

The principle of the mesh filter and its types

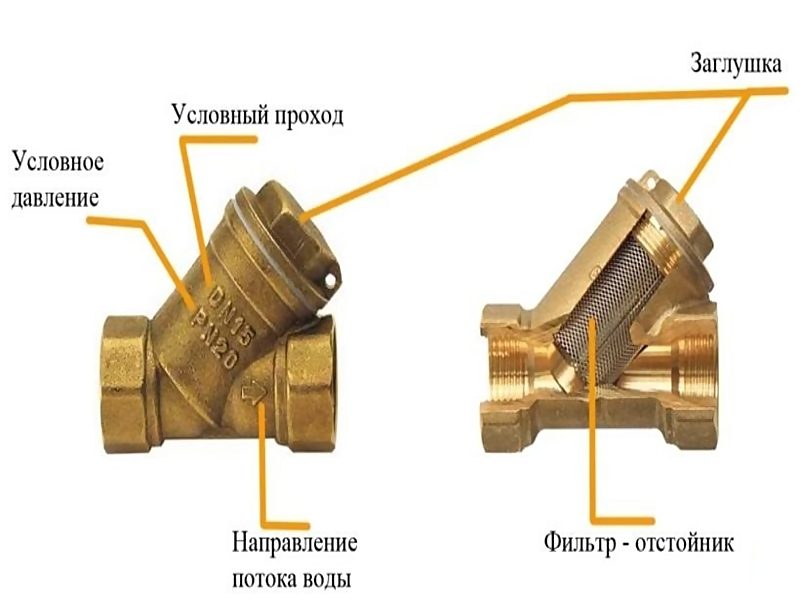

The main filtering element of the device is a grid (cylindrical shape) with passing cells of a certain diameter. It is usually enclosed in a metal stainless housing, which can be equipped with a special plug in the form of a nut or a crane. The shape of the case resembles an elongated flask with the removed nozzles (flanges for simple and quick connection of the device) and a container for the spent substance (sump).

Installation of the water filter is performed at the water inlet to the house or apartment. The installation site is selected before the pipeline is routed to the water supply points. If water meters are provided, then the device is installed in front of the meter. When the faucet is opened, the substance passes through the pipes, overcoming the obstacle in the form of a mesh filter element. It retards all undissolved impurities with a diameter larger than the diameter of the cell passing through the grid.

Since the operating conditions of the mesh filter element can be different, manufacturers offer several types of devices for rough water treatment:

- Slanting and straight grid filters.

Division into direct and oblique devices is carried out by placing the settler. In the first case, the container has an arrangement strictly downward. That is perpendicular to the course of the water. Their distinguishing feature is the overall dimension. To install a straight strainer for coarse water, you need a lot of free space in the area below the pipe. But it is the increased dimensions of the vertical capacity that provide better filtering. In slanting filter grids, the tank is placed at an angle to the flow of water in the pipe. They are convenient to use on pipes that run near the floor or are laid vertically.

- Muff and flange filters-grids.

The breakdown is carried out by the method of mounting the equipment on a water pipe. Flanged devices are suitable for pipelines with diameters in excess of 2 inches (interchanges, trunking systems, etc.). Their main advantage is simple and easy dismantling due to studs and bolts. The second type of device is suitable for pipes up to 2 inches in diameter. They are screwed onto the water pipe, which complicates their dismantling.

- Mud and filters with rinsing.

The separation of the coarse filters is also carried out by the method of cleaning the settler tank. Devices that are not subject to manual washing are mud pumps. These include oblique and some groups of direct filters. They are supplied with a special lid for easy operation. In direct filters, where the grid for the coarse water filter is located perpendicular to the water flow, a tap for discharging the waste liquid is provided.

Pros and cons of the coarse water filter

Filters for coarse filtration of the substance are produced by many manufacturers. But devices adapted to difficult operating conditions offer only a few brands:

- Valtec;

- Honeywell;

- ITAP and some others.

These same manufacturers also release on the market and consumables to the devices - a grid for a coarse filter and other elements. Of course, with such filtering equipment, the degree of purification of the substance is quite low, but taking into account the condition of the water supply systems in 87% of the dwelling houses, one can not do without them. Mesh filters are a cheap way to purify water from mechanical undissolved in liquid particles, which has a number of advantages:

- there is no need to purchase additional equipment for maintenance and installation;

- do not need skills to perform installation and cleaning of the clarifier;

- restoration of effective efficiency;

- cheap accessories;

- high indicators of environmental safety;

- cost-effective maintenance - the replacement of the mesh is less frequent than changing the cartridges.

When buying a strainer, you pay attention to the size of the cells of the element. For coarse cleaning, a mesh of 100 microns is sufficient. Do not forget about the specifics of the location of pipes and their diameter. Having determined the parameters, you can make a purchase.

To pre-purify the water flow to residential or public premises, it is recommended to install filter elements at the inlet of the water supply network. Despite the preparation of drinking water in urban wastewater treatment plants, water meets the sanitary and epidemiological standards in residential or representative premises through a branched network of pipelines.

The inclusion in the measuring unit of water fittings, which helps to maintain the accuracy of the CCP measurements, is recommended by all water meter manufacturers. Therefore, for additional cleaning, a filter is installed, in front of the water meter.

The main provisions for the installation of "mud" filters

The most common devices for rough water treatment, due to their versatility, cheapness and ease of installation, are oblique mesh filters. The reservoir in the slope is equipped with a cylindrical mesh and a plug. The flow of water passing through the filter element is cleaned of mechanical impurities with a size of more than 10-15 microns.

In many cases, such a device helps to save the mechanisms of not only the CPUs, but also many other home appliances that use water in their work. Thinner filters that capture small dirt particles can be installed at the entrance to the instruments or on mixers. When installing a filter, observe several rules:

- the filtering device is installed immediately after the shut-off valve, at the water inlet to the apartment;

- the direction of the water in the pipeline must coincide with the arrow marked on the valve body;

- on vertical sections, the filter is installed with the direction of the water flow from top to bottom;

- the sump is always placed downside down by a cork, under which it is necessary to provide free place to remove the mesh.

The fittings are selected according to the parameters of the apartment water supply system, according to the conditional pass of the pipes and the working head, these data are always indicated on its housing. The connections of the branch pipes, the filtering device, are amplified by a FUM tape or a linen pack. Short-term water supply checks the reliability of installation, in the absence of leaks - the filter can be used without fear.

Depending on the degree of water pollution, the filter cleaning measures can be either a rare occurrence or rather frequent. It is recommended to check the filling of the mud compartment of the filter regularly, at least once a year, without waiting for the decrease in the pressure of water. Prolonged finding of a threaded joint in an aggressive environment leads to a build-up of the lid and it becomes difficult to remove.

Our company, conducts a complex of works on maintenance of apartment metering devices, which includes cleaning of the coarse water filter. Before the meter is installed not only a filter, but also a shut-off valve, the failure of which, in case of inaccurate treatment, can lead to an accident.

Sequence of work:

- shut off the water;

- with a wrench, carefully and without jerks, remove the cover from the slope;

- remove the mesh and clean it with a stiff bristle brush with a short nap;

- at defects of a grid, to update it;

- clean the tank chamber with improvised means;

- replace the mesh;

- screw the cover, replacing the seal on the thread;

- turn on the water and check the connections.

If the filter was included in the sealing chain, it is necessary to warn the housing office about the removal of the seal so that at the end of the event they restore the seal.

To our great regret, the water used in our houses and flats from the water supply system, in most cases, does not fully comply with the accepted hygiene and sanitation standards. And it's not that the liquid can contain any harmful microorganisms or a large concentration of chemicals, because water, as a rule, is subjected to thorough testing at water stations. This is a large number of insoluble particles that enter the water, including those extracted from the well. The water filter will help to get rid of this problem.

The device is universal and is intended for use in private housing construction and cottage cottages, where water from a well or well is used.

The use of the filter under such conditions is obvious, since particles of dirt, clay and other impurities that are always present in the well or well may get into the crane along the pipes, together with water.

In case of apartment buildings Water is not supplied to the consumer in the best condition, given the serious wear and tear of the existing water supply networks in many cities of our country.

Therefore, a coarse filter is necessary to solve the problem with the quality of the liquid consumed.

Main reasons for using the device:

- Prevents the ingress of impurities into the water supply and heating system.

- Reduces the load on other filters used (fine cleaning, aeration, deferrization). As a result of the preliminary cleaning, they receive a smaller amount of impurities, it prevents the ingress of insoluble particles into the cranes, household appliances, hydraulic accumulators, etc.

The coarse water filter is a fairly simple device that includes a grid that stops and does not allow impurities to pass through. It is enclosed in a metal case, which has an inlet and an outlet.

In addition, the device has a special settling tank, where water filtration is carried out.

Principle of operation: the water passing through the filter retards its movement in the settler, so that the impurities in it settle on the bottom; After passing the water through the mesh, the latter effectively delays the dirt.

The mesh element of the filter can be made of several materials. In most cases, it is steel. More rarely - brass or bronze.

Interesting! Virtually every device has good strength and resistance to mechanical damage, withstanding severe pressure drops.

The differences between them are in the way of connection to the water supply system, since some models have a coupling coupling, others are flanged. Using of different types connections is due to the unequal size of the pipes.

When operating 2-inch models and more, a flanged connection is required, with a smaller diameter - a coupling.

The key parameter for all types of filters is the size of the grid cells. The smaller they are, the more dirt settles and does not fall into the tap afterwards. For these devices, the mesh parameter ranges from 50 to 400 μm.

Based on the form of the settler, the coarse water filter is divided into two types:

Based on the form of the settler, the coarse water filter is divided into two types:

- Straight - the settler is located perpendicular to the water flow, forming a T-shaped body with inlet and outlet nozzles.

- Scythe - striking in appearance. It is installed at a certain angle to the water flow due to the design features of the system section. The efficiency of such a device is slightly lower, but within the framework of household needs the filter successfully copes with the tasks set.

By way of cleaning filters are divided into:

The most perfect variant for today is a self-cleaning strainer. It is equipped with two sensors, at the inlet and outlet of the liquid. The sensors measure the pressure and record its differences.

If the output decreases, the device needs to be cleaned. The process of preliminary and subsequent cleaning is carried out through a special valve.

Basic rules for connecting the device

- The coarse filter must be installed in front of the meter.

- Installation of the oblique model must be carried out by the settler down and also in front of the counter.

- It is necessary to ensure the correct location of the direct filter in the horizontal section.

- The direction of the arrow on the filter housing must correspond to the direction of flow of the liquid. This must be checked before installation.

This is a procedure that, sooner or later, needs to be done, even if you have the most modern version of the filter model.

Before disassembling it is necessary to reduce the pressure in the system, which is achieved by pre-blocking the water supply.

Almost all oblique models have a cork. It can be unscrewed with an ordinary wrench.

Almost all oblique models have a cork. It can be unscrewed with an ordinary wrench.

Experienced masters, in the process of cleaning such a filter, recommend immediately to replace the paronite gasket with the tow, which will ensure a more convenient removal of the plug in the future, and does not break the integrity of the entire structure.

In the vertical model, the flask is also removed with a wrench. During the processing of the structure, before carrying out reverse installation, it is necessary to check the condition of the rubber seals that seal the structure.

After disassembling the filter, it is cleaned. The accumulated dirt in the oblique model can be drained into any container. Then remove the mesh and thoroughly cleaned of dirt. If malfunctions are found, the mesh must be replaced.

In the case of a direct filter, the sediment from its reservoir also merges when it is opened, the mesh is washed and old cartridges are replaced.

If a self-cleaning filter is installed in the system, the cleaning process is reduced to opening a special valve for draining the liquid. The structure is cleaned independently with the help of water pressure.

Selection of the optimal model

The main indicators that are taken into account when choosing a device and affect the prices are their performance and the linear size of the retarding particles.

Important! Productivity is determined based on the amount of water consumed to avoid interruptions in supply or a significant reduction in pressure.

When working with low-performance models, it is necessary to install a special tank where water will accumulate while there is no need to use it. When the crane is opened, the required volume of consumption is ensured.

The size of the cells in the grid must be proportional to the quality of the liquid that the filter will purify, the number and types of insoluble particles.

If you use a device with small cells in the grid when cleaning heavily soiled water, the filter will have to be disassembled quite often to get rid of the accumulated dirt.

Since the prices for such designs are quite democratic - the best option successively install models with large and smaller mesh.

In addition, it is necessary to know that the models of designs are constantly being improved by manufacturers, and in different directions. Therefore, filters of known brands, as a rule, have their own individual characteristics, which should also be taken into account before making your final choice.

In any water entering the house autonomously from a well or centrally from a water pipe, there are mechanical impurities. In untreated water there may be grains of sand, particles of scale and rust, fragments of calcareous plaque, peeling off the inner walls of pipes, reeling elements used for sealing pipe joints, and other foreign substances. Water of this quality harms not only the health of people, but also household appliances, shortening the period of its operation, as well as accounting devices installed by residents to save money when paying for utility services.

By installing a coarse water filter in hot or cold water supply systems, it is possible to significantly reduce the amount of abrasive particles and insoluble suspensions. Further, depending on the purpose of use of each particular point of draw-off, it is recommended to install additional fine filtration devices that can remove smells, organic compounds, chemical elements, heavy metal compounds and even some microorganisms. Select a specific filter model will help, conducted in the laboratory.

The device and types of coarse filters

All filters that provide mechanical water purification have a similar device. Inside the body, a metal mesh or other filtering element (disks that cut off large fractions of sand, rust, etc.) is located along the water course. An obligatory constructive element of such filters is a tap, in which the contaminations trapped by the grid settle. When the sump is clogged, the water supply is blocked, and the tap is cleaned and rinsed. The frequency of this procedure depends on the concentration of mechanical suspensions in the water. It is recommended to carry out preventive cleaning of the mud collector at least four times a year.

In different models of mechanical water treatment filters, a single operating principle is laid down. However, this does not prevent them from differing from each other in a number of ways, such as: a filter element, a form, a method of tapping into a water mains network, and a method of cleaning the mud from settling in a settler.

Mesh and cartridge filters

In the mesh filter-sump as a filter element is a metal mesh, made of stainless steel. The grid cells vary in size from 50 to 400 μm. The filter is installed so that the revision cover is located at the bottom. Fixing the filter to the pipeline system is carried out by the usual tools available for each plumber. When performing threaded connections, ensure their absolute tightness, avoiding water leaks.

The mesh filter with an oblique outlet is equipped with a screw cap, which is necessary for cleaning the mesh from contamination

Filters-grids are very popular among consumers because of their long service life, during which no need to replace filter elements. This is their undeniable advantage, which cartridge cartridges do not have, which purify water from mechanical impurities.

Models with replaceable cartridges are attached to the wall, since their design includes a bulb of impressive dimensions. The walls of the bulb can be either transparent or not transparent. Inside the bulb is a replaceable cartridge made of polyester, a twisted polypropylene yarn or compressed fiber. Cartridges have different filtering ability. To perform rough mechanical cleaning of water, cartridges of 20-30 microns are chosen. After clogging the filter element, it is replaced with a new cartridge.

Important! Washing the used cartridge and its reuse in a filter is prohibited!

Installation of cartridge-type models is usually made in tandem with mesh products, thereby providing better mechanical filtration of the water flow. In this case, the screen filters are installed in front of the bulb devices. In this case, the life of the cartridges is increased.

Straight and oblique strainer

All types of mechanical cleaning filters have two nozzles (inlet and outlet), as well as a settling tank in which the water flow is directly filtered. According to the location of this settler, grid filters are divided into two subspecies: oblique and straight. In the first group, the settler is at an angle to the current of the water. Apply oblique filters on pipes located at a short distance from the floor, as well as on vertically located sections of the pipeline.

In the second group, the sump is sent strictly downward, perpendicular to the flow of water. Direct filters have large dimensions, so there must be enough free space under the pipe for their installation. Due to the larger volume of the settler, the vertical filters purify the water more qualitatively. The clarifier is closed using a screw plug or a flange cover.

Mesh filters with a vertical settler are installed on horizontally located pipes, under which there is free space for preventive maintenance

Flanged and box mesh filters

According to the method of inserting the filtering device into the water pipe, flange and coupling filters are distinguished. The first type of products (flanged) is mounted on pipes having a diameter of two or more inches. Such sizes are the main water pipelines, as well as interchanges, performed in the cellars of multi-storey residential buildings. Thanks to the bolted or hairpin connection of the flanges, the filter can be easily removed if necessary, while removing other elements of the water supply system is not required. The installation locations for flange-type models on pipes are determined at design time project documentation to the water supply.

Important! On pipes with a diameter of up to two inches, install threaded filters that screw on them or connect them with quick-release union nuts, called "American".

Mud and mesh filters with washing system

The screen filters are also divided according to the method for cleaning the settler from contamination. Non-flushing products are called sumpers. This category includes all slanting and a series of straight (vertical) mesh filters equipped with a removable cover. To clean the sump of the device of dirt, it is necessary to disassemble the device and rinse it.

Direct filters with a perpendicularly located settler equipped with a flushing system have an outlet valve. This tap allows you to drain the settled sediment into the sewerage system, and also clean the tap by direct or reverse flow of water.

Self-cleaning screen filters produced by the German company Honeywell, which is the leader among companies that manufacture this type of equipment

How is fine water purification done?

Rough (mechanical) filtration relieves water from most of the contaminants, but it is not able to completely clean out a number of chemical elements and their compounds. Therefore, manufacturers offer equipment for fine water treatment, based on the use as a filter element:

- sorption materials (activated carbon or aluminosilicate);

- reverse osmosis membrane;

- ion exchange resins.

It is important to note that the working elements of these filters have to be changed. The frequency of replacement of cartridges is indicated by the manufacturer. This value may depend on the time of use, as well as on the volume of the filtered water.

Multi-stage systems - ultra-thin cleaning

In multi-stage water purification systems after mechanical filtration, the water flow is treated with ultrathin cleaning filters, which are divided into several groups. More information about each of them can be found in this video:

A three-stage filter for fine water purification makes it possible to obtain drinking water good quality. The first stage is responsible for purifying water from mechanical impurities. As a result of this stage, turbid water becomes transparent, but the cleaning process does not stop there. In the second stage, water passes through the ion-exchange cartridge, which changes its chemical composition. Petroleum products, pesticides, iron, chlorine and nitrates are removed from the water. When the water is boiled, after two-step cleaning, no scale is formed on the walls and heating elements of the kettle.

Multistage filters for ultra-fine water purification for drinking without pre-boiling consist of two or three flasks, in which cartridges of different action are placed