Installation of polypropylene pipes in the apartment. Wiring options. What is necessary for the independent installation of the water supply system?

With the development of advanced technologies and the development of new materials in the construction market, polypropylene (plastic) pipes appeared. Due to the affordable price, ease of use and high performance properties, they quickly gained popularity in sanitary works.

This article contains a brief description of plastic products, information on how to carry out the installation poly propylene pipes + instructions for the installation of systems of these materials.

Varieties of polypropylene

There are several varieties of propylene.

The main ones are:

- Homopolypropylene. A sufficiently hard polymer, resistant to bending.

It can contain various additives that significantly change the characteristics of the material.

- 1.1. Antistatic additives prevent the accumulation of dust.

- 1.2. Nucleators give the material transparency.

- 1.3. Fire retardants make plastic more flame resistant.

- Block polypropylene copolymer has a high elasticity and impact resistance. Resistant to alkali and acids at high temperatures.

The most common method of modifying this polymer is the introduction of flame retardants and antistatic additives. - St copolymer of polypropylene has two varieties: transparent and opaque. Transparent is more often used for the production of food containers, and opaque is used in hot water supply.

Despite the low cost, it is quite strong and reliable material.

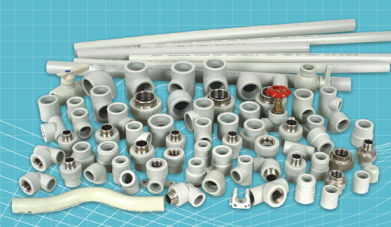

Types and scope of polypropylene pipes

- the product is monolithic. The modern market provides its various types.

Widely used:

- PPH from homopolypropylene. The main areas of its application are industrial pipelines, cold water supply, ventilation.

- RRV from block copolymer of polypropylene. Used in cold water supply, outdoor heating systemsoh.

- PPR of a polypropylene stator copolymer. It finds application in cold and hot water supply, water and floor heating systems.

- PPs -of heat-resistant polypropylene. The maximum temperature of its working medium is 95 ° С.

Practically in any pipelines installation of polypropylene pipes is permissible. They are used in heating and sewage systems, for the supply of drinking or technical water. They can be successfully used in repair work to replace damaged sections of metal pipes.

Polypropylene communications are pipes of different thickness and diameter. They can be purely plastic or reinforced.

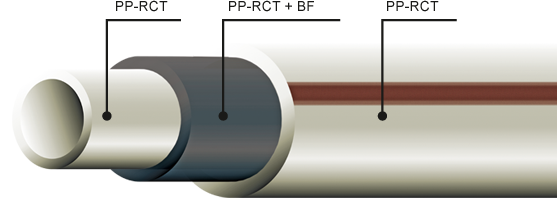

In the cold water supply, pipes made of homogeneous polypropylene are mainly used. For hot water supply and heating systems, they are reinforced with aluminum foil. This technique helps to significantly reduce the temperature elongations, which are pronounced in homogeneous polymer pipes.

The walls of reinforced pipes are three-layered - two layers of plastic enclose aluminum. In a perforated pipe, the aluminum reinforcement is made in the form of a grid with a small diameter of the cells. Such a device has a high resistance to rupture and provides reliability under high pressure loads.

Installation of polypropylene pipes

If the work is carried out the instruction - installation of polypropylene pipes is quite simple. The system is easy to install with the help of pipe end splicing special with nozzles. The joints are reliable.

Provided the technology is complied with, regardless of the quantity, the welding joints do not affect the reliability of the pipeline.

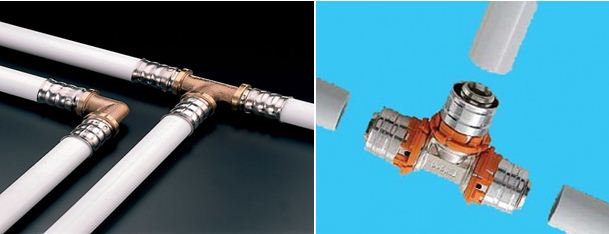

The second variant of connecting pipes is the use of special fittings. This is especially true when the pipe is connected to metal parts.

Despite the easy assembly and other advantages plastic pipes, their installation is better to entrust to professionals.

Do not neglect the protection of PPR pipes from freezing. The pipes themselves, due to their elasticity, can withstand the freezing of water inside themselves.

But the metal parts of the pipeline, including the stop valves, will suffer from this.

Installation instructions

This installation instruction for polypropylene pipes will help to avoid errors in the installation of pipelines.

General information

Use damaged or contaminated material and parts for work. During transportation, storage and installation all material should be protected from mechanical damage and open fire.

During installation, the temperature of the air at the work site must not be below +5 ° C. The quality of the connections depends on this.

Bending of pipes without heating can be carried out at a temperature of + 15 ° C and above.

For pipes with a diameter of 16-32 mm, the bend radius can not be less than eight diameters of the bent pipe.

To cross the pipelines use a special piece - crossing.

Polypropylene parts are connected by means of polyfusion welding, butt welding or electrofitting.

When connecting threaded fittings use special sealing materials. Do not cut the thread on the pipe.

On the installation of polypropylene pipes, the instruction contains recommendations that ensure high-quality performance of the work.

Pipeline laying

When installing the pipeline, it is necessary to withstand minimum gradient in the direction of low places - 0,5%. There it is possible to drain with the help of drain valves or drain valves.

The pipeline must be divided into sections that can be blocked if necessary. For this purpose, valves and ball Valves. Preliminary check their performance.

At the points of installation of the bilge fittings, the pipeline ends with wall angles or a wall set. It is adjustable along the axes, depending on the type of mixer.

Wall angles and sets, before the installation of water-separating devices, must be closed with plastic stoppers.

This will protect them from clogging and damage.

Wall brackets should preferably be attached to a rigid wall set holder. It will ensure the immobility of the knees.

For the distribution pipeline use pipes with a diameter of 16-20 mm. They fit into a prepared channel or stroba.

When laying a pipeline route, one should take into account the propensity of polypropylene to linear temperature expansion. Therefore, when installing an insulated pipeline, the chute must be free.

When the installation of polypropylene pipes is carried out in the assembly shafts, fastening is carried out with the help of supports, holders and clamps.

Pipe laying in the structure of the floor or ceiling is carried out in protective flexible pipes. They will protect the pipeline and, due to airspace, provide thermal insulation.

Installation of risers

Ramps should be installed taking into account the placement of fixed supports and creating a free compensation of linear expansion. Compensation is provided by mobile supports at the base and at the top of the riser.

The separation of the riser into several compensating sections is carried out by installing fixed supports. Between the fixed supports provide compensation expansion pipes.

Pipes can only be cut with a well sharpened sharp tool. It is recommended that a cutting tool for plastic pipes or special scissors be used for this purpose.

The connection of the transitions from plastic to metal in heating systems and hot water can only use transitions with a pressed insert made of nickel-plated brass. In this case, tighten the threaded connections with the key with the tape.

Sealing of threaded joints the instruction for the installation of polypropylene pipes is recommended to be carried out with the help of teflon thread or tape, or a special sealing paste.

Welding

For splicing polypropylene pipes, in addition to fittings, you can use welding - polyfuse, butt or with electrofitting.

The most common method is diffusion welding. It is based on the physicochemical features of the material. Polypropylene for a strong connection sufficiently to warm up to +260 C and tightly press down. When cooling, a reliable connection is formed.

High specifications pipes made of polypropylene led them to the leaders in the construction market.

Polypropylene tubular products due to the convenience and ease of installation found wide application in private construction. In order to save money, it is quite possible to install polypropylene pipes in an apartment or a house with your own hands. It is possible to learn how to properly and safely work with polypropylene pipes at and, from this article.

Features of PP pipes

Polypropylene products have qualities that favorably distinguish it from alternative products:

- Light weight, thanks to which the pipes are easy to transport and work with them.

- Ease of installation. Operations to connect pipelines between each other, as well as with fittings, do not cause difficulties even for novice masters.

- Non-compliance with corrosion, as well as calcareous deposits on the inner surface significantly increase the life of the product.

- High strength makes it possible to use polypropylene products both in low-pressure systems and for pipelines operating under pressure in the bathroom, boiler room and other premises.

- Resistance against low temperatures and freezing of water makes it possible to use products for laying external roads.

- Good throughput and low degree of thermal conductivity ensure high efficiency of PP products.

Spectrum of the use of PP pipes

Pipes made of polypropylene efficiently and optimally used for:

- water supply both hot and cold water;

- heating systems;

- warm floors;

- systems for extinguishing;

- distribution networks.

Polypropylene Pipeline Laying

If the decision is made that polypropylene pipes will be installed by their own hands, then it is necessary to carry out all the steps correctly, carefully and carefully, starting from the selection of the material before the trial commissioning of the pipeline.

Calculation of the number of PP products

The laying of polypropylene pipes always begins with the calculation of the route of the main line. It is necessary to ensure optimal connection of all sanitary devices. The detailed design allows to accurately calculate the required quantity:

For apartments and private houses the best option there will be pipes 20.0 - 25.0 mm in diameter. They withstand sufficient pressure, and their throughput will be sufficient for reliable and uninterrupted transportation of the working environment.

For a water pipe it is possible to use ordinary pipes, and for a heating system it is desirable to use polypropylene products using fiberglass or aluminum foil.

Preparation of pipeline components

Before installing polypropylene pipes, it is necessary to perform, which consists in the following:

- cutting the products into blanks of the required length;

- carrying out the cleaning of the pipe ends;

- performance of facing of reinforced products.

Cutting pipes for obtaining the required length is performed by special cutting:

- precision scissors;

- roller pipe cutters;

- electric scissors;

The most effective roller cutters. They provide a perfectly smooth cut. At home, it is possible to use a metal hacksaw for cutting, followed by sweeping the cutoff from the chips.

Stripping and trimming of pipe sections must be carried out in order to obtain a reliable connection of the pipeline components. This work is carried out using a stripping tool that ensures the removal of a small outer layer of polypropylene and an inner reinforced layer at the required depth.

Piping installation

The technology of installation of polypropylene pipes provides for the possibility of laying them:

- in stitches with subsequent plastering;

- open way along the walls, using a special one;

- in the ground;

- in special channels and mines.

After preparing the products for welding, you can proceed directly to the installation of the pipeline. The following instruction will help to ensure a long service life of the pipeline:

- When laying a heating system from pipelines, installation of the wiring is done with the help of ready-made combs. The unused outputs are closed with stoppers.

It is advisable to install a ball shut-off valve for each branch (branch) of the pipeline at the outlet of the comb. Subsequently, there will be no problems with shutting off the water supply for repairs or maintenance connected to the instrument system.

- The peculiarity of laying the heating system is the need to provide an expansion loop to compensate for a slight increase in the length of the pipe from heating.

Rules for fastening pipes

PP products must be securely fixed. To fix the products, special clips are used. When laying pipes, double, triple, etc. are used in parallel. fastening.

For large-diameter pipes, a fastening is provided in the form of metal clamps with rubber gaskets. For pipe products that are used for working with water, having a high temperature, it is necessary to use sliding fasteners.

Thus, if you know the general rules how to mount a pipeline from polypropylene products, you can provide a reliable system of water supply or heating in your home in a short time without unnecessary financial waste.

Modern technologies penetrate all spheres of people's activities. The construction is not an exception engineering communications, including water supply systems. Pipes of a new type replaced cast iron and steel pipes. Today, piped water from propylene is the best solution to this problem.

It is not difficult to verify this. It is enough to list some of its advantages:

- simplicity , but at the same time reliability of installation;

- economy time and financial management;

- chemical inertness and the absence of salt deposits on the inner surface of the pipes.

Installation of water pipes from polypropylene pipes is not only an interesting, but also a responsible business. Therefore, many prefer to turn to the services of specialists. However, there are a lot of pluses in mounting a polypropylene water pipe with your own hands. Not to mention even such a factor as significant cost savings.

So, you have decided that the replacement of water pipes in the apartment is within your power. Where should we start? What actions and in what order should be taken? Of course, we will have to answer these and other questions. There are many options for solving this technological problem. Choose the most effective of them. The one that will minimize the possible errors in the design and installation. We hope that the information offered will help you in this.

Technical parameters of pipes

Propylene pipes for water supply are connected by diffusion welding using fittings. The polypropylene water pipe can be used for about 50 years under proper operation. The temperature of the liquid should not exceed 95 ° C. The service life of cold water pipes is almost 2 times higher.

Water pipes made of polypropylene are produced in 4 modifications.

- A pipe designed for use only in the feeding system cold water . Nominal operating conditions: temperature not higher than +20 С о; the pressure is 1 MPa (10 atm). Marking - PN 10.

- The version of the pipe that allows the supply of cold and hot water . Operating mode: temperature - up to +60 С о at working pressure - 1,6 MPa (16 atm). The adopted designation is PN 16.

- The product intended for the transportation of hot water and the installation of heating systems . Nominal parameters: temperature regime - up to +80 С о; the liquid pressure is 2 MPa (20 atmospheres). Pipe of grade PN 20.

- Pipe, reinforced with aluminum foil . The main areas of application are hot water and organization central heating. Technical operating conditions: temperature up to +95 С о; the maximum permissible pressure in the pipe is 2,5 MPa (25 atm).

It should be remembered: the hot water supply system can be mounted only from reinforced polypropylene pipes. There are various ways of reinforcement, in particular, with the help of fiberglass, aluminum.

Diameter of plastic pipes for water pipe is selected from the length of the main line. If the length is less than 10 m, pipes with a diameter of 20 mm are allowed. With a length of 10 to 30 m, pipes with a diameter of 25 mm can be used. For lengths exceeding 30 m, it is recommended to use 32 mm tubes. Stands are made of these pipes.

When assembling a polypropylene water pipe with your own hands, consider the following fact. The fact is that under the influence of heating polypropylene pipes slightly elongate. Therefore, you need to leave some space for their normal extension. Otherwise, strong strains may appear in the line.

Plumbing from plastic pipes - Photo 04

Wiring options

In order to independently install a polypropylene water pipe you will need detailed scheme system performance. It is desirable to entrust it to a specialist who has experience in such matters. One of the key requirements for the project is to reduce the number of bends and intersections to a minimum. The scheme should be designed so that the total length of the highway is the smallest, and the project meets the requirements of ergonomics.

Before you start the project, you need to choose an option, that is, decide for yourself how to install a water pipe from propylene. Connection of the line to the water intake devices is carried out both in a closed and open way. The first option is considered more complicated. In addition, all lines built into the wall must be made without joints. If there are connection points to them, access is necessary for inspection and preventive procedures.

An open wiring type is a simpler option. In this case, the installation polypropylene water supply is usually performed as follows. The pipes located vertically are placed at the corners of the room, and horizontally at the floor level. The advantage of this method is that the wiring becomes less noticeable. In addition, we note and such a virtue as the ease of maintenance and repair. This allows you to notice leaks and correct the problem in time.

The layout of polypropylene pipes is also carried out in different ways. The most common are sequential and parallel systems. A distinctive feature of a sequential or tee system is that the pipes from the main to the water consumers are arranged in series.

The main advantages of this method of polypropylene wiring can be attributed convenience of installation and economy. Consumption of materials is minimal. However, one can not but note some of the shortcomings inherent in it. The main one is the presence of mutual dependence of water intake points. This means that the polypropylene water pipe in this case does not allow repair or replacement of one of the consumer devices, without overlapping the entire system. And yet, the simultaneous inclusion of several consumers leads to a reduction in pressure in the water supply system.

Parallel or collector type distribution is characterized by the presence in the system of a special distributor - collector. It is a device with a single input and several outputs. There should be exactly as many points of water consumption as it is provided in the system. This factor and caused the main drawback of such a system - the presence of a large number of broods. The consequence of this is an increase in the cost of the system and the laboriousness of installing a water pipe made of polypropylene pipes.

At the same time, this system has indisputable advantages, including:

- no need to disconnect the entire system when servicing or repairing one of the nodes;

- uniform distribution of water at all points of consumption;

- compactness of the arrangement of all control devices;

- the possibility of installing meters and adjusting the water pressure in case of need to increase the pressure in a particular device.

Installation of water pipes from polypropylene pipes

Installation of a polypropylene water pipe with your own hands assumes knowledge of the basic installation rules. It is also necessary to master some technological skills, namely:

- pipe cutting technology . Cutting of pipes is carried out with the help of special scissors or pipe cutters. The device of cutting tools assumes a perpendicular arrangement of the pipe to the cutting blade;

- method of welding . For welding pipes used the so-called soldering iron or iron. Before carrying out installation work, it is necessary to read his instructions. Then assemble the device and select the nozzle of the appropriate size;

- method of fixation of pipes . The pipes are attached to the walls using clips. They are installed at all points where the corner joints pass. In this case, the maximum distance between adjacent clips should not exceed 1.5-2 m. Double clips are usually used to fasten parallel sections. In this case, the risers are fixed by means of clamps made of metal. They use rubber gaskets.

Remember! At the points where the corner joints along the inner corner pass, it is necessary to arrange the rotation of the pipe at a certain distance (3-4 cm) from the wall surface. When traversing the outer corners, on the contrary, the connection should be closer to the wall than usual.

Installation of a polypropylene water pipe can be started after all necessary calculations, materials are prepared, tools and devices are selected. The recommended algorithm for performing the work is as follows:

- If there is an old system, it is dismantled.

- According to the developed scheme, works of different lengths are cut.

- In the presence of joints of polymeric with steel pipes, the ends of the latter are worn by couplings.

- Welding of reinforcing elements and pipes.

- Produce the fastening of the shut-off valves.

- Prepare channels for laying pipes or punched holes in the walls for fasteners.

- Produce installation of polypropylene pipes for water supply.

The organization of systems designed for high pressure, as a rule, is carried out with the help of so-called pipes vchsg for water supply. Thanks to the globular graphite, which is part of the composition, this material has high strength. These pipes are used for the installation of underground pipelines.

For the competent work on the installation of polypropylene water, we recommend that you listen to the advice of the masters:

- it is more convenient to work together with a partner;

- it is desirable to prepare a workbench for the preparation of blanks;

- the assembly of the line should be conducted from the consumers to the nodal points.

Products made of polypropylene are absolutely non-corrosive, have low weight and long (up to 50 years) service life. That is why they have long superseded metal water pipes from everyday life. It is not difficult to assemble a reliable water supply system or warm floors from polypropylene products, but it will not be possible to make it improvised. To do this, you will need to purchase an apparatus for welding them. And so, let's find out how to install polypropylene pipes with your own hands.

Selection of pipes and connectors

There are several brands of polypropylene (PP) pipes:• PN10: they have sufficiently thin walls, they are intended only for summing cold water and installation of warm floors at the maximum heating + 45 ° С;

• PN20: used in systems of sewerage and cold or hot water supply; while the water temperature in them should not exceed +80 ° C, they are reinforced for reinforcement; When labeling products for hot water, a vertical red stripe;

Pipes for cold and hot water

• PN25: intended for heating network installation with operating temperature of the coolant up to + 95 ° С; to strengthen strength reinforced;

• PN16: occurs less frequently; it is applied for hot and cold water supply, permissible temperature in pipes + 60 ° C.

For water supply in private houses use pipes of 20 mm, equipment of risers 5-storey - 25 mm, 9-storey houses and higher buildings - 32 mm. The layout in the apartments is carried out by pipes of 20 mm. When installing ventilation, a diameter of 400 mm is used. For outdoor wiring and burying them in the ground should be applied corrugated Products that have greater resistance to subsidence.

Propylene corrugated pipes

Important! When supplying hot water, pipes of too large diameter are not recommended; too high a heat load will promote their softening.

Resistance to temperature fluctuations and pressure are determined the thickness of their walls and the type of polymer (they can be made from a block, random copolymer of polypropylene or a special flame-retardant composition). In order to increase the strength, they can additionally be reinforced with fiberglass or foil.

Reinforced and unreinforced pipes

Features of installation of polypropylene pipes

Installation of polypropylene pipes is already done by assembled sections, that is, initially several segments are welded with fittings and turns, and then they are attached to the wall. Connect them in such a way that the number of turns and connections is minimal.To fix the assembled system on the wall, fixing points are marked, then holes are drilled for marking dowels, then it is attached to clamps (clips). The distance between adjacent fasteners is no more than 1 m.

Preparing for installation

Mounting clips

Important! TO heating boilers, having a high temperature of heating, PP-pipes are connected through metal not less than 0.5 m in length. Fastening of metal and polypropylene pipes is carried out with the help of a transitional fitting.

Contact welding (soldering)

Since the water supply is carried out under sufficiently high pressure, the pipes and fittings must be connected as reliably as possible.1. Pipes are cut into pieces of the required length with the help of a grinder, a pipe cutter or special scissors. For stripping of products with aluminum reinforcement a special device is used - shaver.

Shaver for stripping pipes with reinforcement

2. In order for the segments to fit freely into the fittings, they must be removed from their edges chamfer at a slight angle. At the same time, its groove should have a size of up to 3 mm. For this purpose, the faskosnimatel.

Faskosnimatel

3. Pipe ends degreased alcohol or white spirit.

4. They are applied elevation, equal to the depth of the fitting minus a couple of mm (for example, for a 25 mm pipe it will be 16 mm);

Marking

5. Fitting and pipe are placed on both sides of the nozzle soldering iron so that when heated they reach the required mark. The ends of the nozzles have a small cone, so it is necessary to put a pipe and fitting on them with a little effort.

Installation on the nozzle

Apparatus for welding (soldering iron)

6. If the soldering iron is equipped with a temperature regulator, it must be set at 260 ° C.

7. Pipe heating interval depends on its thickness. Having sustained the required time (it is indicated in the instructions to the soldering iron and can be from 5 to 15 seconds), the pipes and fittings are smoothly removed from the nozzle (mandrel) and docked. It is advisable to do this in one motion, without excessive displacements, as quickly as possible - in fact the time of solidification of polypropylene is only 30 seconds.

Important! During the heating process, to avoid damage to the plastic, it is not recommended to rotate the pipe and fitting. Do not and cool it forcibly.

8. Large diameter products are more difficult to join, therefore they are connected by means of a special device.

Council. In order to adapt to welding, it is better to practice a little: buy a few fittings and try to fix them on small pieces.

9. Small streaks formed during welding, removed with a conventional knife.

10. After assembling the water pipe, it is filled with water and check for leaks under pressure. At the same time, it is selected 1.5 times higher than the nominal one. You can increase the pressure with a car pump. If necessary, the problematic joints cut out and solder new sections into the system.

Important! The test of the system is allowed only 2 hours after the end of the soldering.

How to bend polypropylene pipes

Despite the fact that manufacturers do not recommend bending PP pipes, it's difficult without it. You can bend them using:• building hair dryer: when heated they can be easily bent by hand; to avoid breaking, they must first be filled with sand and closed on both sides with plugs;

• cold way (rubber kiyankoy) can be used if the pipe has a small cross section; the bending radius should be small.

With cold bending, the chances of damaging the pipe are much greater, so this method is used less often.

Hot bending

Watch the video, installing polypropylene pipes yourself:

Polypropylene is a light material that is produced by polymerization of propylene (combustible colorless gas) in a solvent (propane, hectane, gasoline) at high pressure. Supplied in the form of powder or granules.

Types of polypropylene - the basis for selecting materials

- - homopolymer of polypropylene (PPH) - has high bending strength, but brittle at low temperature; with the help of various modifications it can be antistatic, transparent and fire resistant;

- - copolymers (PPC) are obtained by copolymerization of propylene and ethylene. These materials have increased strength (when compared with a homopolymer) and elasticity. It:

- - block copolymer (PPB);

- - statocopolymer (PPR);

- - copolymer of polypropylene (random copolymer) PPRC - a strong and light material, resistant to acids and alkalis, withstands temperatures from minus ten to plus ninety degrees, does not collapse when water freezes;

- - metallocene polypropylene (mPP) - may have different tacticity (properties, behavior), including similarity with rubber.

Comparison of polypropylene pipes - the necessary data before installation:

- - pipes from homopolymer PPH (type 1) - products with a large diameter , which are used in pipelines for ventilation and cold water, as well as for the construction of various industrial systems;

- - pipes from block copolymer RRV (type 2) - have increased resistance to mechanical influences, are used mainly for cold water supply and warm floors;

- - PPR pipes (type 3) - the most popular, universal, as they are suitable for cold and hot water, as well as for heating , operating temperature up to 70 ° C. When the gasket is open, a shell protecting from ultraviolet rays is necessary;

- - PPs pipe - flame retardant polypropylene, upper limit of operating temperature is 95 ° С.

With the help of additives it is possible to obtain completely different polypropylene pipes, the application is completely dependent on the type of material used in the production. In addition to the material, the characteristics of polypropylene products are changed with the help of reinforcement. It can be made of aluminum foil (on the outer surface or in the middle of the wall) or fiberglass.

How to install polypropylene pipes

Preparation for installation:

- - make holes for pipes in partitions and walls;

- - note the location of the system;

- - Clean the debris from the place of the gasket.

Evaluation of material:

- - checking the completeness of the pipeline;

- - check marking on pipes and fittings;

- - inspection of external and internal surfaces of all elements;

- - an estimation of conformity of the sizes (first of all - diameters);

- - equipment check.

Pipes and fittings with deviations from tolerances in size and technological defects can not be used. The temperature of the medium during operation should not be less than five degrees.

Rules for soldering polypropylene pipes: according to two types

Soldering of polypropylene pipes can be of two types:

- - Spherical;

- - butt.

Smooth soldering is used for products with a small diameter using a soldering iron. Temperature - 2600 C. After soldering each joint, it is necessary to clean the Teflon layer of heating elements. Connections should be:

- - with a deviation from the center line not more than 5 °;

- - without creases and cracks;

- - with a roller protruding beyond the end of the coupling.

Butt welding is used if the wall thickness exceeds 4 mm. Before welding, it is necessary to work with a face-finder to create parallel surfaces of the elements to be joined. An important aspect is the compensation of linear expansion with the help of competent arrangement of supports and installation of compensators between fixed supports. The width of the U-shaped compensator should not be less than ten pipe diameters. If a loop-shaped compensator is used, the diameter of the loop should be equal to the eight pipe diameters.

In addition to soldering, fittings for polypropylene pipes - detachable and one-piece. For the sealing of threads, the use of fluoroplastic tape is mandatory. For the transition to metallic elements, combined connecting parts are used, complete with nipples and adapter nipples.

Required Tools:

- - welding machine with nozzles;

- - scissors or pipe cutter;

- - Trimming or face;

- - meter;

- - knife, alcohol, rags;

- - The marker.

Installation instructions for polypropylene pipes

- - measure and cut off the pipe, reinforced to clean, remove the chamfer;

- - products of large diameter (more than 40 mm) require cleaning of the oxidized layer;

- - mark the marker with the depth of welding and the connection point;

- - clean and degrease welded surfaces;

- - first put the fitting on the nozzle (if it does not sit tightly, it must be rejected), then the pipe;

- - the heating time is determined by a special table;

- - After finishing the heating, fit the fitting on the pipe, fix it for 20 - 30 seconds (until the seam is partially cooled).

Installation of polypropylene pipes

Installation instructions for risers

In addition to soldering, it is necessary to install risers and fix polypropylene pipes to a wall or other surface. The staircases are laid on the markings produced according to the project. It should be noted where the sockets and clamps will be located. The stand is pre-assembled and placed in a stroke or along walls. Clamp for polypropylene pipes is attached to the wall using dowels. The stanchion is fixed by tightening the pole of the yoke.

Sewer pipes have the same diameter along the entire length and are always laid vertically, from the bottom up. For cleaning, install audits (about a meter from the floor). When installing the sewer, it should be remembered that it requires a valve for polypropylene pipes ( check valve), which can be installed on a common pipe or on each device. Although one valve can only do in a small house.

Fastening for polypropylene pipes

There are three types of fasteners for a polypropylene pipeline:

- - metal clamps with screw fastening;

- - Polypropylene fasteners (with or without strap);

- - fasteners made of polyvinyl chloride.

The clamps are equipped with rubber gaskets:

- - compensating thermal expansion;

- - reducing vibration;

- - Protecting against mechanical damage.

For fixing the system to walls and ceilings, supports for polypropylene pipes (fixed and sliding) are used. The fixed support prevents the pipe from moving and directs the linear expansion to the compensator. The distance between the pores is determined by normative documents. For the ceilings, sliding supports with a strap are recommended, located with an interval not exceeding 20 - 30 diameters.

To stop water movement in the system, ball valves are used for polypropylene pipes. They must be installed at each device with a threaded connection. Polypropylene pipes are not exposed to rust or other deposits, do not rustle during operation, do not require insulation during internal installation. Installation of polypropylene pipes (instruction above) does not require much labor and time.

For hot water and heating it is better to use reinforced materials.

When installing threaded connections, the use of a gas key is not allowed.