Polypropylene piping installation rules are secrets. Typical errors allowed during welding. Pros and varieties of polypropylene pipes

Polypropylene pipes - advantages, characteristics

Polypropylene is a synthesized chemical compound that is actively used in the field of sanitary engineering, including for the manufacture of pipes. The material is flexible, light, excellent performance, which makes it the most popular among other materials. Polypropylene has a low density, so among plastics is considered the easiest. The material has many advantages, including:

1. Durability (up to 50 years of operation).

2. Do not require staining, aesthetic appearance.

3. Ease of material.

4. Simplicity and speed of installation.

5. Minimum heat loss.

6. Resistance to temperature changes, corrosion, excellent heat-retaining qualities.

7. Excellent vibration-proof, noise-insulating qualities.

Great practical experience allows me to perform the installation polypropylene pipes at country houses, offices, apartments. The work does not take much time and effort, which allows the customer to save significantly on installation services and purchase of consumables, and due to low weight - and transportation. The material is absolutely non-toxic, does not release chemicals, which ensures cleanliness and safety. drinking water, which is transported through polypropylene pipes. The condensate does not form on the surface of the pipeline, which confirms the low thermal conductivity of the material. Pipes made of polypropylene may be operated at a temperature of -10 ° C + 90 ° C, and briefly up to + 110 ° C. In the case of freezing of water, the integrity and tightness of the pipes is maintained.

Great practical experience allows me to perform the installation polypropylene pipes at country houses, offices, apartments. The work does not take much time and effort, which allows the customer to save significantly on installation services and purchase of consumables, and due to low weight - and transportation. The material is absolutely non-toxic, does not release chemicals, which ensures cleanliness and safety. drinking water, which is transported through polypropylene pipes. The condensate does not form on the surface of the pipeline, which confirms the low thermal conductivity of the material. Pipes made of polypropylene may be operated at a temperature of -10 ° C + 90 ° C, and briefly up to + 110 ° C. In the case of freezing of water, the integrity and tightness of the pipes is maintained.

Possibilities of using polypropylene pipes.

This type of pipe is actively used for supply and distribution of water: cold and hot, drinking and technical, for heating systems. This is an excellent alternative to a metal pipeline, which is quite large in weight and more expensive. Pipes made of polypropylene are also used in the installation of a warm floor.

Turnkey heating system - design, selection of fasteners

The main elements heating system are:

Heating boiler (gas, electric, wood);

Elements of heating (radiators);

The design of the heating system involves the placement of heating boilers in a separate room, in which a well-organized ventilation system, installation of gas sensors, boilers (not above the lowest point of the heating system). It is equally important to prepare a project that will help to properly install polypropylene pipes in all rooms that need heating. It becomes important enough to display in terms of places in which it is more expedient to install radiators, with a competent and accurate calculation of the length of the pipes between them.

At this stage it is necessary to prepare the fastening elements: couplings, angles, adapters of different diameters and angle of rotation. Couplings are used for splicing pipe segments, and also if there is a need to switch to a different diameter. Angles are used to rotate the pipeline by 45 or 90 degrees. Tees have found their application for joining 3 pipes simultaneously, creating a branch.

Welding - the main point of the installation works

For the installation of polypropylene pipes I use an electric welding machine with welding nozzles of the right size, as well as scissors for cutting polypropylene. Installation is performed in the socket with the help of polyfusion welding, forming a seam of high quality. The work involves several stages:

For the installation of polypropylene pipes I use an electric welding machine with welding nozzles of the right size, as well as scissors for cutting polypropylene. Installation is performed in the socket with the help of polyfusion welding, forming a seam of high quality. The work involves several stages:

1. Measure the desired pipe footage.

2. Preparation (cutting) of pipes.

3. Mark the depth of the pipe inlet in the coupling of the fitting.

4. Welding and installation of the pipeline.

The main feature of the installation of pipes from polypropylene is their method of connection - welding or soldering. For this, I use a special welding machine, which provides a reliable and durable connection. The nozzle of the welding machine is heated and the fitting and pipe are placed on it and simultaneous heating of two parts is carried out simultaneously. In this case, it is important to ensure that each element is fitted tightly, otherwise it should not be used for work, by choosing another one - capable of providing a reliable, durable connection. The heating time directly depends on the diameter of the pipes: the larger the diameter, the longer the heating (5 to 12 seconds).

Now, when the parts are sufficiently heated, I remove them from the nozzle of the welding machine, connect them to each other by the marks that were made earlier. The pouring time of the welded joint is on average 10 - 30 seconds. It is worth saying that before starting the work it is necessary that the material is dry and clean. Otherwise, the connection will not be reliable and airtight. In order to ensure that the installation of polypropylene pipes is carried out correctly, it is necessary to check their patency: they should be blown, and if the air passes without barriers, it means that sealing during welding was not formed and the work was done qualitatively.

Installation of polypropylene pipes becomes relevant in old houses and apartments. Quite often I have to deal with the replacement of the pipeline in the kitchen, bathroom, in the accidents. The production of new modern polypropylene pipes allows to speed up the installation process, and the owners of apartments to reduce their financial costs. In addition, they are well proven in the construction of hot water. In contrast to them, for example, metal-plastic ones, do not withstand high and low temperature changes and high pressure. Additionally, a pressure reducer is required. I suggest:

Installation of polypropylene pipes becomes relevant in old houses and apartments. Quite often I have to deal with the replacement of the pipeline in the kitchen, bathroom, in the accidents. The production of new modern polypropylene pipes allows to speed up the installation process, and the owners of apartments to reduce their financial costs. In addition, they are well proven in the construction of hot water. In contrast to them, for example, metal-plastic ones, do not withstand high and low temperature changes and high pressure. Additionally, a pressure reducer is required. I suggest:

1. Dismantling of the old pipeline.

2. Replace the pipes with new ones.

3. Installation of water meters.

4. Installation of cleaning filters (coarse and fine cleaning).

5. Replacement of cranes, mixers.

6. Installation of a sink, toilet bowl, a shower cabin, water supply to sources that need water supply.

Water supply of your own house or apartment begins with the design. The project should show the layout of the pipeline, indicating the size of the system sections and other important locations. It should also be noted new elements that the customer plans to add to the water supply system. The work involves the implementation of accurate measurements, counting the required quantity consumable material. I usually use polypropylene pipes for the water supply. They have a smooth internal surface, which avoids the accumulation of silt deposits, sticking dirt, as well as corrosive lesions. All this has a positive effect on water quality.

Water supply of your own house or apartment begins with the design. The project should show the layout of the pipeline, indicating the size of the system sections and other important locations. It should also be noted new elements that the customer plans to add to the water supply system. The work involves the implementation of accurate measurements, counting the required quantity consumable material. I usually use polypropylene pipes for the water supply. They have a smooth internal surface, which avoids the accumulation of silt deposits, sticking dirt, as well as corrosive lesions. All this has a positive effect on water quality.

Installation of polypropylene pipes for water supply is also carried out, as in the case of a heating system, by welding. Tip: if you decide to do it yourself, then when purchasing polypropylene pipes it is necessary to take into account their marking: the PN10 marking is used only in the cold water supply system, and PN20 is considered universal and finds its application both for cold and for hot water. Pipes PN25 - reinforced. They have a high level of strength, can be used not only for hot water supply, but also for the installation of a heating system.

It is worth saying that today the installation of polypropylene pipes during the installation of water supply is absolutely inexpensive. This is due to the affordable cost of consumables (an average of about 1000 rubles for the replacement of the pipeline in the apartment, including the cost of the fastening material), as well as the ease of installation work. This is an excellent opportunity to replace the pipeline in your apartment or house as soon as possible, replace the old pipes that have long outlived themselves with new, modern ones. Availability necessary equipment and a great experience in the execution of plumbing work allow me to fulfill orders of any complexity in a short time, leaving every customer satisfied with the quality of the work done and the speed. I will be happy to help you too! In order to make an application for the service you need, you can call the phone numbers listed above.

Recently polypropylene pipes have been widely used in the installation of water supply and heating systems. They became very popular due to their excellent characteristics. Pipes made of polypropylene are characterized by good durability and durability. In addition, their installation is easy enough to do by yourself, without having any special knowledge and skills.

Pros and varieties of polypropylene pipes

A polypropylene system can be used to supply both cold and hot water. However, before acquiring a PP, it is necessary to familiarize yourself with their characteristics.

Benefits plastic water supply system:

- sufficiently long service life (up to fifty years);

- strength;

- absence of corrosion;

- environmental Safety;

- small heat loss;

- the absence of condensate on pipes with cold water;

- light weight;

- no deposits in the water supply and heating;

- low noise level;

- large selection of connecting accessories;

- simplicity of installation works.

Four classes of polypropylene pipes

By changing or installing a water supply or heating system with your own hands, you should purchase PPs that will be withstand water temperature and pressure.

By changing or installing a water supply or heating system with your own hands, you should purchase PPs that will be withstand water temperature and pressure.

- Products for use with cold water are marked P N 10.

- They withstand high temperatures and are used for hot water supply, heating and sewage pipes marked P N 20.

- For heating systems PP with marking P N 25 are intended.

The jacket of pipes with markings P N 20 and P N 25 is made of foil or fiberglass. Due to this, the products withstand hot temperatures and do not deform.

- The surface of the PP must not have any defects.

- Sections of pipes should be smooth and clean, with a smooth surface.

Connecting elements for PP pipes

When assembling, the components of the same material as the products are used:

- Couplings connect straight long lengths of pipes.

- Tee Used to branch the system.

- Angle - to connect segments at an angle of ninety or forty-five degrees.

All the additional elements that are used for connecting, transitions, forks and turns are called fittings. They are of two types: threaded and welded (unthreaded). Threaded products are divided into detachable and one-piece. For the usual joining of two segments during the installation of the heating system, non-threaded fittings are used. And to connect the counter - fittings with thread.

Installation of polypropylene pipes by one's own hands

Stages of work with video instruction

Begin the installation of the system from polypropylene follows from the drawing of a water supply system. In this case, it is necessary to measure the distances from the points of consumption to the point of entry, taking into account all points of connection, branching, branches and turns.

Begin the installation of the system from polypropylene follows from the drawing of a water supply system. In this case, it is necessary to measure the distances from the points of consumption to the point of entry, taking into account all points of connection, branching, branches and turns.

Necessary tools and materials:

- a special tool for cutting pipes;

- adjustable wrench;

- special soldering iron for welding PP (ironing) with nozzles;

- a knife for stripping products;

- couplings;

- pre-formed lengths of pipes: rotary and for the circumference of products in one plane;

- fittings with external and internal thread;

- connecting elements for flexible tubes;

- corner fittings;

- a tap that will attach the hose from the washing machine.

Basic rules for mounting PP

First of all, all products are checked for integrity and cleaned of dust.

- It is strictly forbidden to use dirty or deformed elements.

- During operation, the ambient temperature should be at least five degrees.

- All products made of polypropylene must be protected from fire.

- Separate threaded fittings are used to tie the storage tank or water meter.

- Non-detachable elements are only used for connecting flexible hoses.

- The bending of the pipes is unacceptable, so corner bends are installed on the corners.

Let's get to work

Installation begins with cutting pipes necessary length.

Typical errors allowed during welding

In the absence of skills, mistakes are often made that can be avoided if follow the rules.

In the absence of skills, mistakes are often made that can be avoided if follow the rules.

- The device for soldering polypropylene pipes must be well heated, otherwise welding will turn out to be of poor quality. Before the first soldering, the soldering iron should be heated for at least five minutes and not switched off before the end of the work.

- Low-quality welding will be in case of underexposure or overexposure of elements in the nozzles of the apparatus. In the latter case, the plastic is highly softened and the hole may be completely blocked.

- Polypropylene parts can not be joined too long. They can cool down and a quality connection will not work.

- If the first soldering did not work, then the re-use is not recommended. Also cut off the end of the polypropylene pipe.

- To a poor-quality connection result in irregularities in the shape or crack at the fittings. Therefore, when buying them, you must carefully examine them.

- Acquire components from one manufacturer. This is due to the fact that polypropylene can be used in different grades and have different melting points.

Checking the work done by yourself

First a new water system is checked for cold water leakage. If, after opening the tap, water drips or leaks, you should tighten the thread, check if the tape is wound up and if there are any gaskets.

The second check should be done hot water. The most common leakage can be in flexible pipes, so they are inspected more thoroughly.

Provided that the polypropylene pipes are correctly installed by their own hands, it is possible to save considerably. The main thing is attention and observance of all the rules, you can familiarize with which you can by watching the video lesson.

30 July, 2016Specialization: finishing of facades, interior finishing, construction of dachas, garages. Experience lover-gardener and gardener. Also there is an experience of repair of cars and motorcycles. Hobbies: playing a guitar and a lot of other things that do not have enough time :)

Plastic pipes in water supply and heating systems gradually replaced the metal counterparts, with polypropylene products being the most popular ones. They are sufficiently durable and have good performance characteristics, the only thing, their installation with beginners usually raises a number of questions. Therefore, further I will tell you how to install polypropylene pipes by yourself, and you will see that there is nothing complicated in this.

Piping installation

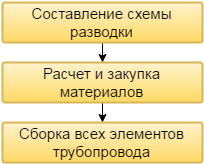

Installation of polypropylene pipes, as, actually, and any other, includes several stages:

Layout diagram

So, installation of pipes from polypropylene by oneself, regardless of the purpose of the pipeline, begins with the drawing up of the scheme. In the process of performing this operation it is necessary to solve the following tasks:

- determine the most optimal location of the pipeline;

- designate the length of all sections of the aqueduct;

- designate the location and number of fittings;

- marking the location of the pipeline on the walls.

therefore drawing up the scheme you need to do very carefully, indicating all the dimensions in millimeters. For convenience, you can use the housing plan.

Materials

As already mentioned above, the number of fittings depends on the wiring diagram. In addition, in addition to the fittings, it may be necessary to mount brackets for fixing the pipeline in the wall, if the installation is open. More details on how to install the pipeline will be discussed below.

Separately, it should be said about the choice of polypropylene pipes themselves. The fact is that they exist several brands:

- PN 10 - PN 16 - can only be used for cold water;

- PN 20 - PN 25 - suitable for heating and hot water supply. This brand is more expensive - the cost of 1MP PN 25 is from 50 to 250 rubles, depending on the manufacturer.

Assembly

Installation and soldering of polypropylene pipes with their own hands is easy, so you can even cope with this task without being an expert. The only thing for this is to have a special welding machine and nozzles of a suitable diameter.

In addition, you need another tool:

- stripping - is designed to remove the upper reinforcing layer, which is necessary for quality parts;

- pipe cutter - allows you to cut pipes evenly.

If you want to assemble the pipeline without welding, you can use metal-plastic pipes, which are connected by compression fittings.

The technology of joining parts is as follows:

- first of all, it is necessary to cut the pipes into lengths of the required length;

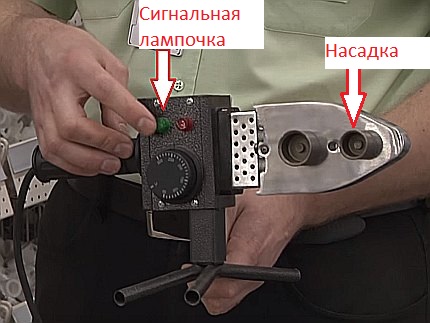

- further it is necessary to include a soldering iron (welding machine) and to heat it. And before you start welding, you need to wait until the machine several times warms up to maximum temperature and turns off. This is evidenced by light indicators;

- while the soldering iron is heated, it is necessary to clean the ends of the pipes. To do this, they are stripped and rotated on them. This procedure resembles the cleaning of pencils with a pin;

- after all the details have been prepared, and the soldering iron is warmed up, insert the pipe and fitting into the nozzles. It is important to maintain the connected parts the exact time. The latter depends on the diameter of the pipeline and is usually indicated in the table that is included with the unit;

In the photo - the order of connecting parts

- when the plastic warms up, the parts need to be pulled out of the nozzles and connected to each other. In this position, they should be held for a while, until plastic has solidified;

- on this principle all the details of the pipeline are connected.

If you are doing this kind of work for the first time, before starting to manufacture the pipeline, you should train to cut pipe fittings with fittings.

Ways of installation

Installation of the pipeline from polypropylene in the room can be done in two ways:

- open - the pipes are attached to the walls with the help of special brackets. This method is the simplest, however, less aesthetic, as communications spoil the appearance of the interior;

- hidden - the pipes in this case are located in stitches made in the wall, after which they are plastered. I must say that it is quite difficult to properly perform the hidden installation of polypropylene pipes, since they are highly prone to thermal expansion.

Installation in the open way is carried out in the following sequence:

- on the markings made on the walls, special brackets are installed. First of all, they are mounted in the places of turns, as well as on flat sections with a meter-and-a-half steps;

- then the pipes are inserted into the brackets and connected to the fittings. For convenience, it is possible to collect individual sections of the pipeline and then fix them in brackets, and then connect with each other.

The process of hidden installation with their own hands looks somewhat different:

- in the beginning it is necessary to perform the marking of the strobes. Their width should be twice the width of the pipe. This is necessary to ensure that they can fit the insulation of pipes, as well as plaster.

To perform the shot bar, use a perforator with a chisel included in the impact mode; - further large areas of the pipeline are assembled and placed in strobes. To fix the structure, use brackets or holders;

- then all the elements of the system are connected to each other;

- if the design has turned out, heat-insulating covers are put on pipes;

- then shtroby closed with cement mortar.

Before sealing the strobes, they must be cleaned of dust. This is necessary for high-quality cement adhesion.

It should be noted that hidden installation requires compliance with certain rules:

- in the system it is necessary to provide expansion joints, since the polypropylene pipes greatly expand (up to 5 mm per meter);

- the split fittings must always remain unsharpened;

- it is necessary to check the pipeline before closing the shrouds.

Here, in fact, and the entire instruction for the installation of polypropylene pipes.

Conclusion

From polypropylene to collect the pipeline of pipes, as we found out, is quite simple. The main thing is to learn how to work with a soldering iron, for which you just need to fill your hand a little. In the rest, you just have to follow a certain sequence of actions.

For more information, see the video in this article. . If you have any difficulties in the process of installing the pipeline or if some points are not fully understood, ask questions in the comments and I'll be happy to answer them.

July 30, 2016.If you want to express gratitude, add a clarification or an objection, something to ask the author - add a comment or say thank you!

If you carry out wiring for water and heating yourself, then it is much cheaper than paying for the work of specialists, since the installation rates are quite high.

For self-fulfillment, you must prepare all the necessary materials and tools, as well as find instructions for installation. First of all, it is necessary to determine the material of the pipes, since it depends on which consumables and tools will be used.

Previously, for water and heating systems used metal pipes, but recently began to switch to polypropylene. Metal has the following disadvantages:

- are susceptible to corrosion;

- to avoid heat loss they must be insulated;

- there is a threat of freezing at low temperatures;

- clogging occurs during operation due to calcareous deposits;

- expensive assembly with the use of welding.

Polypropylene pipes (PP) are manufactured by extrusion from thermoplastic propylene polymer, so they are well welded.

In the manufacture of polypropylene stop valves and fittings, injection molding is used. PP pipes have four types of marking depending on the purpose:

- for cold water supply - PN10;

- for cold and hot water - PN16;

- for hot water and heating systems - PN20;

- for heating systems - PN25.

Simple PP pipes (unreinforced) are used for water supply (PN10, PN16), and for heating systems use reinforced (PN20, PN25).

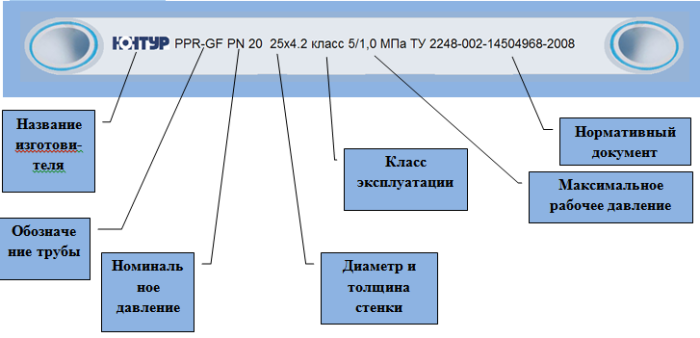

Reinforced consists of three layers. Between the inner and outer layer of polypropylene is a layer of fiberglass or aluminum foil. Reinforcement makes it possible to withstand high temperatures. Below are the main notations on which you can determine the choice of polypropylene pipes.

Depending on the material used, polypropylene pipes are marked as follows:

- PPH - from homopolypropylene;

- RDB - from the block copolymer;

- PPR - from the random copolymer;

- PPs are designed for use with an internal high temperature environment up to 95 degrees.

Systems using polypropylene pipes have the following advantages:

- no corrosion;

- long service life;

- sufficiently high strength;

- resistance to high temperatures;

- absence of deposits during operation;

- monolithic welding seams;

- light weight;

- easy and cheap installation;

- ecological cleanliness;

- affordable price.

Installation of polypropylene pipes by oneself is quite simple, you just have to follow the recommendations that contain the instruction. If the system is old, then its elements are simply replaced with new ones, leaving the old wiring diagram.

If the water and heating systems are re-installed, then it is necessary to draw an accurate diagram, to measure all the pipe lengths and angles. According to the schemes, the necessary connecting fittings, stopcocks, adapters for connecting pipes of different diameters, tees for wiring, plugs, and all that is needed.

The following tools will be needed for welding:

- welding machine - special soldering iron;

- teflon nozzles for polypropylene pipes of different diameters for heating the welded parts;

- pipe cutters, metal shears, wire cutters;

- calibrator for chamfering;

- shaver;

- adjustable wrench;

- marker;

- degreaser.

Having prepared the necessary tools and materials, you can start installing systems.

Possible schemes of water supply and heating systems

The water supply system must be connected to central system water supply and connect to it in certain water supply units. The water supply can be hidden and open. The installation of a hidden one is more complicated and it is better to entrust it to specialists.

An open water pipe can be installed independently. There are three types of wiring for a water supply system:

- collector - the most reliable in design;

- consistent - the most common because of the small cost;

- a little-used system using pass-through sockets.

When designing a heating system, as well as for a water supply, it is necessary to determine:

- places where there will be nodes, couplings and adapters;

- location of radiators;

- how the pipeline will be piped to the radiators.

The radiators can be connected to either one pipe or two, and it can be either side or bottom.

Below are four schemes for connecting a heating system:

The design of the hot water supply and heating system should be done taking into account the linear temperature expansion of polypropylene pipes. The expansion is compensated by the movable fastening.

Piping installation

Beginning the installation of systems, it is necessary to have on hand a competently designed project with an accurate wiring diagram. According to the project, pipes of the required length are cut, and then assembling and welding of the elements of all the system begins together. It is more convenient to make the main blanks on the floor, and then attach to the main system.

It should start from the places of consumption, successively attaching all the segments. To ensure that the water pipe is not visible, it is better to place vertical pipes in the corners, and horizontal ones are closer to the floor. Pipes should be connected at right angles.

If the pipes are hot and cold water are located next to, the hot water pipe should be placed from above, so that the pipe with cold water does not form condensation.

In difficult-to-reach places, the pipeline is mounted separately. In accessible places, structural parts are fixed by means of couplings.

For polypropylene pipes having a diameter of up to 63 mm, two connection technologies are used:

- fusion welding: the other end is inserted into the expanded end of the pipe;

- welding by means of couplings is carried out by joining ends in a coupling.

If a threaded connection is used, fittings with a bell are used. For pipes with a diameter greater than 63 mm, butt welding is performed. If there are appropriate fittings, then coupler welding is used.

Cut off the pipes should be strictly at an angle of 90 degrees with scissors for metal or pipe cutter. If the pipes are reinforced, the metal shell is removed. On the outer part of them a chamfer is made with a special device designed for this purpose.

From the edge of the pipe at a distance of 15 mm markers are placed with the marker, which are necessary for further adhesion. The edges of the parts to be welded must be even, without burrs or defects.

If there are any shortcomings they should be removed. Then remove any dirt and degrease the edges. Work should be done in gloves to avoid burns.

The welding machine, with which the connection will be made, is better fixed to a special stand. Further, the necessary nozzles are attached to the apparatus and, if there is a regulator, a heating temperature of 260 degrees is set. This is the optimum temperature at which the product quickly heats up and the Teflon coating does not deteriorate.

At a lower temperature, there will be no strong connection, and if overheated, the structure of polypropylene may collapse. Usually, the instructions to the device contain all the recommendations for its use.

When the desired temperature is reached, the thermostat fires, the Teflon nozzles are put on pipes and fitting until they stop, and then they begin heating. The heating of the parts is affected by the power of the apparatus and the diameter of the products. Usually 10-15 seconds is enough.

After heating, both parts are quickly removed and connected under some pressure, focusing on the mark. Movements should be smooth. Do not rotate the products in any way so as not to damage them.

After joining, the parts retain some plasticity, so they must be fixed for a few seconds. After welding, you should look inside, so that there is no partition from the melt. When the products cool, a monolithic part should be obtained.

The pipeline is fixed to the walls using clamps. If the welding has turned out to be substandard: there is a skew, an incorrect fitting position, a partition from the melt appeared, then another workpiece must be made. If there is no experience of such works, then before soldering it is better to practice on pruning of polypropylene pipes.

With a little experience, the installation of the system can be done during the day, which is one of the advantages of using polypropylene pipes. Polypropylene systems are reliable and practical.

Their further operation and service life depends on how well the installation is performed.

Replace the plastic wiring of the heating system or the water supply in the apartment is quite simple. To carry out installation of polypropylene pipes with your own hands, you only need a set of special equipment and a minimum of technical skills. What tools are needed for the work and how to use them correctly will be discussed further.

Most polypropylene (PP) pipes are the same only at first glance. A more detailed examination of them will reveal differences in the density of the material, internal structure and wall thickness. From these factors depends the scope of the pipes and the features of their installation.

Classification of PP material

The quality of the welded polypropylene seam and the performance characteristics of the pipes are largely determined by the technology of manufacturing PP.

There are such types of parts, based on the material of their manufacture:

- PPH. Single-layer products made of homopolypropylene. They are used in industrial pipelines and cold water supply systems.

- RRV. Single-layer products from block copolymer PP. They are used for installation of outdoor heating networks and cold pipelines.

- PPR. Single-layer products made of random PP copolymer. They are used in water supply and home heating systems with a water temperature of up to + 70 ° C.

- PPS. Difficult flame type of pipes with operating temperature up to + 95 ° С.

There are still multi-layer reinforced parts made of PP.

When heated at 80 degrees, reinforced PP pipes are extended by 2-2.5 mm / m, and ordinary single-layer pipes - by 12 mm / m

They have an additional internal aluminum shell, which drastically reduces the temperature lengthening, facilitating the wiring and safety of operation. The downside of these products is the need before soldering removal of the upper polymer layer and aluminum to the depth of penetration of the pipe into the fitting.

What does the marking look like?

Select the required pipes and fittings for plastic wiring in the building market can be done independently. You just need to know the legend of the marking.

Indicators can be in a different sequence and in a foreign language, but any decoding should be known to store managers

To determine the scope of polypropylene products, the main indicator is PN. This is an indicator of the nominal pressure in kgf / cm2 (1 kgf / cm2 = 0.967 atmospheres), at which the service life does not change. The base temperature of the coolant in the calculation is assumed to be 20 ° C.

In the domestic sphere, there are 4 main types of PP pipes with different PN parameters:

- PN10 - for cold water supply;

- PN16 - for cold and for warm water supply;

- PN20 - for hot water and heating systems;

- PN25 - for heating systems, especially central type.

Products with PN25 often have a large linear length, so they are almost always reinforced with aluminum foil or strong fiberglass for less expansion when heated.

Appearance and internal structure

Quality PP pipes have an ideally round shape on the cut. The thickness of the walls and reinforcing material should be the same along the entire circumference, there should be no rupture of aluminum or fiberglass.

To trim the top layer of plastic and foil on reinforced pipes, you need to purchase a special tool - a shaver. It is inexpensive and easy to operate

The reinforced pipe traditionally consists of three layers: inner and outer polypropylene and medium aluminum or fiberglass. Surfaces of pipes should be smooth, without sags and depressions. The color of the material can be green, white or gray, but from this the quality and characteristics of the pipes are completely independent.

Advantages and disadvantages of PP

The advantages of PP pipes for the installation of internal heating and water supply are obvious and are confirmed by their undivided dominance in this area. The properties that make this product a priority for the assembly of in-house communications are:

- noiselessness;

- impact strength;

- ease;

- resistance to corrosion;

- durability;

- tightness of joints;

- cheapness;

- insensibility of internal walls to plaques.

But polypropylene pipes also have negative sides, which cause inconvenience during installation:

- lack of flexibility;

- strong elongation at heating;

- the need for a special tool when connecting individual products.

Specialists, who daily assemble PP pipes, have long worked out ways to compensate for these shortcomings, so there are no special alternatives to polypropylene.

Preparation for installation of PP pipes

Water distribution with the help of one hand and pipes can not be done, so you need to understand the schemes of heating and water supply, the necessary tools, the methods of connection and the materials used.

Drawing up the project: layout diagram

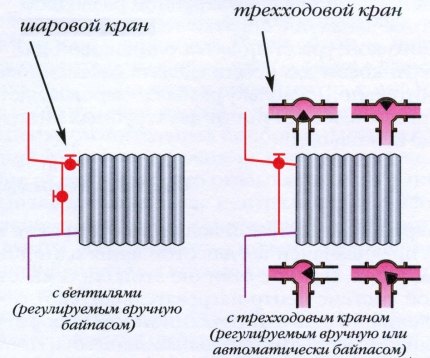

Before buying material for the installation of heating and running water, you need to determine their wiring diagram. Connect the batteries to the heating circuit in four main ways:

- flowing;

- with unregulated bypass;

- with valves;

- with a three-way valve.

The final choice of the installation option is usually determined by the financial possibilities of the owners of the apartment, because the stop valves are not cheap.

Schemes with adjustable valves allow, without damage to the hydrodynamics of the system, to regulate the power of the radiators separately in each room of the house

The water main also has basic schematic diagrams layout design, but there are only two: collector and tee (traditional in the apartments).

The tee scheme is installed in apartments where a small length of pipes and a small number of simultaneously used sanitary devices do not lead to a drop in pressure in the general circuit

The tee pattern is called sequential. It involves carrying one pipe along all the plumbing fixtures, from which taps are successively made with the help of a tee.

The collector scheme implies the installation of water at the inlet of the collector in the form of a flute. It allows you to compactly make several bends in different directions.

The layout can be done inside the walls or in the open. The first option requires detailed calculations that take into account the elongation of the pipes when heated.

Necessary tools for cutting and soldering

A significant disadvantage independent work with polypropylene pipes is the need for special tools. The price of the installation kit is from $ 100 to $ 200.

Complete sets of ready-made sets may differ from different manufacturers. Particularly the overall price is affected by the power of the soldering iron and its functionality

Such a set should include:

- electric welding machine with stand;

- scissors-pipe cutters;

- shaver for removing the outer layer and aluminum from reinforced pipes;

- calibrator and faskosnimatel for control and regulation of the diameter of parts;

- nozzles for heating the soldered elements.

In addition to special equipment, a wrench, marker, roulette and other general economic tools are required for the installation of PP pipes. If one-time installation works are planned, then you can take the soldering set for rent.

Selection of polypropylene fittings

To weld PP pipes among themselves in various combinations, as well as to connect them to plumbing fixtures, PP fittings are used. To them carry;

- adapters;

- nipple bends;

- couplings;

- clutches with thread;

- tees;

- plugs;

- crossings;

- detachable connectors;

- ball Valves;

- clamps.

A few tips for choosing fittings and installing pipes:

Image Gallery

The quality of polypropylene and the wall thickness of the fittings can also differ, so you need to choose them according to the marking of the pipes.

Connection schemes for PP products

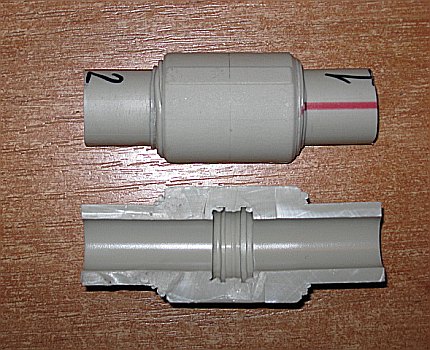

Exist fundamental difference in the soldering of pipes up to 63 mm in diameter and 63 mm in diameter. Pipes that are equal to or larger than this size are welded butt-welded, and those that are smaller are joined by a bell-like method.

The latter assumes the formation of the joint due to the fact that the molten cut off end of the pipe enters a few centimeters into the extended socket of the fitting. The same way, the joints of two pipes are also carried out by means of a coupling.

In the case of a counter-coupling of pipes, it is important that at their junction there is not formed an inwardly rising flow: it will impede the progress of water, reducing the pressure in the system

Depending on the presence of threaded parts, PP joints can be:

- detachable;

- all-in-one.

Plug-in connections mean soldering to the ends of connecting parts of two threaded fittings with external and internal thread. The above-described bell method of joining by soldering two polypropylene products relates to an unbroken type.

Step-by-step instruction for welding PP pipes

After buying all the necessary pipes and fittings, you can start welding them. This process will be considered step by step, with illustrations, so that no questions remain.

Step # 1: trimming pipes

This process is performed using a pipe cutter. If the slice is beveled, a longer edge can form an inflow during soldering and narrow the internal passage of the fitting.

The pipe cutter has a wide base that helps to withstand a right angle when cutting, but this does not mean that you do not need to control the perpendicularity of the cut yourself

Pipe cutters have the maximum diameter limit, so you need to choose the model that fits the purchased pipes.

Step # 2: Tube processing and chamfering

After trimming, it is necessary to form a small chamfer on the part that will fit into the socket. For this, hand-sized calibrators or screwdriver attachments are used in various sizes. Both tools have built-in knives that form a chamfer with standard parameters.

Forming a chamfer for a screwdriver can be directly in hand, without resorting to rigid fixation of the pipe in the vice

To obtain a cut, it is necessary to put the tube on a manual calibrator and several times with a push to scroll around the axis.

On the reinforced pipes, in addition to chamfer, the upper layer of PP and aluminum foil is removed with the help of a shaver. It looks like a cylinder with handles and it fits only one particular size.

After forming the chamfer and removing the aluminum foil, all parts must be wiped clean.

Step # 3: Preparation of the soldering iron

Soldering temperature of polypropylene pipes varies from 260 to 280 ° C, but fans prefer to use non-regulating soldering irons or heating up to 260 ° C. Before switching on, it is necessary to put two-sided nozzles (mandrel and sleeve) on the iron of the soldering iron and place the device on a cross-shaped stand.

The more powerful the soldering iron, the more pipes it can weld in a unit of time, but for domestic work enough 800-watt instrument

Then turn on the soldering iron. When the temperature reaches 260 ° C, the green warning light comes on.

Step # 4: heating and connecting parts

To connect and disconnect polypropylene parts with a soldering iron it is necessary directly without twisting movements. A similar rule applies when connecting heated products

For compliance with the depth of the connection, it is possible to make a mark in advance on the pipe in advance and be guided by it when the product is inserted into the socket. The table below shows the standard heating, connection and cooling time of the pipes, depending on their diameter, as well as the depth of insertion into the socket. When working in a cold room, the heating time can be increased by 1-2 seconds.

The time parameters indicated in the table are indicative. The exact figures should be looked at in the instructions for the specific model of the soldering iron

After heating, the connected parts with direct force must be joined to the intended line. It is important not to allow the turning of parts. Shifts of pipe and fitting relative to each other are allowed only for 4-12 seconds. After this, any movement will have a very negative effect on the quality of the connection.

When connecting parts their axes should be located maximally parallel, because in 20-30 seconds it will be impossible to correct the curvature

After bonding, the polypropylene should be allowed to cool down within the time specified in the table. It is advisable to look at the resulting internal seam to make sure that the inflow does not obstruct the passage. Otherwise, you have to re-solder the parts. This completes the process of soldering.

How to fasten the pipeline

A good distribution of heating or running water is not only the quality of the connection, but also the realization of knowledge of how to assemble the assembled polypropylene pipes. Correct fastening of the plastic wiring to the walls will prevent it from sagging and deformation when heated with hot water.

When repairing it is sometimes necessary to pull the pipe out of the clips with force, so the dowels must firmly fix this small element against the wall

For fixing pipes, apply:

- single;

- typing;

- with clamp.

- on the hairpin;

- paired;

- walled.

New models of clamps and clips are constantly appearing on the market, so their choice should be made directly in the store. Clips basically provide free movement of pipes along the axis, and clamps firmly fix them in one position.

A particularly dangerous consequence of improper installation is the neglect of thermal expansion of the pipes. The length of simple PP pipes can vary with heating by 10-15mm / 1m. With their rigid fixation, deformation occurs in the areas of adhesions, which can lead to rupture of the joint. To remove the voltage, these types of compensators are used:

- Z-shaped;

- U-shaped;

- L-shaped

- circular.

Rules of work with the compensator:

Image Gallery

The most simple and easy to install compensator, but requiring free space near the pipe

After soldering the expansion joints and fixing the pipes to the clamps and clips, you can start testing the assembled system.

Video instructions for soldering and installation

The algorithm for the soldering of polypropylene pipes is best remembered after viewing the relevant videos. Also, the types of fittings and the features of their welding will be shown.

Kinds of soldering irons and the instruction on the soldering of polypropylene pipes:

Secrets of installing PP pipes:

Types of fittings and rules for their soldering:

The above-described technologies for installing polypropylene pipes and fittings are simple and do not require professional skills. Video materials clearly demonstrate the stages of the soldering process, which you can master yourself in a few minutes. Therefore, to assemble plumbing by oneself, it is enough to purchase the necessary materials, find equipment and follow the algorithms described in the article.