Boiler water home made wood for 200 m2. Cast iron radiators in the role of a boiler. Masonry furnace with boiler

The furnaces that burn liquid fuel have been known since the beginning of the last century. True, then they served mainly for the needs of industry. In the home, the units that run on diesel or fuel oil, were widely used in the 1960s and 1980s. It was at that time that refined products could be bought for pennies or even free of charge. Despite a significant rise in price of energy carriers, it is still possible to cheaply heat your home even now. You can say that the fuel for this lies just under your feet, or rather, at each car service. The fused waste oil burns not worse than diesel fuel, besides, the owners of the workshops give it practically for nothing. By the way, it is not necessary to buy a boiler for its combustion. A simple and reliable unit with a water circuit can be built with your own hands, using materials that will be found by every owner.

The design and operation of a waste oil boiler

Fused car oils are multicomponent, heavily soiled substances, which also badly burn. It can be said that as a fuel, the work itself is not "very", since oxygen simply can not oxidize all the chemical diversity that is in it. If you split the oil into simpler components, then it will be much easier to burn them.

The decomposition method is known to modern science for a long time. Flame separation, or, in scientific terms, pyrolysis, is used to produce simple flammable substances from any fuel - oil, coal, firewood, etc. This process is convenient because no additional costs are required for chemical conversions - for this enough heat that is generated when the fuel is burned. The advantage of pyrolysis combustion is also in the fact that this process supports itself and regulates itself, and therefore practically does not require extraneous interference. All that is needed to start the decomposition process is to evaporate the fuel and heat the steam to a temperature of 300-400 ° C. To do this, you can use two methods.

In the first case, the fuel is ignited in the tank, after which it begins to actively evaporate. Effective mixing and obtaining a homogeneous gas-air mixture is provided due to Coriolis force, therefore accurate calculation of the diameter and height of the combustion chamber is important. Fuel vapors rise along a vertical pipe with numerous holes through which are saturated with oxygen of air. In the upper part of the combustion chamber is a barrier, which is needed to reduce the gas velocity and to separate the oxide-nitrogen afterburning zone. It is in it that dangerous chemical compounds react with nitrogen oxides and break down into harmless substances.

The so-called method of self-cultivation, undoubtedly, has attractive simplicity and reliability, however, the tank with burning oil does not allow talking about safety. In order to eliminate this drawback, it will be necessary to complicate the design of the heating unit.

The second method involves the formation of pyrolysis, combustion and afterburning zones directly in the flame, and this requires a special configuration of the burner. In order for the fuel to oxidize completely, the injector must provide a multi-stage formation of the gas-air mixture. In such a device, the primary movement of the fuel flow is provided by the compressor. Thanks to injection, the injected air entrains the atmospheric, and the formation of vapors occurs due to the heating of the burner with a flame torch. Practically the same processes can be observed when the soldering lamp is operating. A similar method is implemented in industrial liquid fuel units. Homemade designs use the same principle, but work a little differently. In them, workings drip into the preheated hot-water tank, where it instantly evaporates and burns at high temperature. In this case, one can not speak of pure pyrolysis, since there is also the energy of decay of molecules in the process of microexplosions.

Types of constructions on working

Depending on the field of application, boilers that use waste oil as fuel can be divided into three groups:

- household furnaces;

- water heaters;

- heating boilers.

Household furnaces are installed in rooms that can not be equipped with water heating for a number of reasons. These units are characterized by a reduced fuel consumption, and their design provides the most complete combustion of oil. Household equipment is practically smokeless. In addition, furnaces are often equipped with emission cleaning systems, which increases the safety of their operation. The main advantage of aggregates of this type is in their mobility. Small dimensions make it easy to transport the oven and install it in a small room. It is also important that the device can be easily retrofitted with a water circuit or a cooking area, if necessary.

Water heaters at the level of the module for afterburning gases have a special platform on which a container with water rests. Its toroidal shape gives an additional advantage, since heating is carried out both from below and from the side of the smoke channel that passes inside the tank. For the autonomous water supply at the entrance to the boiler, a small water pump is installed. Due to the high temperature, water can be heated much faster than in factory water heaters. For example, a 100 liter tank collects temperatures from 20 ° C to 65 ° C in about two hours, while an electric or gas appliance will need twice as much time. If we talk about the cost of a conventional liter of hot water, then when using a mine, the costs are reduced by 20-25 times.

Heating boilers are used for connection to water heating systems, therefore they are equipped with devices for afterburning of exhaust gases, filters and safety devices. Despite all precautions, it is recommended to install equipment for waste oil heating in separate rooms or annexes.

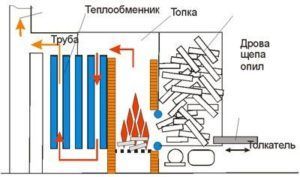

Heating of water in the heating units is ensured by a heat exchanger installed in the combustion zone of the fuel. It can be made as a continuous water jacket, and in the form of a spiral tubular contour. The movement of the thermal agent in the system is possible thanks to a circulation pump operating from electricity. The temperature of the coolant is regulated by lowering the flame temperature. For this, the boiler is equipped with a forced air supply system. By reducing or increasing the speed of the turbine, regulate the supply of air to the combustion zone. Installing the thermostat allows you to automate this process.

Often, the units operating on the combined oil are duplicated by devices using electricity, gas or solid fuel. This ensures the functionality of engineering systems in the event of interruptions in the delivery of work.

Manufacture of a boiler operating on spent fuel

According to the schemes described above, several types of boilers have been developed and are successfully operating. In addition, any solid fuel or gas heating unit can be adapted to work with liquid fuel. Let's talk about the two most common designs that you can make yourself.

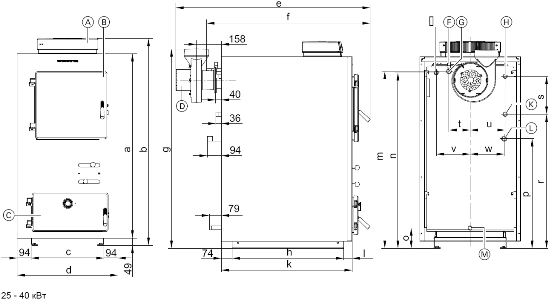

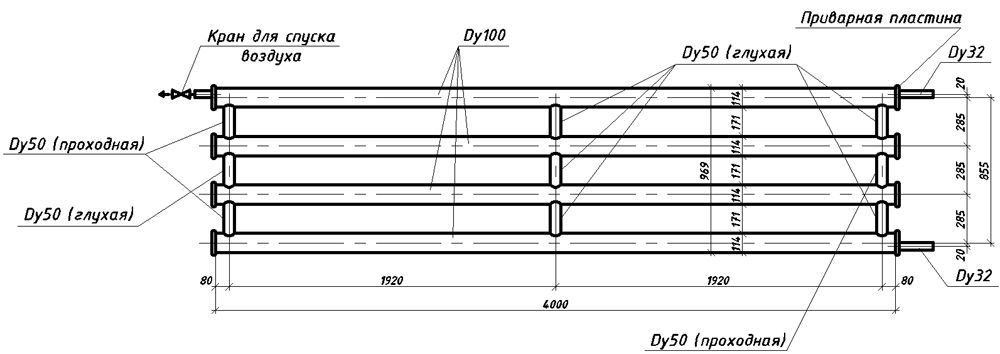

Drawings of heating units

The drawings, which we give to your attention, are checked on really working furnaces, so you can confidently use them for your own projects.

Two-volume

This design consists of two cylindrical chambers connected by a section of a thick-walled iron pipe with holes for air penetration.

The lower compartment is simultaneously a fuel tank, an evaporator and a primary combustion zone. To fill the fuel, ignite and regulate the air flow, an opening is cut out on its upper plane, which can be completely or partially closed by means of a rotary-type hatch. From the bottom the stove is equipped with legs, which ensure the stability of the structure and create a gap between its bottom and the floor.

In the upper plane of the furnace compartment, a pipe with holes is welded. This hollow cylinder is a post-combustion chamber. It produces pyrolysis decomposition and combustion of evaporating fuel (secondary afterburning). On the upper section of the perforated pipe is mounted almost the same capacity as the bottom. The partition, which divides its internal space into two zones, reduces the velocity of the combustion products and ensures the completeness of their oxidation by nitrogen compounds. In addition, the upper chamber is also a heat exchanger, which operates as an infrared and convection heater.

Mounted on the upper module, the chimney creates the necessary draft and draws the residual combustion products out. To protect the process of refilling the work in the lower tank, a tube is welded to it, connected to a separate tank. Filled in the stove oil ignited with rags soaked in gasoline or kerosene. After that, the flap is controlled by the flow of air into the primary combustion zone.

Having installed a water jacket or a contour on a vertical pipe, a boiler is obtained, which can be successfully used in heating or hot water supply systems. In this case, it is important to leave a clearance of at least 50-70 mm to the perforated cylinder to ensure a free flow of air into the secondary combustion zone.

With a flame cup

A drawing of a simple boiler with a flame cup is given below. Its dimensions provide a heat output of about 15 kW. This requires no more than 1.5 liters of used car oil per hour. Air in the combustion zone comes from a small fan or turbine. The supply of spent fuel is carried out portion by piece, for which the oil tank is equipped with a valve, which can regulate the amount of fuel or completely stop its supply.

For post-combustion, the central tube is equipped with a system of holes and slots. Thanks to this design, the same processes are happening around the flame cup, as in a double-wall furnace. Combustible gases are removed through a chimney installed in the upper part of the combustion chamber. When installing it, avoid sharp turns and corners, and the height of the chimney should be at least 4 m. This will provide enough traction to remove the combustion products and ensure the safe operation of the heating unit.

The furnace with a flame cup is a closed device with forced air supply. This contributes to the safety of operation, and also makes it possible to easily and easily equip the water jacket. The diagram shows the working design of the boiler described above, as the housing of which you can use a household gas cylinder.

Necessary materials

To produce a water heating boiler with a flame cup, you need not only a container for making the case, but also other materials (the positions on the above diagram and in the list correspond to each other).

- Propane cylinder with a volume of 50 liters.

- A metal pipe Ø 100 mm with a thickness of 2-3 mm for making a chimney.

- The iron pipe Ø 100 mm is 5-6 mm thick, which will be needed to make the burner.

- Steel sheet with a thickness of at least 5 mm to separate the combustion chamber and the evaporation zone.

- A metal sheet 3-4 mm thick for the manufacture of a visor designed to reduce the velocity of gases.

- A brake disc with a diameter of at least 20 cm from any car.

- The coupling (the same 100 mm pipe, only cut over the entire length) is 100 mm long.

- Steel pipe Ø15 mm for supplying oil to the bowl.

- Ball valve size ½ inches.

- Fuel hose made of oil resistant refractory material.

- Tank for working off of any type.

- Corner or steel profile for making legs.

- Cover made of steel 4-5 mm thick.

- Steel sheet with a thickness of at least 3 mm for the manufacture of a water jacket.

- Connections with Ø2 резь thread for connecting the boiler to the heating system.

Do not forget that to protect from corrosion and improve the appearance of the boiler it will be necessary to paint, so buy a rust converter, a primer, a solvent and an enamel for working on metal. In addition, sealing joints will require sealing materials - plumbing and special paste.

Tools for work

In the process of working on the boiler will need a variety of electric and manual metalwork tools. Here is a list of what you need to get from the bins, buy, or borrow from friends:

- welding machine - it is best to use a DC transformer or inverter, since high demands are placed on the quality of welded seams;

- electric drill and set of drills for metal work;

- angle grinder and two discs - cutting and stripping. Of course, these consumables should be designed for cutting steel;

- dies for threading on pipes;

- electric emery;

- gas key;

- roulette;

- metal ruler;

- a high-carbon steel scriber for marking parts before cutting them.

Since you have to drill a large number of holes, you must always prepare a container with water to cool the instrument. In addition, it is necessary to ensure the safety of welding operations, so it will be useful to stock up a fire extinguisher.

Instructions for the manufacture of a boiler for self-development

It is possible to perform the boiler operation test without waiting for the tie-in to the heating system. To do this, pour in the fuel tank and open the ball valve, until the oil is distributed a thin layer on the bottom of the disk. A small amount of kerosene is poured from above and ignited. Fuel supply is regulated, guided by the rate of its flow and level in the furnace cup.

Video: Manufacture of a heating boiler from a gas cylinder

Strapping. Duplication of the kiln by electric unit

Before connecting the boiler, you should consider not only the method of installation and the location of additional devices and shut-off valves, but also the way to exit the chimney outside. If it passes through a ceiling constructed with the use of flammable materials, then it installs a metal pencil of twice the diameter. Free space between pipes is filled with asbestos or other non-combustible material with good thermal insulation properties.

Considering the high danger of heating with liquid fuel, installation of the boiler is best performed in a separate room with good ventilation. The podium under the aggregate is concreted or covered with a metal sheet, which will protrude beyond its contours by at least 1 meter. After installation, the boiler is leveled by a plumb line and only after that start to connect.

The simplest way to bundle the boiler is to integrate into the gravity heating system. Despite its simplicity, its reliability is very high, since in this case there is no need for a circulation pump and automation devices. Nevertheless, the use of additional equipment makes it possible to accelerate the delivery of the coolant to consumers and to equalize the temperature at all points of the system, which provides fuel economy and increases comfort. To this end, a centrifugal pump and a membrane-type expansion tank are installed on the return line at the very entrance to the boiler. It is necessary to ensure that the system is not depressurized when the temperature and pressure rise. A pressure pipe is connected to the upper branch pipe, and to adjust the temperature of the consumers, a thermostatic head or other control device (a three-way valve, a valve to reduce the section of the supply pipe, etc.) is installed in front of each radiator. To remove air plugs, an air vent is installed at the top of the system.

The strapping of the unit, working on the working, requires taking into account the inertia of this type of equipment. In other words, the change in the coolant temperature is gradual, so the unit necessarily equipped with a safety valve. It will allow you to relieve pressure when it rises to a critical level. A good way to secure and level the temperature is to connect the indirect heater indirectly. It will serve as a buffer, which will take on excess heat in case of excessive temperature rise.

Rating: 276

In our time, autonomous heating finds more and more fans both among private traders and urban residents. Ideal in terms of price and quality, is heating on wood, serving as an alternative to a gas device, with its high cost and expensive installation.

This unit is capable of performing two functions: heating and hot water supply.

Most of the time, modern models of boilers run on gas and electricity. Essential disadvantages are the high cost of the necessary equipment and the mandatory presence of a gas main near the heated premises.

Disadvantages - in a serious increase in the load on wiring and high tariffs for electricity.

There are cases when the heating is in no way inferior to those that are produced in factories and enterprises. In our time, it is possible to make a water boiler with your own hands right at home. With certain skills and abilities, the domestic boiler has every chance to surpass the factory models of water boilers for heating by its technical characteristics. The accuracy of calculations will be of great importance in the manufacture.

All that is necessary to create a simple boiler construction with their own hands is easy to get, it is possible that the required materials are available to the privateer in stock.

When calculating for the boiler, you need to pay attention to the operating temperature and the thickness of the metal. If these parameters are incorrectly calculated, the boiler wall may burn out.

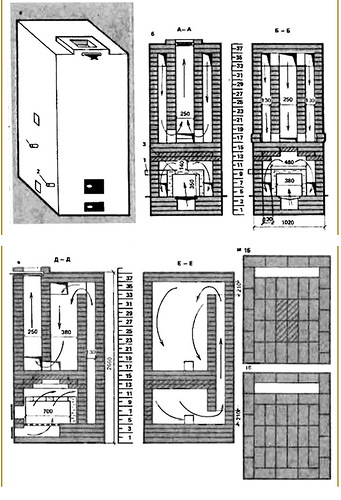

Pyrolysis boiler drawing

To meet some of the given parameters, with the water type by hand, it is possible to use parts of old boilers that have become unusable. These can be decommissioned boilers of steam locomotives or devices that have been damaged. A normally functioning boiler can also serve as a basis for heating equipment. A wood-burning boiler will cost very cheaply if you find parts for it in a landfill or purchase for a nominal fee at a scrap metal reception point.

Undoubted advantages of this heating equipment include the absence of harm to the environment, the high efficiency of the water boiler, the wide prevalence and low price of fuel, cheapness, operational safety, ease of use and autonomy of the installation.

The most important difference between self-made boilers and their factory counterparts is the combustion method.

From this conclusion it is possible to deduce the classification of types of water on wood:

- a classic cauldron - equipped with a single chamber, which serves to store fuel in it;

- pyrolysis boiler - has two chambers and increased heat transfer compared to classical boilers.

Pyrolysis models of solid fuel boilers have a higher efficiency due to the fact that the combustion of firewood in the first chamber simultaneously leads to the formation of gases and their transition to the second chamber, then the combustion of these gases in the second chamber occurs. Thanks to this, it becomes easier to heat the house and the heating process is much faster.

Homemade pyrolysis boiler

A small limitation when using pyrolysis boilers for heating is that only well-dried firewood can serve as fuel for them. Otherwise, the burning of firewood will not occur, which will entail a lack of heating process.

You can do it yourself in many ways.

But, in any case, for proper execution it is necessary to be able to:

- find the most suitable variant of water supply by means of calculations;

- choose the best place for the furnace, based on the design of the boiler and its location in the room;

- conduct the correct and the parameters of the heat exchanger.

After completion of all calculations for the construction of the boiler go to the installation of the heating system.

A complete list of consumables for installation and tools needed to install a water-fired wood-fired boiler:

- profile and;

- rod;

- nuts;

- bolts;

- fan centrifugal type;

- sheet steel.

Information about the installation can be found in those people who conducted a manual installation of a water boiler working on wood.

![]()

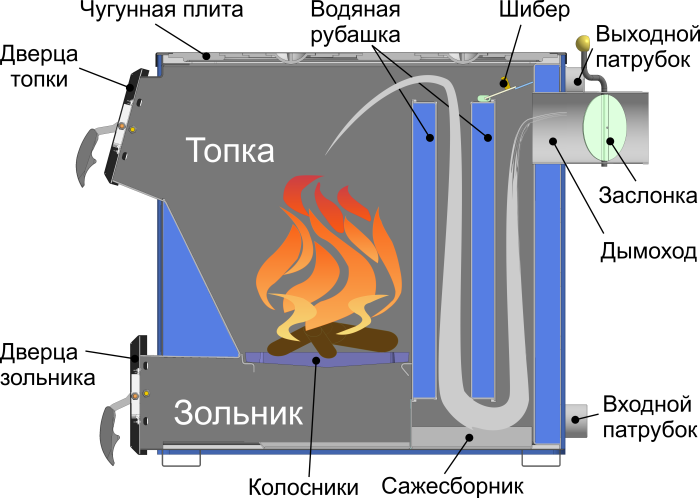

The device of a three-chamber boiler with a water circuit

At the same time, any of the found ways of creating a heating system, you can modernize in its own way. But do not forget that you must first make accurate calculations of all operating parameters of the system and the correct installation of the boiler.

Final installation phase

Upon completion of the installation of the water heating boiler on the wood, as well as the fulfillment of the calculation activities, they pass to the final stage - the installation of the boiler.

We will use the method of Belyaev as a calculation device:

- To increase the efficiency of the boiler, it is necessary to increase the volume of the heat exchanger. In this case, it is necessary to leave the internal volume of the product unchanged and the same.

- The next step is to install the boiler yourself on the prepared place.

- Next, the boiler must be connected to the circuit, which will be.

- After, it is necessary to inspect and check all joints and seams for integrity.

- If, during a visual inspection, no faults are found, a test run of the boiler is performed.

- It must be remembered that the boiler is most effective in the gas-generator mode.

- To increase the attractiveness and aesthetics of the product, it is covered with paint. However, it is important to understand that paint is required with very high refractoriness.

Experience shows that with proper observance of all technical requirements, the most accurate preliminary calculations and careful assembly, a self-made water heating boiler on wood will have a higher efficiency than electronic or gas units. Do not forget that with the help of steam boilers the heat distribution in the house is the way that is more convenient for you. It is also indisputable that water boilers are more economical than their above-mentioned counterparts.

Your contacts in this article are from 500 rubles per month. Other mutually beneficial options for cooperation are possible. Write to us on [email protected]

Application of a self-made boiler for water heating

Homemade boiler for water heating works on the following principle: the fuel burns, thereby heating the coolant. They can be anything, but the most common is water.

Of course, when buying a ready-made unit, it is only necessary to install it, install the system and monitor the operation. The boiler will save money and make a convenient heating system.

Boilers for hand assembly, advantages and disadvantages

As already mentioned above, boilers with their own hands - it's saving. The purchased model will cost twice as much, taking into account all the costs that are invested in it. But self-made inferior to the purchased in terms of efficiency. The principle of operation remains unchanged: the fuel burns and generates heat entering the heat exchanger in which water is heated.

Collected with the help of an individual scheme, they have no guarantee - this is their only drawback. After all, if there is a breakdown or some defect in the work, it is not possible to simply take it for repair or replacement. Therefore, how it will be done, and it will work. The quality, long-term and safety of work depends on the owner. And repair in the event of its breakdown will have to do on your own.

To protect the house and heating, it is desirable to use the following types of fuel:

It is these types of fuel that are considered to be the safest for use in the boiler with their own hands. Not recommended and even prohibited, because they are very dangerous, gas and diesel. Installing them in a dwelling can be very dangerous and will end up lethal with a low level of knowledge that is necessary for installation.

Boilers with a water circuit are divided according to what type of fuel will be used for their operation. Next, consider the most common types of them.

Samples for heating on firewood

The wood-burning boiler is the easiest for self-made. Get all the materials that will be needed to make it, and the tools are either simple enough. Fuel, which consumes the boiler on firewood, namely the wood itself, is always without problems and in the required quantity can be purchased.

The main advantage is that wood-fired boilers are simple and versatile, but there are disadvantages, which are the low efficiency.

The main advantage is that wood-fired boilers are simple and versatile, but there are disadvantages, which are the low efficiency.

The boiler of water heating will most likely be made of a pipe having sufficiently thick walls of large diameter, inside which there will be a pipe of a slightly smaller diameter, which plays the role of a furnace. The space that will remain between the pipes is filled with a coolant.

Such a device is practically universal, since it can act as a solid fuel heating boiler with a water circuit. Absolutely all types of solid fuel are suitable for solid fuel water boiler. The most common types of solid fuels used in the operation of the water boiler are coal of coal and brown, peat briquettes, etc.

Pyrolysis boilers

In comparison with the previous view, these water heating boilers have a high level of efficiency. This is due to a special combustion process. The tree is divided into wood coke and pyrolysis gas during combustion in a furnace of a water boiler at a low oxygen level. In addition to this, a large amount of air gives an ignition with the release of a huge amount of heat. On economy, this type of water boiler outperforms any other solid fuel boiler, since one firewood will last for 12 hours, or even more, others can not boast of such a long burning time, they do not exceed 4 hours.

The combustion process is built in such a way that there is practically no solid waste left. And the gas burning level is easily regulated.

True, such water heating boilers have rather strict requirements for the humidity of the fuel, which will be used. The humidity of the fuel should not exceed 30%, otherwise water vapor forms in which the pyrolysis gas burns much worse, and hence the lesser amount of heat released.

The materials from which the water boiler will be made will cost more than the previous variant, but all the funds spent for its manufacture will pay off in a few heating seasons.

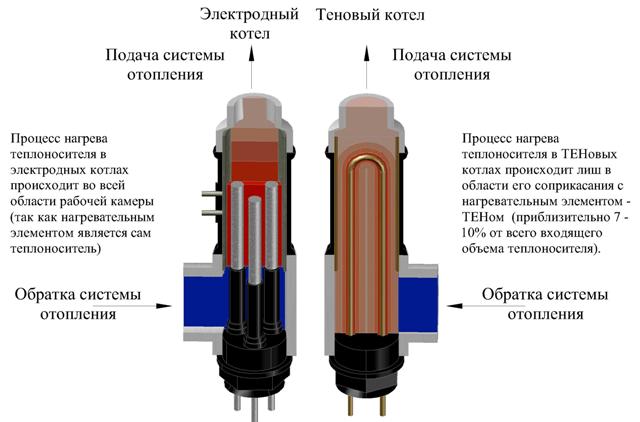

Electrical types of devices

The simplest and most common design for the installation of electric boilers is a vertically arranged pipe inside which the heating element is located, at the bottom there is a return and the top is the supply. And, of course, the water circulating inside.

The main disadvantage is the ban on connecting water boilers with a capacity of 7 kW to a 220 volt network, and 380 volts is not everywhere.

Another simple option, which makes electric boilers - induction. Almost anyone will be able to collect it, since among heating boilers such an assembly scheme is the easiest. This water boiler consists of a plastic pipe with a thick wall around which many turns of enameled wire are attached, connected to the welding apparatus. Usually, it uses its portable prototype, which has an output current of 15 A.

The cut steel wire is poured into the tube itself, pieces of chopped rod are those elements that will be heated by the vortex flows and transfer heat in a pure form. On top of the feed, the bottom of the return flow, and the entire space is filled with water.

Also, heating boilers can be on waste oil. This kind will help to get rid of residues of unnecessary oil and other liquid combustible lubricants. Instead of lubricants and oils, you can use diesel fuel.

For those who know how to own tools on their own, such work will not be difficult, and even save some money. In simplicity of use and cheapness, the first will be heating systems on firewood, since installation is simple and straightforward, and it is quite easy to find the necessary fuel: from processing unnecessary wood and buying it on the market.

The pyrolysis system will be more difficult to install, but will bring more heat and a minimum of waste, since it almost does not leave them. As for the electrical system, everything depends on the tension in the house.

How can the efficiency of the turbojet be increased?

Types of boilers and their application for heating the garage

Air recuperator: only by own hands

Boiler assembly by own hands

The heating system of a private house is a complicated scheme of pipe distribution, the heart of which is a heating boiler. It heats the coolant, which, under the influence of the laws of physics or by means of a circulating pump, moves through the pipes, gets into the radiators, where it gives its heat, and returns to the cooler again. And this process is repeated to infinity.

The modern market of boiler and heating equipment offers a huge range of heating appliances. Unfortunately, the price of many models is not affordable for everyone. Therefore, a question is raised before some consumers whether it is possible to make a heating boiler with their own hands, will this homemade device work just as efficiently as factory analogues? You can make a boiler if you are a good welder and it will work no worse.

Types of heating boilers

First of all, you need to decide which boiler is needed for your home. This will depend on the fuel that will be used for the kindling. Hence the classification:

- gas;

- electric;

- solid fuel;

- oil-fired.

Electric

Any of these boilers can be made by hand. The simplest of them is electric. In fact, this is the tank in which the heater is mounted. From the tank there are still two nozzles connected to the feed and return circuits. There is no chimney, no combustion chamber, everything is simple.

Electric boilers are all good, but they have two drawbacks. First: electricity is the most expensive fuel. The second: when the voltage in the network drops (and this happens with enviable constancy), the boiler stops working correctly. Its power decreases, the temperature of the coolant drops.

The structures of the remaining species are more complex. And they are all practically similar to each other with some differences. As for the gas boiler, a gas service permit is required to install it.

Representatives of this organization may not accept such a heating unit for installation. First of all, it will be required to conduct its crimping in its laboratory.

Having an act is a guarantee that you will still get permission.

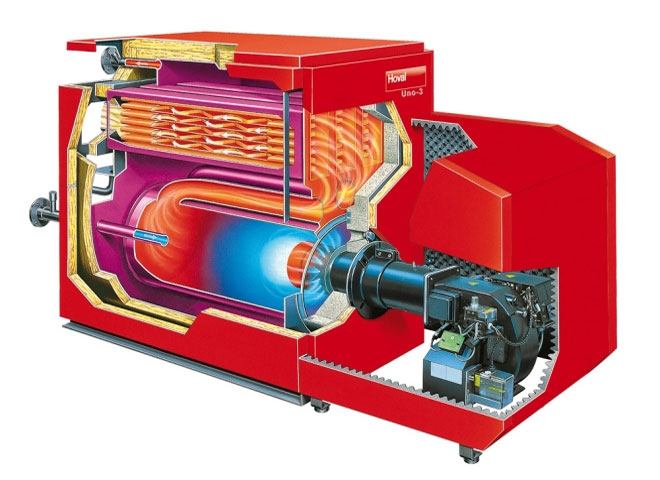

Boilers for liquid fuels

The operation of this option is associated with great difficulties. First, it will be necessary to build a separately standing warehouse near the house where fuel will be stored. In it everything must meet the requirements of fire safety.

Secondly, from the warehouse to the boiler room you will have to pull the pipeline. It must be insulated. Thirdly, in the boiler of this type a special burner is installed, which must be adjusted. This is not so easy to do in terms of customization.

Solid fuel

It is this kind of boilers today, most of them are made by home craftsmen. For small cottages and cottages this is the best option. Especially firewood is by far the cheapest type of fuel.

On how to make a boiler, working on solid fuels, for heating the house and will talk below.

What is needed?

As mentioned above, to weld the heating unit, you must be a good welder. Work at the amateur level here will not work.

Instruments

What is required for this work. You will need tools:

- electric welding machine;

- gas cutter;

- bulgarian;

- a hammer;

- roulette;

- marker or chalk.

- seamless pipe with a diameter of 425 mm;

- pipe diameter of 100 mm;

- pipe diameter of 25 mm;

- metal sheet thickness of 4 mm;

- two drills with a diameter of 25 mm;

- small loops;

- a corner of 25 mm;

- fittings with a diameter of 8 mm.

Many newcomers are looking for drawings of boilers on the Internet or special technical literature and already work on them. In principle, this is the right way.

Most importantly, find the drawings in which the dimensions of the heater are indicated.

Making the case

So, first of all, the details of the future unit are prepared. From the pipe 425 mm will be made the body of the heater. For a small boiler, the height of 1.0-1.2 m, considering the small diameter - is the best option.

Cut the pipe to these dimensions with a gas cutter. We process the edges of the bulgarian.

Holes for firebox and ash

Now it is necessary to cut out two holes in the body: under the furnace and for the ash-pit. They must be rectangular. For a firebox the size 20х10 cm, for a podduval 20х3 cm will fit. They are located one above the other, the furnace hole is higher.

The distance from the edge of the pipe to the puddle is within 5-7 cm. Between the holes, the distance is 5 cm. The edges of the holes are treated with a bulgarian. The cut piece of the wall of the furnace tube will be used as a door. Its edges are also cleaned.

Holes for nozzles

With the cutter, two more holes are cut for the supply and return pipes with a diameter of 25 mm. The holes are opposite each other. In this case, the opening of the return is cut out on the side of the boiler above the furnace: from the furnace hole at a distance of 15 cm.

At a distance of 5 cm only from the upper edge of the body cut out the opening for the supply of coolant. Immediately to these holes, you can weld two slots.

Internal parts

Of the metal sheet, three pancakes are cut out: two with a diameter of 425 mm, one with a diameter of 412 mm. The latter will be installed inside the case, and since the pipe wall thickness is 6 mm, the diameter drops out 12 mm, plus 1 mm for free entry.

In one pancake with a diameter of 425 mm and in a circle of 412 mm, a hole with a diameter of just over 100 mm is cut in the center. A chimney from a 100 mm pipe is being prepared. To do this, cut a length of 120-130 mm. From the 25 mm pipe cut pieces of 50 mm length for the legs of the boiler. From the fittings there is a grate for the ash pan, based on the size of the inner diameter of the casing.

Assembling the heating unit

First of all, a chimney is welded to the pancake 412 mm. Then, within the housing, at an altitude of 30-35 cm from the combustion hole, it is necessary to weld temporary stops. It can be wire or armature. On them a pancake with a chimney drops down.

Basic joints

But now the most important point - you need to weld a pancake and the body of the boiler. It is necessary to weld the seam from two sides and it must be done qualitatively. This joint is the interface between the furnace and the water tank.

Stove compartment

The next stage concerns the combustion chamber. On the back side of the chimney, a ready-made grate is inserted into the casing from the fittings.

Then from a corner of 25 mm are cut out by the Bulgarian some pieces which are welded inside of a copper between a furnace aperture and an ashtray. This will be the stops on which the grill will lie.

Bottom of the case

And the last. It is necessary to weld a pancake 425 mm to the bottom edge of the body, to weld to it four legs from a pipe 25 mm high by 5 cm. Next, the hinges are welded, on which the door of the furnace is hung.

Design for an ashtray valve

The design can be different: in the form of a conventional door, in the form of a gate (this is a flap that moves in the plane of the hole), in the form of a rotary flap with holes in the body. Ready-made products are sold, which are simply welded in place.

You can weld the whole construction with your own hands and attach it to the boiler. Of all the proposed options, the simplest is either a door or a gate.

Testing and connecting to the system

Solid fuel for heating the house is ready. Now you need to check it. For this, a plug is wound on one of the drums, and water is poured into the second one. If the water does not pass through the welded seams, then the welding was carried out at a high level.

To be afraid, that during operation the heating unit will flow, it is not necessary. The finished unit is connected to the heating system of a country house. That is, the connections are connected with the supply pipes and the coolant return.

Chimney installation

The chimney is being installed. Note that this element of the device must go up vertically. If this is not possible, then there should be a minimum number of bends.

In an unheated attic it will have to be insulated.

The first kindling

It is very important to properly conduct the first furnace. In this case, you can not use a large amount of fuel. A small bookmark should be built on the unit itself, especially the chimney. With a sharp increase in temperature, condensation may form on its walls, which will turn into tar, narrowing the diameter. And this is a reduction in thrust, which is responsible for the correct operation of the heater.

Clearance adjustment

During the heating process, the clearance in the ash-pit is regulated. It is necessary to find the optimal size, which will provide the combustion chamber with the necessary amount of fresh air (oxygen).

Be sure to pay attention to the height of the bookmark. Its upper edge should be located at a distance of 20 cm from the inner pancake. This distance will ensure optimum combustion of wood or coal. At the same time, smoke and carbon monoxide will be freely discharged through the chimney.

Principle of operation

In fact, the traditional solid fuel boiler works like a conventional stove. There is also a firebox in which firewood is burning (coal, pellets and other solid fuels). The released energy heats the heat carrier located in the tank above the combustion chamber.

Heating of the coolant in this construction is made from the internal pancake, and from the chimney, which permeates through the tank of water. At the same time, the boiler body also heats up, which creates an accumulating effect that inhibits rapid cooling when the unit is switched off.

The heated heat carrier rises upwards and exits through the upper branch pipe into the heating system's supply circuit. The cooled heat carrier enters the boiler through the lower branch pipe connected to the reverse circuit.

Other options

A solid-fuel boiler for heating a house can be made in the form of a cube made of a metal sheet 4 mm thick. This is a more complex design, in which it will be necessary to assemble a separate combustion chamber. It turns out that a combustion chamber is installed in the boiler body. A coolant will circulate between the walls of the two structures. This is a more efficient option, but difficult to manufacture. It has many welded seams, which reduces the reliability and safety of operation.

Brick stove with water heating boiler. Using a cast iron radiator. Masonry Furnace

For the steam room the best kind of fuel is wood, and with different designs of heaters, a different consumption of this material is obtained. If you want to create optimal conditions for energy consumption, you will need a homemade brick oven with a water boiler. Although this boiler is very compact, it has a high heat dissipation, which is exactly what you need.

Furnace made of bricks with a water boiler

Furnace and boiler installation

Below, we'll look at how to kick out a brick fireplace and build a boiler in it. Also, we will look at how to make such a boiler from improvised materials. As a supplement, the video in this article will be demonstrated.

We use cast iron radiator

Cast Iron Radiator M 140

- If we take one section of the cast iron radiator M 140, it will contain 1.5 liters of water and occupy 0.254m 2 in area. Hence, twelve such sections will amount to a total area of 3m 2. which will contain 18 liters of water. To weld such a container of stainless steel, you will need a lot of time, in addition, the price for such a product will be much higher.

- A homemade water boiler for a brick oven from a radiator can heat a large enough area, but in order for the effect to be maximum, the sections must be separated from each other, thoroughly cleaned and washed with a 6% solution of hydrochloric acid, and then reassembled. After all, most likely you will not buy such a construction, but take it from the old heating system.

Council. During the reassembly of the battery, it is necessary to replace the cardboard gaskets, because the temperature during heating with wood can reach 500⁰ C -600⁰ C. and when heating with coal - and even more. But instead of cardboard, you will need to insert an asbestos cord, first impregnating it with graffiti and linseed oil. Council. The boiler radiator should not be installed in the furnace itself, but behind the furnace, so that it is heated by hot gases and smoke, and not by fire. Feed and return is best mounted perpendicular to the floor.

Features of masonry stoves

The furnace must be laid out with fireclay bricks

- For the construction of the furnace, you can use decorative and building bricks, as well as double silicate brick M 150. But if you want to build a high-quality heater, you will need refractory and fireclay bricks, which must be used for the hottest places in the structure. So, the furnace itself is best spread out from the fireclay stone, and the walls of the boiler and the tube of refractory.

- Clutch can not be stowed in the seam, because it is cracked. Therefore, each brick of the upper row must overlap the joint on the bottom row. In this case, a spoonful dressing is appropriate.

- The use of cement mortar when building a brick kiln is appropriate only on the bottom and on the chimney. That is, starting with the second row, you should go to the clay-sandy solution and use it to the roof. Closing the chimney from above with clay is impossible because of moisture, so here again you can not do without a cement-sand mortar.

- Previously, a brick was simply smashed with a kerchief or a hatchet, and then it was crushed, but with this cut the specimens turned out to be uneven, and it was almost impossible to deduce the exact size. Now, diamond discs are used for this, which can be installed either on the electrocirculation or on the grinder (angle grinder). If only circular cuts can be made with a circular, then the Bulgarian can also process round faces, cutting out a stone for the complicated design of the outer part of the structure.

Water supply to the Bulgarian

- When the oven is made up of solid brick, it means that they want to do it qualitatively and beautifully, which entails a lot of cutting of solid samples. To avoid the large amount of dust inevitable in this process - it is possible to make an addition to the Bulgarian - bring the hose from the electric pump to the disk casing. A tube is welded behind the casing, on which this hose is mounted, only it is necessary to be careful not to pour the electric motor, which will lead to a short circuit.

Masonry Furnace

Foundation with ruberoid

- First of all, the foundation is poured with depth from 50 to 70 cm (depends on the depth of soil freezing). On the foundation, a layer of sand is poured 10-15 cm. and on it - gravel, rubble or construction debris, but with such a calculation to leave 25-30 cm for pouring cement.

- The solution to the foundation is best done not with sand, but with screening, only the ratio, of course, will change and will be, approximately, 1/6. Under the screed and on it, lay ruberoid for waterproofing.

- We make a solution of clay with sand in the ratio 1 clay / 2.5 grit . but the proportion may change, depending on the fat content of the material. It is important that there are no lumps left, so the clay should be soaked in the evening, and you can stretch the clots by hand. Concentration will be good when the mixture will slide off the trowel, leaving only small strips on it.

- Before the beginning of the laying of the brick stove-fireplace, ruberoid along the area of the flooded foundation and cover it with a mortar. The first row can be laid out in the form of a pallet, that is, entirely of brick, on which there will already be a masonry of the furnace itself. Then put the first row of the furnace circuit, the second one and so on.

Installation of brick wedge

- Make a furnace and ash compartment, as well as an ash-pit. Doors must be mounted on galvanized wire or strips of galvanized sheet metal. Brick over the doors need to be trimmed with a Bulgarian, but one of them is best done in the form of a wedge, as in the photo above - this will allow the masonry not to crack.

The boiler is set according to the level

- For the boiler it is necessary to make in advance the protrusions on the brick - they can be cut with the help of a Bulgarian and install a metal corner on the installation site where the boiler itself will be mounted. Do not forget that the instruction requires an even installation, so it must be leveled (to avoid air congestion). In the same place, put the furnace door, fixing it with galvanized wire.

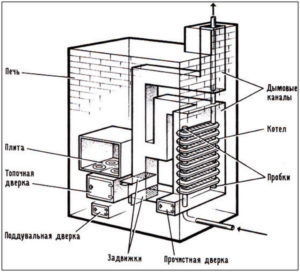

Scheme of a brick kiln with a boiler

- After all, the furnace and the rear part of the structure are put up - a chimney with a cleaning. The height of the chimney will depend on the height of the bath room, but the pipe that will rise above the roof should be no less than 0.5 m from the top point (from the ridge).

Conclusion

Furnaces made of bricks with water heating boilers made by themselves are quite versatile and have a high heat transfer coefficient. They are autonomous, that is, they do not depend on external sources of energy and besides, they can be made of any size, depending on the size of your steam room (see also the article "Brick furnaces for a bath - drawings with orders").

The system of water heating from a wood stove

Every year, the construction of individual housing is increasing, the popularity of countryside private homes is increasing. In modern construction, a large number of heating systems are used, but conventional furnace heating with a water circuit is also widely used, even within the city, where it is not always easy to buy firewood.

Their houses humanity heats by means of firewood since time immemorial, stoves in dwellings have been modified over time, they were invented by boilers with a water circuit.

Advantages of the water circuit

A conventional oven on wood spreads heat unevenly - it is hot near the furnace, and the farther from the furnace, the colder. At home uncomfortable, because there is a different temperature everywhere: went to watch TV - cool, came to the kitchen to bask. With water heating at home there is no such inconvenience, on the contrary, all the heat is evenly distributed throughout the rooms.

In addition, the furnace can not only be heated, such heating on wood is usually installed above the cooking stove, that is, it can be cooked, which increases the efficiency. A furnace with a water circuit is, in fact, a solid fuel boiler, but here, in addition to the built-in system, the furnace itself and the chimneys are additionally brought into the house, which, even after the furnace is completed, remains heated for a long time.

Furnaces with a water circuit are widely used in rural areas where there is no gas supply. When choosing water heating, you do not need to buy an expensive gas boiler of industrial production. A wood boiler is an economical way to heat a house.

Brick stove with water heating - minuses

Water heating from a brick oven on wood

One of the drawbacks of the water circuit is that the boiler reduces the useful volume of the furnace. To compensate for this moment, when laying the furnace, it is necessary to provide the necessary width of the boiler. In the case of a heat exchanger in a ready-made furnace, it is necessary to lay firewood more often when it is fired.

Wizards recommend that the furnace be shifted when the water circuit is installed, because the heat energy will go to the heating of the firebox, leaving the furnace walls poorly warmed. Only the upper part of the chimneys will warm up well.

Houses where there is water heating, should be regularly heated in the winter, otherwise the entire system can freeze and fail.

There are two ways out: use antifreeze or drain water from the system for a while in the house.

The principle of installation and operation of the system

Scheme of water heating two-story house on firewood

Combined heating system of a private house

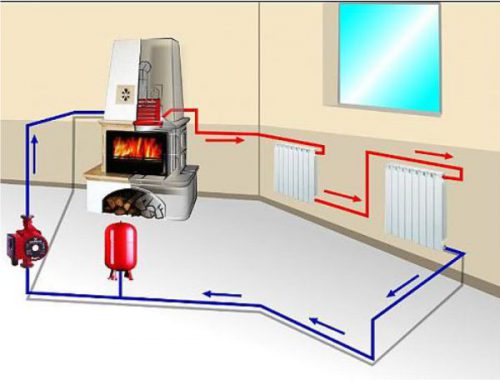

A boiler is installed in the furnace, two pipes are connected to it - one goes the supply of hot water, which is sent through the expansion tank to the system, the other returns the water back to the register. Thus, there is a circulation of water in the system due to the force of the gravitational law.

Often, small, but powerful pumps are installed for good circulation. Such a pump is usually installed on a water returning pipe (return), this method is especially effective when a large room is heated, which allows maintaining the temperature at all parts of the system is almost the same.

How to build a water oven at home?

- There are three ways to carry out furnace heating with a water circuit by one's own hands:

- buy a steel furnace from the manufacturer, whose services include the installation of the system;

- hire a master - an expert will pick up the material, make the device, lay out the oven and install the boiler;

- do yourself.

How to make such a furnace yourself

The principle of the device boiler for water heating

Can you make this system yourself? It is enough, only experience in welding and brickwork in the construction of the furnace. First you need to prepare a boiler (register, coil, heat exchanger).

Such a device can be bought or manufactured independently, using sheet iron and pipes. Since the complete process of making and constructing a water circuit can not be packed into a short review, the main recommendations are given below.

Water heating from a wood-burning stove - scheme

For the boiler, a sheet of metal with a thickness of at least 5 mm is used, and make it a structure such that there is maximum heating of the water, for further circulation. The boiler welded from a sheet steel is simple in manufacturing and operation - it is easy to clean.

But such a heat exchanger has a smaller heating area, unlike a pipe register. The pipe register is difficult to make at home by yourself - you need an accurate calculation and suitable working conditions, usually such specialists are made by order of specialists who install the system on site.

The simplest method of solid-fuel heat exchanger is a conventional gas turbine with an integrated water system. Here you can take a thick pipe as a basis, then the welding work will be much less.

Attention! All welding seams need to be made doubled, since the furnace has a temperature of at least 1000 degrees. If you weld ordinary joints, then there is a possibility that this place will quickly burn out.

Draw the register in accordance with the dimensions of the oven at home. The layout of the rooms of the house and the layout of the furniture must also be taken into account. Here it is necessary to pay attention that it is better to choose a scheme with leaf boilers - they do not have pipe bends connected in one continuous contour. Such a construction is not so troublesome. It is also convenient because after installation you can easily use the hob, which can not be said about some pipe boilers.

Register of smooth pipes - drawing

When the heat carrier moves by gravity, it is necessary to lift the expansion tank higher, and the pipes to use larger diameters. If the pipes are of insufficient size, then a pump can not be dispensed with, as there will be no good circulation.

Boilers equipped with pumps have their pros and cons: you can save by putting pipes of smaller diameter and not raising the system so high, but there is one significant disadvantage - when the electricity is turned off or the circulation pump burns, the heated boiler can simply explode.

Assembly of the structure is better to produce at home, in place, since the device, like individual parts, has a very large weight and dimensions.

Installing the system

Heat exchanger made of cast iron battery

- Before installation pour a solid foundation, on top of which it is better to lay a layer of bricks.

- The grate can be laid at different stages: up to the boiler, if the dual structure, the lower part of which can be equal to or higher than the upper part of the grate, when the furnace is low, and the system is put a little higher, then the grate, doors, .

- The body is installed - usually it consists of two tanks connected by pipes.

- The whole heat exchange system is welded to the boiler: the outflow pipe goes to the expander, goes around the circle, through the radiators and on the other side from below the reverse pipe is welded to the boiler.

Furnace heating with a water circuit allows, first, it is much more rational to use firewood, and secondly, to evenly distribute warm air throughout the heated room.

Having conceived of making a heating system at home with a water circuit on the wood, think over all the stages of the work, and if there are doubts in the successful outcome, then it is better to consult specialists.

Video: Heating system Leningradskaya

How to make a stove with a boiler of water heating with your own hands

The stove with water heating boiler is an excellent solution for country houses, first of all, due to its economy. Certainly, heating a large area with a gas is cheaper, but this possibility is not everywhere, so you have to resort to a firewood.

The furnace can heat the structure of any configuration, the area of which is up to 100 square meters. Such a scheme works as follows: the furnace generates heat, and the rooms are heated by means of heating pipes that are heated by the heat transfer fluid from the boiler in the furnace. The result is a high efficiency and good heat dissipation. Used such a stove for the bath and for a residential cottage.

How to increase the efficiency of the heat exchanger

If the house is equipped with a ready-made brick oven, it is not so difficult to organize water heating on its own. It is enough to place a homemade boiler-coil in the furnace (you can choose another configuration).

For successful work, please note the following:

- the difference in height between the inlet to the heat exchanger and the outlet of the heat transfer fluid from it;

- providing the maximum possible area of its surface;

- does the heat exchanger interfere with the loading and combustion of fuel.

Building a stove with your own hands, consider a number of other factors:

- The products of combustion must leave the chimney as cold as possible.

- High heat transfer of furnace gases inside the furnace increases its efficiency.

- It is better to place the heat exchanger in the chimney, and not in the furnace.

Such rules may seem illogical, because, in theory, the heat exchanger should be best warmed up on an open firebox. Nevertheless, it is necessary to take into account a number of other processes that occur in the furnace.

So, the flame is an accumulation of burning particles of fuel. If you take away their heat, they will not be able to burn completely, as a result, the utility of the furnace will decrease. In addition, for more efficient heating, the coolant must move towards the heat flow. That's the difference in temperature between different parts of the coolant will be preserved, heating will be more efficient, and better circulation will be ensured inside the system. The advantages of this unit are also in the formation of a smaller amount of condensate on it, so there is no risk of corrosion.

Types of furnaces with integrated boiler

The structure can be made of metal or brick with different accommodation of the heater, with a boiler for heating the water for washing, if it is a question of a bath. Dimensions are not limited: the choice of parameters is determined taking into account the dimensions of the room, building materials of the building, as well as the local climate.

It is necessary to consider the design features of two types of furnaces with heating boilers:

- The boiler is built into the chimney. This model has a long service life, the stove walls completely receive heat from the furnace, the heat transfer parameters are unchanged. Disadvantage: you can not heat a large area.

- The boiler is directly in the furnace. You can heat a large area of the room. It is possible to use different types of heat exchanger. Disadvantages: the metal parts are directly in contact with the fire, as a result of which they are destroyed. Due to the low temperature of the heat exchanger, condensate is produced, which causes a lot of soot to stick to the surface later, resulting in lower efficiency.

Types and features of heat exchangers

With your own hands, you can make two types of heat exchangers: tubular and flat. To make the right decision, you need to study their performance and features.

Flat heat exchanger

A popular option, which is used both for stoves in the bathhouse, and for the home. The most simple to manufacture, the surface is easily cleaned from accumulations of soot, the installation is possible both vertical and horizontal, the efficiency is relatively high.

A flat boiler can have a high volume, so you can take hot water for washing directly from the heating system. Installation of an expansion tank with an increased linear dimension is performed, where water constantly arrives after lowering the level below the critical level. This option is quite convenient and helps to solve several problems at once, but there is also a condition - the temperature of the room in winter should not drop to minus.

The key drawback is a sharp decrease in the heat transfer of the furnace walls. This type of heat exchanger is made in the form of the letter "P" and is installed along the perimeter of the furnace, bypassing the door. As a result, it turns out that the temperature of the outer walls is rather low, as a result, warming up the room takes much longer. This is critical only if the oven is installed in a bath, for residential houses where the stove is heated constantly, increasing the warm-up time for several hours does not play any role.

Thus, choosing a flat boiler, think, due to what you can increase the heating rate. One option is to increase the heater and position it directly above the furnace. The second option: the use of a metal chimney for heating, increasing its length.

Tubular Heat Exchanger

The most successful option for the construction discussed. The form can be either simple or complex. The dimensions of such a register are different, the object can be installed from different sides of the furnace. If necessary, the heat exchanger can be easily removed from the furnace. For the manufacture of a water boiler for a brick oven, only seamless pipes are used. This is a very efficient heat exchanger, which is also very easy to clean with soot. To make such a register is much more difficult than the previous version, so it is advisable to consult a specialist.

Cast iron radiators as a boiler

You can build in the brick oven old radiators, and they will perform the function of the boiler. Cast-iron built-in hot water elements have their own characteristics, for example, cast iron does not react very well to open fire. Nevertheless, this method is used, and quite widely. You can use the radiator M-140, which can easily be found in the field of demolition of five-story houses. If you weld a dozen sections, get a heater, the area of which is 3 square meters and 18 liters of capacity. A flat boiler with the same characteristics would require a lot of space. Such boilers can heat large areas.

Before the radiators are welded together, they must be disassembled, cleaned of dirt and thoroughly rinsed with a hot 6% solution of hydrochloric acid. Then rinse again with water. Then replace the cardboard pads located between the sections, because they will simply burn. Use instead of them an asbestos cord with impregnation from a powder of graphite and natural linseed oil.

Collect the elements of the radiator in a certain sequence. In the sections to be joined, screw the nipples with their right and left threads, then wrap them around the impregnated cord from the asbestos and tighten both nipples with a key, make sure that there is no distortion of the sections. After connecting the two sections, you can attach a third, then compress the radiator to check the quality of the assembly. Now you can mount the risers.

On the diagonal it is possible to arrange a cold inlet and a hot water outlet. The other two holes can be plugged with stoppers to circulate water through the full volume. Radiator must be installed in the smoke channel located behind the furnace. This will help avoid contact of cast iron with open fire: the boiler will be heated by hot gases.

To increase the natural circulation of water in such furnaces, it is possible, if you hold the return pipe through its foundation and the space under the floor, thereby increasing the temperature difference between the return and hot line. The battery in the furnace is installed with a slight slope for air outlet and entry into the system. For cleaning, an additional door can be built in the smoke channel itself.

Solid fuel boilers "Prometey"

As an alternative to self-made boilers, Prometey, which operates on dry fuels and consumes electricity as an additional fuel, can be used. The power of the device is from 12 to 80 kW, which is enough for heating from 60 to 800 square meters. Due to the large volume of the charging chamber and the ash pan, a long burning time is ensured, as well as a high efficiency. Boilers with solid fuel can be used in combination with heating boilers that run on gas or diesel fuel. Prometheus is quickly installed in existing systems and simplifies installation.

The distinguishing features of the "Prometheus" boilers are:

- fuel delivery system - semi-automatic;

- 8-10 hours of uninterrupted combustion;

- autoregulation of the coolant temperature;

high efficiency; - housing of corrosion-resistant steel.

"Prometheus" can be built into any heating system, including placing a boiler in the furnace. The design of such boilers allows using them in remote areas where there is no stable power supply. On its basis, a cooking stove can also be equipped.

Masonry furnace with boiler

If you decide to go deeper into the subject, then perhaps you decide to equip Kuznetsov's stove furnace, the principle of which is free flow of gases, which does not require additional energy from outside. Drawings are on the Internet. Here we will talk about a simpler design. So, first you need to fill in the foundation, the depth of which is 50 - 70 cm. On the foundation, sand should be covered with a layer of 10-15 cm, gravel, gravel or construction debris should be placed on top, and a space of 25-30 cm should be kept for cement pouring. The best solution for the foundation is to prepare without the use of sand, replacing it with screening, the ratio is about 1: 6. Under the screed and on top of it, a roofing material for waterproofing should be laid.

Then, a clay + sand solution should be made in a ratio of 1: 2.5, but the proportions may vary depending on the level of fat content of the material. It is important not to leave lumps, but because clay should be soaked in the evening. If the mixture slides off the trowel, leaving small strips on it, then the concentration is suitable. Before the beginning of the masonry, it is necessary to lather the roofing material along the area of the embedded foundation and cover it with mortar. The first row is laid out with a pallet entirely of bricks, where later the masonry will be laid. Then the first row of the furnace circuit is laid out, then the next one, etc. During the masonry you will need an order.

Now there is a firebox, an ash compartment and an ash-pit. Fastening of doors is carried out by means of the zinced wire or a strip of the zinced sheet metal. It is necessary to prune the brick over the doors with the help of the Bulgarian, but it is best to make one of them a wedge, so that the masonry does not crack. Make in advance on the brick the ledges for the boiler, which can also be cut out by the Bulgarian. Do not forget that the instructions require a smooth installation, and therefore you should use the level. Then, the furnace and the rear of the structure are installed, where the chimney with cleaning is located. The pipe must protrude at least 50 cm above the roof.

Furnaces with their own hands for heating the house you can make, not being in this business pro. They are universal and have a high coefficient of heat transfer. A great advantage in their autonomy, because they do not depend on external energy sources. Such boilers can have any sizes depending on the area of the heated room.