Two-pipe dead-end heating system. Video - Hydraulic calculation. Upper and lower wiring

Very often when talking with a plumber you can hear the phrase "heating circuit". Inexperienced people put this phrase at a dead end, because they do not know what it is. And in fact with the heating circuit, you come across almost every day. Let's analyze what it is.

What is it like?

Most often, the heating consists of feed and return pipes. In the supply pipes, the heated coolant from the boiler is supplied. Further, the coolant moves along the feed tube toward the registers (radiators), where it gives off some of the heat. Passing through all registers the tube returns back to the boiler already with the cooled coolant. The connection of the cooled coolant pipe to the boiler is called a return (literally "returned back"). This combination (boiler-\u003e feed-\u003e return-\u003e boiler) forms a closed heating circuit. This is in the simplest implementation.

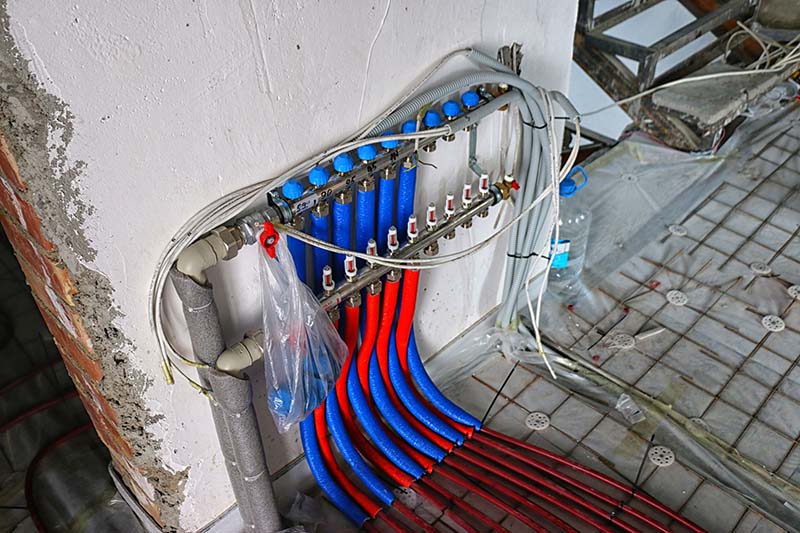

Heating circuit in a warm field

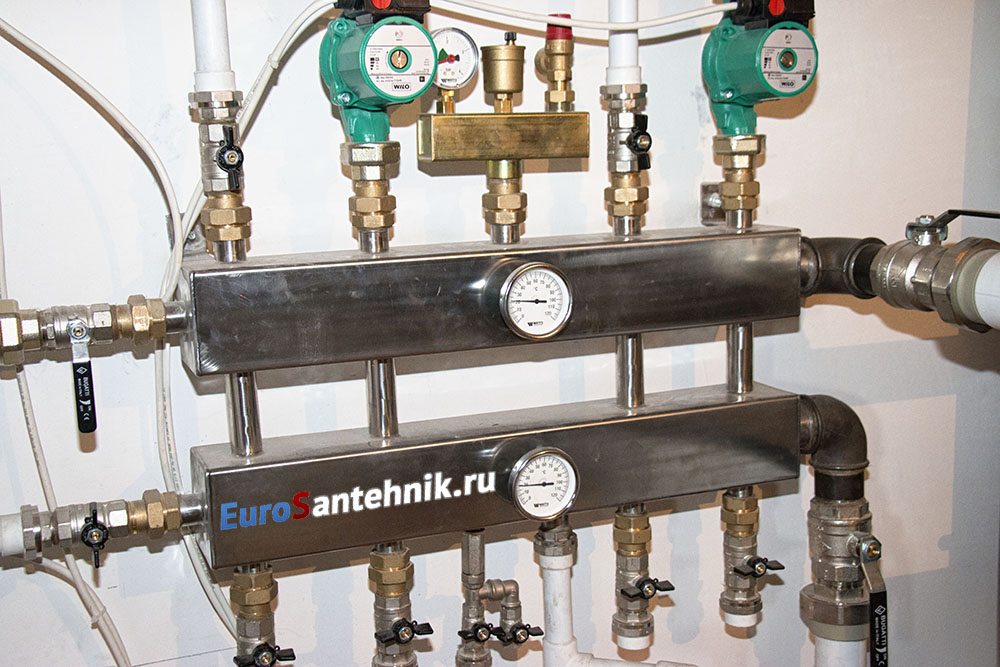

The warm floor also consists of contours. Each contour should not exceed 90 meters. For a warm floor, a special distribution manifold is installed, consisting of a supply and return part. At the distribution manifold there should be no more than 11 heating circuits.

Heating circuits in radiators and other systems

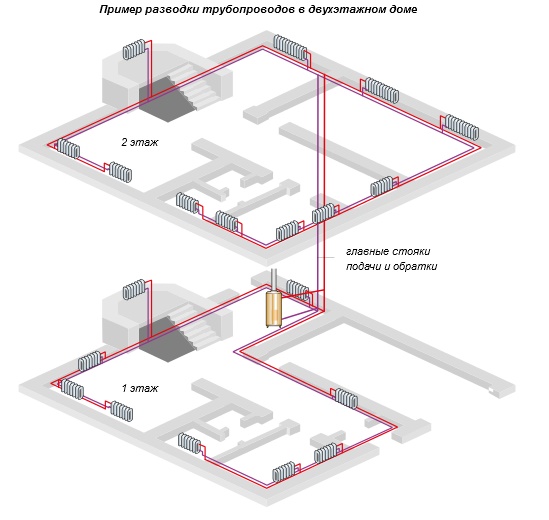

In radiators there can also be several circuits. Usually the number of circuits is equal to the number of floors.

Also, the circuits can be connected to the distribution manifold. This is essentially the heart of the heating system. It is installed in order to correctly distribute heat throughout the house from one or several boilers.

The contours are the same: boilers, boilers, accumulator tanks and so on. In general, everything that has feed and return in the compartment with the boiler or the distribution manifold forms a heating circuit.

We hope now you have understood!

Among the many ways to distribute heat mains in the house, the most common heating system is a two-pipe system. It is practical, reliable in operation and simple in execution, especially if modern materials are used for mounting radiators and trunk lines. If desired, the average user will be able to assemble such a heating system with their own hands, without involving installers, whose performance is often not good.

General Presentation and Scope

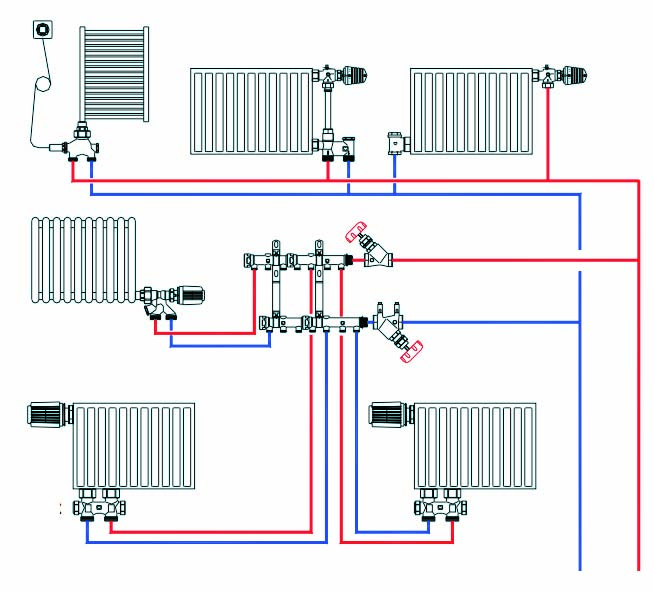

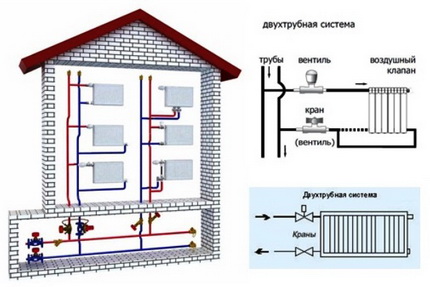

Unlike single-pipe wiring, a 2-pipe heating system is aimed at feeding the same temperature to all heating devices of the coolant. Two separate pipelines are supplied to the radiators, one hot coolant moves from the boiler to the batteries, and otherwise the cooled water returns. The scheme of the two-pipe heating system stipulates that the connections of the heating devices are connected to both branches.

Typically, the movement of water in two-pipe heating systems is carried out using a circulation pump. This allows you to make a pipeline network of any complexity and branching, to ensure the heating of the most remote premises. But, if necessary, the circuit is also self-flowing, without the use of a pump. Large diameter pipes are used, laid open way with a slope of at least 10 mm per 1 m of the pipeline length. Two-pipe heating system of a private house has the following advantages:

- reliability in operation;

- efficiency, due to the supply of water at the same temperature to the heating devices;

- versatility, which makes it possible to lay the branches of heat supply in an open and closed way;

- convenience of balancing;

- possibility of automatic regulation by thermostatic valves;

- relative ease of assembly work.

![]()

Due to the versatility of the scheme, the sphere, where two-pipe heating is possible, is very wide. These are civil buildings of any purpose and number of storeys, as well as production workshops and administrative buildings.

About the ways of laying pipes

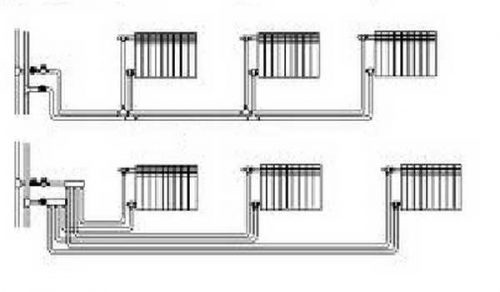

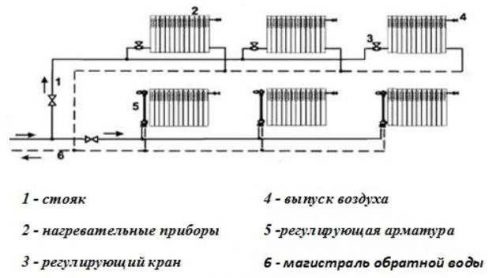

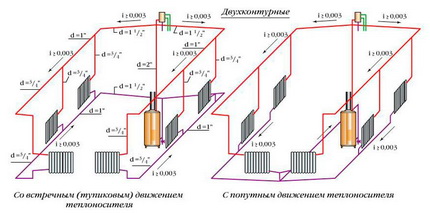

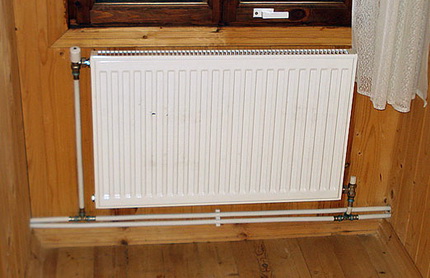

When organizing the heating of private houses, the dead-end scheme of a two-pipe heating system is most often used. The group of radiators is connected to 2 mains alternately - from the first to the last device.

The required water flow in each radiator is provided by preliminary balancing and automatic regulation by means of radiator valves with thermal heads.

In addition to the dead-end scheme, other types of spreads are widely used:

- associated (Tyhelmann's loop);

- collector wiring diagram.

With the accompanying wiring, there are no first and last radiators, this horizontal two-pipe heating system is a ring that supplies a heating group to a group of heating appliances.

![]()

The battery, the first in the account on the supply line, is the last on the return pipeline. That is, the coolant on the supply and in the return moves only forward, and not towards each other (along the way). Due to the fact that the water in the loop passes the same distance, a two-pipe horizontal heating system with a passing motion is initially hydraulically balanced.

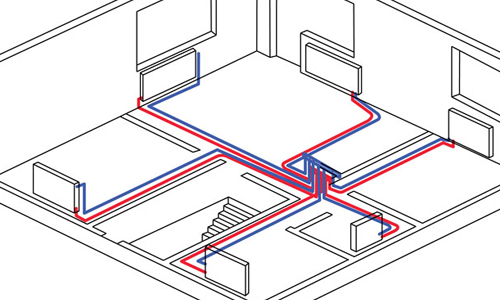

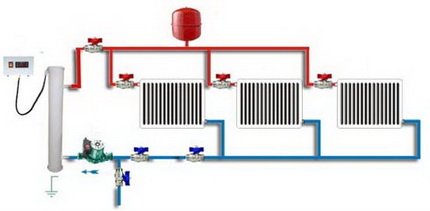

The strong side of the collector heating system with the lower wiring is the two-pipe connection of each heater to one manifold manifold. Such are used in the organization of water floor heating. Laying individual branches to each battery is carried out in a hidden way in the screed or under a wooden floor covering. Regulation and balancing is performed in one place - on a manifold equipped with special valves and flowmeters (rotameters).

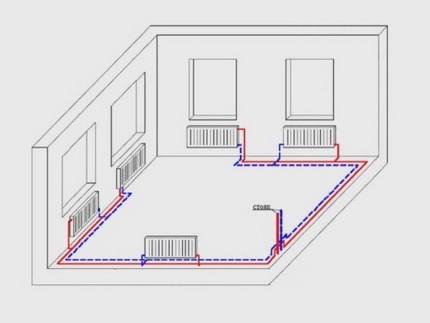

In accordance with modern requirements for interior design in homes, heating with a lower wiring is most often used, which makes it possible to hide pipes in walls and floors or to conduct them openly over skirting boards. Two-pipe heating system with an upper wiring, when the supply line is located under the ceiling or in the attic, is in demand when organizing gravity networks. Then the heated coolant rises to the ceiling directly from the boiler, and then the horizontal pipe diverges through the batteries.

According to the working pressure in the network, the circuits are divided into 2 types:

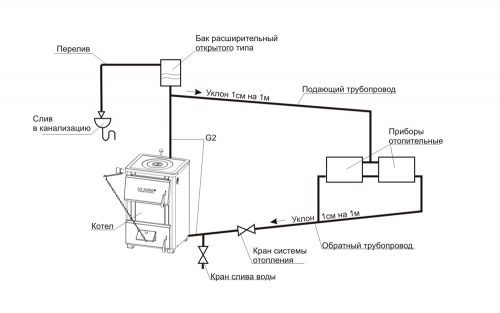

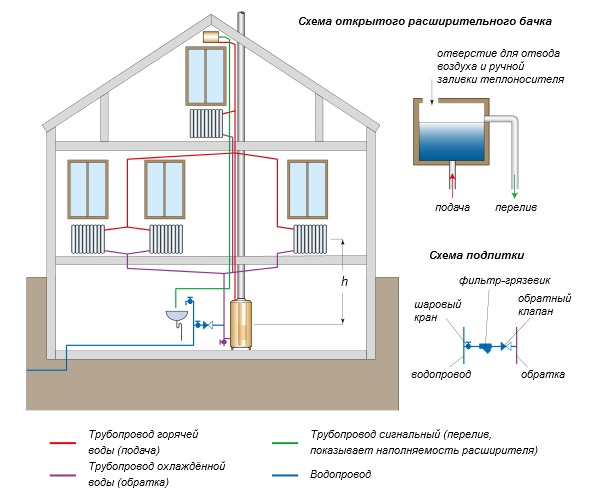

- Open. At the top of the system, an expansion tank is installed, communicating with the atmosphere. The pressure at this point is zero, and near the boiler is equal to the height of the water column from the top to the bottom of the heating network.

- Heating systems of closed type. Here, the heating medium is given an overpressure of 1-1.2 bar, and there is no contact with the atmosphere. The closed expansion tank of the membrane type is located at the lowest point, next to the heat source.

The layout of two-pipe systems is horizontal and vertical. In the vertical scheme, both trunks turn into risers, which tend to inter-floor overlapping in the places of installation of heating devices. It is characteristic that the coolant to the risers is still fed by horizontal collectors, laid in the lower or upper part of the house.

Selection rules

Regarding the choice of a suitable heating system, there are several general recommendations:

- at an unreliable power supply at home, when the circulation pump is often switched off, there is no alternative to a two-pipe dead-end scheme with an overhead wiring;

- in buildings with a small area (up to 100 m²), a dead-end or associated two-pipe heating system with a lower wiring will be appropriate;

- the installation of vertical risers is done in multi-storey buildings, where the layout of each floor is repeated and the radiators are in the same places;

- in cottages and wooden houses of a large area with high requirements for the interior, it is customary to arrange a collector system with laying branches under the floors.

All possible options can not be foreseen, there are too many of them. To choose the optimal, the homeowner is recommended to depict the scheme of the arrangement of batteries, feed them on paper in various ways, and then perform the calculation of the cost of materials.

Before undertaking the installation of a two-pipe heating system, it is necessary to select pipes of suitable diameter.

For the dead-end network of a small house where it is planned to forcibly circulate the coolant, this can be done simply: a pipe with a diameter of 20 mm is adopted on the mainline, 16 mm for the radiators to the radiators. In a two-story house with an area of up to 150 m², the required flow rate will be provided by pipes with a diameter of 25 mm, the connections remain the same.

In the collector scheme, the pipelines are made with pipes of 16 mm, and the laying of the mains to the collector is performed from the pipelines 25-32 mm, depending on the floor area. In other cases, it is recommended to contact the design specialists for calculation, they will help to choose the optimal scheme and sizes of all branches.

For the installation of home heating by hand, you should select the pipes from the appropriate material from the list:

- Metalloplastikovye pipelines. When assembling on compression fittings, no special tools are required, only the keys. More reliable compression joints are performed by ticks.

- Crosslinked polyethylene. This material is also connected by compression and compression fittings, and Rehau pipes by expansion and tightening of the locking ring.

- Polypropylene. The cheapest option, but requiring some welding skills for joints and the presence of a welding machine.

- Corrugated stainless steel pipe is joined by clamping fittings.

Pipelines made of steel and copper are not considered, since it is not everyone's power to make heating out of them; skill and experience are required here. The system is assembled starting from the boiler with the subsequent connection of radiators and shut-off valves.

At the end, the network is checked for leaks using a pressure test pump.

Two-pipe heating system was named, based on the principle used in its organization. Such a system is equipped with two pipes: one pipe the heated coolant is sent to the batteries, the other cooled water from the heating elements is fed back to the boiler.

Two-pipe systems are compatible with boiler equipment operating on all types of fuel, can be equipped with both natural and forced circulation of the coolant. Installation of two-pipe systems is possible both in low-rise buildings and in multi-storey buildings.

Advantages and disadvantages

Let's start with the shortcomings:

- The main disadvantage of the two-pipe principle is the increased consumption of materials. However, this disadvantage is offset by the fact that this scheme uses pipes of smaller diameter. The same can be said about the size of the fittings. Less size - less material costs, which means, and price.

- Another drawback of such a scheme of heating - increased labor costs. This is natural, since the pipes are twice as large.

- No possibility of repairing the batteries without stopping the entire system. The situation can be corrected if the calculation of a two-pipe heating system provides for the presence of ball valves near all heating devices (both on the supply and on the return). After shutting off the cranes, you can repair the battery or heated towel rail.

Scheme of a two-pipe system

The advantages of two-pipe heating include the following facts:

- A thermoregulating head can be installed on each battery, so that the balance in the system will be maintained automatically. With a single-tube device, it is difficult to realize control on individual radiators, since a bypass with a three-way or needle valve is required, which will make the system much more expensive and more difficult.

- In contrast to a single-tube device in a two-pipe system, water of the same temperature is fed into all heating elements - directly from the boiler. The intensity of water supply is regulated by thermostatic heads and taps, so problems with pressure are excluded.

- Small pressure losses and a much simpler implementation of gravity-based heating. If you need pumps for forced circulation, you can use equipment of lower power than in the case of single-pipe systems.

Classification of equipment

The two-pipe heating system of a private house can be open or closed. The latter provides for a membrane expansion tank, which allows the system to operate at high pressure.

A thermal carrier can act not only water, but also ethylene glycol compounds, capable of operating at low temperatures (up to 40 degrees below zero). Compositions based on ethylene glycol are called antifreezes.

It should be noted that the correct operation of the equipment is provided only with the use of specialized compounds specifically designed for heating purposes. Car antifreezes will not work. The same goes for additives and additives: you can use only specially adapted for heating.

It is especially important to comply with this recommendation when operating expensive boiler models, which are controlled by automation. In the event of a boiler failure, the manufacturers usually disclaim responsibility and do not perform warranty repairs if the fault is not directly caused by the heat carrier.

Closed-type systems are characterized by the highest level of safety, therefore most of the boilers of modern production are aimed precisely at such schemes.

Diagram of open heating system with expansion tank

In open systems, the expansion tank is mounted on the upper section. To the tank attach an air outlet, as well as a pipe for draining excess water from the system. From the tank you can take hot water for domestic needs, but in this case it is desirable to make the supply of water automatic. In addition, water used for the needs of residents should not contain technical additives and additives.

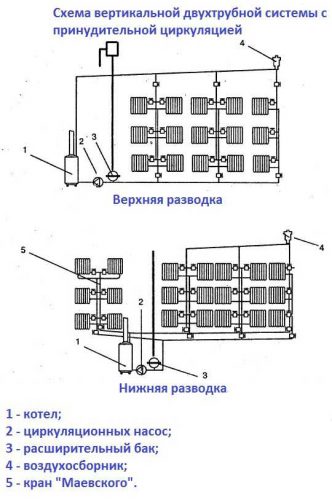

Two-pipe system of vertical and horizontal types

There are two types of organization of the system with two mains - vertical and horizontal. Vertical arrangement of pipes is usually used in multi-apartment buildings. To implement the system you need a lot of pipes, but at the same time it is possible to tap into the apartments on each floor. The main advantage of such a system is the natural return of air, as it rushes upward, where it is withdrawn by means of an expansion tank or drain valve.

Two-pipe horizontal heating system is more common in single-story and two-story houses. To remove air, the Mayevsky cranes are used here.

Upper and lower wiring

The flow of the coolant is performed according to one of two principles: upper or lower. If the wiring is upper, the conduit is located in the under-ceiling space, and the supply pipes go down to the batteries. The return is on the floor. The advantage of this option is that it makes it easy to organize natural circulation, because due to the difference in height and the specially positioned at an angle of the pipe, a good flow velocity of the coolant is ensured.

However, systems with lower wiring are not very popular due to the external unattractiveness of pipes that are conspicuous in the eyes. The problem can be corrected by covering the pipeline with a hanging or tension ceiling.

Note! Both types of wiring are used in two-pipe systems. Differences in the diagrams are clearly shown in the figure below.

Scheme of a vertical two-pipe system

If the wiring is arranged according to the lower principle, the feed pipe is located at the bottom, but just above the return. And the pipes can be installed even in the basement, semi-basement or embedded in the floor. This method of wiring is more aesthetic, and therefore is popular.

However, with the lower method, it is necessary to carefully choose the place for installing the boiler (if it is a natural circulation of the coolant), since the batteries must be located above the boiler. In the case of forced circulation, the position of the equipment relative to the batteries does not matter.

The scheme of water mains in the heating system

Two-pipe heating system of a two-story house is divided into two wings. In both wings, the temperature level is regulated by means of valves. The lower type of wiring and forced circulation is used, so the boiler is attached to the wall.

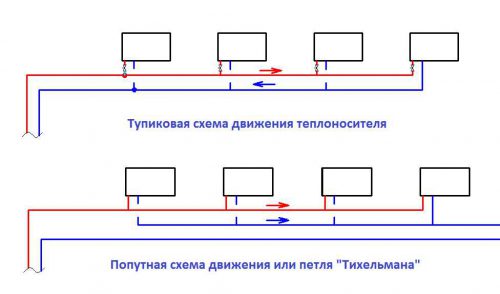

Deadlock and associated systems

A system in which the thermal carrier moves in different directions through the pipes of the supply and return is called a dead-end system. Another option is a system with a passing direction of the coolant (Tichelman's scheme). The accompanying scheme is easier to balance and adjust, especially when it comes to large-scale heating networks.

In the passing system with an equal number of radiator sections, there is no need to carry out balancing. In the dead-end scheme, you can not do without installing all the radiators of thermo valves or needle valves.

Deadlock and associated coolant flow pattern

And it should be noted: even if in a passing scheme there are batteries with a different number of sections, it will be much easier to establish a balance than in a branched dead-end system.

To balance the dead-end circuit, you need to tighten the valve on the first battery tightly. It may well develop a situation in which water completely stops flowing into the radiator. Then it will be necessary to choose: which of the batteries will be excluded from the heating circuit - first or last.

Heating system with two wings

And yet, the installation of a two-pipe heating system is often carried out on a dead-end principle. The reason is that in the backward schemes the return line has a long extension and the installation work is more complicated. In addition, with a small heating circuit, the heat output from each battery can be perfectly balanced.

In the case of a large contour, it can be divided into a pair of wings. However, it should be remembered that to create a system with two wings, one must proceed from the technical feasibility of its construction. In both circuits, it is necessary to install valves to regulate the heat carrier supply power. Without valves, it will not work out the balancing.

Two-pipe heating uses one of three options for connecting batteries: diagonal, one-sided or lower. Optimal way is considered diagonal connection. So you can achieve maximum heat output from the heating equipment (up to 98% of the nominal).

With all the differences between different types of radiator connections, they are all applied in practice, but with different tasks. For example, a lower-level connection does not have a high performance, but this is a good option if the pipeline needs to be placed under the floor.

The camouflaged laying of pipes can also be used in a diagonal and one-sided scheme, but in these cases considerable sections of pipes remain on the surface, which can be concealed except under the walls.

Connection of lateral type radiators is used with a number of sections limited to 15 units - there are practically no heat losses in this case. If there are more than 15 sections, a diagonal connection is required, since only such a method will ensure a normal circulation of the coolant and heat release.

For an autonomous heating system, the main link is necessary - a heating water boiler. The principle of its operation consists in heating the coolant, which passes through the heat exchanger and then goes to the heating devices. Most often these are heating batteries or water warm floors. Thus, a constant circulation of the coolant in a closed circuit is created.

through such pipes the heated coolant circulates

There are several such heating circuits. Most often, the circuit is divided into floor heating, hot water supply and radiator system.

This is very convenient when the house uses a system of water floor heating in conjunction with convective heating (batteries)

Underfloor heating system at home

The contour of the warm floor can also be divided into several podkonutrov. For example, one circuit in the kitchen, another in the bathroom, etc. This is done with the help of a collector and a collector cabinet.

collector for warm floors  Also, when installing underfloor heating, a mixing unit is required. It is his job to mix the straight line with the return to reduce the temperature in the circuit. There is a reason for this - the water temperature in the radiators is higher than the temperature in the pipes of the warm floor.

Also, when installing underfloor heating, a mixing unit is required. It is his job to mix the straight line with the return to reduce the temperature in the circuit. There is a reason for this - the water temperature in the radiators is higher than the temperature in the pipes of the warm floor.

Radiator heating and hot water

Radiator system of water heating can also be divided into several circuits. Often it is done for independence, any rooms from each other. For example, the floors of the building.

Hot water supply is also due to a separate circuit. It either enters the storage boiler, or is located directly in the boiler. Or, the DHW is not tied up at all, on the boiler room, and is carried out at the expense of a separate water heater.

Most often private houses use a combined system of water heating. On the ground floor arrange floor heating, and on the second radiators.

stowage of warm floor loops  It is worth noting that it is necessary to calculate the heat loss of the building and, if necessary, add a few radiators to the first floor.

It is worth noting that it is necessary to calculate the heat loss of the building and, if necessary, add a few radiators to the first floor.

Providing heat in the house is the most important task for its owner. Solve it in various ways, however, according to statistics, most of the buildings in our country are heated with the help of a water heating system. It is the most effective and practical in rather severe climatic conditions. Two-pipe heating system of a private house is considered one of its most popular varieties.

Any heating system with a liquid heat carrier includes a closed loop connecting the radiators, heating the room, and a boiler that heats the coolant.

All occurs as follows: the liquid, moving on the heat exchanger of the heater, is warmed up to a high temperature, then it enters radiators, the number of which is determined by the needs of the building.

A distinctive feature of the two-pipe system is the presence of a supply and return pipe suitable for each radiator

Here the liquid gives off heat to the air and gradually cools down. Then it returns to the heat exchanger of the heater and the cycle is repeated. The simplest circulation is in a single-tube system, where only one tube fits each battery. However, in this case, each next battery will receive a coolant that has come out of the previous one, and, therefore, is also colder.

To overcome this significant shortcoming, a more complex two-tube system was developed. In this variant, two pipes are connected to each radiator:

- The first is the supply, through which the coolant enters the battery.

- The second one is a leading or "reverse" master, according to which the cooled liquid leaves the device.

Thus, each radiator is equipped with an individual adjustable coolant supply, which makes it possible to organize heating as efficiently as possible.

Since the delivery of the heated coolant to the instruments is made almost simultaneously by one pipe, and the collection of the cooled water is different, the two-pipe systems are characterized by an optimal heat balance: all the batteries of the system and the circuits connected to it operate with practically equal heat transfer

Why choose such a system

Two-pipe water heating is gradually replacing traditional single-tube structures, as its advantages are obvious and very weighty:

- Each of the radiators included in the system receives a coolant with a certain temperature, and for all it is the same.

- Ability to carry out adjustments for each battery. If desired, the owner can put a thermostat on each of the heaters, which will allow him to get the desired temperature in the room. In this case, the heat transfer of the remaining radiators in the building will remain the same.

- Relatively low pressure losses in the system. This makes it possible to use an economical circulating pump of relatively low power for operation in the system.

- If one or even several radiators fail, the system can continue to operate. The presence of stop valves on the supply pipes allows repair and installation work without stopping it.

- The possibility of installation in a building of any number of storeys and squares. It will only be necessary to choose the optimal type of two-pipe system.

The disadvantages of such systems usually include the complexity of installation and the large, in comparison with single-tube structures, the cost. This is due to the double number of pipes that have to be installed.

However, it should be borne in mind that pipes and components of small diameter are used to equip the two-pipe system, which gives a certain cost saving. As a result, the cost of the system is not much higher than that of a single-tube analog, but it gives much more advantages.

One of the significant advantages of a two-pipe heating system is the possibility of efficient room temperature control

Varieties of the two-pipe system

The two-pipe design is characterized by a variety of varieties, which can be classified according to different signs. Let's consider the main ones.

Open heating wiring

Any hydraulic heating system is a closed circuit in which the expansion tank is connected. This element is necessary, since the heated liquid increases in volume. For open wiring, a tank is selected that allows the liquid to communicate with the atmosphere. In this case, its part inevitably evaporates, which leads to the need to constantly monitor its level.

Two-pipe heating scheme of the open type is the simplest and cheapest variant of the system construction. The weighty minus of it is that in the frosty period the coolant, which is in direct contact with the atmosphere, quickly cools (+)

This is a very important nuance, which must be treated very responsibly. Insufficient liquid level in the system leads to "boiling" of the boiler and its failure. In addition, the open system assumes the use of only water as a coolant. More practical in this regard, the compounds of glycols or antifreezes, during evaporation form toxic vapors, therefore they are used only in closed constructions.

Closed Circulation System

It differs from the open by the presence of a closed expansion tank. Does not need constant monitoring by the owner. The design assumes the installation of a surge tank of a membrane type, which is designed to compensate for a sudden drop or increase in pressure in the system. Thus, it prevents equipment breakdowns due to sudden overloads.

In the closed circuit, an expansion tank of a membrane type is installed that does not communicate with the environment, so the coolant does not evaporate from the system

The membrane tank makes it possible to keep the optimal pump and boiler pressure in the system. In addition, the closed design allows us to use as a coolant any fluid that is suitable for its parameters. This makes it possible to get the most efficient and economical system with the necessary parameters. For example, not afraid of freezing, if it uses antifreeze.

According to the method of circulation of the liquid coolant, two-pipe heating systems are divided into two large groups.

Design with natural circulation

The basic principle of the system is as follows: the boiler heats the heat carrier, which expands as the temperature increases. The density of the liquid decreases. Due to this, the colder and therefore dense water gradually pushes the heated liquid up. It rises to the highest point of the system, where it begins to gradually cool down and gravity moves to the radiators.

In the batteries, the water gives off the stored heat and, even more cooling and increasing its density, moves to the boiler. It is obvious that the coolant passes through the entire cycle by gravity, without the use of additional equipment. Due to the fact that this happens quite slowly, the air displaced by water manages to move to the peak upper point of the system, which allows getting rid of unnecessary airing.

![]()

The figure shows a simple diagram of a two-pipe heating system with a natural circulation of the coolant. Its characteristic features include a pipeline of large diameters, due to which the hydraulic resistance decreases, and the mandatory bias along the flow of the coolant is of the order of 2 to 3 mm per running meter

An undeniable advantage of this design is its long service life. The absence of moving elements and the circulation pump, as well as the closed circuit of the system with a finite amount of mineral salts and suspensions, substantially prolongs the time of its operation. Experts argue that the life of structures with natural circulation, equipped with polymer pipes and bimetallic radiators can be about fifty years.

A disadvantage of such schemes is a relatively low pressure drop. It is necessary to take into account also a certain resistance, which radiators and pipes render to the movement of the coolant. Therefore, the range of such a system will be limited. Building codes are recommended to use heating with natural circulation within a radius of no more than 30 m.

In addition, such a system has a sufficiently high inertia, therefore, with the kindling of the boiler and until the temperature stabilizes in the heated building, a considerable amount of time passes. Negative moment can be considered that all pipes must be laid under a certain slope, so that the liquid can move in the right direction. The heating system with natural circulation is capable of self-regulation.

A two-pipe system with natural circulation is capable of self-regulation: the lower the temperature in a heated room, the higher the velocity of the coolant

The lower the ambient temperature, the higher the circulation velocity of the coolant. In addition, several factors affect the progress of the fluid along the heating circuit: the cross-section and material of the distribution pipes, the radius and number of turns in the two-pipe heating scheme of the private house, and the presence and type of the installed shut-off valve. By influencing these factors, it is possible to achieve the greatest efficiency of the heating system.

Wiring with forced circulation of coolant

In the circuit described above, a circulation pump is switched on, which moves the heating medium through a closed heating circuit. This gives significant advantages. First of all, the speed of the fluid increases, due to which the building warms up much faster. In this case, all the radiators connected to the system receive a coolant of approximately the same temperature. This allows them to warm up as evenly as possible.

When using a circuit with natural circulation, this is not possible, since the temperature of the fluid entering the radiator depends on the distance it is removed from the boiler. The further the battery, the colder the coolant. Forced circulation makes it possible to regulate the level of heating of individual elements of the network. In addition, if necessary, you can overlap its individual areas.

The use of a circulation pump allows the membrane expansion tank to be incorporated into the system, that is, to perform it in a closed version. Thus, the amount of evaporated liquid is significantly reduced. In addition, the installation of the structure is greatly simplified, since it is not necessary to lay the pipes strictly at a certain angle, accurately calculate their diameter and lift height.

Another advantage of the design with forced circulation is the ability to make painless enough to make the necessary changes in its layout and layout. To equip this structure, pipes and accessories of smaller diameter are used, which makes it much cheaper. In addition, such systems are more economical due to the fact that the difference in the temperatures of the liquid coolant at the inlet and outlet of the boiler is much less than that of the analog with natural circulation.

The presence of a pump in the circuit prevents the appearance of airflow from the heating main. In general, wiring with the use of forced circulation is considered more effective, but they also have flaws. The most significant of them is energy dependence. The pump can not operate without being connected to a power source. When the power is turned off, this heating system stops. With frequent outages it is desirable to have an uninterrupted power source.

Among the shortcomings usually include financial costs. Some of them are the price of the circulation pump, as well as the cost of the reinforcement, which is necessary for its normal functioning. That as a whole increases the price of installation of the system. In addition, monthly it will be necessary to pay bills for electricity, which ensures the operation of the circulation pump.

From the correct choice of the pump depends largely on the efficiency of the heating system with forced circulation

The heating circuit can be arranged in two different ways, which determine the location of risers and pipelines in space.

Horizontal and vertical layout type

Assumes the connection of heating appliances to the horizontal highway. It is mainly installed in one-storey buildings of a large area. Stojaki in this case is optimal to place in the corridors or utility rooms. The advantage of this type of arrangement is the lower cost of the system itself and its installation. The main drawback is the propensity of the structure to be earthed, so it is necessary to install Mayevsky cranes.

The horizontal wiring differs from the vertical variant in that the number of vertical lines in it is minimal. Plus it is that the supply and return lines can be laid under the floor, minus the fact that it is undesirable to use polymer pipes for a buried gasket and it is absolutely necessary to install a circulating pump on the circuit

The radiators are connected to vertically arranged risers. This option is especially good for buildings with several floors, since it makes it possible to connect each floor separately to the heating riser. The main advantage of the system is the absence of air congestion. In this case, the arrangement of a heating scheme with a vertical layout will cost more than a horizontal analogue.

Vertical layout of the system allows you to connect each floor separately to the heating, which is very convenient

Two-pipe heating system with top wiring

The main distinctive feature of this design is the laying of the supply pipeline on the upper part of the room, the return is taken along its lower part. An important advantage of such a system: high pressure in the pipeline, which is due to a significant difference in the levels of the return and supply pipes. Due to this circumstance, their diameter can be the same even with arrangement of a circuit with natural circulation.

But in this case the expansion tank, which is located at the highest point of the circuit, is most often found in an unheated attic, which can cause problems. As an option, it is possible to consider the arrangement of the tank inside the ceiling, when its lower half remains in the heated room, and the upper part is taken to the attic and as much as possible insulated. If the owner is not particularly concerned about the presence of pipes under the ceiling of the room, it is desirable to have a supply line above the level of the windows.

In this case, the expansion tank can be located under the ceiling, provided that the height of the riser is sufficient to ensure the normal velocity of the coolant. The return will need to be mounted as close to the floor level or even lowered under it. However, in the latter case, when fitting the main line, it will be impossible to use connecting elements to prevent the appearance of a leak.

The figure shows the layout of the upper wiring with the associated and counter-current natural movement of the coolant. The systems relate to a two-circuit category, according to which the boiler is installed in the central section of the network and divides it into two approximately equal in length contours

The appearance of the room with the pipes laid under the ceiling is not aesthetically pleasing. In addition, some of the heat goes up, which makes the heating system with an upper wiring less effective. Therefore, you can try to assemble a circuit with a supply line passing under the radiators, but this will improve only the appearance of the system, does not affect its shortcomings in any way.

The pump connection makes it possible to easily achieve the optimum pressure in the system even when using pipes of minimum diameter. The maximum effect of a heating system with an upper-type wiring can be obtained in a two-story private house, as natural circulation is stimulated by a large difference in the installation height of the boiler in the basement and second-floor batteries.

The preheated coolant will be sent to the expansion tank, which is placed in the attic or on the second floor. Whence on an inclined main the liquid starts to act in radiators. In this case, it is even possible to combine the distribution tank and the expansion tank responsible for the presence of hot water. If a non-volatile boiler is installed in the house, a completely autonomous heating system will be obtained.

Another very good option for a two-story house is a combined system combining two and one-pipe sections. For example, a single-tube design is mounted on the second floor in the form of a water-heated floor, and a two-pipe structure is installed on the first. The ability to regulate the temperature in all rooms is fully preserved.

A two-pipe heating system with top wiring does not decorate the room. The supply pipe must be placed above the window if the building is not equipped with a warmed attic

The main advantage of a two-pipe heating system with a top wiring is high flow rate of the coolant and absence of airing of the main line. That is why it is used quite often, without paying attention to significant shortcomings:

- unaesthetic kind of rooms;

- large consumption of pipes and components;

- the lack of the possibility of heating large areas;

- problems with the placement of the expansion tank, which can not always be combined with the distribution tank;

- additional costs for decoration, so that you can disguise the pipes.

In general, the system with the top wiring is quite viable, and with correctly performed calculations it is also very effective.

Two-pipe design with bottom wiring

The scheme assumes installation of feed and return from the bottom of the batteries. Unlike the system with wiring of the upper type, the direction of the coolant movement is changed here. It starts moving from the bottom upwards, passes through the batteries and is sent back to the boiler in return. Systems with a lower wiring may include one or more loops. In addition, it is possible to arrange a dead-end wiring and a circuit with a passing motion of the heat-transfer fluid.

The figure shows a two-pipe type heating system with a lower wiring. The lower scheme of laying the supply line is advantageous in that it does not require as much heat insulation of the pipeline as when laying it in an unheated attic. Loss of heat is also significantly lower

The main drawback of the design is air-blasting. To get rid of it, the Mayevsky cranes are used. And if the system is installed in two or more floored houses, it is assumed that such a crane will have to stand on each battery. This is certainly not very convenient, so it is recommended to lay special air lines that are included in the system.

These air vents collect air from the heating main and direct it to the central riser. Then the air enters the expansion tank, whence it is removed. Heating circuits with low wiring and natural circulation are used quite rarely, as they have a number of limitations. First of all, this is the fact that most of the batteries included in the circuit are finite.

For this reason they have to be equipped with graduates. If in the system there is an expansion tank of an open type, then it is necessary to lower the air almost daily. Installation of airways, looping feed pipes, allows to level this defect. However, they significantly complicate the scheme and make it more cumbersome. Moreover, the "air" is laid on the top of the room.

A significant advantage of the bottom wiring, consisting in the absence of a paved main line, is lost. The number of pipes used for installation in this case is quite comparable with the number of parts required for top wiring. Therefore, for the arrangement of a two-pipe system with a lower wiring, the option with forced circulation is most often used.

Externally, systems with a lower wiring look much more attractive. Pipelines are made of pipes of small diameter, pass under the radiator and are almost invisible

The significant advantages of such a system include:

- Compact placement of the control area of the entire system. Most often it is installed in the basement.

- Reduction of heat loss, which gives the laying of pipes along the bottom of the room.

- The possibility of connection and operation of the heating system until the completion of construction or repair work. For example, the first floor can be heated, and on the second floor the necessary work will be carried out.

- Considerable heat savings due to the possibility to distribute it over the heated premises.

The shortcomings of the bottom wiring include a large number of pipes and components required for installation and low fluid pressure in the supply line. In addition, the need to install Mayevsky cranes on heating radiators, as well as the constant removal of air plugs from the system, can also be considered a negative moment.

Video on the topic of the article

In the presented video review the shortcomings and advantages of heating systems with natural and forced circulation are considered:

Detailed analysis of the two-pipe heating scheme for a three-story country house:

How to independently equip a two-pipe heating system in a country house:

A two-pipe type heating system is a widely used method of practical and efficient heating of housing. There are many modifications of this scheme. It is important to choose the right option for your home and make a competent calculation of all system parameters. Only then the house is guaranteed to be warm and cozy.