We clean the well with a drain pump. Ways to clean the well with your own hands. A simple way to clean the well in the country

Autonomous water supply is achieved by creating your own well. But this structure requires constant care. About how to clean the well yourself, and we will discuss this article.

Drinking water must be clean. But over time it spoils. Factors that lead to contamination of the well:

- getting into it leaves and branches;

- penetration and decomposition of frogs or mice;

- clogging the filter on the bottom;

- formation of silt and other sediments;

- raising the water level (leads to the penetration of sand and clay);

- breach of seam sealing.

All of the above phenomena lead to a turbidity of the water. It may cause rust or unpleasant taste (smell). The regular cleaning is an integral part of the proper operation of the well. This procedure is carried out with a period of 4-7 years. A more precise period is established based on the characteristics of the soil structure.

Technology of cleaning the well

There are the following ways to clean the well:

- manual;

- automated.

Naturally, the implementation of the process by hand is marked by increased complexity and laboriousness. Simultaneously with the pumping of water from the walls of the well with a brush, all deposits are removed. After the removal of all water, the walls are disinfected using chlorinated water. After 10-12 hours, the "chlorine" is washed clean water.

More acceptable is the automated way of cleaning the well. This process is carried out by using a drain pump.

Types of equipment for cleaning the well

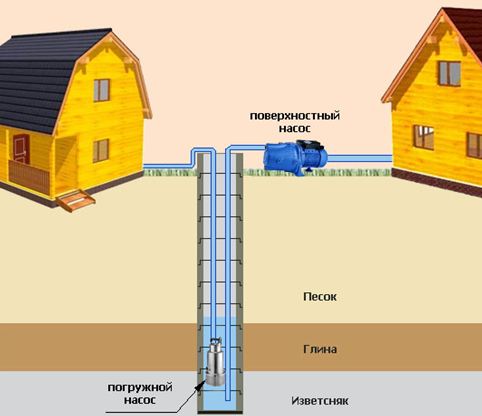

To clean the well with your own hands, you can use both submerged and superficial drainage pump.

Submersible pumps lower the water. This equipment characterized by:

- increased productivity;

- long operating period;

- small size;

- light weight;

- versatility (used both for pumping dirty water, and for pumping clean);

- presence of float protection.

The disadvantages of submersible pumps include:

- impossibility of pumping water from a depth of more than 20 m;

- insufficient water pressure;

- lack of water purification function.

Advantages of drainage pump installed on the surface:

- the most powerful head;

- increased reliability (does not come into contact with water);

- uninterrupted work during the day;

- the ability to install equipment anywhere in the land;

- affordable cost.

"Minuses" of surface pumps:

- too noisy work;

- the impossibility of pumping water from a depth exceeding 8 m;

- availability of technical skills related to the operation of equipment (checking the correct rotation of engine components, qualitative connection of nozzles).

Features of drain pump connection for cleaning the well

The drain pump for cleaning the well must work correctly. To do this, follow a number of rules. At the initial stage, it is necessary to carefully study the instructions for using the equipment (especially with regard to limitations). This will depend on the use of a particular model.

Preparing the drainage pump for operation requires the following:

- connection of the pipeline (hose) with the discharge branch pipe;

- installation check valve on the pipeline or hose (if there is a float switch);

- checking the correct rotation of the equipment shaft;

- fixing the pump in a vertical plane (the branch pipe is directed upwards);

- dipping equipment into the well.

Verification of the correct rotation of the engine is carried out as follows:

- the pump is laid on a level surface (the table is quite suitable);

- equipment is turned on and off immediately;

- visually determine the direction of rotation of the shaft (it must be clockwise).

If the drainage pump is connected to the pipe, the correct rotation is determined as follows:

- equipment is connected to the power grid;

- appropriate measurements are made;

- stop the supply of electricity;

- one phase is replaced by another;

- the pump is again supplied with electricity;

- measurements of pump power are again performed;

- choose the best option.

Procedure for cleaning the well

Naturally, it makes no sense to use drainage equipment designed for pumping clean water. According to the scheme for work on cleaning the well, it is best to use models that:

- have the maximum power;

- flow the liquid together with the fibers and small contaminants;

- have special wheels, grinding the largest particles of silt, dirt and other debris;

Ideal when the drain pump is equipped with the float mechanism to adjust the depth of the dive. In this case, there is no longer any need to control the process of cleaning the structure (this is done when equipment can not be overheated).

According to the instructions, cleaning the well with a drain pump consists of the following stages:

- measuring the distance to the bottom;

- immersing the pump at a level of 0.6-0.8 m from the bottom;

- its inclusion;

- pumping out dirty water;

- natural supply of clean water from the aquifer;

- the destruction of silt at the bottom (with the flow of pure water);

- turn off and raise the pump;

- removal of dirt from the filter equipment;

- re-immersion and cleaning of the well.

The duration of the cleaning of the well is 5-6 days, the frequency - 1 time in 3-7 years.

To clean the sludge from the sludge, you can use a conventional electric pump. The only condition is the implementation of its modernization:

- one of the pipe ends is covered with a protective mesh;

- the second end of the pipe is equipped with a receiving pipe, to which a reliable cord is attached;

- the pump housing is installed and fixed to a wooden pole (the metal plate, bolt and nut are used as fixing elements).

The pump is immersed by descending the pole and rope. Pumping water occurs until the bottom appears. The equipment case is always in the water. With the help of a rope, the angle of the pump is adjusted when it is necessary to remove silt from the walls of the well.

The process of pumping out dirty water is subject to control. Particular attention is paid to changing the sound of the equipment. This can occur due to the accumulation of a large amount of silt on the protective mesh or the descent of the intake pipe to the bottom.

Video on how to clean the well:

Alexey 30.01.2015 Pump stations

The presence of water in the house is a prerequisite for a comfortable stay. But often in suburban settlements there is no main water supply and it is necessary to search for an alternative source.

For example, a well, which is a structure designed for water abstraction of groundwater.

It, as a rule, is a hand-made, fairly wide, vertically arranged pit with fortified walls and a device for lifting water on the surface.

There is a well from the head with a lifting mechanism, a mine and a water intake (bottom). At the bottom is usually located a kind of filter, made of a layer of coarse sand and a layer of gravel. Over time, the voids in the gravel are filled with silt and sand and the well becomes useless - the water becomes cloudy. Therefore, if the construction of such a structure is planned, then a pump is required for cleaning the well.

Operation of autonomous water supply system

The cleaning process consists in immersing the device a distance of half a meter from the bottom, then the pump for cleaning the well is turned on and the pumped water is filtered. After that, the clean liquid under pressure comes back, which leads to the destruction of deposits in the filter layer.

The cleaning process consists in immersing the device a distance of half a meter from the bottom, then the pump for cleaning the well is turned on and the pumped water is filtered. After that, the clean liquid under pressure comes back, which leads to the destruction of deposits in the filter layer.

This operation is recommended to be repeated once or twice a year, takes a cleaning cycle about a week. To prevent contamination, you can constantly keep a small pump in the well for constant cleaning of the well, which will allow you to enjoy fresh water without interruption.

Types of pumping equipment

Typically, the wells are divided into types according to the type of lifting mechanism:

- Crane;

- With collar;

- With Archimedian Vit and others.

However, the water intake in them can also be different, according to the type of water intake they are divided into three types:

- Incomplete water intake - a structure in which the bottom of the well does not touch the waterproof layer, the water enters it through the lower part.

- A full receptacle is when the bottom of the source is located on the waterproof layer, and it is filled through the walls.

What is a mud pump for wells? There are such devices of two types:

- Submersible;

- Superficial.

Submersible pumps fall directly into the well a short distance from the bottom. By the principle of work are divided into centrifugal and vibratory.

Surface pumps as already seen from the name are located on the surface, the suction hose is immersed in the well, they are often stationary and are used in industrial production.

Due to their simplicity and reliability, the greatest spread in private households submersible pumps. Such an aggregate consists of a body, an electric motor, and a suction unit with a filter. The main difference between these devices and the usual ones is the presence of a filter that allows working in contaminated environments.

There are some disadvantages of these models. Firstly, they can not cope with wells of great depth, and secondly they are not able to purify water, which makes them not suitable for autonomous water intake systems. Unfortunately, universal pumps that can work in any conditions and can be used for any purpose do not exist.

What to look for when choosing

Drainage view

One of the main criteria for choosing such an aggregate is the degree of contamination. Typically, this parameter is determined by the maximum size of the particles of contamination, which can "digest" the pump.

The criterion is the depth of the well. The larger the parameter, the more productivity the pump needs to successfully raise the water.

The final, but also important factor is design features equipment. These include the location of the suction hole, the material from which the device body is made, maintainability. This factor is little influenced by the conditions in which the pump will operate, for the most part they affect the performance of the device, and depend very much on its price and manufacturer.

Review of the best equipment

NPC model - 400D

Let us dwell in more detail on specific models of pumps. To begin with, consider a submersible centrifugal pump NPC - 400D, a Chinese company Caliber. The power of this model is 400 W, the capacity is about 7000 l / h, it can work at a depth of up to 7 meters.

The size of the transmitted particles is 5 mm. Made of cheap plastic. Weight is 5 kilograms. It differs in its simplicity and relatively low price - just over 2,000 rubles. Cheap, not whimsical, perfect for a suburban area.

Now consider for comparison the German submersible drainage pump SDP 7000 of the well-known company Karcher. With a lower power of 320 watts, this unit has the same capacity (about 7,000 liters / hour) as the Chinese. However, it exceeds it by the depth of the dive - it can cope with a distance of 8 meters. And also on the maximum size of solid particles, this device is able to cope with pollution with a diameter of 20 mm. He surpasses the predecessor and the performance characteristics. In the equipment of this brand everything is thought out to the smallest detail.

Model SDP 7000

Its body is made of high-quality, ultra-strong materials. It is equipped with a comfortable, ergonomic circular handle, which makes it convenient to carry. Also it is necessary to pay attention to the optimized connecting branch pipe, which allows connecting any hoses, including large ones, without adapters.

Equipped with this device and a float switch with adjustable level, which will allow it to be used in automatic mode.

Perhaps, its only drawback is the price of 5,000 rubles, but is it much for all the listed advantages? You decide.

Necessity of equipment and operating rules

The desire to have in your home a source of clean water leads to considerable expenses for its maintenance. One regular cleaning is capable of demanding large investments. But they can be significantly reduced if you use a pump to clean the wells. Suitable for this purpose. However, only the correctly selected pump can work efficiently.

Thanks to the regular use of such equipment, you can achieve stunning results and use exceptionally pure water. But for this it is necessary to comply with the requirements specified in the operating instructions. After all, as a rule, for such purposes, submersible equipment is used, whose serviceability can not be easily verified.

This feature requires good tightness, for which the pumps of these models have a special chamber filled with oil, which protects the engine of the unit from contact with water. It should be regularly checked for presence in it the required quantity composition and, if necessary, is poured.

After a long operation of the equipment, the oil must be replaced, usually this process is performed after the expiration of 200-250 operating hours.

Only by observing all these rules, you will be able to ensure a long and reliable operation of the pump to clean the wells.

Conclusion

Having considered all the features of the drainage equipment, it is easy to choose the model corresponding to the specific requirements. If its seasonal operation is expected at the dacha, then it is possible to confine ourselves to an inexpensive domestic pump. For permanent residence outside the city will require a more powerful and at the same time expensive model. But in any case, do not buy equipment from unknown companies, very often it is of low quality. Having saved on it, you risk getting unrefined water, unsuitable for food.

The service life of the hydraulic structure depends on the quality and regularity of the preventive maintenance. The cleaning of the well involves the removal of existing contaminants in the water intake and the prevention of possible siltation of the aquifer.

Knowing how to properly clean the well yourself, you can not attract contractors and save money.

Before clearing the well in the country house with your own hands, you need to determine the types and causes of contamination. The reasons for the deterioration of water quality are determined by the main organoleptic characteristics: color, odor, content of foreign impurities.

There are the following types of pollution:

- The appearance of turbidity of water. This occurs as a result of reducing the tightness of the water intake structure and penetration surface waters in the mine. Verhovodki saturate drinking water the smallest particles of sand, clay and dirt, which are layered on the bottom of the structure. Other reasons are clogging of the bottom filter and poor quality of aquifer filtration.

- The presence of technical and biological debris in the water. The causes of such contamination are possible deformation and damage concrete construction, so that in aquifer gets debris. Another reason is clogging up the bottom with silt, which prevents the intake of clean water from the mine.

- Clogging of fallen leaves, broken branches, feathers and other extraneous objects. This is due to absence. With strong gusts of wind in the water intake shaft can be clogged with land debris, which prevents the penetration of clean water into the well. In such a situation, effective cleaning of the private well, as well as disinfection of the structure and aquifer will be effective.

- Changing the color of water. If the water source acquires a darker shade, this indicates an infrequent operation of the structure. If the water turns green, this indicates the multiplication of small algae and protozoan microorganisms. If the liquid has acquired a reddish tint, this is a sign of an elevated level of iron. The main reason is the poor quality of the aquifer.

- The appearance of an unpleasant smell of sulfur compounds in the water. If the water source begins to smell rotten eggs and acquires an unpleasant aftertaste, this is the first sign of a breach of the integrity of the structure, which leads to leakage of sewage and sulphurous compounds from the ground.

Important! If hydroconstructions are regularly operated throughout the year, then the wells are cleaned every 3 years. If the wells are used only in the off-season, then preventive work is conducted annually in spring and autumn.

Preparatory work and safety rules

Often, site owners do not know how to clean the well properly, so do not follow simple safety rules. Before starting work, it is recommended that you familiarize yourself with the basic requirements:

- Cleaning of the wells should be carried out with assistants - one will go down to the bottom of the shaft, the second will be responsible for the supply of the tool, the third for the insurance. In unforeseen situations, assistants should remain on the surface and do not descend into the mine to ensure the lifting of the person from the well.

- To ensure complete safety during the cleaning process, it is necessary to use a safety rope or cable, regardless of the depth of the structure.

- All works in the mine are carried out in boots, a helmet and a protective suit.

- Before cleaning, it is necessary to check the absence of hydrogen sulphide and chloride fumes. This is done in the following way: a burning candle goes down into the mine, if the flame does not extinguish, then the oxygen level is high. To remove existing gases, a portable turbine, preheated to a low temperature, can be used. The furnace is lowered by an ashtower down and kept for some time to discharge the gases to the surface.

- If a metal ladder falls into the mine, it must be equipped with a special support, the rope device securely attached to the outside of the well.

What is the cleaning of hydraulic structures?

To ensure the high quality of the work carried out, experts recommend the use of special tools for cleaning wells. The most reliable and affordable of them are filters, which are:

- Bottomless. Presented by a filter cushion of fine-grained pebbles and sand, buried at the bottom of the water intake shaft.

- Coal. Membrane filters with a coal base are capable of retaining large rock particles, and multistage filters provide purification from silt, chemicals, pesticides, metal salts, calcareous deposits.

Equally effective is the bucket - bucket with movable jaws on the locking spring. Such a device for cleaning the well allows you to clean the bottom of the structure without going down into it. This happens in the following way: the clamshell in the open state is fixed on the cable and falls to the bottom. At the moment of a strong impact, the jaws catch, catching the bottom sediments, after which the device is removed to the surface. The grab is cleaned of dirt, the lowering / lifting procedure is repeated several times.

The grab is of three types:

- manual - for wells and wells of shallow depth. Constructively consists of a ladle and a cable;

- mechanical with a hoisting winch. Additionally equipped with a winch and 2-4 ropes;

- deep. It is intended for cleaning of summer cisterns and wells of great depth.

The most effective in the fight against blockages is a drainage, or mud pump for cleaning wells.

Preventive measures for cleaning the structure

The main task of any owner should be regular preventive cleaning of the wells, which will ensure the supply of high-quality water for domestic and household needs. Sanitation of the aquifer is carried out at the end of the winter period, after melting of the snow cover.

Effective cleaning provides for complete disinfection of the aquifer and the hydraulic structure. To do this, use a weak solution of potassium permanganate - 1 tbsp. l. for 10 liters of water. Prepared water is poured into the bottom of the shaft. 3 hours after disinfection, we completely pump well water.

Manual cleaning of the well

Manual cleaning of the well in the country is a complex and responsible process that requires special skill and some knowledge. It is carried out with strong clogging of well water, siltation of the bottom of the mine and the ingress of foreign objects. If the well does not have a great depth, then you can safely proceed to manual cleaning.

How to clean a well in a dacha by hand? To begin with, you need to prepare:

- boots;

- protective clothing and helmet;

- a metal bucket;

- ladder (metal or rope);

- brushes with stiff bristles and soft sponges.

The main work is carried out after the preliminary pumping of water from the mine. Pumping equipment can be used for pumping.

After removing the liquid, you can proceed to the stage-by-stage cleaning of the structure. The upper part of the structure is thoroughly cleaned with a rigid brush, then the ladder is fixed, after which the lower rings are cleaned on it, creating a reliable stop. When the structure is completely cleaned of accumulated contaminants, it can be taken as a bottom cleaning of the mine.

The bottom is cleaned of debris, drainage stones are washed with water and re-laid out. If there are damages in the concrete structure of the mine, preventive maintenance is carried out: cracks and potholes are covered with a solution based on cement and plasticizer.

When the silting is strong, the bottom filter is thoroughly cleaned, and the poor quality areas are covered with new material.

Once the well is cleaned completely, it is recommended that the aquifer be further disinfected and the well design decontaminated.

Measures for disinfection can be carried out as follows: a weak 10% solution of chlorine diluted in a 10-liter bucket and carefully process the walls of the mine. After the treatment, cover the structure with a protective cover and leave it for a couple of days. Finally, pump out water at least 3 times with the help of a pump or pump.

Drainage cleaning of the well using pumping equipment

If contamination of the aquifer by pathogenic microorganisms, algae, depressurization of the joints and organic debris is observed, then the well is thoroughly cleaned by a drain pump with pre-pumping water.

After the repair and drainage of the well is completed, it is necessary to make complete disinfection of the mine and aquifer.

How to make repairs and complex cleaning of the well, see in the video presented.

One of the most important measures for servicing the well is cleaning and disinfection. Properly executed cleaning of the wells with their own hands guarantees an increase in the service life of structures and a high quality of the water source.

Drainage pumps are used in different situations. As a rule, they are used for pumping water, in particular from contaminated wells. They have different purposes and capacities. About their varieties, shortcomings and advantages will be discussed in the material below. We will also touch on the topic of cleaning the well from quicksand by a pump.

Scope of application:

- choice of water in the event of an accident;

- pumping out fluids from flooded premises;

- cleaning of the well from the quicksand by a pump;

- for watering landings;

- in the system of fountains;

- in the water supply system of the house.

Let's analyze the types of drainage pumps for a well

Submersible. The unit is lowered to the bottom of the shaft for cleaning from quicksand. Actively used by summer residents and residents of private sectors, since it has an acceptable price, is easy to operate, it is possible to install independently.

It is divided into two subspecies: vibrating and centrifugal.

Surface. Used on the surface, and into the well I lower only the pressure hose.

The difference between a submersible pump and a surface pump

Submersible drainage pump

The advantages of this unit include:

- small size and weight;

- long term of use;

- are used for pumping clean and polluted water;

- high performance;

- in the pump system there is an automatic mode.

Cons of submersible pumps:

- relatively weak water pressure, the maximum height of water lifting in some types of units is 20 meters;

- dirty water does not become purified during the ascent, and therefore it is not always appropriate to use it for the organization of water supply systems.

The work is carried out by submersible drainage pump

Vibratory submersible pumps are used in the summer season to supply clean water. For installation in a well on quicksand, such an aggregate will not work, as it provokes the movement of sand mass at the bottom.

However, summer residents often choose the "Baby" pump to clean the well on quicksand, since low cost and availability of replacement parts allow repairs in case of breakage after heavy loads.

The centrifugal unit can be used for deep wells. It provides a head of water up to 60 meters, has high productivity. This is a perfect pump sample for a well with quicksand, as it does not cause vibrations and sand rise. But if the rules of operation are not observed, oil spills on the surface of the water may be observed.

Aggregates of surface type

They are installed on the surface, in a technical room in the house. This avoids the electrical connection to the well.

Benefits:

- high power provides good head pressure;

- the unit has high reliability and long service life;

- installation in the house allows you to have constant access to the pump;

- acceptable price.

Disadvantages:

- not applicable for wells over 9 meters in depth;

- noisy work, which requires the organization of an isolated installation site;

- competent exploitation requires certain skills and knowledge.

The technology of applying the pump when cleaning the well

Before choosing a particular unit, it is necessary to study its characteristics. Some are used only for running clean water, while others can be used for pumping dirty. Some models are equipped with a crushing mechanism that grinds large debris.

Cleaning the well on quicksand drainage pump can reduce the time of pumping water at times. Experts recommend using the unit with a float. Once the pump reaches the bottom, it will automatically turn off. The mechanism without the float must be constantly monitored, so that, on the surface of the water, it does not start to overheat.

The process of cleaning the well:

- pumping water;

- cleaning the bottom of silt and sand;

- change the bottom filter;

To draw water from the well it is enough to lower the unit and it will quickly perform the necessary work.

However, you need to know how to configure and apply it:

- at the first immersion the pump is not lowered to the very bottom, but kept at a distance of 50-100 cm from it;

- the pump is turned on, and the dirty water is drained from the well to the large capacity of 300 liters;

- using an external pressure pump that uses already drained water, and generating a jet of water, clean the walls of the shaft and the bottom of the plaque and dirt;

- the subsequent pumping out of water is made until the bottom becomes clean;

- the pump filters are periodically cleaned.

Qualitative cleaning of the well with a powerful pump and proper organization of the bottom filter will allow to forget about the problem for several years.

The nuances of choosing a drainage pump you can peek in the video below.

We hope that the article was useful to you. We will be grateful if you share it in social networks.

Pumps for cleaning wells can be of several types. Before you pick up, you need to know how to do it. And after that, only make a choice which pump to clean the well.

After all, this is all done by our own hands and therefore we must choose the most the best option. The video in this article will help you understand the task. Help and instructions for the work.

Clean the well

If the price of a job that a private firm undertakes, does not suit you, it is quite realistic to clean yourself and save some of the money. But in return you have to spend your time and energy.

It is performed better by a pump, it greatly facilitates the work. A mud pump for cleaning wells pours out water without problems and you do not need to do it manually.

So:

- First of all, it is necessary to check whether there is no accumulation of dangerous gas for the person at the bottom of the well. It is done this way: on the rope in the well, gently lower the lighted candle.

If it is extinguished, then you can not go down-there is a cluster of gas, the concentration of which is dangerous to humans. Obviously, it is necessary to remove the gas. This is done simply by using a conventional vacuum cleaner.

Attention: This method is not as effective compared to using a burzhuyka. It is put near the well, take a pipe, one end of which is lowered to the water, and the second is fixed to the blower. And you start to heat the stove. Thus, the gas is drawn outward.

You also need to know the safety precautions. While in the mine, watch your condition, and at the slightest deterioration, go up.

Once again, I repeat that you should not be alone, the presence of a partner who insures you, be sure.

Stages of work execution

All work is done in several stages:

- Go down into the shaft and use a metal brush to thoroughly clean the walls of dirt, moss, mucus and other deposits. Rinse several times with water.

- We proceed to clear the bottom and water from debris. It is collected with a fine mesh. The filter, if present, must also be obtained, cleaned of silt and sand, or replaced with a new one.

- Further it is necessary to disinfect the well. To do this, you need to know its volume, which is determined by multiplying its depth by the cross-sectional area.

- It is done by means of a pump. First, the pump for cleaning the wells should pump out all the water and then water or wipe the mop with a cloth rag with a special solution (water with chlorine lime - for 1 liter of water 20 grams).

- Then we prepare a solution for water disinfection. While the water will be collected in the well, take a container and dilute in it a solution (200 mg of bleach per 1 liter. cold water), close the lid tightly and mix.

- Then defend and pour into another container without sediment. We pour the solution into the well, mix it, close it, so that the chlorine does not evaporate. The procedure must be repeated for another day.

- After disinfection it is necessary to remove. When it is typed, it is pumped out again. Do this until the water stops smelling chlorine. However, you can not drink it for another two weeks, and then it must necessarily be boiled.

Attention: Another point to pay attention to is the stagnation of water, if you do not use the well for a long time, which is especially important for summer residents. Such water can not be drunk, it must be pumped out.

- And in order to avoid stagnation, lower it into the shaft vent pipe (diameter 20 cm), the bottom of which should not reach the water of 15 cm, and the upper end should protrude above the top of the well at 1-1.5 m. Moreover, the top of the pipe should be closed with a fine mesh and make a cone of rain.

Protection of the well

The structure is usually round in shape and open from the top. If you leave everything as is, then it will get dust, leaves and other debris, which will lead to instantaneous contamination of the water.

So:

- The simplest and most logical decision is to close it. The easiest way to make a lid (wooden or plastic), but we advise to build a full-fledged mini-house, inside of which there will be a well.

- Approaches to the construction should be protected from penetration of animals, in particular cats and dogs. Their wool is also a source of pollution. For this you can make a fence.

Attention: Take the rule at least once a year armed with a flashlight to inspect the walls of the well. In order to do this better, lower the powerful lantern on the rope inside the shaft. That will allow you to see a large area. If you do a regular cleaning and do not run, then it can be done more qualitatively and with minimal costs.

- It is also necessary to ensure that the structure is safe for children, fencing it.

- If you find an object in the water, it should be extracted very quickly, and if it turned out to be a dead animal, then you should clean the water from the well. To do this, you need a pump to scoop out all the water, disinfect the mine, and then fill the structure with clean water.

If you need to go down, it is strictly forbidden to do this alone, you must be insured from above, in order to help get out. - Carrying out all the requirements for care, the frequency of cleaning will be approximately once a year, and sometimes even less. It is necessary to understand that in any case, when used on walls, various deposits, bacteria, will accumulate.

Due to seasonal temperature fluctuations, cracks may appear, they may shift, and in the cracks formed, dirt will accumulate. - Water can become cloudy and get an unpleasant smell. After a while these signs will disappear, but this only means that all suspended particles, i.e. muck, settled down. These and other deviations will be the reason why you should immediately clean the well and water in it.

Of great importance is the competent installation of the structure initially, the device of the clay lock, the laying of the filter on the bottom, etc. Therefore, make a well by all rules and then it will serve you for many years.