The drain pump does not pump water well the reason. The basic malfunctions of drainage pumps. Device and principle of operation of drainage pumps

Drainage pumps are widely used in various spheres of human life.

With their help, water can be supplied from open sources (pools, ponds, etc.) and closed (well wells) sources.

They are indispensable in the flooding of living quarters as a result of accidents or natural disasters.

Numerous manufacturers of this equipment Among the main advantages of its products are reliability and long life. In most cases, this is true, but nevertheless, like any other equipment, drain pumps need maintenance and can fail for a number of reasons, including the following:

- violation of the rules of installation of equipment;

- violation of the rules and norms of operation (overload or prolonged work in the "dry");

- untimely or unskilled maintenance of the pump;

- pumping liquids with solid inclusions of large size.

Consider the symptoms of the most common breakdowns of drainage pumps:

- The pump hums, but the water does not pump.

The reasons for this "behavior" of the pump can be as follows:

- the shock absorber mount on the pump stem has loosened. This is one of the few situations where repairs drain pump You can not do it yourself without special equipment and without practical skills. It will be necessary to disassemble the body and tighten the two fixing nuts. Upper counter;

- the valve is damaged. Replacing the valve at home is difficult to produce. It is advisable to contact the service center;

- the pump stem is broken. In this situation, repair of the drain pump is almost impossible. It's easier to buy a new pump.

- When the pump is turned on, the cables "fly out" and the cable melt. The winding burned. With such a breakdown, an independent repair of the drain pump is not possible. Elimination of such a malfunction must be carried out in specially equipped workshops, because The replacement of the armature winding must be accompanied by a thorough testing of the pump.

Important! The listed faults are basic for the vast majority of drainage pumps. Any other failures in the pump, somehow "flow" from them.

Saving or quality?

Of course, in this version the question sounds too categorical, but, in the overwhelming majority of cases, choosing between self-repair equipment and contacting the service center, we choose one of the named priorities. Modern submersible pump is a complex electronic-mechanical unit, an intervention in the work of which requires the performer special knowledge and practical skills.

How to choose a drain pump read.

Service centers have at their disposal special equipment, the use of which allows to significantly optimize the process of testing and repair of pumping equipment.

Advice! Unqualified repairs can entail costs significantly higher than the cost of repairing the drain pump.

Repair of the drainage pump by one's own hands, alas, is not always possible. Certain faults can only be eliminated by specialists in the conditions of a specialized workshop. Some failures can not be fixed at all - it will not save even the replacement of the part, you will have to buy new equipment. The list of self-fixes is short, but consideration is still worth it.

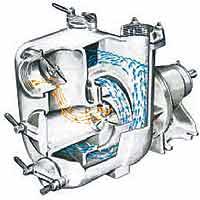

- the motor drives the impeller fixed to the shaft;

- the impeller plates disperse liquid inside the pump casing;

- under the action of a centrifugal force, the liquid enters the outlet;

- the vacated place immediately takes up the liquid that enters through the inlet.

The holes are located at different levels. It depends on the type of pump: submersible, surface. Submersible take water from below, and not from the side.

Diagram of drain pump

Video: Dilax Drainage Pumps

Unplanned repairs by one's own hands or in the workshop will not be necessary if you follow the simple rules of operation of equipment detailed in this video clip of the manufacturer. It also tells about the principle of the device.

Basic malfunctions of drainage pumps

The pump does not work if:

- There was a short circuit due to a sudden voltage drop in the electrical system, the winding burned.

- The float (if it's a float device) jammed below the trigger level (keep the well walls, hoses, power cable).

- The impeller jammed with mechanical inclusions trapped in the body.

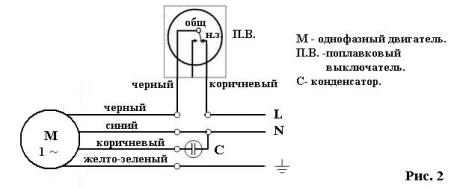

- The capacitor has failed.

The pump does not work, but it hums if:

- The valve has failed.

- The mounting of the shock absorber on the rod is loose.

- Stock stopped.

- The power cable is out of order (the wires inside the common cable have been frayed).

The main malfunctions are listed. Diagnosis is required to identify individual breakdowns.

Important! Before you beat the alarm, first check the network - maybe problems with electricity, not with the pump.

How to repair a drain pump yourself

Of all the listed faults of drainage pumps, only a few can be eliminated by hand. Really release the float (here instructions are hardly needed), remove the wedged impeller mechanical inclusions (you can not tighten the impeller, as in the video below), fix the shock absorber, repair the cable. To secure the shock absorber, it is necessary to disassemble the body and simply tighten the nuts on the mounting bolts by screwing the upper one. This is the simplest of all. Cable repair will take time, but it's feasible. In some models it is easy to replace the capacitor.

All the rest is not done without the masters, and the ragged stock in general is so difficult to fix, that the acquisition of new equipment is much more expedient. It will not be possible to replace the valve yourself (difficult, unprofitable) and repair the winding - a specialized tool will be required. However, this does not apply to cheap Chinese pumps: they either take new ones or repair themselves, since highly qualified repairs will cost more.

Video: repairing the drain pump yourself

The citizen tells us how to fix the device, and what mistakes he made while doing this - the anchor was damaged, the impeller broke (oh, and the Chinese impellers are strong). A person works cheerfully, on a pair with a TV, that's why it's very difficult to hear a lot, but everything is perfectly visible. With his own hands, he only broke in the beginning, and then he repaired.

Repairing the drain pump power cord

If the power cord fails, the pump will not turn on (obviously), but sometimes the fault can not be detected visually, that is, the wires are torn inside the insulating cable.

Before trying to repair the cable, you need to understand where it is broken. The two most probable are the place of connection to the pump, the length at the fork - that is, the most frequently bent areas. Here you need a medical method - palpation. That is, you have to squeeze your fingers with your fingers so that the torn wires are connected (they can not get out of the submarine anyway) - thus you will find the breakage place (if you do not forget to turn on the equipment).

To fix the cable broken at the entrance to the housing, it must first be removed. Demolition is required. Here surprises may await: in some GNOM-x bolts are not designed to be twisted with normal screwdrivers - they are made for a 3-petal bit (rare, now hexagonal holes are more often). The manufacturer's motivation is unknown.

Important! When removing the cover, do not pull it, do not tear it sharply - you can accidentally break off the wires, and they will entrain the winding of the motor. Gently swing, gradually the lid will loosen.

Inside the case there is a tensioning device. It must be removed by unscrewing the 3 bolts. Remove the tension washer. Remove the cable. Cut it further off the wire break and insert it back. Here, another surprise may lie in wait - the swollen cable will not pass into the hole intended for it. It will be necessary to lubricate it with engine oil (it is better not to consider the option with removing the coupling: you can disfigure the part).

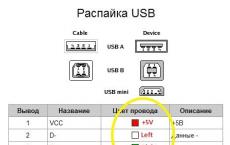

All detachable wires need to be labeled, so that they can be properly connected without interrupting the "ground", "zero" and phase (ground wire, usually yellow-green, "zero" - blue, but anything can happen).

After inserting the cable, replace the tensioner, tighten the bolts, assemble the circuit, isolate the connections. When installing the cover, make sure that the stud is in the groove. Do not press.

We talked about idle pumps. It also happens that the pump turns on, but then turns off - it is able to work, but for some reason does not want it. Such a behavior of the device is explained either by a short circuit in the circuit or by a blockage in the flow region. It is not difficult to check the circuit and repair the malfunction (the closure in the pumping equipment circuit is no different from any other closure). If in the process of checking the circuit, it was not possible to detect the fault, the matter is in a clog. Remove the filter, the diaphragm, and clean the flow area.

If the pump stopped pumping as much fun as before, the worn impeller most likely worn out - it is necessary to change. The widened gap between the impeller and the diaphragm can also cause a decline in equipment performance. The gap must be adjusted.

In order to prevent and prevent blockages in the flow area, it is recommended that after running the pump with contaminated fluids run it in clean water - this will help remove any accumulated impurities.

Important! Be sure to disconnect the equipment from the network, if you are going to look for breakdowns - do not forget about safety.

Independently little that can be repaired (even the bolts adjust the trick, even the replacement of the wire is surrounded by difficulties), and therefore we must protect the equipment. Here, as with crimes: the best method of struggle is prevention.

If the drain pump has to work in inappropriate conditions, it will fail. The drain pump does not cope with large inclusions (the permissible fractions are specified in the instructions). If such inclusions are suspected, use a fecal pump with a chopper.

Repair of drainage pumps is a very important solution to the problem for long-term operation of devices in good condition. It's no secret that this unit will not be replaced for its sites during the thawing of snow or torrential rains, when excess water can do a lot of damage to the structures, flooding the cellars or washing away the foundation of the house.

With the help of a drain pump, water can be pumped from the pool or pit, or from any tank. How to repair a drainage pump with your own hands offers to get acquainted with this article.

What are the types of drainage pumps

According to their purpose, such pumps for pumping out dirty liquid are divided into:

- . This type of device is used for pumping liquids from small tanks.

The unit is installed on the ground, at the edge waste pit. To drain the waste, a hose is lowered to the bottom of the container.

When the pump is running in automatic mode, it is necessary to bring it to the switching lever float mechanism, he will monitor what level of water in the reservoir or foundation pit. When the sewage is raised above a certain mark, the float with them rises and turns on the equipment.

Such a device must have two pipes:

- entrance, to draw water from the sink pit;

- the output through which the liquid is withdrawn beyond its limits.

When working, make sure that no water gets into the engine, which can lead to damage to the machine. Therefore, the transfer of effluents must be carried out faster than their level can rise in the excavation.

Tip: To sewage system the pumps are fed through the nozzles. In this case, when mounting the unit, it is necessary that the diameter sewage pipe was known fairly accurately, up to a millimeter.

The main advantage of surface drainage devices is their mobility. The device can easily be moved to any place, and need to repair it can be done easily and quickly.

- . Such models are most often used for cleaning deep vessels and for large-scale floods, for eliminating excess water. In this case, the aggregates are lowered into the tank or trench, where it is necessary to pump out the liquid, and the water is sucked through the holes located in their bottom, and not through the inlet hoses for drainage pumps.

The mesh filters of the apparatus protect it from the ingress of stones and other large particles into the pump impeller.

The use of a float or a plastic bubble allows, with a certain volume of drains, to automatically switch on a submersible pump. To prevent possible shortages, when the device is immersed in a liquid, manufacturers have provided a quality electrical insulation.

The indisputable advantages of drainage pumping equipment for liquid are:

- Versatility.

- Long service life.

- There is no need for mandatory regular maintenance.

If it is necessary to pump out or pump a heavily polluted liquid, it is better to prefer sewage or faecal pumps. They have a special cutting or chopping tool and can pump and process liquid in which there are large household waste.

Tip: In this case, it is better to use an automatic sewerage system that allows the commissioning of bathrooms that do not have a connection to public sewage.

Device and principle of operation of drainage pumps

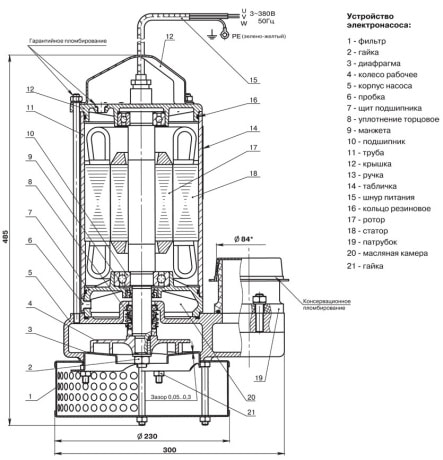

The main elements of the drain pump are:

- Engine. If the price of the pump is a small engine is located in the inner housing, made of plastic.

- The condenser motor, which has a thermal protection switch that prevents overload, has more expensive upgraded units. Here:

- the cases are made of high-strength polypropylene, reinforced with fiberglass; it is possible to manufacture the pump body from stainless steel or plastic, and for the motor housing and shaft is taken stainless steel;

- the working shaft is made of stainless steel.

- The case is internal.

- The case is external.

- or impeller, are located on the shaft in the outer casing of the pump. The configuration of the wheel determines how much dirt particles can pass the pumps.

When the pump is running, the space between the housings is filled with water, forming a "jacket" for cooling, which protects the unit from overheating.

- For automatic shutdown and start-up, the pumps are equipped with float switches that control the water level in the tank, protect the device from "dry running" and from flooding, monitor the timely activation of the pump.

Quality, and with a long pump life, work can be obtained if the content of fibrous inclusions is minimal, and the size of solid particles does not exceed 5 mm. The smaller the installation depth, the better.

Advice: The operation of drainage pumps with increased sewage temperature is limited by the time specified in the operating instructions. This is due to the fact that the cooling of the engine occurs when heat is released into the liquid that is pumped.

What are the criteria for selecting drainage pumps

There are several rules that must be observed when choosing an assembly:

- Take into account the type of pumped liquid. Determine how much particle it can pump without problems.

- To study the main parameters of the drain pump, which will help to choose the most suitable model. These values include:

- head. This value for an average product is approximately from about 7 to 10 meters. At high-pressure models it is possible to achieve a pressure more than 30 meters. Indicators of the head of the device will depend on the distance to which the liquid will be fed;

- performance. For example, for a 40 m3 tank, a device with a capacity of up to 10 m3 / h is sufficient. To use the units for industrial purposes, models with a capacity of 100 m3 / h and even more are required;

- depth of submergence of the pump. Its maximum value can vary from 5 to 15 meters, and the minimum is only from 0.3 to 0.9 meters.

Tip: It is mandatory for the unit to operate, its pumping part should be located under water.

The general view of the drain pump is shown in the photo.

The life of the device has a direct effect on:

- The quality of the material used to manufacture the elements of the device.

- Temperature of pumped liquid. It should not exceed + 50 ° С.

- The diameter of the conditional pass. This index affects the amount of suspensions and solids in the liquid.

- Presence of protection against overheating. Most often in the models are built in just two devices:

- float switch, needed to prevent engine overheating;

- thermostat, turns off the power when the water level has reached a critical level.

Repair of submersible pumps

Sometimes there is a situation when you need a repair. In this case, it is necessary first to find out the cause of the failure.

Most often this can be:

- Improper operation of the equipment - exceeding the operating parameters of the device.

- Long period between maintenance.

- Work unit in a "dry". If the pump is used for a long time in this mode, the pump may fail.

- The solid inclusions in the pumping liquid are too large.

- The installation of equipment has not been carried out qualitatively.

- Defective: relay, accumulator, no filter, there are other manufacturing defects.

All of these causes can lead to rapid wear and damage to the device.

If the cost of the unit is too high, you can repair the drain pump yourself, but only for those who have the skills to handle such units.

When the first signs of malfunctioning appear submersible pump It is required to check the status and working capacity of such elements:

- The piston must have elasticity, on its form there should be no deformations or any mechanical damages.

- When blowing air on the side of the intake of liquid, it must pass freely on both sides.

- Between the piston and the coils of the electromagnet, the optimal distance should be from 0.4 to 0.5 cm. For larger intervals the coils will be beaten, with less - the motor will overheat.

- Between the valve that covers the inlet openings and the housing, the clearance should be between 0.7 and 0.8 mm.

Tip: Very often the poor performance of the equipment is caused by the failure of any elements, and the voltage drop in the mains. Therefore, before starting disassembly and starting self-repair of submersible pumps, it is necessary to initially check the voltage in the network, it should be 200-240V. If everything is normal here, you can start disassembling by making a special notch on the areas to be joined at the junction.

How to self-repair a drainage pump in detail shows the video in this article. Only the timely elimination of malfunctions in the operation of the unit will allow to operate it for a long time without any problems.

According to statistics, submersible drainage and fecal pumps are broken in 95% of cases by the fault of the consumer due to improper operation, and only in a small number of cases there are any other reasons (factory marriage or some unforeseen factors).

You often hear from customers that:

- All pumps are bad (and especially the one that was sold to me - initially a low-quality pump, probably the "left" Chinese) ...

- we did everything right, according to the instructions, and the pump somehow burned out ...

- we put the automatic defense, which was supposed to turn everything off ...

- and in the pump, in general, the passport is thermal protection (if it is at 220V), but it did not work ...

- etc. etc.

Let's try to figure it out.

1. Regarding the sale of substandard pumps:

No trading company will sell deliberately low-quality goods, because otherwise it will be necessary to constantly conflict with consumers, repair the goods at their own expense and bear adjacent costs, not to mention the fact that the image of the company suffers, etc.

The overall quality level of pumps produced in the 21st century is consistently high, with very few exceptions. The company "PUMPS AMPICA" does not sell poorly proven models, excluding them from its range.

Thanks to many years of experience in pump sales, we have developed a stable range of quality, time-tested models from a variety of manufacturers.

2. Concerning the manufacturer:

There is no market for quality European submersible pumps at a price below 7 ... 10 thousand rubles.

All that is sold below this price is made in China. Many European companies only stick labels and pack Chinese pumps.

At least 70% of European companies produce their pumps in China and sell them under their own brand. This does not mean that they are bad. It is impossible to collect quality products "on the knee". Modern production is almost completely automated.

It is extremely difficult to spoil anything in the process of assembly. In addition, the time has already passed when China did not monitor the quality of products. This is an entire industry and no one will lose a huge sales market in Russia.

Naturally, buying a submersible pump in a large supermarket for 500 ... 900 rubles, you should not count on its trouble-free operation during the rest of your life.

Such goods are sold as "zavlekalochki", as accompanying. Everyone understands that the buyer will not be due to 500 ... 900 rubles to go to the service center to repair the pump to the other end of the city (or send it by mail to the service center, sometimes this is a "pleasant" surprise for the buyer).

Because of such "superproducts", confidence in Chinese goods is lost (but, we repeat once again that in gross stores only gross sales are important).

Summarize:

- there are no cheap European pumps,

- 2/3 of European pumps are actually produced in China and you will pay half the price only for the brand of the manufacturer,

- do not need to buy pumps in large supermarkets for 30 cents. The proverb about "cheap cheese" has not been canceled.

3. We (customers) did everything correctly, according to the instructions ...

Half of the people who "did everything according to the instructions" did not open it. It is enough to ask 2 questions to determine this.

Do not be lazy to read the instruction manual of the pump. It takes a little time, but it gives an idea of what is good, what's bad for a pump.

4. We had a machine gun ...

The automatic circuit breaker is installed by a conventional one, which does not track small current changes. Its power is chosen 2.5 times higher than the power of the electric motor of the pump (because of the large starting current). While this machine "swings", the pump is already overheating and will fail.

In a mind, you need to put not an ordinary automatic machine (which, basically, only from a short-circuit in the network saves), but an automatic motor protector. This is a special device that allows you to accurately set the working current of the motor and monitors its slightest increase due to the wedging of the pump shaft.

In this case, the motor protection circuit allows exceeding the set value of the motor current at the time of its start.

Usually we offer automatic protection of the engine manufactured by ABB MS series. These motor protection circuit breakers are more expensive than conventional network automatic machines, but they reliably protect the pump motor from overheating.

Conclusion:

- for the protection of the motor, it is required to install the MOTOR PROTECTION AUTOMATA, and not the usual network circuit breaker, you do not need to save on this,

- You should read the instructions, especially the places that are highlighted - there's just about all this written.

5. Regarding thermal protection:

Thermal protection is built into the winding and represents a relay that switches off the motor power when the heater is heated.

It should be understood that every time the winding overheats, its insulation is fused, that is, irreversible changes occur. After some time (with the next overheating), the insulation must be completely melted in some place and a short circuit of the winding will occur, which will lead to the failure of the electric motor.

That is, thermal protection is not a panacea for all troubles, but only emergency protection, which is capable of saving the electric motor several times and nothing more.

6. Work without water.

The submersible pump motor is cooled by the pumped liquid. Submersible pumps are of two types: with jacket cooling and without it.

Pumps with a cooling jacket can not work fully immersed in the liquid, because water will pass through the surrounding pump housing and cool the motor.

Pumps without cooling jacket should always be completely submerged in the pumped medium.

Hence, there are 2 basic errors when installing the pump, which lead to overheating and failure of the motor:

- operation of the pump in water, with a temperature higher than indicated in the passport for the pump (in the normal version up to + 35 ... 40 ° C, and up to + 60 ° C in heat-resistant version).

This is often the fault of public service employees in the event of accidents in the hot water supply system.

When a pipe breaks through hot water requires pumping it out of the wells, to carry out repairs. External pump does not work, because just does not suck hot water because it boils in the suction pipe and you have to use a submersible pump, which in a few minutes "dies" from overheating.

There are solutions for this problem, but here we will not touch them.

The operation of an incompletely submerged pump or pump without water. And in one and the other case the motor overheats and breaks down. The usual automatic defense does not track this.

Solution:

- installation of the pump in the pit,

- use of automatic water level monitoring (for example, float switch).

A common mistake: the installation of small capacity in a large area capacity.

In this case, the water level during evacuation decreases very slowly, and the pump can remain for a long time not completely immersed in the liquid.

For example, such a mistake was made by our customer when installing the pump in the repair dock, where it was planned to pump out the water after installing the vessel in it.

7. Operation of the pump outside the operating range of delivery and head.

Let's analyze on a concrete example: the drainage pump GNOM 40 / 25Т.

The pump stood in a foundation pit and fed water to a height of 7 meters through a 100 mm hose. Then came the pouring of water on the ground.

Inspection of the pump revealed that all 3 phases were burned in the pump motor, indicating that it was overheated.

The recommended pressure of such a pump, according to the passport, is 18-25 meters. That is, it is the range in which the motor operates without overload.

When the pump is operated with a head of 7 meters, the pump operates in the feed range, which is significantly higher than the operating range (the lower the head, the greater the supply in any centrifugal pump). In this case, the operating current in the pump windings is greatly increased, which leads to overheating of the motor.

When operating outside the recommended pressure range, install a valve at the pump outlet and set the supply so that the operating current in the motor windings matches the one specified in the passport (in this case 12.5 A) + install the motor protection unit.

Otherwise, the pump will operate with overload, and the motor may be damaged.

When running the pump with a head of 7-10 meters, the most optimal use of the GNOM 53-10T pump. In this case, feed adjustment is not required.

As you can see from the above example, you do not need to take a pump with a "margin" for pressure, because this can lead to its failure (although it seems that once the pump delivers 25 meters, then when filing for 7 meters, there should not be problems).

8. Pump operation on the closed valve / work through the narrowed pipe

Sometimes it is required to drain sewage into the sewage system, in which there is some pressure (the so-called pressure sewage system). In this case, it is required to select a pump whose pressure will be 0.5 atmospheres higher than the pressure in the sewer.

Moreover, the pressure at the entrance to the sewer pipe must take into account the head loss from the pump to the point of entry into the sewage system.

If the pressure at the entrance to the sewer is not enough, then the liquid from the sewer pipe will flow through the pump into the septic tank.

To prevent fluid from flowing, in this case, a check valve must be installed.

If the pump pressure is incorrect (less than in the discharge pipe), then when the pump is turned on, it will work continuously on the closed line, which will lead to overheating and failure.

Often, customers save on pipes and buy pipes of smaller diameter than required. This leads to:

- the pump performance decreases (it can start to work outside the operating range), which leads to its overheating,

- the pipe may become clogged, which will cause the pump to work on a closed pipeline, that is, work with overload, and, consequently, overheating of the electric power and its failure.

Some manage to use fecal matter on a pump that can pump particles up to 50 mm with a pipe of 32 ... 38 mm and then wonder that for some reason the pipe is clogged and the pump is out of order.

If you really want to save on pipes, you can put a fecal pump with a chopper.

In this case, the pipe will not be clogged by coarse particles (but the pipe diameter must still be calculated in advance so that the pump does not work with overloading).

The diameter of the pipe depends on the pump capacity and its length.

Below is a table on which you can determine this:

9. Pump operation with liquids of high density and viscosity.

When working with liquids that do not correspond to the passport data, the electric motor starts to work with overload, which leads to its overheating. Then everything follows the scenario described above.

10. Work with highly abrasive fluids; a large number of large solid particles.

When pumping fluids with a large amount of abrasive, the shaft seal quickly wears out, which causes liquid to enter the motor housing and cause it to malfunction.

Often, reading in the instruction that the pump can pump liquids with particles up to 35 ... 50 mm (most household faecal pumps), consumers think that such particles can be stones, nails, reinforcement, pieces of cement, etc. and in large quantities. In fact, this is not the case at all. If such particles constantly fall, then this will lead to the destruction of the impeller and the compaction. Such pumps can pass large particles, but mostly soft.

Quite often, construction companies digging foundation pits, save on industrial equipment and buy household pumps for pumping water (why, it will be clear below).

Ends it is always the same: bring pumps that are completely clogged with sand and stones, pumps with broken impellers and housings.

And, as always, we hear the same thing: the pumps are bad, they immediately burned out, etc.

And now, for your information: special pumping pumps are required for pumping out from pits. They are made of special wear-resistant steel and have electric motors of increased power.

The prices for such pumps start from 120 000 rubles (who is interested, you can see on our site in the section "Sand and slurry pumps).

And they buy pumps, for the same purposes (especially economical builders), for 10-20 thousand rubles.

11. Frequent on / off switching of the pump motor.

Any electric motor at power-up, consumes current several times higher than the working one. Therefore, there is a limit on the number of pump starts per hour (the more powerful the motor, the fewer starts per hour it allows).

For comparison, we give the table:

A common mistake when installing the pump is that users reduce the length of the cable float switchso that it would turn on "more often". Sometimes it turns on so often that it exceeds the permissible limits, which leads to overheating of the windings and the pump's failure.

Alternatively, the pump is lowered into a narrow well in which a high-power pump is installed. If a lot of water is drained into this well, for example, with a prolonged shower, the productive pump quickly pumps out the water, turns off, then the water quickly fills the narrow well, the pump turns on, etc. In this case, the permissible frequency of the motor starts to be exceeded, which will lead to its failure.

It happens that the pump stands in a narrow well and pumps the water along a long pipe up the slope. If you do not install a non-return valve at the pump outlet, this will cause the pump to pump out water and turn off (if equipped with a float). After that, the water from this pipe because of the slope, will drain back into the well and fill it, which will lead to the inclusion of the pump. This process can be repeated until the pump burns down.

And naturally, we will hear the familiar phrase: "the pump is bad."

This fault is sufficiently well revealed when the pump is inspected - the starting winding burns at 220V pumps.

12. Pump operation under reduced voltage; voltage surges.

When the pump is operated at a lower voltage (which differs from the set value by more than 5%), the operating current in the motor windings greatly increases, which leads to its overheating.

This situation can arise for two reasons:

- problems in the power network (in our country half of the country at rush hour the voltage in the network is lowered),

- the use of a long power cable, without the correct selection of its cross-section, depending on the length and power of the motor.

If you put a long cable with a small cross-section, then because of the increased resistance, the voltage that reaches the pump motor can be significantly different from the supply voltage.

- the electric motor may fail due to power surges in the network.

For example, if you have a 220V network in a dacha, and next to you, the handicraftsman continuously welds something with electric arc welding, while he is sitting in a different phase, then at the time of his miracle operation (well, if it is factory production, not manufactured by the skilled craftsman) there are very large voltage fluctuations. All this together can lead to failure of the pump motor.

13. Pull the submersible pump to the surface by the power cable (behind the float).

This is one of the most common ways to "kill" a pump.

When pulling by the cable, there is a violation of the tightness of the cable entry connection to the motor housing. This leads to the ingress of water into the motor and its failure.

It also happens that the cable is not sealed (for example, it was dropped on the power cable when carrying the pump).

Outwardly this does not appear in any way, but, over time, water through the cable gets into the electric motor and disables it.

14. Use of poor-quality start-up equipment.

We had one client who "killed" 2 pumps at an interval of one day. In the event of a defect, it was found that the electric motor operated in 2 phases instead of three (two windings of the electric motor were burnt).

When the first pump was brought. we strongly recommend checking the pump starter. But, as usual, it was said that we ourselves all know, etc. and the like, and you have "bad pumps".

After the second pump was brought with the same malfunction, our customers were smart enough to replace the starter (the price is 500 rubles). After that the problem disappeared. That's because of the reluctance to listen to the advice of professionals, you can save 500 rubles on the starter and pay for repairs of 30,000 rubles.

15. Connecting the pump to electricians who do not understand what is going on.

Now there are many incompetent "workers" who do not understand anything in electrical engineering, but, nevertheless, they undertake to connect any equipment. Savings can come not only with the loss of money, but also with injuries and a fire.

Recently, one such person called and was unhappy that he did not have a 3-phase pump that does not work with a float switch. As it turned out, to turn off the pump, he broke one of the phases of a three-phase electric motor.

It's good that the owner of the pump suspected something was amiss and called us on his own.

Before the "murder" of his pump remained very little ...

16. Work in aggressive environments.

Many people think that if the pump is made of stainless steel, then it can be shoved into any container and shake any chemistry. Usually, this belief ends after a few minutes of running the pump (the last minutes in his life).

Undoubtedly, there are such pumps, but only they cost from 150,000 rubles and more.

The pump has many more parts that must be able to withstand the aggressive environment. Conventional pumps are not designed for this purpose.

We want to sum up all of the above:

1. All the reasons given in this article for the failure of the pump were real.

2. To design the pump, it is better to consult with specialists and answer ALL the questions they ask, no matter how "dumb" they do not seem to you.

3. ALWAYS install the motor protection.

4. If voltage is applied to the installation site, install a voltage regulator.

5. The pump must only be used for its intended purpose.

6. Where higher reliability is required, it is worthwhile to complete the pumps with control and protection cabinets.

The organizations that managed to persuade to equip the pumps with control cabinets, with all possible protections, made sure that not all pumps are "bad", but only those that are exploited by people who do not follow the equipment and who do not care what happens to him.

Automation monitors various critical situations and has protection from the "fool".

We hope that this will help someone to make the right choice of the pump, and someone will survive the failure of their "faithful assistant" and not blame all the blame on the sellers and the manufacturer.

Drain pump in the countryside - a kind of wand-zashchalochka in the occurrence of unforeseen situations. By design, it resembles equipment for supplying drinking water, but it has the ability to move contaminated media with large inclusions. We will try to understand the weak sides of the unit and find out whether it is possible to repair the drainage pump with our own hands if necessary.

The ability to pump water with fine gravel, large inclusion of sand, organic residues is a very useful quality when you need to pump out water after flooding or drain the pond. Drainage units are designed to work in such conditions, but exceeding the load often leads to breakdowns.

To get acquainted with the internal filling of the device is better right after the purchase in order to represent what details can fail in case of clogging or breakage. For this, it is not necessary to open the housing or disassemble - it is enough to study the circuit that is attached to the instructions for connecting and maintaining the device.

The suction opening of the pump unit can have a different arrangement: for submersible models it is located in the lower part and is equipped with a filtering net

Apparatus for private use on country plots they do not differ high power or complex stuffing. Unlike heavy industrial equipment, they are compact, relatively light (average weight - 3-7 kg), they consist of steel or plastic parts, although cast iron is still used for the production of industrial models and some domestic ones.

The main components of the submersible mechanism are a pump unit that pumps water and an electric motor that rotates the shaft with blades. The engine is located inside a rugged case, which is made of stainless steel or reinforced polypropylene and is double. Water circulates between the outer and inner walls, preventing cooling.

Image Gallery

Modern models are equipped with thermal protection, which works when the device is overloaded. The impeller is attached to the axial shaft - a screw device that supplies liquid into the housing. When the unit is turned on, the impeller starts to rotate, take water from outside and push it along the walls to the outlet. To replace the first portion of water comes the next - and so until the mechanism stops.

Adjusts the frequency of the float switch. It monitors the level of fluid in the reservoir or natural body of water, and when it is sharply reduced, it turns off the machine in automatic mode.

Scheme explaining the operation principle of the float switch: the float floats to the surface of the water mirror - the mechanism starts to work, it goes down - stops

As you can see, the drain pump device is quite simple, and if you have ever dismantled and cleaned a submersible well pump, then you can cope with this category of equipment. The faecal aggregate, which has an additional node for crushing too large particles, differs slightly.

The difference between submersible and surface models

The immersion apparatus is useful for cleaning deep tanks, for example, a newly commissioned well. The first liquid that has accumulated in it can not be called drinking, since there are many large inclusions of sand and clay. During the day, it is necessary to pump out the contaminated liquid so that clean, usable water comes into its place.

The Gardena Classic drainage pump is designed for pumping dirty water, has a capacity of 6 thousand liters per hour with a maximum immersion depth of 7 m

Unlike the submersible, surface pump Do not use for deep tanks, it is more suitable for pumping water from the pool or basement - when it is flooded. At the bottom of the tank is placed a hose for reception of dirty water, the second hose serves for draining the drains.

If the pump is used in an emergency, it is appropriate to use a float device that will monitor the critical level of water rise. Plus, the design of the mechanism allows you to pump liquid with large pieces of dirt - up to 5 cm (rarely - 10 cm).

It is clear that the aggregate of the surface type differs in its structure. Inside the metal case, the working shaft and wheel are fixed, and the engine can be different: for centrifugal products - single-phase with external ventilation, for self-priming - asynchronous bipolar. Despite the contamination of the environment for pumping, do not allow the pump to work with a liquid in which petrol, kerosene or other petroleum products and chemicals are dissolved.

Causes of damage to drainage equipment

It can break both new equipment, and has served more than one year. A newly purchased unit may fail due to a manufacturing defect made during assembly: a damaged piston or an improperly connected valve. Often breakdowns occur due to inefficient installation, if:

- lowered the unit to an insufficient depth;

- allowed air to enter the water intake compartment;

- the water inlet is above the water and is not covered with liquid.

These shortcomings can easily be corrected by a simple test, but it is better not to allow them.

In the installation scheme of the drainage submersible pump, in addition to the location of the main equipment, one can see the installation of a pressure pipe with check valve and a latch

Most often, problems arise during the operation of equipment. The manufacturer sets the control parameters, within the framework of which it is necessary to act (they are stated in the technical certificate of the product). If the equipment is used incorrectly, not for the intended purpose, it simply will not withstand the load.

For example, for a drainage device, the transfer of dirty water is the norm. This means that problems can arise if you start moving a clean drinking water (for which wells and well models are intended). On the contrary, too much contamination clog filters, causing the pump to stop operating.

Also, trouble is expected if the equipment is idle, in the "dry" mode - there will necessarily be an overheating, which can not always be corrected independently. As a result of oversight, the case may end with expensive service repairs. The lack of prevention, rare technical inspections can also cause a breakdown. Many troubles can be avoided by warning them by replacing one of the parts or by an elementary cleaning.

Image Gallery

Malfunctions and ways of their elimination

There are a number of opportunities to repair the equipment yourself, provided that the broken part can be replaced with a new one or a simple technical procedure (for example, cleaning). To do this, you have to disassemble the case, make a diagnosis, identify a problem and pick up an identical part.

If you rarely use drainage equipment or plan to use it in case of accident (flooding) only, do not rush to buy an expensive pump - it's much easier to replace a cheap model. Pumps Caliber - from 2500 rubles.

The available actions include replacing the condenser, impeller or float, repairing the electric cable, fixing the shock absorber, removing large pieces of clay and sand stuck inside the case.

If the cast iron casing is cracked, the valve fails or the winding is no longer functioning, contact the service center or think about buying a new pump. Inexpensive drainage devices of Chinese production are inexpensive, so ordering serious professional repairs is not practical.

The power cord is out of order

The flexible element - the cable - is always in the risk zone, because due to regular twists and kinks (which often happens during transportation and reinstallation of equipment), wires under a layer of plastic or rubberized protection are torn, resulting in a power failure of the pump.

It is necessary to find the place of the gap and make the connection. This operation is easy to carry out if the break occurred near the plug - you just need to clean it and connect the wires, finally carefully isolating the work place.

During the extraction of the cable, try to mark and memorize the fixing points of each wire (it is of different colors) so that in the reverse installation you do not confuse "phase", "ground", "zero"

A cable break in the area of connection to the pump requires more time to repair. First, it is necessary to remove the equipment from the water, wipe it and dry it, then disassemble it to get to the internal connection unit. Prepare to the fact that instead of hexagonal holes come across triple, which is why there will be a difficulty with the selection of a screwdriver.

The cover should be removed carefully, without jerking and effort. Unscrewing the bolts holding the tension element, you will be able to view the cable and determine the area of the rupture. A worn piece is removed, the cable is reassembled, we attach the tension element, fix the bolts.

The water supply stopped

The engine is working properly, however, the fluid either stopped flowing at all, or is caused by small uneven jerks. The reasons for the strange phenomenon can be several:

- The part of the supply line is clogged. This is a branch pipe or feed pipe. There was a kind of clog from beams of algae and pieces of clay. Disconnect the pipes and clean them. Probably, the pipe length is longer than recommended by the manufacturer, and therefore there is not enough pressure for the head of the required power.

- The impeller was worn out. The blades are bent or damaged. It is necessary to disassemble the device, replace the parts, first visually (as far as possible) by determining the cause of the malfunction.

- The liquid is oversaturated with dirt and debris. Therefore, water has a thick consistency and is difficult to pump. The problem is solved by lifting the suction hole a certain distance from the bottom, where the precipitate accumulates.

- The engine power has decreased noticeably. What can be determined even by the sound. There may be a malfunction in the supply of electricity, the failure of bearings, the depressurization of the oil compartment. It is necessary to disassemble the case to clarify the cause of the failure and replace the worn parts.

The most common problem is filter clogging. To clean the mesh and suction hole, you can try to pass through the pump a number of clean water. If this procedure does not help, you should disassemble the cabinet and clean all the chambers, removing pebbles, algae and chips.

When disassembling, you may encounter an unpleasant "surprise" - the fusion of rusty mounting bolts with the body. Bolt heads need to be cut off gently by the Bulgarian, and in place of the old fasteners, install new screws

When deconstructing the unit, be sure to use the manufacturer's diagrams or instructions. They will help you to remove parts in succession, quickly find the places where the bolts are fastened. In some cases, wear of the fasteners or loosening of the nuts causes the parts to shift, which also affects the performance of the machine.

Engine does not start

You connect the power supply - and the pump does not work, does not make noise and does not pump water. Prepare to have to inspect all equipment. Here are the most common causes of engine failure:

- Electricity failure due to wire breakage. We check the cable to the touch and find the place of break. If the emergency area in the area of connection to the pump - act as described above.

- The stator winding has failed.It happens because of the work "dry". If you can not replace yourself, contact a specialist.

- The bearing jammed. We check the part for suitability, we clean or change the results of the diagnosis.

- The suction device was clogged with debris. We clean the blades and lattice, check the integrity of the operating elements and the grid.

- The float switch broke. To check its operation, it is necessary to close the relay. Perhaps the problem is in the wire that connects the float to the pump.

If a capacitor fails, replacement is required. In some models, it has special access, which is a separate hole in the body.

The pump switches itself off automatically

When the pump is turned on, it starts to work, but after a while it stops spontaneously. Most likely, the protective mechanism works because of an engine overheating. The cause may be a heating cable. It is worth checking the conformity of the mains voltage and the parameters specified by the manufacturer. If the data does not match, you need to purchase a stabilizer.

The cause of overheating or spontaneous disconnection may be the oxidation of wires that need to be cut off or replaced. The problem becomes apparent after a complete check of the remaining parts of the pump

Disconnection can also occur due to the clogging of lobes with debris. In this case, we recommend a complete cleaning procedure, that is, open the case, clean the inner chambers and impeller, check the filter.

If clogging occurs quite often, read the instructions to the product to clarify the size of the fractions. It is possible that the pump is not designed for pumping liquids with large particles of debris - only the fecal pump will be suitable for grinding

Switching on the pump knocks out the electrician

When the pump is turned on, plugs or cables burn out. The reason is worth looking for in the details directly responsible for wiring electricity - the cable or stator winding. The serviceability of the wires can be checked with a tester, if a worn section is found, the entire cable should be replaced or (if the gap is near the end), shorten it.

Winding repair is a labor intensive and requiring special knowledge. Even with a carefully conducted secondary winding, a short circuit can not be ruled out. If you do not have time to fiddle with a burnt out part, take the device to a service center - it may be advisable to buy a new pump after diagnosis.

If you have decided to repair the winding yourself, try to take into account all the parameters - from the number of turns to the thickness and the mark of the wire

Preventive measures and regular maintenance

As you can see, the inevitable wear and tear of the equipment operation can become the cause of wear of the parts. In order for the unit to last longer, try to follow the manufacturer's recommendations. For example, position the casing so that the suction device is at a certain distance from the base of the tank and does not capture the coarse particles.

At least once a year, check the serviceability of the cable and internal parts, disassembling the case as far as possible. Do preventive cleaning, which will increase the life of parts several times. Do not confuse drainage device with fecal - it does not have a special chopper and does not cope with the movement of large inclusions.

Videos from folk craftsmen will help you organize the disassembly of pumps of various brands and fix troubles yourself.

Overheating of the stator due to violation of the intermittent operating mode:

Peculiarities of repairing the Pedrollo pump:

How to fix the drain pump Whirlpool:

Disassembly of the pump Praktika DNG-400:

Repair of the drain pump by one's own hands is quite possible and desirable, if it is enough to clean or replace the spare part for repair. Complex emergency cases - rupture of the hull or rotating shaft - are not subject to independent repair. Elimination of serious problems should be entrusted to specialists, and if replacement is impractical, then buy a new pump.