Waterproofing of concrete structures: materials and methods for protecting concrete from corrosion. Than to waterproof concrete rings

In any system of water supply and drainage, it is extremely important to ensure a competent waterproofing structure, so that leakage and the entry of groundwater into reservoirs are avoided. This issue is also relevant for the protection of special structures - wells made on the basis of concrete rings, as they are often used as containers for drinking water, or an autonomous sewage system.

Wells constructed using prefabricated components, it is advisable to erect for the implementation of a storage tank of technical, drinking water or organization sewage system. The above two options are particularly demanding to prevent leakage of underground sources inside, as this can adversely affect water quality.

Note that improper installation and processing of such a system can lead to deterioration of soil and groundwater conditions where the corresponding reservoir is located. For this reason, waterproofing sewerage wells, made on the basis of concrete rings, is carried out already at the stage of constructing the structure.

Septics

Wells for sewerage require mandatory waterproofing, ensuring reliable protection of the environment from contamination in it. Note that they can have not only a huge amount of organic substances, but many pathogenic organisms. Of course, contaminated soil can adversely affect plants and human health.

Drinking wells

Drinking wells tend to be isolated from penetration of soil surface waters. This is explained by the fact that they contain all kinds of bacteria and large suspensions. The presence of even a small part of such a solution in the reservoir can cause significant damage to the human body.

Figure number 1. Waterproofing of seams

When should waterproofing be updated?

Rings made of concrete from the outside and from the inside are usually processed even at the initial stage of the construction of the well, since the material from which they are made easily absorbs moisture. During the operation of the structure, it may be necessary to restore the protective coating, which may be indirectly indicated by the following factors:

- - appearance of the displacement of the rings relative to each other;

- - too fast and excessive filling of the sewage system;

- - mechanical and chemical destruction of well components, with the formation of cracks, which will inevitably cause leakage of contents;

- - determination of foci of corrosion of reinforcing elements, which leads to seepage of ground moisture through septic waterproofing.

In each case, it is necessary to immediately restore the protective coating and seal the joints. Lack of proper attention can lead to an unpleasant smell, in the case of sewerage, or deterioration of the quality of drinking water in the corresponding wells.

A reliable device of concrete elements, taking into account the influence of aggressive media and substances on them, is feasible only with septic tank waterproofing.

Video number 1. Waterproofing of a well

Protection with plaster

Often, the construction of containers using exterior and interior decoration by means of a special component, cement, which has a low% shrinkage and water permeability. It is applied to the surface by means of compressed air, under considerable pressure. As a result, a compact and even layer is obtained along the entire working area of the structure.

Processing is carried out with the use of "cement-gun". It is recommended to lay the solution in two layers, with the thickness of each should be within the range of 5..10mm, with a minimum air temperature of at least +5 degrees. The following layers are applied when the previous one is completely dry, which may take a total of about 10 days.

In view of the high evaporation, in the hot time, the applied coating must be watered after 4..5 hours. In moderate conditions, this interval can be increased by 2-3 times.

Bituminous waterproofing

The most simple and reliable method of sealing is the use of hot bitumen. The material is an excellent insulator, but it does not tolerate temperature changes and is prone to delamination over time. In view of this, mastic and additional components are added to the bitumen mixture.

Before starting work, you will need to thoroughly clean the outer and inner parts of each ring. Then, the first bituminous layer prepared using gasoline in the ratio 1k3 is applied. Further application of the material is provided with a solution in the ratio 1k1. All layers are desirable to withstand until the final drying. Each subsequent stratum on the basis of hot bitumen is distributed by a roller or brush.

Picture number 2. Bituminous waterproofing of concrete rings

Over the frozen bitumen, the mastic is laid in a layer of 2..3 mm. On the outside of the concrete rings, on top of the mastic, a roofing felt or any other insulating element is fixed.

The advantage of bitumen waterproofing septic tank is the ease of carrying out the work and their relative availability. At the same time, it is impossible to obtain a 100% guarantee of protection, and for drinking tanks, the method is not recommended.

Penetrating protection

Penetrating waterproofing has proved to be a sufficiently reliable, proven and effective way of protecting concrete rings. Excellent parameters show innovative and progressive compositions, including Penetron, Lakhta, Hydro S and others, capable of maintaining their characteristics throughout the life of the wells.

Each of these components can easily penetrate the pores of concrete, fill all the cavities and crystallize in them. The resulting structure retains its breathing basis, while acquiring unique waterproofing qualities. As a result of the treatment of the base of each ring, from the outside and from the inside, a surface with a uniform and hermetic composition is provided. This allows it for a long time to withstand high pressure and pressure aggressive media.

Depending on the temperature conditions, humidity, porosity and density of the material, the crystallization time of the composition, as well as the depth of its penetration, may differ. Note that the increase in moisture affects the acceleration of the process of creating crystals. This behavior of the material allows the concrete rings to attach a special property of "self-healing".

It should be understood that the penetrating waterproofing of the septic tank is carried out exclusively on a properly prepared surface. For this purpose, concrete is grinded mechanically or chemically, until a uniform rough surface is formed.

Figure number 3. Waterproofing of a well

Polymer cement protection

The most advantageous in terms of availability and simple application is polymer-cement or coating waterproofing. It is carried out by distributing a special mixture made on the basis of cement, liquid glass and polymers. This protection has the same efficiency as bitumen, and can last a much longer period.

Conclusion

Apparently, waterproofing septic tanks and wells on the basis of concrete rings is not easy, however it is impossible to do without it. It is important to take a responsible and careful approach to this issue. In the absence of the necessary skills and knowledge on the choice of waterproofing, it is advisable to entrust this matter to professionals.

Without additional protection in an aggressive environment, concrete structures lose their strength characteristics. Therefore, waterproofing septic tank from concrete rings is necessary. If you do not pay proper attention to this process, you will very soon face many unpleasant problems. Their elimination is time spent, nerves, and sometimes not so little money.

In concrete, under the influence of moisture, lime leaching is observed, which manifests itself as the appearance of stalactites and outgrowths on the surface of the rings. The material destroys the magnesium salts contained in groundwater.

Reacting with lime, they create a water-soluble compound - calcium sulphoaluminate, which water flushes out of the body of the concrete, destroying it.

The impact of groundwater and the liquid component of effluents on the walls of a concrete well is gradually leading to disruption of structural bonds in the thickness of the artificial stone. The result of violations - cracks and caverns, through which untreated waste can seep into the ground

Carbon dioxide, also present in groundwater, triggers destructive processes in concrete, reacting with calcium hydroxide. Water, falling into microcracks and pores, turns into ice when the temperature decreases. An increase in its volume leads to faults and large cracks in the already porous structure of the material. Biological corrosion of concrete is caused by microorganisms living in water.

Solutions of salts, contacting with metal reinforcement, located in the body of concrete, cause electrochemical corrosion of steel. Because of its gradual destruction, the strength characteristics of the product are reduced, and then the design is completely useless. Replacement of concrete rings is associated with many difficulties, and sometimes simply impossible.

Without reliable waterproofing, the first well of the septic tank will receive thawed and rainwater, overflowing it and disrupting the normal operating cycle of the system

If you do not protect the septic tank from the effects of destructive factors, then dirty water will enter the ground, and infect it with microorganisms. An unpleasant smell will appear on the site, and representatives of the supervisory authorities will be your frequent visitors. All these reasons are enough to allocate funds and time to perform high-quality waterproofing of the septic tank, thus avoiding problems with frequent and labor-consuming repairs.

Particular attention should be given to the waterproofing of the bottom of the first well at its junction with the lower ring. The base is concreted using a grid as an armature.

Being exposed to aggressive factors, iron concrete rings begin to break down, and the reinforcement rust. Therefore, already at the construction stage of the septic tank, waterproofing

Types of waterproofing for septic tanks

To increase the strength of the concrete rings on the outside and inside, there are many materials. The most commonly used are:

- Sprayable formulations. The rings are processed from the outside using special equipment.

- Injection protection. Happens on epoxy, mineral or polyurethane basis. For septic tanks it is used in extreme cases, since it is expensive.

- Lubricating compositions. Bituminous and bituminous. These are film-forming mixtures, creating a thin, water-impermeable layer when applied in several layers.

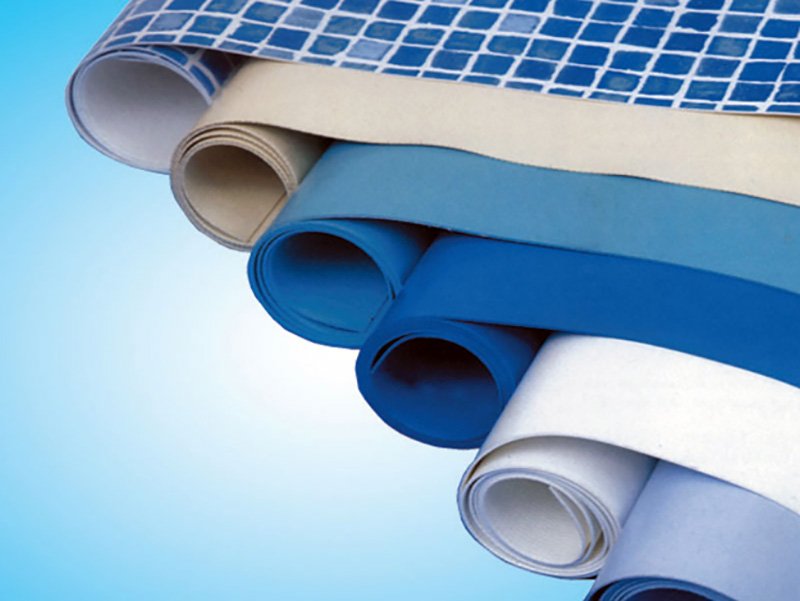

- Rolled materials. They are used for pasting waterproofing. They are a stabilized bitumen or bitumen-polymer mastic applied to a fabric base made of geotextile or fiberglass.

- Penetrating compounds. In the thickness of the concrete, insoluble crystalline hydrates are formed, creating a reliable hydro-barrier on the application side to the depth of penetration declared by the manufacturer.

The construction market receives many different waterproofing materials, to understand them and choose the right one is not so simple.

Of the existing types of waterproofing it is necessary to choose the most accessible both in technological and in financial terms

By the criteria of durability and reliability, each type of waterproofing differs from each other. So, bitumen protection begins to crack after a few years, and the mastic has a longer service life.

Material for waterproofing by spraying

This type of insulation allows you to create a monolithic seamless layer. Water-repellent emulsions are sprayed onto the surface of concrete rings under high pressure. The composition penetrates into the splits, cracks, pores and completely fills them, blocking the drains in a confined space. In the composition for spraying there is a polymer composite, water and fillers such as talc, calcium carbonate, titanium dioxide, barium sulfate.

The use of waterproofing, applied by spraying, has many advantages:

- Fast execution.

- Excellent adhesion with concrete surface.

- Fast congealing.

- Durability. Operates up to 20 years without loss of initial efficiency.

- Resistance to rapid temperature changes.

The sprayed waterproofing significantly improves the performance of the septic tank, thereby preventing the penetration of waste water into the surrounding soil.

To spray the waterproofing will require special equipment. This is not cheap, but very effective

This type of waterproofing provides adhesion to the surface of concrete rings at the molecular level. It can be applied over the old layer by spraying. The main thing is to remove the excess moisture from the surface before it.

Lubricating compositions for septic tank protection

Compared with other waterproofing technologies, the advantage of using coating materials is that they can be applied to surfaces with any geometry. No special devices and mechanisms are required. There are 4 groups of lubricating compositions, distinguished by a base, which is used as:

- bitumen;

- cement;

- polymers.

The fourth group includes mastics, which contain sealants in their composition. Regardless of the substrate, the waterproofing coating fills the slightest cracks, eliminates defects and makes the surface monolithic.

Some brands of bitumen-polymer mastics contain volatile toxic compounds. Sometimes they provoke disorders of the nervous system, lead to poisoning, therefore, you need to work only using protective equipment - a respirator, gloves, special robes.

Bituminous waterproofing waterproofing is very popular, but does not have a long life

When the groundwater are at great depth, then reinforce the insulation of the lower septic ring. If they lie high, then the top of the structure must be sealed.

Bitumen-polymer coating compositions

The mastic of this type contains polymer additives and latex, due to the presence of which the material characteristics change for the better. When applied to the surface, an elastic, very strong layer is created that retains its properties at low temperatures. But for the bitumen-polymer composition to work, it needs to be applied in several layers.

The mastic is relatively inexpensive, it can be applied on its own, and if leakages appear somewhere, the layer can be easily restored.

The presence of polymers in the composition of the mastic makes it very effective. The low popularity of this kind of mastic is explained by the high price

In addition, compared to other waterproofing technologies, the advantage of using lubricants is that they can be applied to surfaces with any geometry. No special devices and mechanisms are required. Distinguish mastic with bitumen base and with additives in the form of polymers for cold and hot application.

Mastic for hot application is first heated to 160 degrees C, so that the bitumen passed into a plastic state. Afterwards, they cover the surface of the concrete rings. Cold formulations are diluted with a solvent that evaporates after the insulation layer has hardened.

Isolate mastics one- and two-component. Bitumen, polymer is present in their composition, and additives that provide individual properties are different. Depending on the second component, the compositions are called: bitumen-latex, bitumen-rubber, bitumen-oil, bitumen-polyurethane.

Polyurethane and rubber make the material particularly elastic. The coating stretches well, without cracking. The mixture with the rubber is applied in a cold way. It has antiseptic properties and high heat resistance.

Rubber mastic well resists the influence of an aggressive environment, withstands the hydraulic head

The surface covered with a mixture of oil ingredients does not harden. It is sticky, well resists the aggressive influence of groundwater and soil, does not crack, tolerates frosts as low as -50 degrees Celsius, and high temperatures.

Rules for the application of coating materials

Waterproofing is applied after sealing inter-ring seams and places where the pipes go into the septic tank. The process itself consists of 5 consecutive stages:

- Cleaning of the surface from dirt, detection of defects, cracks and elimination of them with the use of sealants or putty.

- Application of bitumen primer as a primer. It is first prepared by following the manufacturer's instructions, then the surface is covered with a construction brush. The bitumen primer can be made with their own hands, for which they take gasoline or refine the engine oil, heat and add crushed pure construction bitumen. Stirring, the mixture continues to heat up to 200 degrees C, after which the primer is ready for use. Apply the first layer, and after it dries it is the second one.

- Leave everything for 24 hours. During this time, the primer will dry completely and its fine particles will penetrate deep into the concrete.

- Brush the mastic with a brush, pre-mixing the composition thoroughly. If the mixture is too thick, it is diluted with any organic solvent. After the first layer is completed, the time for drying it is set aside and the procedure is repeated.

- Check the quality of the applied layer after it dries. If flaws are found, treat the surface again and leave for 2-3 days to dry.

Bituminous mastic is much cheaper than bituminous materials with polymer additives. It perfectly adheres with concrete, has good water-repellent characteristics, is resistant to the effects of chemistry. Bad render bitumen mastic minus temperatures, the coating becomes brittle, covered with microcracks. Enough of such waterproofing for 5 years, a maximum of 7.

Liquid bitumen has elasticity, good adhesion to the concrete surface. This keeps the layer from rupturing and cracking. Lack of one - a short service life

Some brands of bitumen-polymer mastics have volatile toxic compounds in their composition. Sometimes they provoke disorders of the nervous system, lead to poisoning, therefore, you need to work only using protective equipment - a respirator, gloves, special robes.

Clay lock device

A good result is the treatment of the rings with bituminous mastic, followed by the installation of a clay lock. It means that the space between the concrete rings and the ground is filled with clay without any impurities. It is necessary to ensure that after melting snow or heavy rainfall the water does not fall into the septic tank.

Clay lock prevents the impact on the concrete walls of the septic structure of flood waters, thawed and rainfall

Do not recommend it immediately, but after the soil settles and becomes compact. A lock made earlier will be destroyed when the ground subsides. Clay is covered with small layers, each time carefully tamped. The material must be on the entire surface. Not the slightest emptiness is allowed, otherwise the work done will not work.

Waterproofing of septic tank surface

This kind of material is used for waterproofing the outer surface of rings of reinforced concrete. First, to improve the adhesion, the surface of the rings is primed using the "Betokontakt" type compounds. When the layer dries, the visible defects are eliminated on the walls of the septic tank, filling the cavities and caverns with a solution including cement, sand and PVA glue. Between the rings, seams are sealed. When the repair patches dry, they are primed.

The roll-up waterproofing should be installed after all defects have been removed on the surface of the concrete rings

To fix the roll material on the surface of the rings, the walls are coated with tar or bitumen mastic, and then the waterproofing is glued. One layer is not enough, it is practiced to make layers 3-4. In the end, they take the mastic and apply it to the seams between the strips.

Plaster under pressure

For internal and external waterproofing apply and plaster under pressure. Non-shrinkage waterproof cement is supplied under high pressure created by compressed air. The sealing layer is obtained uniformly and densely.

The application of this method is not always justified due to considerable financial costs. To implement it, you need to have a special device, the so-called "cement-gun". Work is carried out at a temperature of at least +5 degrees C, lay two layers, the thickness of each - from 5 to 10 mm.

To apply a subsequent layer, you have to wait until the previous one grabs, which sometimes takes up to 2 weeks. To prevent cracking of cement on a hot day, it is moistened every 3.5 hours. In cooler weather, the interval is increased to 12 hours.

Waterproofing penetrating or capillary

This type of waterproofing is the most reliable. Materials, after deposition on the concrete surface, penetrate into the pores, crystallize, fill all the voids. Filamentary crystals penetrate into the structure of concrete, colour microcracks and become one with his body. They do not degrade the air permeability of the surface, but, sealing its structure, do not allow water to pass through.

Penetrating insulation improves the quality of concrete, makes it strong and moisture-proof

Crystalline hydrates are not decomposed and are not washed out of concrete, so this septic tank protection serves for a long time. The layer on the surface of the rings only fixes, and for some time retains active chemical constituents, which play the main role in creating a high-quality waterproofing structure. Some manufacturers claim that as soon as all the chemical processes are completed, the layer can be removed.

The degree of porosity and humidity of the septic rings affects the duration of crystallization and the depth of penetration of the insulating material into the thickness of the concrete. At high humidity parameters, crystals form faster, and with decreasing of this index the process slows down. With treated concrete surfaces, microcracks themselves are tightened.

Application of penetrating waterproofing, popular compositions

The application of penetrating waterproofing is preceded by careful surface treatment. It is completely cleaned by applying special chemical solutions or a mechanical method. When the result is a smooth surface, it is saturated with moisture, pouring water from the hose under high pressure. Active components of the composition for waterproofing penetrate to the same depth as water.

The treatment begins with the seams. It is better to do this while assembling the rings. They are laid on a layer of cement mortar, then treated with a penetrating mixture. Next, apply the mixture on the entire surface, following the manufacturer's instructions exactly, otherwise the waterproofing layer will not meet the stated requirements.

The mixture is prepared in small portions. To mix it with water, use an electric drill, working at low speed and equipped with a spiral nozzle. On the surface of the rings, the composition is applied using a nebulizer, roller or paint brush. You need at least 2 layers with an application interval of 1.5 to 3.5 h.

The second treatment is started when the first layer has not yet dried completely. It should be a coating with a total thickness of 1.5-2 mm. The material takes a lot - about 1 kg per 1 square. m.

For penetrating waterproofing, the following compositions are used:

- Lakhta. Inexpensive dry mix, made on the basis of cement.

- The "Kalmatron". The composition includes portland cement, sand, patented active reagents.

- "Hydro S". Waterproofing coating based on mineral raw materials.

- Penetron. Penetrating mixture, which creates a barrier, preventing capillary suction of liquid.

If you process the septic tank from outside and inside, you will end up with a durable hermetic structure with a homogeneous structure.

Materials for sealing inter-ring seams

Seams between reinforced concrete rings are a weak link in the septic tank. Most often, the first leakage appears here. For this reason, their sealing is necessary. As an insulator, reinforcing cloth, rubber band sealers, rubber gaskets with bentonite granules, polymer cement in combination with a jute or hemp rope are used.

Through the seams between the rings water begins to seep in the first place, so start the waterproofing should be from their sealing

In the first and second cases, isolation is obtained efficiently, but it is expensive, and the reinforcing web must also be irradiated with ultraviolet. Rubber gaskets are cheaper, they fill the gap, creating a plastic layer. Select them, focusing on the thickness of the walls of concrete rings.

Firms that produce penetrating waterproofing produce auxiliary mixtures. They seal not only the seams between the rings, but also the insertion of pipes, wide cracks. They also include high-quality cement, quartz sand of the finest fraction, chemically active additives. They have excellent adhesion to concrete.

To seal a seam or a crack, along them a bulgarian and a perforator make a mortar to a depth of 2.5-3 cm and a similar width. Clean it from dust, small particles, moisten with water, apply a primer. When the primer is dry, fill the grout with an auxiliary compound. After the seam and part of the surface around it is treated with a basic waterproofing mixture.

Among the additional materials there is a group designed to eliminate the pressure leak. They are distinguished by a rapid grasp with simultaneous expansion. Around the leaks, they simply clear the surface, then with a puncher make a sample reminiscent of the shape of the swallowtail. From the mixture, a plug is formed, with dimensions slightly exceeding the dimensions of the sample, pressed forcefully into the leak location, and retained until it is fully set.

Leaking is a common phenomenon in a septic tank, so you should always have a means at your fingertips to remove it

When the water stops flowing, the cavity is primed with a basic composition, completely filled with an additional solution, allowed to dry, moistened. Next, a 2-layer coating is applied using a basic waterproofing mixture. If the technology is observed, the probability of a repeated leak is 0.

Popular accessories include:

- WaterPlug. Hydroplomb is used to eliminate a weak leak. It is seized within 3 minutes.

- Peneplag. The quick-setting mixture stops the most intense leak in 40 seconds.

- AQUAFIX. Hydraulic cork, hardening under the influence of moisture for a short time, so it is well suited in case you need to eliminate leakage.

- Penecret. Applied for sealing joints, places of entry of pipes into the septic tank.

- MEGACRET-40 - repair composition based on cement with the inclusion of polymers. Suitable for sealing of inter-ring seams, as well as for sealing cracks. It has excellent adhesion to the concrete surface, is applied easily, does not shrink.

All manufacturers declare that their mixtures have a unique patented composition. In practice, their characteristics, as well as the methods of creating a protective layer, are approximately the same. The final result is influenced by the fact that the surface and the waterproofing composition are so well prepared.

Video reviews on the implementation of waterproofing septic tank

Here you will see how to eliminate active leaks:

A video clip on how to fix the concrete rings so that they do not move relative to each other:

Using any version of waterproofing septic tank, remember that the guarantee of obtaining a high-quality durable coating is the exact observance of the technology. Do not neglect the recommendations of manufacturers, concerning both the preparation of mixtures and their application.

One of the indispensable conditions for achieving a comfortable living in the country or in the a country house - is the availability of all plumbing fixtures and their normal functioning, which can not be achieved without good sanitation. Immediately comes the idea of installing on the territory of his estate septic tank of reinforced concrete rings . It is not difficult at home to build such a building. To do this, you must excavate the digger or manually pit, and use the truck crane (or manually) to install reinforced concrete rings.

After the installation works, it is necessary to seal the septic tank for its proper operation. In this article, let's look at all the details of the sealing work. Taking advantage of these recommendations, it will not be difficult to do the work on your own.

Purpose of sealing

Currently, the use of a septic tank made of concrete rings is popular among owners of cottage areas and private houses. But it's no secret that for the septic to work properly, it is necessary to perform its waterproofing - this will make it sealed. This work should be done without fail. If you neglect these rules, then the septic can become a source of infection on the backyard. The sewage will seep through the unsealed walls of the septic tank, thereby infecting groundwater. Yes, and getting the groundwater itself inside the septic tank will overflow it and lead to improper operation. This is why sealing concrete septic tank so necessary and represents the protection of the entire concrete structure.

For sealing, it is mainly used:

- bitumen waterproofing;

- penetrating waterproofing;

- polymer-cement waterproofing;

- plastic inserts;

- silicone.

In its structure, silicone has a high degree of density. Processing the entire surface of the concrete rings, the silicone falls into all the holes and cracks. This prevents both the ingress of a septic tank of groundwater and the release of impurities into the ground. Of course, other means are used for sealing, but silicone is the highest level of protection.

Sealing process

So, in the excavated pit with the help of a truck crane you have installed concrete rings. If the edge of the ring has a special lock for mounting, then its connection will be tight. Rings with a flat edge do not have good density, so joints must be sealed with a cement-based sealant.

Special tightness should have a bottom ring with a bottom of the pit. When the design of the ring has a poured bottom, the issue of additional sealing does not apply. But if you installed a simple ring, the bottom of the pit must be concreted before installation. The bottom of the pit is concreted using a reinforcing mesh. From the pieces of reinforcement to the size of the bottom of the pit, the net is laid out on a brick. The rods are connected with each other by wire and are poured with concrete with the addition of crushed stone. After installing the ring on the self-made bottom, all the cracks formed between the bottom and the flat edge of the ring are well sealed. Sealing is also carried out with a cement-based sealant. Further, the sealing is performed depending on the location of groundwater. After all, this whole process is designed to prevent contact of sewage with soil and water.

Sealing of the septic tank from concrete rings is carried out in two ways:

- With a low location of groundwater, enhanced sealing is performed on the bottom of the septic tank. This prevents germs from entering the ground and water through the cracks.

- With a high groundwater table, there is an instant infection due to contact with sewage. Therefore, the sealed upper part of the septic tank is reinforced.

The best option is to fully seal the concrete septic tank. It is carried out by means of installation of plastic cylinders. The cylinder is made of polyethylene with a wall thickness of 8 mm. Its height can be from 1 to 4.5 meters. The material from which the cylinder is made has a high tightness. It is more profitable to install a single cylinder, to reduce the consumption of silicone for sealing joints.

The polyethylene cylinder is cut with a jigsaw to the desired size and inserted into the concrete rings. All joints and seams, for complete sealing, are filled with silicone. To rain and melt water did not fill the septic tank, additional strengthening of the top of the cylinder is performed. To perform this work, use annular stiffeners.

After all the sealing work is done, the pit with concrete rings is covered with earth and the septic tank is ready for operation.

After the first winter, it is necessary to check the design for leaks. Because of frost and thaw, the soil is displaced, and the concrete rings can move from their place, thus breaking the seal of the septic tank. To avoid trouble, it is necessary to immediately begin the restoration of the septic tank and its tightness.

To carry out isolation of a septic tank from concrete rings is not an easy matter and can be done by one's own hands. To do this, you will need to familiarize yourself with the technology of the work, collect some information and purchase the necessary materials. For a better overview, you can watch the video at the end of the article. And if everything is clear, start work safely.

Video

This video demonstrates how the water leakage between concrete rings is being liquidated:

This video shows how on a concrete ring the waterproofing test of Raberite was carried out:

Water supply, centralized or for private farming, must be protected as much as possible from direct contact of drinking water and groundwater, the soil itself and the harmful chemicals contained in it. The same protection is provided for sewerage, but with the reverse purpose - that waste water and harmful chemical impurities do not penetrate into the groundwater and do not enter the sources of drinking water. Excellent protection is the application of moisture-proof materials on the surface of concrete or metal pipes of sewerage. For example, the waterproofing of the well from concrete rings is done with bitumen, bitumen mastics and other liquid compounds that do not allow water to pass through and do not adhere to it. Mastics are applied both from the inside and outside to the concrete ring, and each of these layers has its own purpose.

For sewage industrial and self-made tanks, the isolation of the system is paramount, since even a small leakage of waste water to the ground pollutes the environment and nearby sources of drinking water, especially if this leakage goes unnoticed and exists for a long time.

Features of waterproofing

Sewage or water well of concrete rings - the construction is cheap and not labor-consuming, so such wells are often erected for a variety of needs. Concrete is a durable material, but the material passes moisture in both directions, so the waterproofing of concrete rings is a mandatory measure in any case. Harmful both the infiltration of waste water into the ground and the ingress of dirty water (precipitation, unfiltered groundwater, surface water flows) into the source with drinking water. Waterproofing is applied in several layers, which ensures high insulation of different levels of water treatment and reliability of the system as a whole.

Work on the arrangement of waterproofing of concrete wells can be divided into main and auxiliary ones. The main waterproofing of the septic tank from concrete rings is carried out at once - during the construction of the concrete well, and not only the inner and outer walls of the well are waterproofed - it is necessary to organize high-quality protection of joints and seams on the connections of well elements. If the well is already built, then it is necessary to monitor the condition of the waterproofing, and update it as necessary. Repair of waterproofing is carried out:

- The septic tank made of concrete rings began to fill quickly with the same amount of water consumed by the tenants of the house;

- Concrete rings moved relative to each other or cracks appeared in the material;

- For a drinking well - if a small suspension, mud, visible mote appeared in the water.

Each of these manifestations indicates the contamination of water or the environment, so it can serve as a signal to urgently tackle the renovation of the layers of waterproofing and sealing joints and seams from the outside and from the inside.

Materials for waterproofing

From the functional purpose of the concrete structure from the rings, it depends on how it should be protected from external or internal moisture. There are few methods - waterproofing of all concrete surfaces, and protection against moisture penetration of seams and joints by compaction, coating or other solutions.

To create a waterproof layer on the entire surface of the concrete, coating materials such as mastics, adhesives, and compositions based on cement are used. For waterproofing seams, technological holes, joints, cracks, adhesive compositions with hydrophobizing additives are used.

Innovative technologies offer a method of spraying concrete with special compositions based on mineral mixtures. Thus, any surface - with cracks, seams or damages - becomes monolithic due to a new monolithic surface layer. Special waterproof membranes also permanently protect the concrete surfaces from moisture penetration from both sides.

Lubricants and roll materials

Bitumen (tar) mastics have been known for a long time, and are considered not only the simplest and cheapest way to protect concrete from moisture, but also the most common and universal method that can be used for almost all concrete structures, and not just for concrete rings in wells.

Next on the popularity are liquid rubber, polymer liquid substances and composite materials - they are often used to protect the concrete from the outside so that the synthetics is less in contact with drinking water. For sewerage wells, this protection can be used both outside and on internal surfaces. Waterproofing works with such substances are carried out with the deposition of several layers and with the use of reinforcing fiberglass mesh.

Mastics based on bitumen, like paint and varnish materials and compounds based on liquid rubber after solidification, seal not only the seams and joints of the structural elements, but also the entire protected surface of the ring of concrete.

Roll-based waterproofing materials on a soft base also fit well on the concave or convex surface of the concrete ring, therefore they are used to protect the wells both inside and outside. Such materials are fixed either with the help of special glues, or in combination with the use of bituminous mastics. Special skills in working with such materials are not required, therefore for the private sector this is a rather popular solution that ensures the proper quality and durability of protection.

Membrane polymer materials

Membrane waterproofing is a synthetic material with limited moisture permeability. On such membrane films there is an adhesive surface layer by which the membrane is attached to the surface to be protected. Membrane film does not allow the penetration of moisture inside the concrete rings of the sewage or water well, protecting not only the seams and joints, but the entire surface without exceptions.

A greater and more reliable effect can be achieved by using a combination of membrane films and polymer mastics - so the surface, inaccessible to moisture penetration, will surely be solid and dense - after all, the film can be easily damaged during attachment or during operation.

Mineral waterproofing mixtures

Such mixtures are applied with the help of special equipment, which supplies mass to concrete with high pressure. Application under pressure allows filling all pores, dents, cracks, joints and seams of concrete, creating an absolutely monolithic and waterproof layer.

This technology of waterproofing and sealing the surface of a concrete well from rings is used for all surfaces - both for interior and exterior. The main advantage of such mixtures is that the surface treated with this method does not need to be protected additionally, since the solidified layer is mechanically strong and absolutely does not allow moisture to pass through. And to exclude even the minimum diffusion of the waterproofing agent into the water when protecting the inner surfaces of the concrete ring, the layer can be covered with a mineral paint or a membrane film.

Before applying, fixing or laying waterproofing on the walls of a concrete well, the surface must be prepared. Preparation consists in cleaning the concrete of dirt and dust, sealing joints and seams with cement mortar of the well, plastering particularly uneven areas. Then, the well must be dried naturally, after which, for a specific design, choose the most suitable method of waterproofing and implement it. The most reliable methods of protection from moisture in private conditions are coatings and protection with a membrane film.

After drying the well, all old protective layers should be removed, if any, and for better diffusion of liquid waterproofing materials, all surfaces of the reservoir are covered with a deep penetration primer with water repellent properties. The joints of the rings are primed several times, as well as several times are applied waterproofing materials, since these are areas of increased risk.

How to apply waterproof composite materials

The coating can be based on bitumen or synthetic composite materials, and most often it is heated before application. But any coating should be laid in 2-3 or even 4 layers, laying between the reinforcement belt reinforcement of polyester fiber. For the first composition of bitumen-based coating, four parts of any solvent based on gasoline or white spirit are added to one part of the mixture. Mastic is applied with a roller or a wide brush, it is also possible to use a pneumatic sprayer, but for washing it will require a lot of the same white spirit.

A few hours after the application of the first layer of bitumen mastic, the reinforcing web is attached to the frozen surface (it is simply glued to bitumen), and the next layer of mastic is applied, but without dilution of bitumen with solvents. The second solution will be viscous, so it is preheated and applied with a wide spatula on the long handle. Since both layers consist of the same components, the diffusion will be sufficiently deep, and the use of reinforcing polyester will further strengthen both layers. The second layer must be smoothed until it hardens with a special studded roller to release air from a viscous and dense substance.

Membrane films are produced with a primary layer of glue, so they do not need to be used to fix additional compositions. The membrane is attached to the second layer of bitumen after complete cooling and solidification of the mastic - about a day later.

Seams and joints of concrete rings are treated with waterproofing materials before the whole surface is treated, and then together with the general protection. After laying the rings on each other, the joints are first poured with a cement-sand mortar into which liquid glass or hydrophobizing additives are added to watertightness. The proportions of the solution are standard, 1: 3, liquid glass is added 1-2%, hydrophobizator - 0.1%. The holes under the sewage pipes or water conduits are covered by the last waterproofing.

Concrete wells, intended for sewage or sewage, are also protected at their base, which is usually made of a flat ring or concrete slab. Joints at the junction of the first (lower) ring and the plate are important to seal and waterproof in the same way as the rest of the surface of the well to prevent mutual penetration of groundwater and sewage.

A widespread out-of-town method for collecting wastewater into a well system requires careful sealing of septic tanks from concrete rings, which are the main constituent element of the storage and treatment of sewage water. Non-hermetic conjugation of rings leads to the filtration of fecal effluents into the soil and further to the ground horizons of groundwater, their infection with pathogenic microflora. There is also a reverse process - the filling of the septic tanks groundwater, which leads to their premature filling.

Constructions created with the use of reinforced concrete elements are often represented by structures that are not subject to temporary destruction. This opinion is only partly true. Reinforced concrete is a strong and durable material, but it requires protection. Sewage drains contain a huge set of aggressive components that negatively affect the material of the rings and can lead to the following:

- violation of the structure of the concrete mass due to leaching processes;

- development of corrosion processes in reinforcement belts;

- critical weakening of bearing capacity;

- complete loss of structural qualities of reinforced concrete products.

Underground location of septic tanks naturally makes it difficult to carry out repair and recovery measures. A large amount of excavation, raising rings on the surface for restoration or replacement requires the involvement of earthmoving and lifting equipment. This leads to large financial costs, a violation of the landscape improvement of the site. Great inconvenience delivers the forced termination of access to objects of municipal improvement.

A septic tank made of concrete rings, whose waterproofing is carried out at the stage of its construction, can be effectively used for many years, while requiring minimal maintenance. Properly executed waterproofing septic tank made of concrete rings, in addition to protecting against premature destruction of the structure itself, relieve other unpleasant phenomena. Manifestations of unsatisfactory tightness of the septic tank can be the contamination of water in wells and wells by pathogens and the spread of smells of decomposing impurities along the site.

There is an opinion about the futility of carrying out measures to seal ring joints. As a weighty argument, the composite design of the well is shown, the sealing of which will easily destroy the seismic shock, seasonal punching or other motions of the soil. Insinuations on this topic are untenable for several reasons:

- Concrete rings during the construction of wells can be reliably fixed from possible displacements by metal fasteners.

- The industry is produced well rings, in the design of which are integrated special locks that prevent the elements from shifting relative to each other.

- Technological methods of waterproofing are known, which exclude the possibility of breach of tightness, even if the ring gets some displacement relative to the other.

The violation of the technology for performing works to seal the conjugation of the rings leads to the same consequences as arise in the complete absence of waterproofing.

Known and used different ways and types of sealing of ring couplings. Performing work on some of the techniques involves the use of equipment with specific properties. Other technological processes are available for high-quality implementation only by specially trained specialists. There are also techniques for arranging waterproofing, available for execution by one's own hands. A valid choice in favor of one or another method of sealing can be done only by getting an idea of the technological features, advantages and disadvantages of each of them.

Known and used different ways and types of sealing of ring couplings. Performing work on some of the techniques involves the use of equipment with specific properties. Other technological processes are available for high-quality implementation only by specially trained specialists. There are also techniques for arranging waterproofing, available for execution by one's own hands. A valid choice in favor of one or another method of sealing can be done only by getting an idea of the technological features, advantages and disadvantages of each of them.

All the differences between the methods of waterproofing lie in the field of materials used, ways of performing processing and budgetary load. The most common are 6 types of waterproofing.

Penetrating chemical compounds

Many specialists in the field of protection of reinforced concrete structures consider this type of concrete protection to be the best of all existing ones. Penetrating waterproofing is performed with the use of formulations with specially developed physicochemical properties. Chemical mixtures penetrate the concrete mass of the structure, filling themselves with pores and voids followed by crystallization. This process has a prolonged action: increasing the humidity level initiates its slowdown, and the decrease on the contrary - acceleration. This allows the waterproofing compounds to quickly fill the cracks appearing in the thickness of the concrete.

Significant disadvantages of penetrating waterproofing include its high cost and labor input. Concrete Surfaces well rings require thorough preparation and preliminar treatment.

Application of bituminous materials

Giving various construction materials waterproofing properties by treating them with heated oil bitumen is one of the most used methods in the near past. The appearance of modern waterproofing materials left this method only one advantage - its low cost. Bitumen coatings have a low resistance to variable temperature changes. Low adhesion with concrete surfaces provokes peeling and cracking of the waterproofing bituminous layer.

Another type of material, having a bitumen component as a basis, is a specialized mastic. In its composition additives are integrated with special properties, which are designed to increase the durability of the waterproofing layer and significantly increase its service life. The advantage of using mastics in front of bitumen is also a cold method of applying them to an insulated surface, which greatly simplifies and speeds up the work.

In order to improve the waterproofing properties and extend the life of bituminous coatings, experts recommend that they complement the wrapping with roll-up waterproofing. For this, a ruberoid can be used, but the best effect results from the use of surfacing roll materials.

Polymer-cement mortars

Hydraulic isolation of well rings in septic tanks can be performed with the use of cement compositions with the addition of modifying polymer components. The cost of various polymer-cement compositions is higher than bituminous materials, but there are significantly fewer penetrating chemical mixtures. The solutions are applied in 2-3 layers by a usual maklovice - a wide flat brush. The application process does not take much time, because the application of the second and subsequent layers is done without waiting until the previous one has dried.

Hydraulic isolation of well rings in septic tanks can be performed with the use of cement compositions with the addition of modifying polymer components. The cost of various polymer-cement compositions is higher than bituminous materials, but there are significantly fewer penetrating chemical mixtures. The solutions are applied in 2-3 layers by a usual maklovice - a wide flat brush. The application process does not take much time, because the application of the second and subsequent layers is done without waiting until the previous one has dried.

Clay waterproofing lock

The presence at a short distance from the site of exits free from sand clay layers allows you to perform external waterproofing of the septic tanks with the arrangement of a clay castle. The space surrounding the fixed and fixed rings is filled with clay with compaction by ramming each poured layer. Clay locks, as a rule, supplement bitumen hydraulic isolation. For obvious reasons, this method can not be used in the internal cavity of a well.

Plastered hydraulic insulation

The method consists of two-layer plastering of the inner or outer surface of the well using special equipment. As it is used cement guns, with which a plaster solution is applied to the walls of rings under high pressure. The method was not widely used for several reasons. In addition to attracting specific equipment, the process takes a long time.

Plastic sheath insulation

Effective hydraulic isolation of the wells from the inside can be done by installing a sealed polymer insert into the septic cavity. The latter is a structure of strong polymeric materials, the linear dimensions are selected by the corresponding cavity of the well. Additional rigidity of the construction is provided by integrating in its surface reinforcing elements in the form of ribs. Access to the interior of the insert is via the hatch provided by the structure.

Effective hydraulic isolation of the wells from the inside can be done by installing a sealed polymer insert into the septic cavity. The latter is a structure of strong polymeric materials, the linear dimensions are selected by the corresponding cavity of the well. Additional rigidity of the construction is provided by integrating in its surface reinforcing elements in the form of ribs. Access to the interior of the insert is via the hatch provided by the structure.

The use of a polymer insert allows you to restore an old well, which has lost the required performance, a well of concrete rings. The space remaining between the insert and the inner surface after the end of installation is filled with a cement-sand mortar.

Sealing of circumferential seams

Without a thorough sealing of the joints of the rings, even the best hydraulic surface insulation will not provide full results. Seams between adjacent concrete rings are the most vulnerable place of any well construction. It is in these places that the first filtration in both directions begins with violations in the orientation of the rings. To prevent leaks, use proven methods:

- The conjugations of the rings are sealed by gaskets with beads integrated into the rubber mass.

- The annular joints are sealed with a rubber band reinforced with UV-curable cloth.

- The joint between the rings can be concreted with a polymer-cement mortar. The role of the deformation compensator with this method is additionally performed by rope made of natural materials.

The need to perform high-quality hydraulic septic isolation is not in doubt. It is important the best choice type of insulation, thorough preparation and professional execution of works.