Form for the production of rings of rings. Dimensions of concrete rings for a well: production and installation

| Name | Price with VAT) |

| Ring shape KS-7-9 | 21,000 р. |

| Ring shape KS-10-9 | 23,000 р. |

| Ring shape KS-15-9 | 35,000 р. |

| Shape of the ring KS-20-9 | 47,000 rubles. |

| Ring cover shape 1 m | 8,000 rubles. |

| Ring cover shape 1.5 m | 11,000 rubles. |

| Ring cover shape 2 m | 14,000 rubles. |

Advantages of demountable forms for well rings

1. The forms are easily disassembled and moved around the site by 1-2 people, do not take up much storage space.

2. The parts of the form are connected by means of wedge locks, which reduces the assembly-disassembly time by several times, just one bolt joint.

3. The formwork has cavity-forming devices for the production of rings with process holes 50 mm in diameter.

4. The form for the production of RC rings is made of metal with a thickness of 2 mm, which ensures its strength without additional amplifiers.

|

| The formwork parts are connected by locks, which repeatedly shorten the assembly / disassembly time |

|

| Hollowers for production of rings with technological holes 50 mm in diameter |

|

| Form with a diameter of 1 m in transport / warehouse form |

| |

| Form with a diameter of 1.5 m in transport / warehouse form |

|

| The alignment of the formwork for the rings is made using spacers that are removed after filling the formwork with concrete |

|

| Inside form |

|

| Ring cover shape 1 m in diameter |

|

| Ring cover shape with a diameter of 1.5 m |

|

| Finished ring after molding |

|

| Filling caps facilitate filling of the mold |

Starting business in the production of reinforced concrete products , and selecting our forms for well rings , you can recoup investments within 1-1.5 months of work, because the average profit per one ring is 1000 rubles. In a day on one formwork it is possible to make 5-10 concrete rings if you use hard concrete or 2-3 rings if you use mobile concrete from a concrete mixer or a mixer.

Produced by us collapsible molds for concrete reinforced concrete, during the long-term operation by us and our customers have confirmed their operational reliability and have proven themselves with the best side during their entire service life. Durability and excellent consumer properties are due to the special design of the shape with ring amplifiers and the optimum metal thickness of 2 mm, while molds for the production of concrete rings are not inferior in strength and durability to the formwork, made of thicker metal, and have an ideal geometry. The strength and ease of demountable forms increase their mobility, make it possible to use them in an open area not equipped with lifting mechanisms, which is especially necessary in rural areas and other areas not provided with a three-phase power grid. For all the time, more than a hundred forms for well rings various sizes and covers to them. All our clients were convinced of short terms of manufacture and high quality of formwork, many of them became our constant partners and at expansion of the production again address to us for forms for the manufacture of concrete reinforced concrete.

The formwork is intended for the production of RC rings by the method of vibration casting and has an undeniable competitive advantage over analogues. Components forms for concrete rings, manufactured by us, are interconnected by means of special wedge locks and are disassembled in a matter of seconds with the help of a hammer alone. Unlike the forms fastened with bolts, at the time of assembly - the disassembly of which goes to half an hour, with bolts to be replaced every week, tk. The edges of the bolts are erased, the thread is clogged with concrete, and the bolts are completely useless.

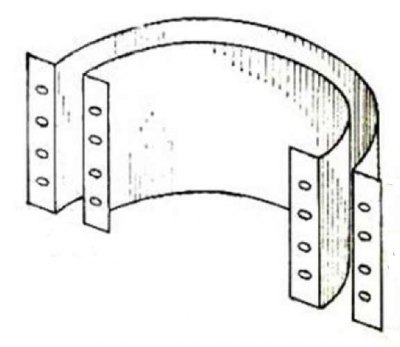

Our molds for well rings are made of metal 2 mm thick and have a frame made of profile pipes dimensions 40x40 or 30x30 and corners 40x40. The molds consist of two cylinders, which represent the outer and inner shaping surfaces of the RC ring. Both the outer and inner parts of the form for RC rings are collapsible. The outer formwork consists of two (three) parts, and the inner formwork of three. Thus, the shape for the ring is mobile, moves through the workshop or site without lifting mechanisms by forces of two or three people.

The concrete ring is molded directly on the floor of the shop (floor) if it is sufficiently level, or as a base metal or wooden pallet can be used. Very good for this ends of cable reels, they can be purchased at firms selling cable products for a mere penny - 100 - 200 rubles. To prevent adhesion of the finished product, polyethylene film is placed under the mold, and the walls of the demountable form for concrete rings are lubricated with special emulsion grease, and in its absence by working-off.

After preparation, the solution begins to be laid in the formwork layer by layer, each layer 20-25 cm high. After that, the concrete is compacted by a bayonet, metal or wooden rod. This is necessary to ensure that the mortar fills the formwork more densely, displaces the ambient air and fills possible voids. When the level of concrete in the mold exceeds the average, spacers can be removed, parts of forms for RC rings will not move relative to each other. After filling the mold with concrete, the upper edge is smoothed with a trowel, this surface should be as flat as possible. To compact the concrete in the formwork it is also possible to use a deep vibrator, this will save considerable time.

Form for the production of well rings can be disassembled after the solution has seized. Rings can be produced at any positive ambient temperature. From the impact of rainfall and direct sunlight, freshly formed rings should be covered with tarpaulins or a film. Also, to improve the hardening conditions of fresh concrete well rings it is recommended to water 1-2 times a day.

Autonomous source drinking water on a suburban area is a good alternative to central water supply. Very often, a well or a well is the only way to get water not only for eating, but also for watering the garden and garden. Despite the fact that wells are gaining increasing popularity, traditional wells are not worth dumping.

The simplest version of such a source is from concrete rings. Forms for the production of well rings can be purchased ready or made by hand. The article will tell in detail how to do it yourself.

General information

The classical form for the well rings is reminiscent of a cylinder, but there are also rectangular variants. It should be noted that they can also be with and without lock.

Traditional products have an end flat. If there is a lock, then they are endowed with docking ends. According to experts, in this case, the rings have better tightness, and the whole system is reliable.

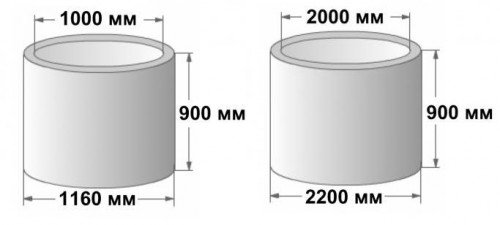

The standard sizes of the base rings are divided into groups:

- great - weight 1.5 t, inner diameter 2 m;

- the average - weight 1 ton, height - 900 mm, inner diameter - 1.5 m;

- small - weight 600 kg, height 900 mm, wall thickness - 160 mm, internal diameter - 1 m.

In addition to the standard well rings, there are also output of wall gates that differ in height and are used to create a sector of the well projecting above the surface of the site. They have a lower height than standard options. An important element of the construction of the well is, included in the kit and having a certain diameter.

Annually, the production of reinforced concrete rings is getting better due to the constant introduction of new developments. For example, when laying metal fittings, laser cutting is now used. Innovations contribute to the production of high-quality and reliable products. Due to the simplification of production, the final cost of the reinforced concrete rings is steadily decreasing.

We make rings for a well from reinforced concrete

In this case it is necessary to purchase or manufacture, or maybe rent out special forms of well rings. For the creation of the outer and inner diameters, metal formwork is used.

In the free space between the formwork sheets, wire or reinforcing wire mesh is installed, and then the entire structure is poured with concrete solution. It is best to compact the mold with a vibrator, if at home it is not, then it is carefully made with a wooden bar.

You must remove air from the mixture so that the concrete is compressed as best as possible. If everything is done correctly, as a result you will get a very strong product that can withstand heavy loads and perform its function efficiently enough.

With the independent manufacture of products, often installed special travel braces. Special production locks are often installed at manufacturing plants. This allows the design to have a dense and reliable fixation of the trunk, which eliminates the displacement of its elements.

Technology

Tip: do not rush, the main thing is to carefully follow all the steps, then you will get the expected result.

Below is a step-by-step instruction.

At first glance, it is complex, but in the process of making you will understand that everything is simpler than it seems.

- To create a shape, pick up 2 barrels of metal, which will match it, usually their price is waste. The fact that they will be technological vyshtampovka, the manufacturing process will not affect. If the barrels are not found, you can take air ducts or pipes of the desired diameter.

Collect the formwork cylinders and connect the individual sheets together. A good result is observed for formwork, created from plastic cylinders. - Make two longitudinal markings on the outer side of the outer barrel of the future shape, which will divide it vertically into two equal halves.

- Take a pair of door awnings and set them on the markings so that their bends are on top and along the markings, and the leaflets are located at the edges of the line. Attach the canopies with welding or rivets.

- Copy the markup onto the inner ring of the formwork. In the place of mounting canopies with only one side, cut off each lower hinge-fixing bracket.

Tip: Be careful not to damage the outer ring during operation.

- Remove the cut spindles and open the resulting shape. Lock shutters will be cut off spindles or others, but suitable for the diameter.

- Prepare the inside. Use a prepared form or a metal barrel for this. Put two marking lines inside, which are placed one from another on a 1/3 segment of the circumference. Take care that the cylinder is not divided vertically into equal parts, the difference between the width of one part and the other should be almost 2 times more. Install the canopies on the inner formwork, as well as outside.

- Copy the layout from the inside to the outside. Then cut the cylinder neatly along the lines, so as not to disturb the inner awnings. Cut the spindles, pull them out and develop the resulting shape. Adjust the comparability of the parties.

Ensure that in the assembled form the inner formwork is 50-100 mm higher than the outer one. The outer part of the structure should be easily opened, closed and fixed. Internal - it is easy to open inwards.

After releasing the ring, first remove the inner shape. Then the canopies are freed from the spindles, gather the smaller part of the mold inward and pull it out of the fresh product, the outer one is removed by opening to the outside. This form for the production of well rings can be used many times.

Conclusion

It is not difficult to make a mold for a well of a concrete ring. To do this, you need to pick up the corresponding metal sheets and collect them in a certain order. In the video in this article you will find additional information on this topic.

Buy quality forms for reinforced concrete rings it is possible, having addressed to experts of the company "Factory metallform". Our company has been working since 2006. During this time, we have significantly grown in terms of technical equipment of production and qualification of employees. All this allows us to accept orders of any complexity and to fulfill them exactly in the terms stipulated in the contract. Our specialists regularly undergo advanced training. Therefore, if you want to purchase molds for well rings, additives for concrete or specialized equipment for construction, they will always help to make the right choice or give competent advice on the issues of interest.

Forms for well rings - purpose and device

Vibroforms are used to make rings for wells. The production process fully complies with all GOST standards - when making rings, the vibration method is used. After filling the mold, the product is molded, and the endurance of the finished ring in the mold after it is formed is not implied.

Our company is engaged in the manufacture of several types of similar devices, namely, models KS 10.9, KS 15.9 and KS 7.9, which are standard, but differ in size. We also manufacture non-standard vibroforms, which are a somewhat simplified and simplified version. The advantage of using such forms for rings is that they can be used not only in enclosed spaces, but also in the open air, construction sites. This is very beneficial in terms of saving time (construction is progressing much faster) and cash, since it is not necessary to spend it on hiring equipment to transport finished rings.

The shape of the ring shape is significantly different from the design of metal forms for piles, slabs and other reinforced concrete products. The main difference is a higher level of complexity. So, the vibroform realized by our company consists of two basic elements - a hollow internal core and a metal welded structure. Let's talk about each element in more detail.

The core is a cylindrical element, which has special metal disks in the middle and lower parts. These discs are designed to preserve the internal geometry of the fob. In the upper part, the core has a conical shape. It also has a special technological hole. It is designed to release air from the device, as during vacuuming, a vacuum can form. Because of this, the product can collapse during the decking process. Also, some models of our vibroforms are equipped with a special vibrator IV-98, as well as lifting loops, which greatly simplify the process of shaping the finished rings.

The second element of the form for the rings is a metal welded construction (or external piercing), which has a thickness of up to five millimeters. To impart maximum stiffness to the stitching, the product is strengthened by the channel and the corner in the upper and lower parts of the metal mold. On some models of vibroforms implemented by us, the vibrators are mounted on the outer obeyachtke from the side. Also, the forms of models KS 15.9 and 20.9 are equipped with additional metal plates. On these plates there is already a special vibration platform on which the vibrators are mounted.

At your request, we can make two holes on the outer mold of the form for concrete rings, which will be covered with plugs. These openings ensure that holes are available on the finished reinforced concrete ring for the well for its transportation and installation.

We have, in addition to the usual well rings, you can purchase special lock rings, which are perfect if you need to install more than five rings at the same time. If you are at a loss to choose the right product, our specialists are always ready to give valuable advice and help to make the right choice.

Also at us you can purchase lock well rings as separately, so complete with metal forms. Lock rings or simply "locks" are a bunch of several reinforced concrete rings. Their main difference from ordinary rings is that they have a crest of docking elements, as well as a flat end. These rings are used in order to prevent even the slightest displacement of the shaft of the well, as well as to increase its watertightness, which is provided by creating a tight junction of the lock type.

Buy metal forms or get more detailed information from our managers on a single free phone that you see on the site.

Metalloform for well rings 5 mm + 3 mm

M / f. COP 7.3 - 18 030 rubles

M / f. COP 7.6 - 27 000 rubles

M / f. COP 7.9 - 32 220 rubles

M / f. COP 10.3 - 24 030 rubles

M / f. COP 10.6 - 34 920 rubles

M / f. COP 10.9 - 39 160 rubles

M / f. COP 15.3 - 45 970 rubles

M / f. COP 15.6 - 52 020 rubles

M / f. COP 15.9 - 58 050 rubles

M / f. COP 20.3 - 62 200 rubles

M / f. COP 20.6 - 70 200 rubles

M / f. COP 20.9 - 78 100 rubles

When erecting engineering communications During the installation of water supply systems, sewerage, drainage of the private plot, it is necessary to construct wells for various purposes. At the same time ready-made reinforced concrete rings for wells are purchased at large factories or from individual entrepreneurs engaged in the manufacture of such products. In some cases it is more profitable to buy a form for self-made of data concrete structures and in place cast rings in the right amount. There are different types of blanks, differing in size and configuration, using which, you can get reinforced concrete products of different diameters and heights.

This video shows the work of a self-made installation, with the help of which concrete rings for wells are made. It should be noted that for one product, two workers take only 15 minutes.

Preparation of maximum strength concrete

For the manufacture of reinforced concrete rings for the well, mature cement of grade M400 and higher is required. Cement is considered mature, from the date of production which has passed more than a month. In addition to cement, water and sand, as well as gravel, are needed. It is important to observe the ratio of all the ingredients to obtain concrete of maximum density. For this, each part of the cement is taken:

- sand (2-2.5 parts);

- water (0.5-0.7 parts);

- gravel (3-4 parts).

The preparation of concrete begins with the mixing of sand and cement. Then water is added to the mixture of materials, and the kneading process continues. Next turn comes to the gravel, which must be wetted with water before addition. In a form installed on a flat floor or steel pallet, first place the reinforcing mesh, which secures the eyes, necessary to move the finished ring. After that, they start pouring the mold with concrete. The thickness of the reinforced product is from 0.6 to 11 mm. Depending on the dimensions, the volume of the manufactured ring changes, which affects the amount of the solution to be mixed.

Important! If you make rings for a well yourself without the use of reinforcement, then increase the wall thickness to 15 cm. The life of such rings is very large. To prevent displacement of the cylindrical walls, a spacer of wooden wedges is placed between them.

The production of concrete rings on an open construction site is recommended to be carried out under a canopy to avoid precipitation in the solidifying solution

List of necessary equipment

The work on the manufacture of concrete rings is carried out on a spacious construction site. The list of mandatory equipment and necessary devices can include:

- concrete mixer (shovels and metal sheet, on which the concrete solution is manually kneaded);

- blanks for rings (special shapes);

- vibrator;

- lifting devices, since the weight of a single reinforced concrete ring for a well can reach 500 kg or more;

- frame reinforced (can be purchased ready or woven independently from the wire).

How to make a form for a well ring yourself?

With the independent manufacture of a cylindrical shape, two metal barrels are selected, the diameters of which allow to make a ring of installed dimensions. Instead of barrels, air ducts or pipes of the appropriate diameter can be put into operation. If there are no ready-made cylindrical shapes of the desired diameter, they are made from separate steel sheets, connected to each other by simple window or door awnings. Data connecting elements attached to the metal form by welding or rivets.

Important! You can perform formwork not only from metal or plastic cylindrical "glasses". With light plastic forms it is easier to work with small mechanization of manual labor.

Concrete rings Is a highly demanded product used for the construction of hydraulic and sewerage facilities. And the demand exists not only on the part of large construction companies, but also on the part of private entrepreneurs, individual developers, who want to provide themselves with a comfortable life.

For the production of these products, special forms are used to produce well rings, manufactured by the industry in accordance with standards that regulate their sizes (GOST 8020-90).

Factory Forms

For the construction of different types of wells, use wall rings of different sizes. They are manufactured by pouring concrete into special shapes, which are a double metal formwork of cylindrical shape.

Their outer and inner diameters correspond to the values regulated by Gosstandart, as well as the difference between them, equal to the thickness of the finished ring.

The formwork metal has a thickness of 3 to 8 mm. It is installed vibrators in the number of one to four, depending on the size of the ring, designed for ramming the concrete mixture.

For reference. The process of producing rings using such forms is extremely simple.

They are installed on a metal pallet, a reinforcement 6-10 mm in diameter is poured in, a concrete mix is poured in and vibration is included. As the solution settles down due to ramming it is added. After the product has obtained a certain strength, the mold is removed.

At the standard sizes of the form can still differ slightly from each other, which must be taken into account when purchasing them.

The main difference is in the possibility of making rings with a different shape of the ends:

- Rings with even ends are installed on each other with subsequent sealing of joints and tightening with metal clips;

- Rings with locks have a comb on the upper end and a groove on the bottom. They provide a more dense and reliable connection, preventing the rings from shifting relative to each other in the horizontal plane.

The price of such products is always higher when sold.

To form such a lock, the formwork is supplied with the formers - welded in a circle metal strips. They are located on the outside of the inner ring of the formwork and on the inner side of the outer ring.

In addition, the form for the wells rings can be designed to produce rings with metal transport loops, which are rigidly connected to the frame from the armature. A can provide formation in the walls of the ring through holes-eyelets for fastening the lines.

When planning to purchase forms, pay attention to these moments, as well as the thickness of the metal from which they are made. The more it is, the stronger and more durable the product, and the more geometric will be.

Homemade forms

Own shape for casting rings is beneficial in all respects. Of course, it can be purchased, but the high cost of such products (from 40 to 80 thousand rubles) does not justify the independent manufacture of rings for personal needs.

Another thing is if you are going to set up their production for sale or get a form together with neighbors in the garden cooperative. Then this enterprise makes sense.

But if you need to make only 3-4 rings to build a water well or cesspool, it is better to make the formwork for them with your own hands.

What will it give you:

- Savings on the purchase of finished products;

- Absence of costs for the delivery of rings to the site - they can be done directly at the construction site of the well;

- Confidence in the quality of raw materials used;

- The opportunity to earn, renting the formwork for rent to neighbors or independently producing well rings for them.

How to make formwork

The best form for the production of well rings is obtained from metal drums or pieces of large diameter pipes, plastic cylinders. These products have a regular geometric shape, which is difficult to obtain from sheet metal without special equipment - leaf bending.

Note! The difference in the diameters of the two drums used should be at least 7-8 cm for the production of reinforced rings and at least 15 cm for the manufacture of products without a reinforcing skeleton.

You will have to make four parts about the shape shown in the drawing:

The sequence of works is as follows:

- Both bottles cut off the bottom, the inner barrel is made above the outer one by a few centimeters;

- The marking is made on a large barrel, dividing it by two vertical longitudinal lines into two equal parts. The markings must be on both the outer and inner sides;

- By means of welding or rivets along the marked lines on both sides a steel corner is fastened. It can be solid, to the full height of the cylinder, or three pairs of segments are welded to it exactly opposite to each other (above, below and in the middle);

- Then holes are drilled in the corners for their subsequent bolting. Drill both corners at once in one step, so that the holes exactly match;

- After this, the barrel is gently cut from the inside along the line of marking by a Bulgarian with a thin circle, so as not to damage the welded corners from the outside. The outer formwork cylinder is ready.

In the same way, an inner cylinder is made, with the only difference being that the corners are fixed not to the outer cylinder but to its inner wall.

Note! The smaller barrel is labeled differently - so that one part of it is twice as large as the other. This is necessary so that when the formwork is removed it easily folds inwards. Therefore, the distance between the lines of marking should not be half the circumference, but its third.

For ease of use, you can weld to the elements of the formwork of the handle - outside on the large cylinder and inside on the small one.

To make it easy to move the rings during the construction of the well, drill through the walls of the formwork through holes with a diameter of 4-5 cm, during which wooden plugs will be inserted during the filling of the solution. After they are removed from the finished ring, lugs for the lines are formed.

In addition, it is possible to fabricate metal spacers from the reinforcement, which are put on the upper ends of the formwork to prevent the rings from shifting during the filling of the solution.

How to make a concrete ring with a homemade shape

For the production of rings, standard materials are required: cement, sand, gravel or gravel, water. They will be much stronger if they are reinforced with metal wire or rods.

So:

- Cement is desirable to use a high grade (not lower than M400) and mature (produced at least a month ago);

- The mass fraction of sand should be 2-2.5 parts per part of cement;

- Gravel fraction - 3-4 parts;

- The water content is 0.5-0.7 parts.

It is this ratio of components that provides the maximum density of concrete.

To prepare the solution, first mix the cement and sand, fill it with water, mix it, and then gravel, previously soaked in water, is covered.

Council. To be engaged in manufacturing of any concrete products it is desirable at temperature not below +8 degrees. The production site should be placed under a canopy or in a place protected from the sun, as too rapid evaporation of moisture leads to a decrease in the strength of concrete.

The following instruction is as follows:

- Place the mold on a flat, solid surface or in a metal tray, exposing the outer and inner formwork so that the distance between them is the same throughout the entire circumference. Pull the halves of each cylinder with bolts through the holes in the corners;

- Place a reinforcing bar welded from metal rods between the walls of the mold. You can also use a wire 2-6 mm thick, laying it with turns as it is poured into the shape of a concrete mix;

- If there are no metal spacers, make wooden wedges, the length of which is equal to the distance between the walls, and install them slightly above the average level between the cylinders in three to four places;

- Begin to evenly pour the solution into the mold, every 15-20 cm making it seal around the circle with a thick wooden or metal rod (for example, a shovel handle). This procedure will replace the vibration used in the factory manufacture of rings;

- When the concrete level reaches the struts, they need to be removed and continue filling the mold to the edge of the outer ring;

- The last stage is a careful leveling of the solution on top. The more smoothly the end part of the well rings is, the easier it will be to join and seal them during the construction of the well.

Shoot the formwork when the product will gain sufficient strength. Depending on the ambient temperature and air humidity, this can happen either in a day or in 3-4 days.

To remove unwind the fixing bolts, then first fold the inside of the smaller cylinder, then open the larger one.

After the formwork can not be moved for a few more days. All this time it is recommended to wet it with water to ensure better strength of the concrete. To use it will be ready in 10-14 days from the moment of manufacturing.

Conclusion

Having looked at the video in this article, you will be able to better understand how to produce strong and quality concrete rings from which you can build a water or sewage well. Of course, this will take quite some time, taking into account the independent execution of the formwork, but you will significantly win in the price and can later use the mold for casting new products for your friends and acquaintances.