Schemes of heating a private house with a double-circuit boiler. Stages of arrangement of the gas heating system in a private house. Features of mounting of heating boilers

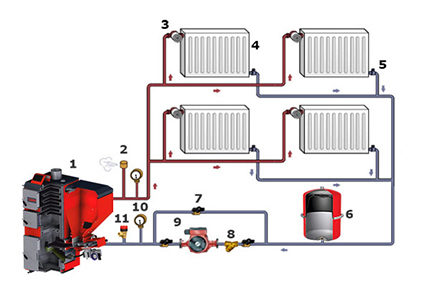

The heating boiler is a device in which fuel is burnt and the heat transfer fluid is heated. Heat still needs to be fed into the water contours of radiators, a warm floor, a boiler, etc. It is necessary to have a binding scheme - everything that connects it to the appliances in the rooms.

Assignment of strapping

- Maintaining a stable coolant pressure in the system.

- Removing air from the liquid that interferes with its circulation. With the formation of an air stopper, the passage of water through this place ceases. AT the correct scheme air vents are installed.

- Cleaning of the coolant from contamination. Mechanical impurities worsen the operation of the equipment. In this connection, it is necessary to install filters for cleaning.

- Compensation for the temperature expansion of a liquid. In order for the liquid not to destroy the system by excess pressure, a reservoir compensating expansion is installed.

- Connect one or more circuits to the system.

- Accumulation of hot water with a connected boiler.

The simplest circuit with one circuit

The most simple circuit The piping of the gas heating boiler is compiled in accordance with its characteristics and requirements.

The strapping also includes connecting the gas supply to the burner.

Tying the gas heating boiler: diagram, photo

The simplest system with one circuit is made in accordance with its characteristics and requirements. From the supply side, the ball valve is also installed.

On the return or pumping pipe, a pump is installed to create a fluid circulation, which ensures a uniform distribution of the heat transfer medium through the rooms. Before it is connected a strainer, located downstream the settler. Before entering the liquid into the boiler, it is advisable to install a fine filter.

Close to the boiler set expansion tank closed type. In it there is a membrane, allowing to dump superfluous pressure at temperature expansion of a liquid.

After the pump, the coolant flows through the circuit to the radiators. More modern is the decoupling through the collector - a special water collector, from which the liquid is distributed along several contours. It is placed in a separate cabinet, from which the coolant is distributed through pipelines.

The scheme for tying the gas heating boiler contains a safety valve. When boiling the coolant from overheating, the expansion tank may not cope with the pressure drop. The consequences can be as follows:

- breaks in pipelines and leaks of joints;

- destruction of fittings and pipes;

- explosion of the boiler capacity.

Install as close as possible to the boiler, because it starts to increase pressure.

On some units, safety groups consisting of a relief valve and a manometer are installed. The instruments are mounted directly into the water jacket of the boiler, but can also be installed on pipelines. On gas and electric boilers these devices can be replaced by others, where, when the critical temperature is reached, the burners or electric heaters are switched off.

There are many options for connecting heating equipment to boilers, but the basis for classification is the division into natural and forced circulation.

Natural circulation

The principle of operation is based on a reduction in the specific weight of water when heated. The hot liquid is forced out cold, passes through the heaters, gives off some of the heat and returns to the heating back into the boiler.

The installation of the supply and discharge pipes is carried out with a slope of at least 3 0, so that natural circulation takes place and the air in the system accumulates less.

When natural circulation Tying the gas heating boiler (the diagram below) is done so that the radiators are located above the supply pipeline.

The return goes from above also with a slope. When proper installation and the choice of pipe diameters, the natural circulation of power is almost inferior to forced circulation.

Advantages of the method:

- simplicity of the system;

- ease of installation;

- quiet operation;

- durability.

The system is suitable for heating not big house with a total floor space of not more than 100 m 2. The drawbacks include the duration of warming up of premises and the inability of temperature regulation in individual rooms.

Gravitational scheme is used mostly in small houses and in the country, with only one heating circuit. Numerous pipes spoil the interior, if they do not hide in the walls.

Forced circulation

The method has become most common, since the pump pumps through the system a heating medium and the heating efficiency is increased by 30%.

Advantages include the possibility of temperature control and a small flow of pipes during installation. The system is still much more expensive, because it is more complex and requires more devices. The installed elements require balancing, and the entire system - regular service. In addition, a source of electricity is needed.

If you install a combined system, it will combine the advantages of both previous ones. It can be switched to any mode by using the bypass installed with the pump. In this case, the work of heating will not depend on the supply of electricity to the house.

Strapping with polypropylene

Plastic pipes came to replace metal everywhere, including for water pipes. For heating use multilayered reinforced products, high pressure. Thanks to the connections, a monolithic piping of the gas heating boiler with polypropylene is obtained. Schemes are created in any complexity and in a short time.

Important! The simpler it is, the more reliable it is, and the productivity is higher.

Unlike the coolant, the gas is connected to the boiler through a metal pipe with the gasket sealed and does not burn.

Tying the floor gas heating boiler: scheme

The dimensions of a conventional floor boiler are small, but it takes a lot of space to install it together with the harness. All equipment including circulation pump, bends, bushings, manifold, cranes and devices are difficult to place compactly.

Most models are made single-circuit, and for hot water requires a boiler with all connections.

The hot water supply system requires a separate pump (in the absence of a central water supply), and a thermostatic mixer.

Gas to the boiler must be properly connected. To do this, you order the project documentation, which is made up of specialists. Entering the house gas pipe If there is a trip device in the event of an emergency. Gas connect special services, using special pipes, hoses and other equipment.

Wall-mounted boiler installation

Boilers can be hung on the wall even in the kitchen. They take up little space. The piping of the wall gas heating boiler (the diagram below) comes complete and can even be integrated in the boiler. The compact arrangement of equipment requires less space, but similar models are more difficult to maintain.

The disadvantage of wall-mounted boilers is low power. In addition, the devices do not work without electricity, and the natural circulation of the coolant is rarely used for them. On the other hand, almost all boilers are already equipped with electronics and electricity is necessary for them. In places with its unstable supply it is possible to supply an uninterrupted power supply.

In most wall-mounted models, a double-circuit gas heating boiler is provided, the circuit of which allows the supply of a house hot water.

The disadvantage of the two-circuit variant is the shutdown of the heating during the consumption of hot water. This is especially noticeable when the boiler capacity is small. If it is enough, the temperature of the coolant drops by only a few degrees within a couple of hours. This applies to houses with high-quality thermal insulation and a sufficient number of radiators with thermal inertia.

Conclusion

The scheme of tying the gas heating boiler is compiled in accordance with its characteristics and requirements. For a summer residence the system of natural circulation through one contour approaches, and for the big house - with compulsory and многоконтурной.

Choosing a dual-circuit boiler for the house, the consumer should understand that this unit is significantly different from a single-circuit one. First, the design. Secondly, by the presence of an additional circuit, which provides the house with hot water for domestic needs. Thirdly, the scheme of tying the gas double-circuit boiler.

The main differences between the two options

Tying the gas boiler

If we compare these two units, it turns out that a single-circuit one can also be used to heat water for domestic use. But in this case a separately standing tank - a boiler with a heat exchanger located in it - is connected to the boiler. Hot water for heating passes through this heat exchanger, leaving part of its heat and thereby heating the water.

In the case of a dual-circuit boiler, everything is completely different. Water for domestic needs is heated in the combustion chamber, passing through the second circuit. There are no boilers and other appliances, so heating is done directly without intermediaries. The only point to pay attention to is constructive feature unit and a technological approach to heating water in two circuits. If water starts to be used for domestic needs, it turns off automatically, and the heat carrier in it temporarily does not heat up.

How can this affect the private house heating system and the indoor temperature? If the house is equipped with high-quality thermal insulation, then the question of how the boiler works and how the mode is set does not matter. Periodic disconnection heating system will not affect the temperature inside the house, so there's nothing to be afraid of. For example, the fact that for a couple of hours of switching off the temperature inside the house will drop by a maximum of 2-3 degrees. And such a shutdown due to the selection of hot water is very rare.

Scheme of piping of a boiler with a pump

If the house has insufficient thermal insulation, or the building has very large rooms, then the question of the inertia of heat reduction must be addressed in other ways. For example, install more radiators or increase the number of sections. For this it is necessary to select radiators from a material with reduced inertia. Cast iron batteries slowly heated, but also slowly cool. So for such houses it is the best choice. We add that it is possible to reduce the degree of coolant cooling by increasing its volume. Again we return to the radiators and their number, and also take into account the diameter of the piping piping, namely, increase this figure.

And the last. If for some reason the amount of hot water consumed exceeds certain norms by the time indices, it is necessary to revise the option with the purchase of a two-circuit gas boiler. Even optimal scheme strapping here will not help, because such heating can not provide heat to the house without a long heating of the coolant.

Important! Use a dual-circuit boiler in a system with a natural circulation of the coolant is undesirable. The fact is that a decrease in the temperature in the system with the second circuit switched on not only causes a decrease in the temperature in the premises, but also is fraught with difficulties in collecting heat when the first circuit is switched on. Several such trips, and you can forget about a comfortable temperature - it will be distributed unevenly across radiators.

Although such a situation is possible only if the house is installed boiler, made by own hands. Ready-made units go on sale with already built-in circulation pumps. But to consider the scheme of tying, where natural circulation will be used, is still necessary. After all, it's no secret that power cuts in suburban townships are a common thing. With multi-storey houses there can be problems, but there is not one-story houses. So the owners of these houses are better to install bypasses, cutting off the contour, where the pump is built.

Strapping schemes

In fact, the circuit diagram of a single-circuit boiler does not differ from that of a two-circuit boiler. Yes, this is not necessary. It basically takes into account which boiler will be used - wall or floor. Sometimes the place of installation of the device and its power may affect the tube interchange. But if you correctly calculate and correctly plan the location of the circuits, it will no longer matter, for the wall-mounted boiler is wiring or for the floor.

Let's consider several options related to the size and floor of the house.

One-storey house in a small square

The ideal version of the strapping is the so-called Leningrad bench. This is a single-circuit circuit in the form of a ring, through which radiators are installed. That is, the feed pipe is also a return flow. In the center there is a double-circuit boiler.

What are its advantages?

- Slight consumption of materials.

- Simplicity of the scheme.

- A small coolant flow.

Single-pipe system

Usually such a circuit is used in small houses, where not a lot of people live. And this is a small expense of hot water. Already a plus. But in order to avoid problems, it is better to increase the volume of the coolant by making the system inert. Therefore, it is recommended that larger diameter pipes be used for heating purposes. For example, if you want to install a pipe 40 mm, then you should take 50 mm.

Now, as for the pipe, which removes the coolant from the boiler. Do not mount it horizontally right away. It is necessary to take into account the vertical segment, which experts call the overclock collector. Remember about power outages! Therefore, you need to create a system that can work under a scheme with natural circulation. But after a vertical riser, you can conduct the pipeline horizontally with a slight slope.

And the last thing is the installation of the expansion tank. This must be done necessarily. And the volume of the tank should be 10% of the volume of the coolant.

Two-storey large house

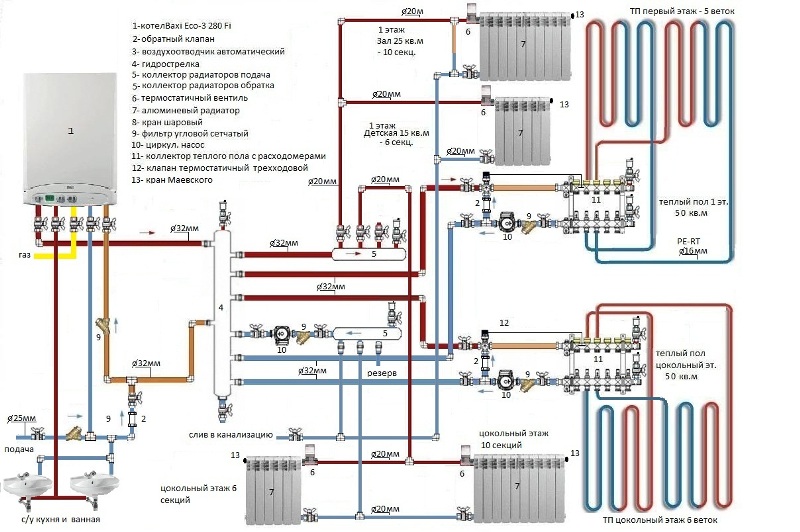

Wiring plan for Baxi double-circuit boiler

It should not be tricky, because the optimal solution is a two-pipe scheme with top filling. That is, from the double-circuit gas boiler, the riser, supplying the heat carrier, rises upward. In the attic, it is divided into contours, which are lowered into the rooms by risers. It is to them that the radiators are connected, but they do not open the riser itself, which is very important. All the risers, having passed two floors, are closed on the reverse circuit, which supplies the coolant to the boiler.

In case of two-story house You can suggest another scheme where two boilers will be used - one on each floor. This simplifies the circuit by dividing it into two separate circuits. We add that this scheme of binding is considered economical in the sense that it is possible to lower the temperature inside the system if one floor - usually the second one - is used by household members seldom.

The universal scheme

If you make a small initial expenditure, then there can be any. That is, it will not affect the efficiency of heating operation so much. To do this, you will have to purchase and install a conventional water-heating boiler with a volume of 200-300 liters. It will play the role of a battery of thermal energy and thereby increase the inertia of the system.

Install such a tank anywhere, connecting it to the circuit. It can be a basement, a place next to the boiler, on the street and so on. Here the convenience of installation and maintenance is important. The tank must be well insulated.

Conclusion on the topic

As you can see, the scheme for connecting a gas dual-circuit boiler is not limited to one option. And even those described are not the ultimate truth. There are many approaches to creating an economically justified heating system. But in the case of a dual-circuit boiler it is necessary to take into account all the nuances mentioned above.

The piping of the heating boiler is a system of pipelines and equipment designed to provide coolant to the radiators. Simply put, it's everything, except for batteries. Do not be afraid of the abundance of pipes, devices and technological stages. After reading the article you will be able to work this job. And if the heating boiler itself is arranged, then it will serve longer, and it will take less money.

The first step is the selection of a heating boiler, the performance of which must be determined beforehand.

The calculation of the required capacity of the heating unit is affected by many factors, such as:

- the volume of the building;

- the number of windows and the total area of the glazing;

- number and area of doorways;

- thermal conductivity of materials used in the construction of walls;

- degree of insulation of load-bearing structures;

- average annual temperature in the construction region;

- the location of the building, i. on which side of the world comes the main, traditionally the most glazed, facade.

However, there is an average indicator that, without in-depth calculations, allows you to determine the required performance. For the central band for the starting point (but not the guide to action!), You can take 1 kW per 10 m² of heated area. To the calculated capacity of the boiler, it is necessary to add a stock of at least 20%.

Heat for heating buildings is obtained by processing fuel in boilers heating the coolant

Types of heating boilers

Conditionally the heating boilers can be divided into autonomous and manual loading.

Autonomous boilers, depending on the fuel used, are:

- solid fuel;

- electric;

- gas;

- oil-fired.

The order in the list determines the cost of heating, depending on the type of fuel: gas boilers will be the cheapest in operation. Boilers are equipped with automatic control of the set temperature of the coolant. Can work all year round all life time. There are wall-mounted and floor-standing.

Image Gallery

Boilers for manual loading include boilers for solid fuels. As fuel used wood, peat, coal. Require the participation of a person to load fuel. Maintaining the right temperature of the coolant is also a part of the person's responsibility. Execution of boilers - outdoor. Equipped with a minimum set of automatics. Heating boilers are one- and two-circuit. A double-circuit boiler is connected with a water pipe, which is built to heat hot water.

Heating systems with a heating boiler should provide the necessary temperature in the treated premises. The strapping scheme should be oriented to the uniformity of heat supply to all devices

Independent heating boilers and the principle of operation

In most modern gas boilers for autonomous heating the temperature of the coolant is maintained automatically. Inside the unit there is a heat exchanger heated by a burner on liquid or gaseous fuel. The boiler's thermal sensor constantly monitors the temperature of the coolant.

As soon as the temperature has reached the preset level, the burner goes out and the heating stops. If the coolant temperature falls below the set limit, the burner is ignited again. Such ignition-damping cycles can occur quite often, there is nothing wrong with that.

If you plan to install a heating system with high capacity, then there is a possibility of overheating of the coolant. In such schemes of strapping, it is necessary to provide a thermal accumulator

The vast majority of installed heating boilers heat the coolant by processing gas or liquid fuels. This is facilitated by ubiquitous gasification and high reliability of boilers.

In the schemes of tying with solid fuel boilers, there is no provision for the regulation of the heat supply, the burning process can not be controlled. If the combustion stops, the circulation pump stops (click to enlarge)

Pros of gas and liquid fuel boilers:

- ease of maintenance;

- a lot of security systems, often duplicating;

- part of the equipment is included (circulation pump, manometer).

Unconditional dignity is a high efficiency, which on average is 98%.

For heating systems, water can circulate at a temperature of no more than 105 ° C, steam heated to 130 ° C or air up to 60 ° C. When the operating parameters are exceeded, the safety group

There are also disadvantages:

- in the absence of electricity, the whole system stops, a threat of defrosting is created;

- high price;

- the circulation pump works around the clock;

- can only be used in closed systemsoh.

When installing an autonomous boiler, you need to consider the constant costs of electricity. The circulation pump runs continuously, regardless of whether the coolant is heated or not.

Solid fuel boilers for manual loading

AT solid fuel boilers loading and ignition of fuel occurs manually. The combustion intensity can be adjusted in a limited range. The operating time is determined by the burning time of the fuel of one load.

Solid-fuel boilers are the most universal solution, their advantages include:

- independence from electricity;

- can be used in closed and open systems;

- low price.

Units of this type work on the most affordable form of fuel.

There are significant disadvantages:

- as a rule, are delivered with a minimum set of equipment;

- require constant monitoring by a person;

- have a low efficiency.

For the solution of traditional "winter" problems one of the options may be the use in one heating circuit of two boilers of different types. In the normal mode, an autonomous boiler operates, and in the event of an accident on a gas or electric line, a solid fuel heating unit is manually started.

Such a scheme will not allow the heating system to sub-cool and freeze. The second option, maybe the use of a special, non-freezing coolant - antifreeze.

From the type of heating unit depends largely on the choice of scheme for tying the boiler heating.

When installing a solid fuel boiler it is very important to observe all the distances from the walls

Types and schemes of heating

The purpose of the heating system is to transfer heat from the boiler to the radiators. The energy is transferred through the circulation of the coolant.

The heating circuit can be realized in the following ways:

- open one-pipe circuit;

- closed one-pipe circuit;

- closed two-pipe circuit.

Two-pipe closed heating circuit is the most progressive, has the highest efficiency. However, it is the most expensive and difficult to implement.

When heated, the heating system increases the volume of the coolant, the excess coolant is collected in the expansion tank. When cooling, the reverse process occurs: the coolant is reduced in volume, the heating system draws the coolant from expansion tank. By the way the organization of the expansion tank, the system is divided into open and closed.

Open circuit of the heating system

When open system the expansion tank is open, freely communicates with the atmosphere. The general arrangement is as follows: the heating boiler is located at the lowest point, the expansion tank is in the uppermost, with respect to the radiator. The greater the difference in the height of the expansion tank and the uppermost radiator, the better.

Image Gallery

![]()

Circulation of the coolant in an open single-tube system occurs naturally, heated water moves or its mixture with antifreeze due to gravity. Cooling the coolant becomes heavier, because of which it gradually descends to the lower level of the system. Heavy substance is pushing out a lighter, hot coolant. So they constantly alternate, i.e. the coolant moves along the ring of the heating system.

The boiler's piping scheme in the open heating system does not require the mandatory installation of control devices. In case of overheating, it will spontaneously get rid of the excess heat carrier (click to enlarge)

Such an organization of the heating system has its advantages:

- the simplest scheme;

- there is no need for electricity, because the coolant moves by gravity;

- weak sensitivity to emergency pressure increase (for example, when boiling).

The device of the system with natural movement of the coolant will need the least amount of money, because it makes no sense to equip it with automation, bypass valves, a circulation pump.

Unfortunately, there are significant drawbacks:

- constant contact of the coolant with air, leads to gas contamination;

- the possibility of cooling the coolant in frost;

- relatively slow circulation of the coolant;

- it is impossible to achieve the same temperature of the radiators;

- a large volume of coolant is required.

With an open system, the constant contact of the coolant with atmospheric oxygen leads to increased corrosion of pipelines and radiators. The formation of various contaminants reduces the efficiency of the heating system in general.

With aluminum and bimetal radiators, this system works poorly.

With a flow system with natural circulation, it is important to observe slopes. The expansion tank is at the highest point of the system

An open single-pipe heating system is the easiest to implement and the least efficient. It is used with manual loading boilers. It is used, mainly, for heating small private buildings in one two floors.

Closed circuit heating system

When closed circuit heating system expansion tank is made in the form of a steel container inside which is a rubber pear or membrane under the pressure of air. With the expansion of the coolant, the pear shrinks and releases additional volume.

In a closed heating system, the excess pressure when the coolant is overheated is removed using a Mayevsky crane

Compulsory circulation of the coolant makes it possible to heat up all radiators faster and more evenly. In this case, the coolant by means of special air vent valves once again gets rid of all the gases in it. Pipelines remain clean and corrosion does not occur.

Image Gallery

The layout of the boiler and the expansion tank can be any: the boiler can be located in the basement or on the first floor. Expansion tank, as a rule, is installed next to the boiler.

The advantages of a closed system:

- clean heat carrier;

- guaranteed circulation

- free arrangement of equipment;

- the minimum amount of coolant;

- small diameter of pipelines.

Disadvantages of a closed system:

- constant overpressure;

- increased cost.

A closed, single-pipe heating system remains, quite inexpensive, allowing the use of all types of boilers.

With the heating system closed, there is freedom of installation. The expansion tank can be next to the boiler

Single-pipe heating system

According to the way the coolant moves along the pipeline scheme and the devices included in it, the heating systems are divided into one- and two-pipe systems.

With a single-pipe heating system, the main line of a large diameter - the feed - extends from the boiler. She acts as a transporter of hot coolant and collector it in a cooled form. The radiators are connected in series to the pipeline by two thinner pipes. One of them takes the coolant, the second one lets out.

The heat carrier alternately passes all the batteries, parting along the way with a part of the thermal energy.

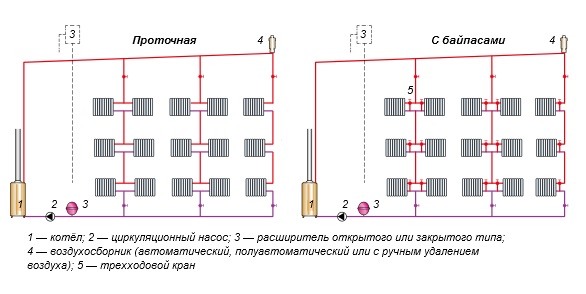

- Flowing. In the flow diagram there is no feeder riser as a structural element. The radiators of the upper floor are connected to the analogues on the lower floor. In this scheme, you can not use adjusting cranes to not block the access of the coolant to the following devices.

- With bypasses. According to this variant, the radiators are connected by risers, but are separated from the contour by the closing links. The coolant comes from the supply pipe. Distributed by portions of all devices, which comes in almost at the same time, so that it cools less.

The heating circuit with bypass allows you to adjust the temperature and repair the failed device without disconnecting the entire system. In this respect, the flow variant loses the same way as the coolant cooling rate. But a flowing variety is easier to implement.

AT single-pipe systemsoh with forced circulation The heated coolant rises on the main riser and is distributed over the series-connected batteries

If a single-pipe circuit is used in a heating circuit with a natural circulation of the heating medium, there are no return risers at all, and only the upper wiring is used to connect the devices.

With a two-pipe heating system, one pipeline supplies a hot heat carrier heated by the boiler. The second - takes and takes it in a cooled form back to the heating unit. The receiving pipe is called the feed, the collecting pipe is called the return flow. The heating radiators are connected in parallel.

The coolant in the coldest radiator has the lowest temperature, accordingly it is stronger than the rest of the pressure. The circulation of the heat carrier is the more intense, the greater the difference in temperature between the supply and the return connection. As a result, the cooler will warm up more quickly. Thus, the temperature in all devices connected to the same manifold is equalized.

Pluses for heating with two pipes:

- adjustment for the temperature parameters of one radiator does not affect the rest;

- hydrodynamic stability of the entire system;

- it is easy to connect devices for regulating the supply of hot water;

- all pipelines can be hidden in floors or walls;

- high speed and efficiency.

Two-pipe systems come with an upper and lower wiring, with dead-end and passing transportation of the coolant. There are with its natural movement and with forced circulation, stimulated by circulation pumping units.

The two-pipe heating system is more complicated and more expensive than the one-pipe system, but it significantly exceeds the level of comfort conditions (click to enlarge)

In circuits with natural circulation, the boiler is installed

Of the minuses, we can distinguish the following:

- double number of pipelines;

- relatively high price;

- need for the use of shut-off and control valves.

The two-pipe system, despite its complicated design, is the preferred solution, especially when used with autonomous boilers.

The heat carrier is disassembled from a pair of collectors

If you do not resort to complex heat engineering calculations, then you can take advantage of many years of experience in the construction in the middle lane. For the construction of the supply and collecting lines, it is recommended to use two-inch pipes (Ø 50mm) connected to the boilers. The sockets are made of pipes of the same size.

Depending on the number of sections, the batteries are connected to the supply and return of pipes by 1.5 "(by 25-35 sections), 1" (by 10-25 sections), 3/4 "(less than 10 sections).

When constructing an autonomous heating system with one or more boilers to achieve the greatest efficiency and comfortable microclimate, a two-pipe system is suitable. It can be used on any objects. Works with any type of radiators and any boiler. The selection of the heating scheme depends on the desired price-quality ratio and the purchased boiler.

Implementation of the heating system

Armed with the necessary knowledge of the principles and merits of each scheme of heating, you can make an order of actions:

- choice of the scheme of heating;

- selection of the heating boiler;

- acquiring necessary equipment;

- installation.

For the device open, single-pipe circuit heating, it is enough to have a thermometer (in most cases, comes with a boiler) and an expansion tank, usually homemade. For closed systems, the minimum necessary equipment is similar and discussed below.

Acquisition of necessary equipment

The mandatory list of equipment for closed heating systems includes:

- expansion tank;

- overpressure relief valve;

- circulation pump;

- automatic vent valve;

- in the case of a two-pipe system, collectors (another name is combs);

- pipes.

When purchasing a boiler for autonomous water supply, part of the equipment can not be purchased. The equipment offered for sale, as a rule, is already equipped with a circulation pump, safety valve, expansion tank, manometer.

Before choosing the necessary equipment, you should draw a chart in scale and draw up a list of required elements

Features of mounting of heating boilers

Heating boilers are produced in the floor and wall version. Depending on the version, they are installed.

In a row of wall-mounted boilers there are turbines. These are boilers that forcibly divert the exhaust gases and supply air to the combustion chamber. In such boilers, super efficient fuel processing takes place, which means that the exhaust gases have a low temperature. The gas outlet and the air supply are made by means of a special one. Pipe horizontally with a slight bias is displayed on the street. Slope is necessary to drain the condensate to the street, and not inside the boiler.

The choice of the scheme of the walling of the wall-mounted boiler can only be of the closed type, since all wall-mounted boilers are autonomous.

In all other boilers, including manual floor loaders, the exhaust gas is discharged into the vertical chimney. The part of the chimney that faces the street must be insulated to prevent condensation.

For a floor, solid fuel heating boiler, a solid base and a platform of non-combustible material (sheet of iron, ceramic tile). The scheme for tying the floor boiler of manual loading can be open and closed, one-pipe and two-pipe.

![]()

When installing a wall-mounted boiler with coaxial tube. The best place is the external wall of the boiler room, so the pipe length will be minimal

Selection and installation of expansion tank

Even if an expansion vessel is already installed in the heating boiler, it is strongly recommended to install an additional tank. The volume of the expansion vessel is chosen based on the volume of the coolant. A good option for mounting the expansion tank will be installation on a standard manifold, together with an automatic vent valve and a manometer.

Before installing the expansion tank, it must be pumped with air to the recommended pressure, usually 1.5-2.0 Atm. It is better to install the expansion vessel next to the boiler.

For reliable operation of the device, it is necessary to check air pressure at least once a year

Installing the circulation pump

The necessity of using an additional circulating pump, its parameters are determined by hydraulic engineering calculation. There are several general remarks.

The operation of the circulation pump is designed for a temperature of the order of 60 ° C. Therefore, it is advisable to mount the pump on the back of the pipe, with a cooler coolant. Also for safety reasons, if the coolant overheats to steam, when installing the pump on a straight pipe, the impeller of the pump will stop working, which will lead to even more overheating.

The direction of the coolant flow is clearly marked on the body of the circulation pump. The orientation of the circulation pump can be any, but the rotor should always remain in the horizontal plane.

It is permissible to mount the pump, so that the shaft rotates in the sliding sleeves. Otherwise, the pump will quickly fail

Automatic air vent valves

Even with the formation of air pockets, for the removal of gases, there will be enough one valve. Sooner or later the air will dissolve in the coolant through the valve. However, the rate of dissolution is small and this withdrawal can take up to several months.

The correct setting is only possible on a fully inflated system. In order not to wait several months, several automatic valves must be installed.

A good place to install automatic valves - on the combs and collectors.

The safety valve, pressure gauge, automatic air vent valve makes sense to be mounted together - in the safety block

Site Selection and Collector Installation

The purpose of the collector is distribution of the heat carrier by consumers. Consumers can act warm floors, heating radiators, coils in the bathrooms.

Structurally, the manifold is a section of a pipe with several outlets. The number of bends must correspond to the number of consumers. For a two-pipe system, the number of collectors is at least two. For each tap, the volume of the supplied coolant is regulated.

When organizing the heating of a two-story or more house, a pair of collectors is made for each floor. If there are warm floors, for them it is necessary to allocate a separate collector. There is a couple for each floor. Individual reservoirs are necessary for the following reasons:

- due to the difference in hydrodynamic resistance of pipelines between the nearest and the far radiators of heating;

- at various characteristics of consumers;

- for a reliable setup of the entire system.

Due to the different hydrodynamic resistance, it may be necessary to install an additional circulating pump in the boiler's piping circuit, for example, on a collector of warm floors. For ease of adjustment, collectors are mounted in one place, in a special cabinet.

The collector is an excellent place for mounting auxiliary equipment: pressure gauges, safety valves, flowmeters

Selection of pipe material for a single-pipe system

For single-pipe systems, the most common are steel pipes. A large choice of diameters and not high cost make this choice preferable.

When installing pipes, the slope should be at least 5 mm per running meter. Aesthetically inclined pipes look worse, but ensure reliable circulation of the coolant, even if the circulation pump is switched off.

Connection of heating radiators, in an open system, produces a pipe with a minimum diameter of 32 mm. The straight and return lines are made of pipes with a larger diameter, a minimum of 50 mm.

Steel pipes are a practical material, but are prone to corrosion and require painting. Polymer pipes have less hydraulic resistance, therefore smaller diameter can be used

Pipes for a two-pipe system

The two-pipe system does not require large diameters. The pipe material can be various: polypropylene, metal plastic, etc.

The main thing is that pipes can withstand pressure and temperature. Since the two-pipe system does not require natural circulation, the pipes are hidden in underground space or in walls. All pipes must be insulated to prevent heat loss.

Pipes connecting the collector have a diameter of 20-25 mm., Connect heating appliances 16-20 mm. respectively.

The use of modern materials and installation techniques does not require welding. All editing is done as in the designer

Each bending of the pipe adds hydrodynamic resistance, if possible it should be avoided. A big difference in the hydrodynamic resistance of the branches of one reservoir makes it difficult or impossible to regulate.

After mounting all components, pressurization with increased pressure is mandatory. The pressure should remain constant for at least 24 hours. If the heating system has successfully passed the test, the piping of the heating boiler can be considered complete.

How to choose the most suitable heating unit:

Comparative analysis of heating system options:

At first glance, heating systems seem complicated. At the same time, the principles by which the heating system works are very simple. Correctly designed and executed system is able to work for years without any interference.

Heating systems using gas as a fuel have excellent efficiency and reliability. Generators of thermal energy in them have high efficiency and are safe in operation. There are several ways to organize gas heating for a private home. There are solutions both budgetary in performance, and more expensive with maximum economy and stability in operation.

Without combustible fuel, there will be zero sense for any variant of the in-house heating system in standalone version. Gas is the first thing to think about when planning in a country house gas heating.

Not all settlements in Russia are gasified. However, "blue fuel" can be obtained not only from a tube or a cylinder with liquefied fuel, but also from a gas holder.

In the absence of the village gas main it is possible to use the option with an autonomous supply of fuel from a gas holder for storing gas in a liquefied state

Natural gas, consisting mainly of methane, is supplied to private homes through pipes. Its liquefied analogue is a propane-butane mixture, which for transportation and storage is pumped into containers. The pressure in such cylinders and gas tanks is about 15-18 atmospheres.

When heating in a private house with the help of balloon tanks of 50 liters last winter will have to change every 2-3 days. If for country cottage the autonomous gas supply is chosen, then it is best to prefer a gas tank that can be up to 20 cubic meters in volume.

The choice of capacity per cubic capacity depends on the level of consumption of liquefied hydrocarbon gases (LPG). Here it is necessary to take into account not only a hot water boiler, but also a fireplace and a gas stove, if they are used in the house. For a cottage of 150 sq.m. it is recommended to install a gas-holder in volume in 2000-3000 liters. And for a country house of 300 sq.m. an option for 8000-9000 liters is required.

The main disadvantage of gasholder - it can be installed only in a large area, the capacity according to the requirements of SNiPs should be at least 10 m from the house

At the cost of connection, the gas pipeline is in most cases more advantageous than the reservoir in the ground. But only when locality already gasified. Possible situations where the installation of gasholder will cost less than connecting to the main pipeline. Everything depends on the specific conditions of connection in the region and the remoteness of the village from the big gas main.

When using a gas holder, you do not have to worry about the pressure in the pipe. It is extremely simple to operate. You just need to regularly call specialists to check it for safety, and do not forget to make a refueling. It takes no more than three days to install the entire system.

If an autonomous gasification option is chosen, the gas boiler should purchase one that is designed for LPG operation. On sale there are models designed to function exclusively on the main natural gas. But most gas heat generators are adapted for burning both types of this fuel. It will only be necessary to change the jets, and also to reconfigure for a different valve mode and electronics.

Selecting a heating gas boiler

Modern heat-generating equipment for gas has a variety of automation and is able to operate in several modes. It can be floor and wall. The second option is more compact, but has power limitations. If the model is chosen for a large private house, you will have to purchase a powerful unit in the floor version.

Gas boilers are subdivided according to the type of execution, type of ignition, energy efficiency, number of circuits and combustion method (+)

The principle of functioning of the gas boiler is extremely simple - the combustible is ignited in the burner by means of piezoelements or electronic ignition, then as a result of fuel burn-up thermal energy is generated, which is transferred to the water by means of a heat exchanger. The latter is already used as a coolant in the heating system or is consumed in the DHW.

By the efficiency of traditional convection gas boilers lose condensation. The performance of the former does not exceed 90% of the energy consumption. Manufacturers of the second guarantee an efficiency of 100%, in some models promised 105 and even 110% (+)

The heat exchanger in the gas boiler can be made:

- from steel (stainless steel);

- copper;

- cast iron.

The most common variants of steel. This metal is cheap and plastic, due to which cracks from constant heating / cooling in it appear less often. But steel elements with constant interaction with water of the gas heating system, equipped in a country house, quickly begin to corrode.

Cast-iron heat exchanger is the most durable, steel is cheaper, and copper is most effective in capturing heat transfer to water

Cast iron is less prone to corrosion, but it is quite heavy. Most models of boilers with cast-iron heat exchangers are outdoor. On the wall, such heavy and oversized equipment is difficult to mount. If you need a compact and extremely light heating unit, then best option - with a copper coil. However, it is the most expensive among analogues from other metals.

To supply the cottage with heat and hot water, you can choose a scheme with two single-circuit boilers or an option with one dual-circuit installation

The number of circuits in the water-heating boiler on the gas depends on the scheme of the strapping and the principle of its use. One heat exchanger is initially intended for the organization of a gas heating system in a private house. For DHW it is necessary to install one more boiler or to immediately select a two-circuit model.

Heat hot water for domestic needs is best in a storage tank. Streaming models are less economical. The gas they spend on heating will be more.

Represent a fully equipped miniature boiler house. They have their own circulating pump, expansion tank and safety group. Most types of wall-mounted equipment serves two circuits (+)

Which combustion chamber is better

To ensure that the gas in the furnace of the boiler burns, it needs a constant supply of oxygen. It is taken directly from the boiler room or drawn from the street. The first option implies a natural influx of air, and the second - forced by the fan.

Gas boilers are equipped with two types of combustion chambers:

- Closed - oxygen feed is produced through the gap between paired pipes of different diameters. Combustion products are diverted through the internal channel.

- Open - air in the furnace comes from a room with a heating unit through check valve. The combustion products are drawn out in a circular fashion through a smoke channel.

The first option is independent of the area of the room. Suitable for rooms of any size. The coaxial view of the chimney from the unit with a closed firebox can be displayed through a wall or an upper ceiling with a roof.

In the second case, it is necessary to install a high-level chimney in 5-6 meters, otherwise the drafts for sucking in the combustion chamber of the necessary volumes of oxygen will be insufficient. But gas boilers with an atmospheric burner do not need to be connected to the mains. There is no fan in them, everything happens naturally without forced circulation.

The boilers with closed cameras and forced air injection in comparison with open air have a higher efficiency, but they require constant power supply for operation

Water heaters with gas with an open firebox are recommended to be placed in special rooms with good ventilation. If you mount them in living rooms, they will greatly reduce the amount of oxygen in these. Without forced ventilation system here already will not do. And this is additional spending on the installation and subsequent operation of equipment for air ventilation.

Characteristics of condensation models

In conventional gas boilers, the water vapor generated by the combustion of gas flies into the chimney. In the process of combustion, it is formed a little, but it nevertheless carries in itself a sufficiently significant volume of thermal energy. In order not to waste this heat, condensing boilers were developed.

The flue gases in the condensing boiler, before leaving the chimney, pass through a secondary heat exchanger where the cold water supplied to the unit is heated slightly

The principle of operation of these units is based on the fact that when cooling the steam of waste gases, it releases heat to the water from the return of the heating system. The temperature of the coolant increases slightly, but as an additional source of heat energy, the recuperator is perfectly suitable.

The condensed water from the condensing boiler is discharged through a special branch pipe into the sewage system or a separate container. Here one should clearly understand one nuance - the condensate formed is actually a weakly concentrated acid. And at an hour it can leak to 4-6 liters.

If this liquid is poured into the septic tank, all microbes living in it will be destroyed. If there is a cleaning station in a country house, sewage system Condensation from the boiler can not. With the design of the chimney all is easier, it is enough to take one that is designed for boilers with a closed chamber.

Gas fireplace - the original solution

At the cost of equipment, gas fireplaces are comparable to electric or wood analogues. But gas fuel is much cheaper. And unlike firewood, gas heating with the help of a fireplace in a country house assumes no problems with ash. Plus, you do not have to constantly monitor the work of the furnace and take care of the logs of logs.

Fireplaces that process gas in thermal energy, are used in heating systems, because Do not have the devices necessary to maintain two circuits

By type of installation, fireplaces on gas are:

- walled;

- island;

- built-in.

According to the general design and internal filling (burners, automation, combustion chambers), they completely repeat gas boilers. In both cases, the technology for connecting to networks is identical. Differences exist only in the principle of heating the premises.

By the principle of connecting and organizing a heating system, gas fireplaces are similar to floor heating boilers (+)

The hot water boiler is originally designed for heating water, and a regular fireplace - for convection of air from the body and the front screen, followed by burning of fuel.

Schemes of water heating in a private house

For heating cottages are equipped with heating systems with water as a coolant, consisting of:

- water boiler (single-circuit or dual-circuit);

- pipelines and fittings (metal or polypropylene);

- bypass, which allows to disconnect individual heaters from the network;

- batteries (cast iron, aluminum, steel and bimetallic);

- expansion tank.

Gas heating units are equipped with a specific safety system, including a solenoid valve and thermocouple. The devices are interconnected by wires. If the heating system is functioning normally, the junction of the thermocouple is heated by a pilot. At this time, the current flows freely through the coil of the solenoid valve, which ensures the open position of the valve. When the thermocouple cools, the gas is blocked by a solenoid valve.

According to the scheme of connecting the batteries they are single-tube and two-tube. In the first case, water is supplied and taken away from the radiator by means of a single pipe. In the second, the heater is connected to two separate pipelines (supply and return).

Heating pipes to batteries can be connected on the bottom, top, side and diagonal scheme

Heating circuits by the principle of movement of water in the pipes come with forced and natural circulation. With the device of the second variant, the coolant circulates in the system due to convection and gravitation. A compulsory scheme involves the installation of a circulation pump.

To ensure the normal operation of the system with two or more circuits connected to the collector, it provides for the installation of a hydro-gun. The hydraulic pointer eliminates pressure drops and the likelihood of a water hammer.

The expansion tank can be open and closed (divided in two by a sealed membrane). For gravity heating systems, there will be an open option. Closed tank For circuits with forced circulation.

When using an open expansion tank, the water is saturated with air so that it does not become a problem, the system should be supplemented with a circuit for removing it

For small cottages it will be enough natural principle water movement. However, if the residential building has two or three floors, then a pump can not be dispensed with. The length of the circulation circuit in the first scheme is limited to 30 meters. For a greater distance, the boiler can not "press" water.

With a natural circulation of the coolant in the gas heating scheme of a private house, there is no pump. If the boiler is chosen to be non-volatile, the entire heating system is independent of the power supply. It simply does not have electricity consuming elements.

On the one hand, it is more stable in operation, but on the other - the quality of heating in it is lower (the water reaches the farthest from the water heater radiators cold). Especially the latter concerns pipelines and batteries made of steel or cast iron. These materials have high hydraulic resistance, which reduces the heat carrier current.

In addition to the use of standard radiators in a country house, it is possible to organize gas heating with the help of a "warm floor" (+)

Possible and the option of organizing a combined heating system. In it, the circulation pump is connected to the main through the bypass. If you need to quickly warm up the air in the rooms, it turns on to accelerate the circulation of water. In other cases, it is cut off from the main pipe by shut-off valves, while the system continues to function in a natural (gravitational) mode.

What you need to arrange gas heating

Gasification and gas-based heating in a private house are carried out in several stages:

- Preparation and subsequent approval in the supervisory bodies of the project of gas heating.

- Acquisition of consumables, a boiler and other equipment.

- Connecting the house to the village gas networks.

- Installation of gas equipment and piping systems with batteries.

- Filling of pipes with coolant.

- Verification of operability by trial run.

Independently prepare for your a country house the project of gas heating with all schemes and calculations without a diploma of heat engineering is impossible. In addition, the documentation has yet to be coordinated with the gas specialists. It is best to entrust all these procedures to the employees of the relevant design and installation organization.

The scheme of arrangement in the private house of gas heating should be calculated to the smallest detail. If the boiler is too powerful, it will burn excess fuel. And if the capacity is insufficient, the unit will have to work at the limit of possibilities, as a result of which it will fail before the deadline.

Video reviews for those wishing to heat the house with gas

Nuances of organization of gas heating of the cottage:

Principles of coolant circulation in the heating system of a private house:

Self-assembly of various heating systems for country cottages:

Competently prepare for a private house calculations and schemes for organizing gas heating in the state only experienced heat engineer. Compilation project documentation and its coordination is best entrusted to professionals. But the further installation of the heating system can be done independently. Only the skills of installation work will be required here, as well as the strict adherence to instructions and the project.