Hand pump for water from the well. Reciprocating hand pumps. We construct the non-return valve.

The purpose of water pumps is to pump water that does not contain any solid inclusions - leaves, sand, clumps of dirt, grass, etc. Such equipment is widely used by gardeners and residents of private households for watering the garden and garden, as well as for maintenance of economic needs. A mechanical pump helps fill the summer shower and makes it possible to cook food or close the conservation for the winter even when there is no electricity. He is an indispensable assistant in the household, so there is almost every house.

Characteristic differences

A feature of a mechanical water pump is the very principle of its operation. It is activated by means of a person's physical effort, aimed at the lever mechanism or the pump button of the device. Pressing can be done by hand or foot, depending on the design of the equipment. As a result of the use of force, the flow of water through the hoses is pumped in the right direction. Everything is quite simple and understandable.The use of a hand pump for drinking or domestic water is justified with a small volume of its consumption, because for a long time a person will need to make significant physical efforts.

It should also be taken into account the fact that the speed and height of the rise of the water flow by any mechanical pump is noticeably less in comparison with the same indicators related to electrical analogues. Consequently, in most cases, its effectiveness may be negligible. But in the situation with a lack of uninterrupted supply of electricity, a hand pump will always come to the rescue, providing people drinking water, and the garden and garden - life-giving moisture.

Irreplaceable are hand pumps, installed on large plastic bottles in offices or in kitchens. They allow filling a glass or a vessel without lifting or tilting the heavy container. It is enough just to press the button to get a stream of water.

Pros and Cons of Hand Pumps

The main advantages of mechanical pumps used for pumping drinking and domestic water are:

- primitive construction;

- unpretentiousness in operation;

- simplicity in work;

- ease of installation;

- universality of nodes;

- independence from power supply;

- durability;

- economy;

- the possibility of independent production.

The last point can play a significant role in reducing the cost of the pump, but it is not always the right decision. The fact is that the docking of structural elements is often performed poorly. In this connection, the equipment is rendered ineffective. To avoid such situations, it is recommended to buy a hand pump at retail outlets. But this does not mean that home master its production is prohibited.

The disadvantages of mechanical devices for pumping water include the need for physical strength and low productivity, as mentioned in the previous section.

Classification

Until now, in the streets of the private sector, even in large cities there are water intake columns, but they have nothing in common with mechanical pumps, although they are also equipped with hand levers. From the columns, when the handle is pressed, the water is poured out under pressure created by pressure present in the centralized water supply networks. The pump, for creating internal pressure, has to be constantly pumped up, applying physical strength. And the water in it comes not from the pipes, but from a well or a well. It is interesting that both those and other devices used for water supply remain in our time quite in demand, despite the progressive development of modern technologies.

Mechanical pumps are divided into three main groups:

- piston, including rod;

- pump, or diaphragm;

- winged, or slide.

Conventional reciprocating pumps for drinking water used for bedding aquifers at a depth of less than 7-10 m. The boom equipment is equipped with rods allowing to raise water from wells with a depth of up to 30 m. The elongated rods are immersed in aquifer to a depth of at least a meter. Diaphragm pumps are intended for pumping liquid medium in water supply systems. Household compact pumps are placed on plastic containers with drinking water.

Vane pumps are a rotary mechanism in a housing with a suction pipe, lowered into a tank or a pond, and an outlet pipe connected to the hose. The water, in this case, is pumped through the rotational movement of the hand drive, without pressing the lever. Such aggregates are the most expensive of all the mechanisms under consideration.

Pumping equipment is installed, based on its operating mode and materials of manufacture. In this regard, there are several options for installing the pump. When choosing a product, it should be borne in mind that there are models on the market that can only be used in the summer. In this case, the body can be made of plastic.

Often a household pump requires a portable pump. For example, for the intake of drinking water a well is meant, and for household needs it is necessary to pump river or lake water. But more often equipment is installed permanently. In this case, the part towering above the ground is recommended to be insulated for the winter in order to avoid freezing.

Principle of the piston pump arrangement

The main elements of the most simple design of the hand pump are the cylinder and the piston inside it. By means of the drive, it is connected to the handle, which is taken out. When pressing on the lever, the piston rises, and after elimination of the force - it drops. Thanks to this movement of the working element, pumping of drinking water takes place.

In the lower position of the piston, the liquid medium enters the space above it through a special valve. When the working element is lifted up, the water enters the discharge pipe. At this point, the pressure in the lower chamber is discharged, as a result of which water is sucked from the well through the inlet valve. The water is supplied portion by piece.

The efficiency of the pump depends on the accuracy of grinding the inner surface of the cylinder to the outside of the piston.

If the working body inside the housing is not sufficiently dense, the pressure difference required for the operation of the equipment will not be created. But no less important element is the check valve. From its quality and reliability depends directly on the performance and durability of pumping equipment.

Check valves are manufactured in two types:

- membrane - from a thick rubber plate, the edges of which are raised or lowered depending on the pressure created;

- ball - similar, but with fixed edges and an additional element in the form of an ideally matched ball that opens or closes the suction opening.

Pumps for drinking water bottles

Such pumps are compact in size and installed on the bottle instead of cork. They are widely used in offices and at home. Pumps are convenient in operation - every time you press a button a certain portion of a pre-filled water is drained into a glass or other vessel.

Mini pumps are produced from food plastic. They are equipped with one or two bottoms lowered into the bottle, and a strictly vertically oriented tap, through which a mug, a kettle and even a pot are filled. A qualitative pump must have:

- filter;

- fastening ring with gasket;

- additional attachment-adapters;

- attractive appearance.

When buying any mechanical pump for drinking water, you should focus on its performance and dimensions, as well as the material of manufacture. An important criterion is brand fame, since a company that produces low-quality products is unlikely to achieve popularity.

The garden plot and the presence of a well on it are a joy for every nature lover. Especially if electricity is supplied to the village and there is a possibility to pump water for irrigation from a well with the help of a powerful unit.

But what if in the event that there is no electricity at all or was it temporarily cut down? Of course, you can carry water to the beds and just buckets, but it's tedious, and just long. Especially if the garden and vegetable lands have a large area.

We bring to your attention the solution of the dilemma - assembling the pump for water with your own hands. And believe me, such a water machine will work though slightly slower than an electric pump, but still, it's productive enough. Let's consider some variants of the pumps collected by the hands.

Feasibility of manufacturing a hand pump

Whether it is necessary to think that manufacture of home own pump is not favorable and to what will not result. Are ready to prove to you the opposite, referring to several advantages of such work:

- First, at hand, the summer house will always have a device for supplying water from the well to the top, even if the electricity is cut off.

- An important point is the economy family budget. So, tariffs for light grow, as on leaps and bounds, and the powerful pump in a working condition kicks many kw. Such cycles of pump operation, even with the purpose of watering the beds for a month can lead to a tidy sum for the average family.

Important: you can only assemble a manual piston pump with your own hands. All other types of pumps (vane, membrane, slide) are more complex in self-assembly.

The work and arrangement of a piston unit for a well

In the bulb (casing) of the pump is installed a piston, which, under the influence of physical force on the lever moves up and down. The piston has an inlet and an outlet, closed by valves. When the lever is pressed, the piston goes down the flask and opens the inlet valve. Water fills the working chamber, the pressure in it rises. Due to the pressure difference, water is pushed out through the outlet valve of the device.

Important: the pump capacity of the piston type is on average 2-3 liters per cycle (pushing the lever). But this can be increased if the cross section of the body and the piston in it is increased. Most often, such pumps are used for an Abyssinian well. But with reliable fixation of the pump it can be used with a conventional well.

Stages of work on the creation of a pump

- First you need to prepare the cylinder body. It can be made from a cut pipe of the desired cross-section. It is desirable that the diameter of the pipe is not less than 8 cm. And its length was 1 meter.

Important: The cross-section of the body for the hand pump should not necessarily be circular. It can be both a square and a polygon. The main thing then to adjust the section of the piston to the shape of the body.

- Now, to the body of the pump, you need to weld the two brackets in such a way that the future lever is placed between them freely. Brackets are attached to the top of the pump.

- The next step is drilling holes for the inlet and outlet branches. Accordingly, the holes are made in the lower and upper parts of the case.

- The lower part of the body must be closed with a lid. This can be a metal, fixed by welding, and just larch. The latter is in excellent contact with water without rotting.

- Also it is necessary to close the top opening of the bulb with a lid. This is not necessary, but the presence of the lid will increase the efficiency of the pump and prevent splashing of water at the time of its rise.

- In the upper lid make a hole for the rod. It should be in the form of a gap.

We make the piston for the pump

Now you need to make your own main working pump assembly - the piston. It should be made from such materials:

- A disc of metal, the thickness of which should be about 3-4 cm;

- The cut of dense rubber of the same section as the piston (the thickness of the material must be at least 5 cm).

- Through the entire surface of the piston (metal disk) we make holes about 1 cm in diameter. There should be several.

- On top of the disc cover with a rubber gasket and connect them.

- Through both elements of the piston in the central part it is necessary to make a cut in order to securely fix the rod.

- A rod made of metal or steel can be used as a rod. Its length should be 1-1.5 m. Pass the rod through the hole formed in the piston and fix it from below with a strong nut.

- The upper end of the rod is attached to the lever after it is withdrawn through the upper housing cover.

Make the lever

It remains to make the working lever of the pump. To do this, take a pipe 3 cm in diameter and a length of about 35 cm. One end of the tube must be flattened with a hammer and a hole is made for the bolt. In the future it is through it will be a bolt, which also will be located in the two brackets. This is how the lever is attached. The bolt is also supplied with the upper end of the rod, securely fixing it. The outer side of the working lever can be wrapped with electrical tape or put on it a piece of rubber hose for easy hand grip.

The inlet valve is assembled from a cut of dense rubber. Its diameter should be slightly less than the inlet. In the central part of the valve we form a hole and mount a guide in it. Thanks to it, the valve will always return to its place after the piston returns to its normal position.

Important: The guide must be longer than the distance from the drain pipe to the lower end of the pump body.

The finished pump is placed on a pipe, the length of which must reach the water mirror in the well. It remains to reliably fix the pump at the walls of the source to unhindered to lift water from it.

Pump that works by fire

Another simple pump design for the well. In this case it is necessary to prepare such materials:

- A metal barrel with a volume of 150-200 liters;

- The tap for the outlet;

- Water inlet hose;

- Bricks for laying a small stove.

The structure is assembled in this way:

- First, lay out a small stove from the brick so that it becomes a barrel.

- Now in the lateral part of the tank we make an inlet at the top, and in the side part below - the outlet under the tap.

- To the inlet pipe we attach a hose, the length of which will reach the water mirror in the well, to the output one - the tap.

To work such a pump will be according to the following principle:

- First, pour 3-5 liters of water into the barrel.

- In the furnace, we build a fire and wait until the water warms up well.

- Put out the fire in the oven. After that, the heated air will go into the well, and the pressure in the tank will become thinned. As a result of this phenomenon, water will flow into the tank. Once the barrel is full, you can open the tap and take water from the tank through a standard hose attached to it.

Pump on solar energy

And you can make such a pump for the well, which will work from the sun. To make it yourself, you will need:

- A metal can of any capacity (the more, the better, but, as a rule, take a tank of 50 liters;

- Rubber heating pad;

- Metal tube in the form of a lattice, filled with propane-butane;

- Two valves - input and output.

Assemble the structure in this way:

- In the can is mounted a rubber heating pad (pear), pre-hermetically connect it with a tube in the form of a lattice;

- The grill is located on the sunny side of the well, however, like the can;

- To the inlet branch pipe we fix the hose, and its second end is lowered into the well;

- The outlet is closed with a valve in the form of a tap.

To work such a self-made pump will be under the influence of heating of propane-butane in the tube. That boils at the lowest temperatures. As soon as the tube heats up, it must be poured cold water, after which the material will cool down. This in turn will lead to inflation of the pear, and water will begin to flow into the tank. The tube will again heat up and immediately cool down due to the water passing through the system. The process of uninterrupted pumping of water from the well will be ensured.

So, it became clear that it is very easy to make a pump for a well with your own hands with minimal skill.

If there is no electricity supply, a pump with an old good manual drive will help to extract water from the well or well.

Someone, without philosophizing slyly, will buy such a pump in the store, but an enterprising and diligent master will certainly try to make it himself.

After all, making a hand pump for water with our own hands, as we shall see, is not difficult.

To date, many designs have been invented that can pump water.

The most effective so far remains centrifugal pump, in which the water is pumped by a centrifugal force due to rapid rotation.

However, it is almost impossible to make such a pump by oneself, and even more so with a manual drive.

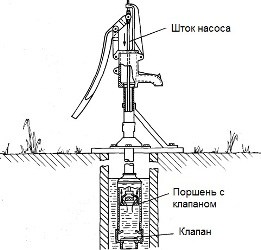

Hand pumps are mainly piston. The body of such a pump is a tube in which the piston moves with the rod. Check valves are installed in the lower part of the body and in the piston.

Moving upwards, the piston sucks into the body a portion of water, then it moves over the piston when the piston moves, and when the next rise the piston is pushed out through the drain hole. At the same time, a new portion of water is sucked into the body at the same time. The movement of the piston upward is called the working stroke, and downwards - the idling.

Manual water piston pump for own water - manufacturing options

As a body of a homemade piston pump, it is possible to use a pipe or any cylindrical shape product - a sleeve from an internal combustion engine, a hydraulic cylinder, etc. The piston can be made of almost any material. The most accessible and easy to process is a tree, but its service life is not long. The most durable and easy to manufacture is a plastic piston.

The drain pipe must be rigid (steel or plastic) or be reinforced. An elastic tube, for example, made of rubber, will be periodically compressed by atmospheric pressure.

Homemade hand pump

If the pump is used to lift water from a great depth, its stem, because of its large length, is made of light material, for example, a duralumin pipe. It is also necessary to change the ratio of the levers of the rocking arm, taking into account the increased weight of the water column, which each time must be lifted to the user.

The drive for the piston pump can be a log-swaying wave (wave pump) or the like of a swing with two alternately filled containers (a butterfly pump).

Instruction for manufacturing

The simplest wave pump can be assembled from a set that at first glance seems ridiculous:

- a tube of brass or stainless steel;

- two necks from plastic bottles (with lids);

- a piece of fine technical rubber;

- hose.

The instruction for manufacturing the device is as follows:

- In the center of each lid, it is necessary to drill a hole 10 mm in diameter.

- From the rubber cut out two valves, in shape resembling petals.

- The petals are placed in the lids so that they overlap the hole, and the narrow part is pressed against the wall of the lid. Thus, after screwing in the neck, the narrow side of the rubber lobe will be clamped, and the opposite side will be free. Such a design will only allow water to flow in one direction.

- The crochets are inserted into the tube so that one of them passes the water inside, and the second - lets out.

- It remains to secure the hose from the exit side.

If such a device is tied to a float floating on the waves, then with each downward movement it will absorb a certain portion of water, which will gradually move along the hose.

To produce a more complex variant, it is necessary to prepare such materials:

- a section of a plastic pipe for sewerage of 600 - 700 mm in length and 50 mm in diameter, as well as a tee, two plugs and seals of the same diameter;

- a piece of plastic pipe for sewerage with a diameter of 24 mm;

- two half-inch check valves;

- bolt M6 or M8, as well as washer and nut for it;

- technical rubber;

- several clamps.

The pump can be assembled in several variations.

Draining through the handle

This is the simplest version of a self-made piston pump. Its stem, made of a plastic pipe with a diameter of 24 mm, simultaneously plays the role of a drain pipe. The device is manufactured in the following order:

- In the center of the plug with a diameter of 50 mm, drill a dozen holes with a diameter of 5-6 mm.

- From the inside to the plug, use a bolt with a nut or rivet to attach a piece of fine rubber, so that it overlaps the drilled holes. This simple design will play the role of a non-return valve.

- The plug with an improvised check valve must be fixed with self-tapping screws at the end of a 50 mm sewage pipe. The joint should be sealed with a rubber seal. Do not forget that the rubber valve should be inside the sleeve.

- In the center of the second plug, it is necessary to drill a hole 26 mm in diameter. At the final stage of assembly, this part will need to be fixed on the second end of the sleeve. It will serve as a guide for the stock.

- Now it is necessary to equip the future stock ( plastic pipe diameter 24 mm) by a purchase check valve. To do this, it must be screwed onto a short steel pipe, which is then inserted into the heated pipe. After installing the branch pipe with the valve, the pipe must be pulled off with a hose clamp, which is removed only after the plastic has completely cooled down.

- The piston will serve as the upper part of the vial from the sealant volume of 340 ml. A good warm-up, it is placed in the sleeve, as a result of which the future piston will take the necessary shape. Then, most of the vial is cut off from the vial, and the apex is attached to the check valve installed in the rod. To do this, use a union nut or barrel - an external threaded coupling.

It remains to assemble the pump. The piston is installed in the sleeve, then the plug with the hole in the center is put on the rod and screwed (without sealing) to the sleeve. To the free end of the rod, it is necessary to attach the fitting to which the hose will be attached.

The easiest way to provide yourself with water on a country plot is to dig a well. : recommendations for site selection and construction instructions.

The easiest way to provide yourself with water on a country plot is to dig a well. : recommendations for site selection and construction instructions.

Tips for installing and operating a pumping station read.

Pick up submersible pump more complex than the surface, because the device is directly in the water, which is intended for drinking. Here you can see the Aquarius pumps. Consider specifications and a lineup.

Assembling the side drain

A small improvement will make the operation of the pump more convenient, since the stem will be released from the hose. The difference from the above-described design is quite small: to the sleeve from above it is necessary to attach the tee, it is possible with an oblique elbow.

Ready-made hand pump

At the same time, several holes must be made in the rod immediately behind the check valve, but so that the pipe retains sufficient strength. Now the hose needs to be attached to the tee tap - the water will go out through this hole when the piston is raised.

Spiral Hydraulic Piston

This ingenious invention is able to use the flow force to feed water over a not very long pipeline.

The drive of the plant is a partially recessed wheel with blades, rotated by a river or a stream. On its lateral surface, a plastic pipe with a diameter of 50 to 75 mm is laid in the form of a spiral. To fix it, it's easiest to use plastic clips.

To the inlet pipe (outer end of the spiral), a bucket with a diameter of 140 - 160 mm should be attached.

Hand pump at the cottage

From the spiral to the pipeline, water will flow through a special device - the so-called pipe reducer, which should be removed from the non-working pump factory-made. The reducer is installed in the center of the wheel.

This model works as follows: at the moment of rotation of the wheel, the intake branch passes a certain distance under water, capturing a certain amount of liquid. Then the branch pipe rises vertically and the water in it under the influence of its own weight rushes downward and as the wheel rotates it moves to the center of the spiral, from where it enters the pipeline.

Pump assembled from a compressor

Such a pump is called an inkjet. A similar device is whitewashed ceilings, only a vacuum cleaner is used instead of a compressor.

Such a pump is called an inkjet. A similar device is whitewashed ceilings, only a vacuum cleaner is used instead of a compressor.

All that is needed is to make a T-shaped structure of two tubes 30 and 10-20 mm in diameter, cutting a smaller tube into a larger one in any convenient place.

Now one end of a pipe with a large diameter must be connected to the outlet of the compressor, and the second - to send to the tank.

The free end of the small pipe must be lowered into the water. Due to the pressure drop in the moving flow of air (Bernoulli's law), water will rise from the source and flow to the reservoir in the same flow of air.

Vacuum pump is used for storing food products, and also indispensable in installations of fermentation and distillation. It is not necessary to purchase this unit in a store, you can try to do it. You will find the instructions for manufacturing in the article, and also learn how to fix the device in case of breakage.

Vacuum pump is used for storing food products, and also indispensable in installations of fermentation and distillation. It is not necessary to purchase this unit in a store, you can try to do it. You will find the instructions for manufacturing in the article, and also learn how to fix the device in case of breakage.

About how to independently find water on the site for the well, you will learn in the material.

Video on the topic

Although it is believed that hand instruments and equipment are "the last century", but often in the modern 21st century, they can not be dispensed with. Especially it concerns country sites, where interruptions with electricity, and sometimes its complete absence, are a common thing. And without light, you can not grow a garden-garden, nor prepare food.

In such cases, there is no sense in using electrical appliances, the hand-held equipment will just be useful here: a cooking stove or water pump to raise water and water the area.

In the article, we will talk about the varieties and principles of the operation of devices, we will analyze what kind of application is used for.

Why a manual pump is needed at the cottage

There are many cases where use is not only impractical, but even impossible. Of course, if we talk about residential a country house, then there must be electricity in it, but country plots may not always be supplied with electricity. Although residential houses are not insured against light interruptions.

Therefore, the installation of manual hydraulic equipment is necessary in the following cases:

- As a backup (emergency) unit along with the electric pump, in the event of an unexpected power outage.

- With the complete lack of power supply to the country.

- With the daily rise and consumption of a small amount of water.

- If there is a shallow well or well at the site (see).

- When using a well or a well with neighbors.

- With irregular needs in water supply.

In addition, the manual water pump has a number of unquestionable advantages over the colleagues working on electricity:

- The absence of rotating parts, which are contraindicated in solid particles.

- Simplicity of design allows using the pump in any conditions.

- Universality of units and parts - if any part of the unit fails, it is possible to select a similar replacement.

- Ease of installation and dismantling of equipment does not require the availability of special expensive tools and the presence of qualified professionals.

- Application of certain types of pumps for sources of any depth.

- Absence of financial costs in the operation of the unit, that is, there is no electricity consumption.

- Reliability and durability of the device.

- Affordable price, which is several times lower than that of other devices.

Of course, with all its merits, a manual water pump is inferior in performance to other devices that run on liquid fuel or electricity.

Important! The downside is also that some effort is required to raise water, which is problematic for children, the elderly and people with disabilities.

Types of mechanical pumps

All water hand pumps for cottages are piston, but nevertheless distinguish several types of units. Consider the device and the principle of operation of each species.

Reciprocating

This species raises water from a depth of not more than 7 meters. It consists of a lever with a piston attached to it (rod with a disc at the end), which moves inside the cylinder in a reciprocating way - up and down.

The principle of the device is as follows:

- The lever goes down, the piston rises, under the disk formed a vacuum with a rarefied pressure, water from the source through the opened valve is sucked into the lower cavity.

- The lever goes down, under pressure the lower valve closes, water from the cavity enters the space above the piston.

- The lever again rises, the liquid on top is forced into the outlet pipe, and below the valve opens again, and water is sucked in.

The cycle will be repeated as long as the lever works, once the handle stops, the flow of liquid stops. The pressure that displaces water into the outlet pipe is created at the top of the pump - at the outlet.

Rods

Manual water pumps of this type are installed in vertical wells up to 30 meters deep. The unit also includes a piston disk, but located below the rod (rod). The bar itself must be so long that the piston is 50-100 centimeters below the surface water table.

The principle of operation is the same as that of reciprocating pumps, but the difference lies precisely in the length of the rod, which, after injecting water into the over-piston space, travels a greater distance upward through the passage pipe. In other words, the sucker pump pushes out a larger volume of water for one stroke of the lever with fewer reciprocating movements of the disk.

The shortcomings of such pumps include the comparatively cumbersome structure and the frequent breakages of the rods, for the replacement of which it is necessary to partially dismantle the column.

Winged

Self-priming manual water pumps of this type are designed for lifting water from a depth of 1-9 meters. They consist of an impeller connected to a lever, and four valves. The handle, moving up and down, untwists the wing, which successively opens the valves for suction and simultaneous displacement of water into the outlet pipe.

Important! The vane pump can pump a variety of fluids, starting clean water and ending with aggressive liquids, the main thing is that the material from which the pump body is made is resistant to chemical attack.

In such cases, use alloys (stainless steel, bronze, etc.) that are stable and not destroyed from aggressive media. Pumps of this type are simple in the device and are easy to handle, repair does not require special knowledge, it can be done by one's own hands (see), the attached instructions detail all the main points to eliminate the problems that have arisen during the operation of the devices.

Membrane

Such units can pump highly contaminated liquids containing large abrasive particles. These include also known to any trucker fecal pumps. Due to the absence of friction parts, the mechanism works without interruption, in addition, the pump does not require frequent lifting and cleaning, since it is equipped with a self-cleaning piston and valves.

The membrane (diaphragm) pump body is made of cast iron or an anti-corrosion alloy, which significantly increases the service life of the unit. The depth of pumping liquids does not exceed 6 meters. The principle of operation is the same as that of other pumps - the upper supply valve, the lower suction.

Conclusion

I must say that the performance of all the types of pumps presented is almost the same, about 1 liter per second, which means that 40-50 liters can be pumped in 1 minute. This will fully satisfy the needs of watering a small area and cooking.

Modern industry produces not so many varieties of hydraulic units of this type. But all the same among the models provided, you can find inexpensive water pumps for manual dacha, which will facilitate work on the garden and vegetable garden and at the same time serve as elements of decorating the local area. Models of interesting elegant forms are produced, some even include elements of artistic cast iron.

In addition, some craftsmen make manual pumps themselves. Specialists say that this work is not difficult and even a beginning gardener can do. But this is the topic of another article.

We talked about the main types of hand-held household pumps, and having looked at the photos and videos in this article, you will get a full picture of these undoubtedly necessary units for the country plot.

Alexey 26.05.2015 Pump stations

The hand pump has its advantages over downhole type devices. When selecting them, you do not need to look for a device of a certain size, since a well can accommodate even a large-sized pump, unlike wells.

But before buying a well device it is necessary to get acquainted with its characteristics in advance, in order to obtain a manual or mechanical pump for a well whose productivity corresponds to a certain depth.

What kinds of devices are there?

Classification is conducted on different parameters. So, if we consider pumps in terms of their application, then we can distinguish the following types:

- Submersible;

- Semi-submersible;

- Surface.

Considering the first of the above options, it should be noted the convenience of its maintenance. This is due to the fact that such instruments are located on the soil surface. And it is allowed to install the pump not only in the immediate vicinity of the well, but also at some distance from it. A manual surface pump for a deep well is not suitable, since usually devices of this type demonstrate good performance only at shallow depths.

Semi-submersible option is different in that it is installed on a special "float". Its main advantage is the location of the motor above the surface of the water. This allows you to take water from the well, even with a small number of it. A device that is completely covered with water in such a situation will not be able to function, since it must be completely covered with water.

Semi-submersible option is different in that it is installed on a special "float". Its main advantage is the location of the motor above the surface of the water. This allows you to take water from the well, even with a small number of it. A device that is completely covered with water in such a situation will not be able to function, since it must be completely covered with water.

If we consider the instruments from the point of view of their constructive features, then we can distinguish the following options:

- Centrifugal pump for the well.

- Vibrating.

- Devices with vortex supply of liquid.

- Devices with screw feed water.

Of the above, the first two options are in demand. A centrifugal pump for wells is equipped with an impeller, through the rotation of which the water is withdrawn. This happens at a certain rate, respectively, the performance of the device is determined primarily by its power, at which the pump motor accelerates to a certain number of revolutions per minute. The main drawback of this type of device is the inevitable development of the mechanism nodes, and this entails the obligatory repair of the device.

Watch a video about the types and types of pumps:

Vibration pumps for wells are completely free of this minus, since their mechanism does not contain any rotation elements. The principle of operation is completely based on the occurrence of vibrational waves. A special membrane comes into motion, which is able to bend in both directions. In one position, this element sucks water, in the other, it pushes out. But even such devices have their flaws. It's about the increased noise level that the pump emits.

Screw type pumps for wells in some cases are suitable for use much more than other types. For example, if you have to work with polluted water. In such conditions, the screw device will not lose its effectiveness.

Specifications overview

Calculation of the necessary water pressure

A full choice of the device can not be done without knowledge of the values of a number of parameters, among which:

- Depth of well;

- Dynamic water level;

- Size of the ring of the well;

- Distance from the water level to the soil surface.

Of all the parameters, it is most difficult to measure the depth of the well. But even this can be done if you arm yourself with a rope with the cargo attached to it. But these efforts are worth the result, because correctly made measurements will allow selecting a mechanical submersible pump for a well with specific dimensions.

Of the main characteristics are:

- Power. The higher its value, the greater the output of the pump. This is due primarily to the intensity of the water supply, which is achieved by adjusting the pressure in the system.

- Performance. This parameter is determined by the amount of water that is pumped by the device. For example, manual type The pump for the well will not be able to provide the same performance as the automatic pump. This is due to the design features and the lack of the need to manually press the lever, as all the pump performs its actions on its own.

- Degree of intensity of pressure. The higher the productivity (and, accordingly, the pressure in the system), the stronger the pressure of the water jet. Thus, when choosing a device, these three parameters are considered in the aggregate. But we must not forget that the power, pressure, and overall performance of the device - all these characteristics must correspond to the size of the well, in particular, its depth.

- The material of the product body determines the duration of its operation. If surface pumps are chosen for wells, then it is not necessary to insist on stainless steel as the main material of the housing. Submersible devices must be made of stainless steel, because they are constantly in the water. Thus, the probability of the beginning of corrosive processes is excluded.

Models overview

Universal model - screw submersible pump NVP "Aquarius". It can be used not only for pumping water from wells, but also for use in wells. This is due to the compact dimensions of the device. The capacity of this pump is 1.15 cu. m / h. Sufficient depth is up to 32 m in one version and up to 63 m in the other. The value of the nominal value of the force of ejection of water (head) corresponds to the depth at which the device operates. The power is 550 and 1 100 W, respectively.

Watch the video about Aquarius model:

But automatic surface pumps For the wells of Grundfos models JP 5, JP 6 are much more effective, as the performance of such devices is 3.5 cubic meters. m / h. But it should be taken into account that high efficiency is achieved to a large extent by the fact that devices of this type operate at shallow depths of up to 8 m. The maximum head is 40 m. And the power of such devices is slightly higher: 775 and 1 400 W, respectively.

If you select a manual pump, then you can pay attention to the option of the device brand "Dachnaya". In one working stroke, this device pumps 1.25 liters of liquid. The depth of the well is no more than 8 m. An orderly more efficient technique is a centrifugal submersible pump for a well. The water meter 32/60 provides a capacity of up to 60 l / min. This device operates at a power of only 600 W, and the head reaches a value of 32 m.

User rating

Quite often, the model Grundfos JP 5 is chosen. Despite its modest characteristics, this device provides high performance. Buyers who have had experience with this pump model, overwhelmingly respond positively to it. Devices Aquarius and Watermelter are approximately equally in demand, as they work at great depth.

The only remark about concerns a slightly lower productivity than claimed by the manufacturer. So, for every 10 m of the depth of the well there is a slight decrease in pressure.

hand pump for water

Taking into account all of the above, it can be concluded that, with a sufficient range of device models, it is possible to accurately pick up the most efficiently functioning model, it is only necessary to take into account the size of the well.

Otherwise, the mismatch of the device parameters and the depth of the well will lead to the fact that the technician simply can not cope with its main task and the water pressure will either be too weak or, conversely, too strong. For simple needs, the least functional devices are suitable, you can even use a hand pump, if a small depth of the well allows.