Connection of a single-circuit gas boiler to the heating system. How does the DHW function work in heating boilers? Nuances of the binding device

Not all cases in the house immediately it turns out to make connection necessary communications. In most cases, the DHW is carried out at the end of the repair or in the period when the cold season approaches. As a rule, for this system, often a boiler is installed . But as you know, with constant operation this device consumes a large amount of electricity. And in order to make the water heating more economical we suggest you to understand how to connect it to the heating system. This will allow the water heater, during heating, to consume thermal energy heating and only in summer to heat water with electric heaters. Let's compare different techniques.

Connection to a double-circuit boiler

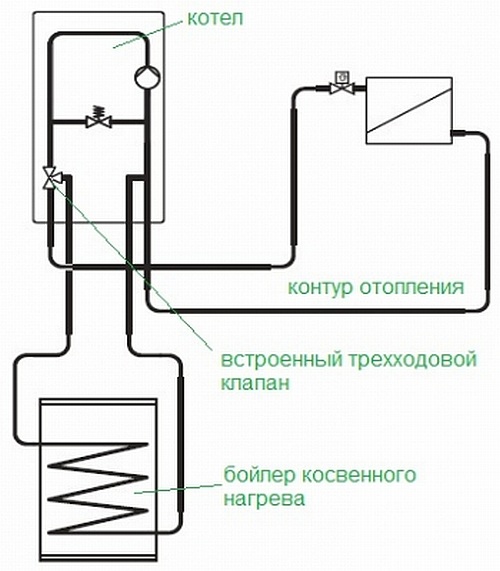

In order to water heater the heated water from the two-circuit heating system came in, a three-way tap is mounted. It switches the supply of coolant from the batteries to the water circuit coil. In such a scheme, it is important to ensure that the signal is applied to the three-way valve. Also, it is not necessary to install a coil on the coil circulation pump. The main work is done by the heating system, which contains this device. The recirculation pump is only necessary if the system includes a thermostat. As a consequence, when connecting a water heater to a dual-circuit heating system, you can select equipment based on your needs.

To increase the hydraulic circulation capacity of the heating system, recirculation pump . Due to this, it is possible to perform control / adjustment by thermal inertia, i.e. hydraulic friction heating.

There are boilers with a built-in boiler, both wall-mounted and floor-standing. Such equipment is more expensive, plus you can completely get rid of excess fittings. But on the other hand floor have built-in water heaters up to 100 liters. This imposes clear limitations. Moreover, such samples stand in the region of 60 thousand rubles. If to compare with the price of a water heater, then there is a significant difference, which varies within the limits of 4.5 thousand rubles. Considering this it is much more profitable to buy a device.

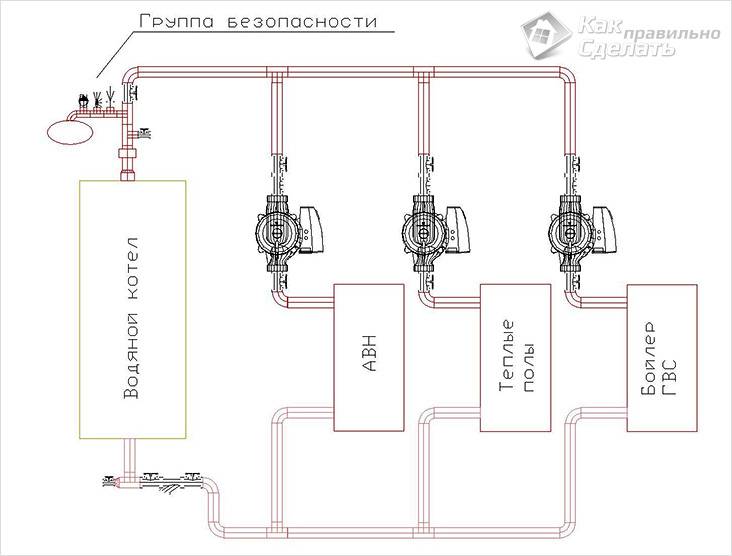

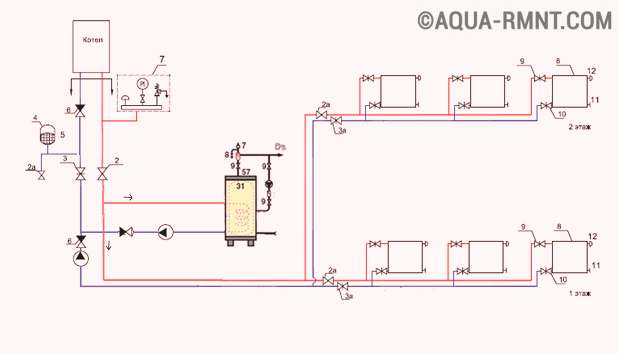

Let's compare several options for connecting a water heater indirect heating:

- Using a three-way valve.

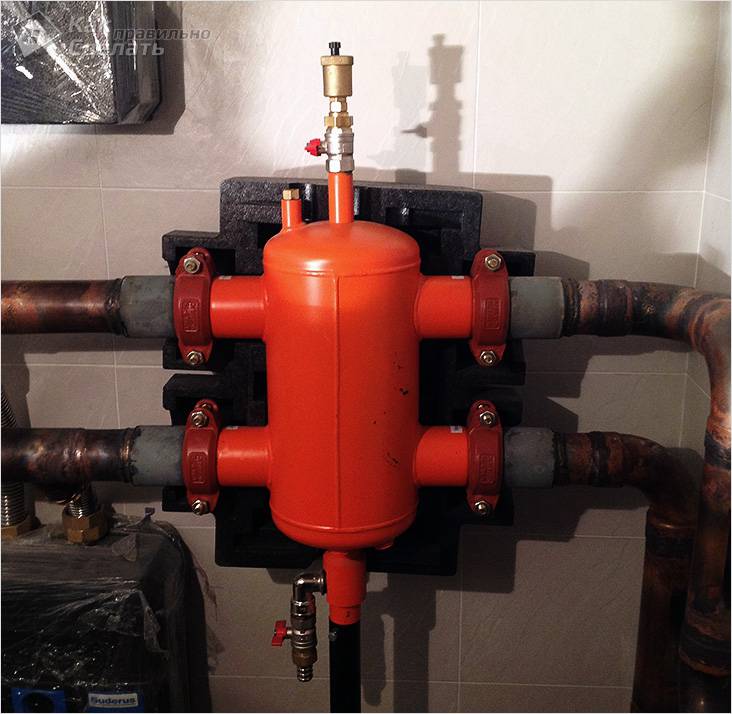

- Using the hydraulic arrow.

- The method of air circulation.

At the bottom of this method lies 2 circuits: heating from the boiler and heating. A three-way valve will distribute warm water between them. To control the valve is used automatic (thermostat). As soon as the water temperature in the heater circuit reaches the preset level, the automation will signal the three-way valve. After that, warm water enters the batteries. This method is considered the most popular.

If you set the limit temperature, it is important to consider to what extent the boiler warms up the water. Accordingly, the temperature in the water heater circuit should be set lower than in the connected device. Otherwise the coolant will be constantly sent to the water heater.

![]()

Pumps will direct warm water in different contours, i.e. the water heater is connected in parallel. Each pipeline is equipped with a pump, the operation of which is controlled by a thermal sensor.

Check Valve is introduced into the system after each pump. This will prevent conflict between the two branches.

When DHW is switched on, the heating temporarily stops working. Given the fact that the water heater is heated in a short time, hot water in the radiators does not reach a critical temperature. If two boilers are used, the DHW heating and the heating operation will be uninterrupted.

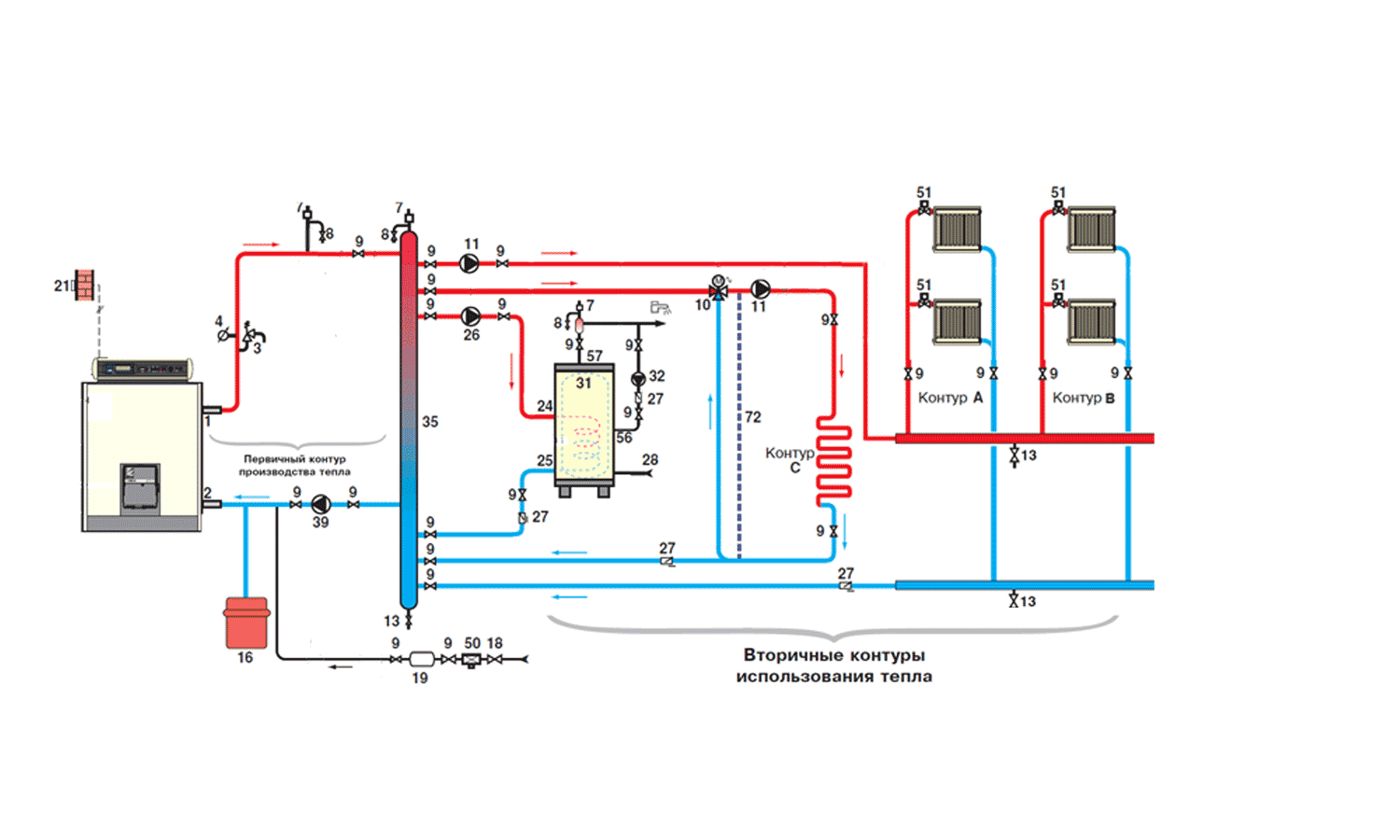

When using circulating pumps, it is important that the flows are equal. To do this, you can use the hydraulic arrow and hydraulic distributors. This is especially effective if it is necessary that the warmed-up heating medium be sent to floor heating, a boiler and radiators. To level the difference in pressure in the circuits, the parallel action of the hydraulic module with the hydrocollector. Although they can not be used, installing balancing cranes. But in this case, it will be difficult to mount and adjust the system without the help of a specialist.

This connection technique is only possible if there is a third input in the boiler. It will be possible to connect the recirculation of the coolant to it. Due to this, the process of heating water can be done very quickly. As a consequence, you get rid of the problem of draining cold water from the tap until it goes hot. This is a significant saving.

As a result, a loop will be formed along which water will be constantly (forcibly) circulated. You will also need to connect the following items:

- Expansion tank. With closed valves, a stable pressure will be maintained in the hot pipeline.

- Safety valve. It will protect the water heater from pressure surges.

- Automatic air vent before check valve. This will completely avoid the pumping of the pump before its direct start.

- Check valve. If the system high pressure and as a result the water overheats, the hot coolant will not enter the pipeline from the cold water. It is installed at the inlet to the water heater.

The maximum pressure that is allowed in the expansion tank is not allowed above the preset pressure in the safety valve.

So, we considered the main options for connecting an indirect heater. We highlight the pros and cons of this method:

Pluses:

- You can use several heaters at the same time.

- Possibility of recycling.

- The DHW and heating flows are separated.

- High performance.

- Significantly unloaded electrical network during heating.

- The internal surface of the water heater has contact with running water.

Disadvantages:

- More expenses are required for the conversion of the heating system.

- The first heating of water takes more than one hour.

- It is necessary to have a separate room in which it will be possible to arrange all the equipment.

In this case, a circuit is used where two pumps are mounted. This will completely eliminate the use of a three-way valve. A similar system has already been described above, where the contours are parallel. As soon as the thermostat is signaled, the pumps leading to the tank are turned on. Also, a non-return valve must be installed that does not allow mixing of the coolant.

With this connection of the water heater, the recirculation method is also used. In this case, the heat carrier is continuously circulated by the pump. Thanks to this, the heated water enters the tap faster.

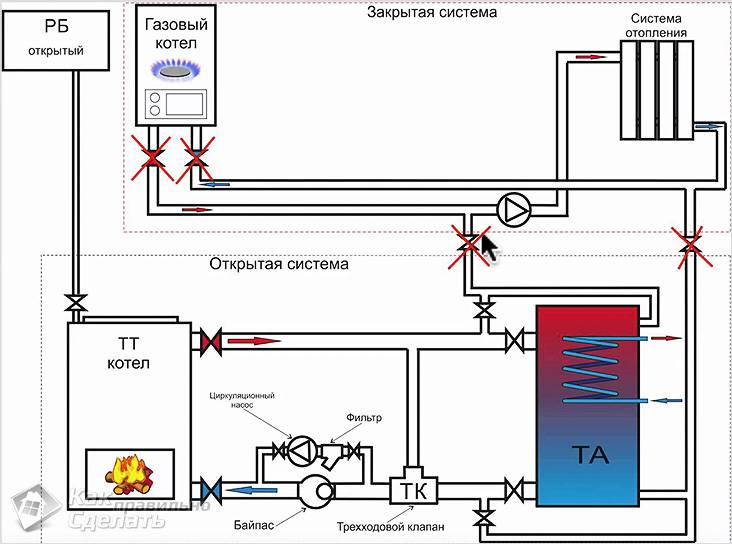

In this case it is allowed to have a system at the same time, which will allow the coolant to be dumped in emergency order and the possibility of connecting the hot water system. Often on batteries are mounted thermostatic valves, but remember the risk of overheating. If a water heater is installed, there is no such problem, because The excess warm water will be sent to the tank. But remember that such a boiler connection is possible with natural circulation.

So, the following security group must be mounted:

- Shut-off valve.

- Drain cock.

- Shutoff valve and reverse.

- Pump on the water heater.

- Flow valve.

- Safety group of the water heater.

- Expansion tank.

When performing installation work, it is important to avoid any errors. This can lead to unpleasant consequences. For example, it is important not only to take care of close location water heater to the boiler, but also to set the correct direction of the nozzles to the pipeline for easy installation. Another common mistake is the wrong connection of the pressure pipe and the coolant inlet. Cold water is always fed to the lower branch pipe, and hot water to the top of the water heater. There is also a risk of incorrect connection of the pump. It is important to observe the parameters stated by the manufacturer.

So, we have considered with you possible methods of connecting a water heater to the heating system. We hope this information will be useful for you and help you to accomplish this task yourself. We also provide diagrams and video material for help.

Video

The principle of the indirect heating boiler is shown in the video:

Those who live in a private home are forced to solve the problem of providing hot water. Usually in private houses and hot water supply is organized from a heating boiler, since there is little where it is centralized. Hot water must flow simultaneously into and out, and into the taps, therefore it is absolutely necessary to connect the boiler to the boiler.

For heating and DHW, two-circuit and single-circuit boilers with boilers can be used.

If you have one or two points of parsing, a lot of water is not required. In this case, the unit will be inside the house and your choice is a two-circuit boiler.

Double-circuit boiler in the heating systemBut for the organization of hot water and heating in a large, two-story house with a boiler in the street you need only a single-circuit boiler with a boiler. It will cost more, but if you organize a hot water supply in a private residential cottage, do not skimp on it, you will still come to this decision.

Two-circuit boilers are not designed for several bathrooms, and they should be located directly next to the place of use of water, otherwise the heat losses will be large.

Advantages of a double-circuit boiler

If you want to establish a DHW in a small or a dacha, then you can use a two-circuit unit.

A two-circuit boiler provides 20 liters of hot water per minute. He is simple and economical. In order to have hot water in the house, you just need to bring a pipe with it cold water, and then on the other hand hot water will be at the outlet.

Double-circuit gas boiler with built-in boiler

Double-circuit gas boiler with built-in boiler On sale there are units with built-in boilers. A double-circuit boiler with a built-in boiler will provide you with a stable heating of the water and will adjust the heating of the house. But, one must understand that the volume of such a drive is limited by the functionality, it is small. Even in floor boilers volume does not exceed 150 liters, and in wall-mounted and even less.

In such configurations, the heating system is a secondary function, the original place is occupied by hot water and this refers to the drawbacks of this scheme. When hot water is used for its intended purpose, it will not enter the heating pipes as a coolant. During this time, the temperature in the premises may drop by a few degrees, although this is not critical.

At the same time, it will not be possible to heat the water and let the coolant into the heating batteries.

Additional indirect heater connection

Connection of an additional boiler

Connection of an additional boiler In those private houses, which already have a double-circuit boiler and change it to a single-circuit one, it is not possible to increase the amount of hot water by connecting an additional indirect heating boiler.

This is a more time consuming process, perhaps you will need additional devices that need to control the hot flows, because they are not in all dual-circuit units. It is quite possible to buy such devices for connecting a boiler, but it is clear that such an installation will cost more.

A few years ago, this connection was a problem, now you can freely find a kit for combining two devices

By connecting indirect boiler to a two-circuit boiler, you solve the problem of recycling. That is, coming home, you can turn on the tap and from there hot water will immediately flow. And with a permanent residence in a private home, this is very important. And although the dual-circuit boiler is cheaper, but do not save on comfort, an indirect heating boiler is necessary.

Connecting the water heater to the dual-circuit fuser will occur in several stages.

Initially, it is necessary to install a boiler, then connect all the devices to a single system and connect a two-circuit boiler.

The boiler and boiler must be installed near to be connected automatic device. This connection will require a circulation pump.

If you connect a boiler, the boiler should be either solid fuel, but not electric, otherwise the boiler will take on a large amount electric power, more than a half. In this case, there will be problems with heat.

Good luck in solving problems!

A private house, country cottage or any other accommodation can be made comfortable and cozy. First of all, it is necessary to conduct communications - heating and hot water. And now, for this, you do not need to buy expensive powerful units and equip an entire boiler room. A compact gas heating boiler, connected with an indirect heating boiler, will cope with the task set. The harness can be made both at the time of installation of the boiler and after, when the need arises.

Indirect Heated Boiler and his choice

The boiler is a container for the coolant - water, with a heating element built into it. The water heater works on the principle of a drive: the water in it is constantly, and the sensors monitor its temperature. differs from direct heating boilers primarily in that it can not operate autonomously. The boiler is not connected to electricity and has no burners or furnaces. To heat water it needs a boiler. The selection of the heating boiler and the indirect heating boiler must be thought through to the smallest detail.

Must be combined and correctly selected for capacity. If the boiler's output is less than the boiler's capacity, a significant over-expenditure of electricity will be obtained, since it takes a lot of time to warm up the water. It is also important to consider that the boiler will also work to maintain the temperature, which will also affect the boiler's wear and energy consumption. The best option when the heating of water consumes no more than 50 percent of the energy spent by the boiler for heating.

When choosing it is important to check whether the sizes and types of connectors are suitable for making the strapping. Normally, standard connectors are made, but if the manufacturers are different, you need to be extremely careful, otherwise the thermal sensor, which is connected in 2 ways to the boiler or to the module, may not work correctly or not connect at all.

Gas boiler with a boiler is better to choose one manufacturer, this will save you from a lot of hidden problems that you can only learn about when you connect. If the work is carried out with your own hands, it is important to follow the scheme of the strapping at each stage. One option is to consider a gas boiler with a built-in boiler: these units are slightly larger in size, but easier to install.

Also it is important to remember the auxiliary equipment, the most important is the circular pump. The pump will "drive" the heating medium through the heating system forcibly, so the temperature will be even and in the pipes it will be less likely that air bubbles will occur. The electric pump is also convenient for rapid warming up of premises.

Constructions of heating boilers allow you to choose two versions - floor and wall. By power, they can not yield to each other, so the choice depends only on the owner's preferences. Wall units look more compact, they do not occupy useful space. As for the configuration, the wall-mounted boiler is slightly "richer", it already has a pump and expansion tank. can also have a flow or storage type of heating of the coolant.

Installation

The device of the indirect heating boiler is simple, it consists of a heating element in the form of a coil, a protective electrode, insulation, and all this is enclosed in a metal case. For the strapping, it is necessary, following the diagram, to connect the boiler to the circulation pump. Connection sequence: hot water outlet, circulation circuit, circulation pump, check valve, discharge to sewer, safety valve, a valve, a flow regulating valve, a manifold for a manometrevalent valve, an emptying system, a connection to water supply network, expansion tank of the circuit.

When connecting, it is important to remember:

- connection of cold water should be from the bottom of the boiler;

- the hot water outlet is produced from the top of the tank;

- the recirculation point should always be in the center of the boiler.

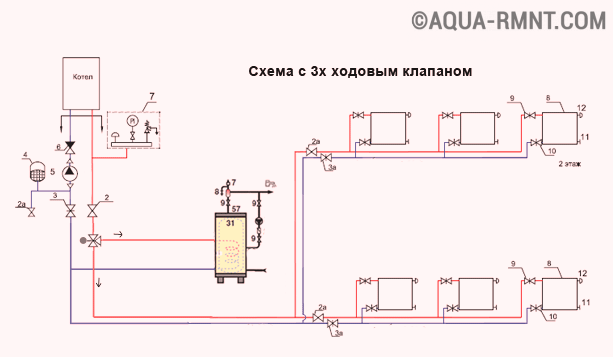

The boiler can be connected to the boiler using several schemes: use a three-way valve, a hydraulic arrow or use two pumps at once.

How to connect the boiler to the boiler using two pumps at once and is it profitable? All three connection schemes have a place to be, and the connection features for all are different. The scheme, which involves two pumps at once, differs only in that it is convenient when all the circuits are arranged in parallel; In the scheme also the use of a non-return valve is used. The valve prevents the mixing of coolant flows. Thus, it turns out that each pump of indirect heating and the boiler operates its pump, the water circulation is faster and better. The pumps are controlled via a temperature sensor located on the storage device. It is important to remember that the heating circuit is not the main one!

If the floor or wall heat-generating unit is properly selected and installed, heat and coziness must come into the house.

You can connect the gas boiler to an indirect heating boiler different ways. The task of a storage water heater is to heat up and have the necessary amount of water for hot water in stock. The boiler must be able to provide heat energy for heating appliances and a heater, for which it must have a certain power reserve. The method of tying the boiler depends on the complexity and branching of the heat network at home. In order to choose it correctly, it is worthwhile to study the drawings of several schemes for tying both units together.

Parallel switching of units

The simplest parallel circuit for connecting an indirect heating boiler to a heat source operating on natural gas is appropriate in such situations:

- the boiler is of a wall type and equipped with its own circulation pump;

- the heating system is simple, consisting of the same type of radiators, - radiators or warm floors;

- the water heater has a small volume.

Parallel piping of the boiler is simple: the upper branch pipe of its heat exchanger is connected to the supply line of the gas boiler, and the lower one from the return pipe. As a result, the circulation of the heating medium through the heating system and in the heat exchanger of the water heater occurs simultaneously and to the same temperature. Its regulation is carried out on the boiler, which creates a lot of inconvenience:

Hence it follows that the prime parallel connection The boiler of indirect heating to the heat generator is suitable for a small house with a small number of radiators.

Connection method with separating unit

To connect an indirect heating boiler with the separation of heat carrier flows to heat and hot water, a three-way thermostatic valve is used. It is installed on the supply pipe from the boiler, and the branch to the water heater is connected to the outlet branch pipe of the valve, which is initially open. The three-way valve is controlled by a remote temperature sensor. With this connection, the gas boiler with the boiler operates according to the following algorithm:

- First, when the heating medium is heating, the circulation provided by the boiler pump only occurs in the water heater circuit. The three-way valve directs the entire flow to ensure hot water supply.

- When the required temperature in the DHW circuit is reached, the sensor triggers and causes the three-way valve to direct the flow to the heating system and close the tap to the water heater.

- When the temperature in the tank drops or if there is a tap in the DHW network, the separation valve again redirects the coolant at the sensor signal to heat the water in the boiler.

Although some drawbacks of the previous connection scheme are eliminated here, this method is still suitable only for simple systems with the same types of space heating. The alternate operation of the water heater and batteries allows them to operate more efficiently, the main thing is that the boiler's capacity is sufficient. But, since the boiler is in priority before the radiators, at high costs in dHW system the heat generator may not have enough time to heat water in the heat supply network. Therefore, with a large number of people living in the house, this scheme of connecting the boiler to the boiler can create inconveniences.

Connection with two pumps

An important advantage of this method of strapping is the ability to function in the summer and provide the house with hot water when the heating is not working.

When the elements are mounted correctly, a three-way valve is not required, the flow is redirected by alternately activating the circulating pumps.

Each of them is controlled by an overhead thermostat, which fixes the water temperature in the tank of the water heater. If it is not sufficient, the pump of the hot water circuit works, the coolant works for hot water supply, and the circulation in the heat network is suspended. When the set temperature is reached, the thermostat switches off the DHW pump, after which the heat pump unit starts.

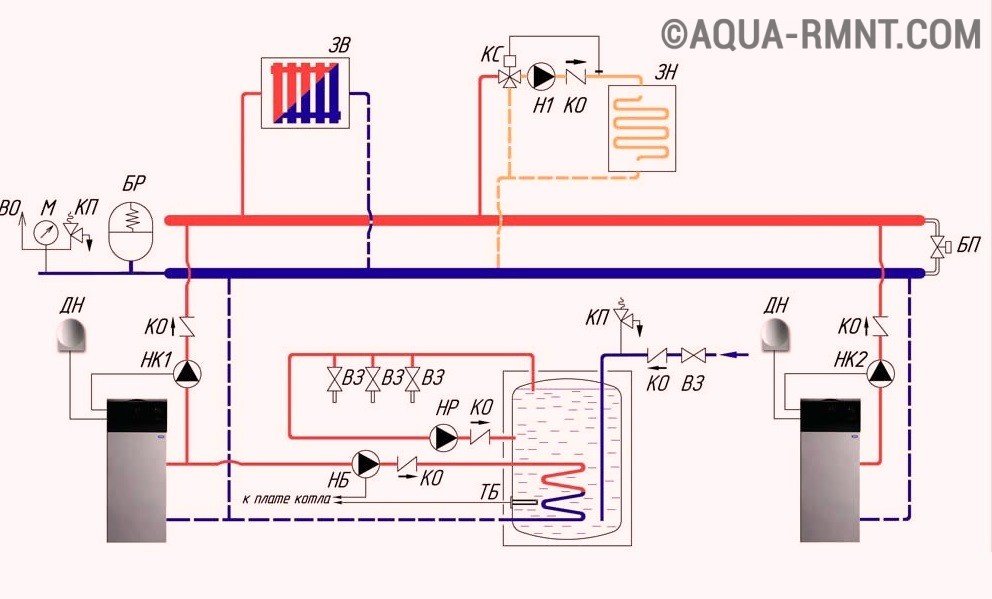

When the area of the cottage is large and it is heated by various systems - radiators, heated floors and skirting boards, then simultaneously connect a single-circuit gas boiler and accumulator water heater will not work. A branched network with several circulation pumps providing separate heating branches requires the installation of a hydraulic separator with distribution comb. To it also an indirect heating boiler is connected, and with its pump unit.

With this option, it is also customary to connect the pump to the boiler through a thermostat to save energy and not to take the coolant away from other heating circuits. This scheme has the following advantages:

- properly selected by capacity single-circuit boiler will provide the required quantity heat all branches of heating, including an indirect heating boiler;

- each branch is separated and hydraulically separated from the heat generator, therefore heating network does not affect the operation of the water heater and vice versa;

- the circuit will always work stably, even with a large water level in the DHW network, organized with hot water recirculation.

These advantages are due to the use of expensive equipment in the harness. Hence the drawbacks of the scheme - high cost and complexity of installation, but country cottage a large area and inexpensive heating - the concepts are incompatible.

How can I bundle equipment?

There is a widespread opinion that the connection of the boiler to the double-circuit boiler can be performed by connecting the DHW circuit of the heat generator with an indirect water heater. There are 2 options for the development of events:

- The family uses a two-circuit gas heater, but its performance does not suit the owner. Then he buys an indirect heating boiler and connects it to the secondary circuit of the boiler, using an additional circulating pump.

- Initially mislead the landlord acquires a storage water heater together with a dual-circuit heat generator and binds them as described above.

This method of docking the units is erroneous and will not lead to an increase in the capacity of the system for hot water. The reason - in the limited capacity of the secondary heat exchanger of the boiler, designed to produce 7-12 liters per minute of water, heated to 30-35 ° C. While the capacity of the water heater tank is from 100 liters, it is necessary to heat this volume of water to 50-55 ° С.

During the time the boiler heats up, the heating system will remain without heat, and the building will begin to cool down. When, finally, the boiler switches to heating, it will have to work at maximum for a long time to restore the microclimate in the house. Therefore, the connection scheme of the dual-circuit heat generator to the indirect heating unit does not differ from the piping with a single-circuit boiler.

Moreover, you do not need to buy a dual-circuit heat source to work with the boiler. A single-circuit gas boiler of the appropriate type is suitable here. The best option, recommended by specialists, - both units are manufactured by one manufacturer.

The indirect heating boiler has long been known as one of the better ways ensure that a private house or giving enough hot water. Quite successfully these devices are also used in apartments, offices, enterprises, etc. The principle of the boiler is so simple that it is not so difficult to make it yourself. However, the efficiency of this device depends to a large extent on how well the indirect heating circuit is selected.

Basic principles of boiler connection

The water in the device is fed to two circuits. The first is the heating circuit, which is usually connected to the house heating system. The second circuit is designed for heated water, which comes from the water supply system, and then is discharged to the bathroom, the kitchen, etc.

When figuring out how to fix, first of all, remember the following principles:

- Cold water should be fed to the bottom of the boiler, and the hot water outlet should be at the top of the unit.

- must enter the tank from top to bottom, i.e. water or antifreeze is supplied to the upper pipe of the boiler and returned to the system from the lower one.

- The recirculation point will be located in the center of the boiler's capacity.

Compliance with these principles will maximize the efficiency of the device, since the water temperature in the upper part of the boiler remains high enough, and then the coolant will heat and colder water in the lower part of the tank.

Strap options for different situations

Most often, when connecting an indirect heating boiler, three main schemes are used:

- variant with three-way valve

- application of two circulation pumps

- use the hydraulic arrow.

In addition, it is worth considering the use of a recycling system, which significantly improves the quality of domestic hot water in a private house or apartment.

How to use a three-way valve?

When you consume large amounts of hot water, the most commonly used connection is an indirect heating boiler with a three-way valve. In this case, it is necessary to create two heating circuits: the main one, which heats the room, and a separate circuit necessary for heating the water in the boiler. A three-way valve is used to distribute the coolant flow between these circuits, which is controlled by the boiler thermostat.

The three-way valve in the indirect heater circuit is used to regulate the flow direction of the coolant. The valve is controlled by a boiler temperature sensor

This system works as follows. When the temperature of the water in the tank drops below the set value, the valve directs the heat transfer medium to the heating circuit of the boiler. After the water has heated to the required level, the valve returns the flow of the coolant to the main heating circuit. In this case, the main role is played by heating the water in the tank of the boiler, and not the heating circuit.

Note! In an area with very hard water, it is recommended to use an indirect heating boiler with a three-way valve instead of a double-circuit boiler, the elements of which fail too rapidly under such operating conditions.

For correct operation of this type of system, it is very important to properly adjust the thermostat. The point is that if the maximum value of the water heating temperature in the tank is higher than the heating water temperature in the boiler, the water in the boiler will be heated constantly. Switching to the heating circuit will not occur, since the maximum temperature in the boiler will not be reached.

System with two pumps

Instead of a three-way valve, you can use a system with two recirculation pumps and a non-return valve. In this case, the installation of the indirect heating boiler also includes two parallel circuits: the heating circuit and the boiler circuit. To control each of the circuits, a separate circulation pump is used.

In the scheme of the binding of an indirect heating boiler using two circulation pumps, the heating circuit and the boiler circuit are mounted in parallel, however the main role is played by the boiler circuit

Since the hot water line has priority, the boiler circuits are installed before the pump of the heating system. For controlling the pumps, the same temperature sensor of the boiler is used, obeying the signals of which the pumps are switched on and off. A two-pump system can be very convenient when using a heating system that includes two boilers. In this case, one boiler is fully used for heating the room, and the second is connected to both the heating system and the boiler.

When the water in the boiler cools, the flow of the coolant is sent to heat it, and upon completion of the process it returns to heating system. A non-return valve is required so that the flow of the heat transfer medium does not mix.

Do not be afraid that the quality of heating of living spaces will suffer because of the use of a boiler for circuit heating. The water in the DHW system heats up very quickly, usually less than an hour. In this short time, the rooms just do not have time to cool down.

How does the hydraulic arrow work?

In modern private homes and even in ordinary apartments, the heating system can be quite complicated. In addition to the radiator line, it often includes the heating circuit of the boiler, the warm floor system, and other elements.

The hydraulic arrow in the piping circuit of the circulation pump is necessary for regulating the heat carrier flows and compensating for the pressure difference in some parts of the complex heating system

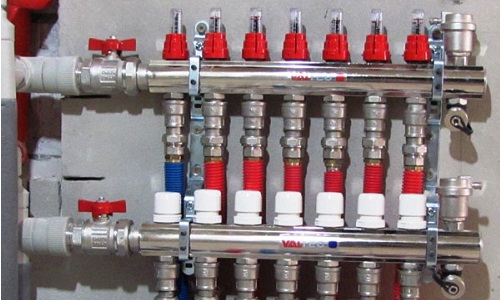

Each such circuit is provided with a separate circulation pump. In this case, the flows in different circuits of the circuit need to be balanced. To control such multi-circuit heating systems, a hydraulic distributor is used, which can include a hydraulic arrow and a collector. Neutralize pressure drops in separate circuits can also be done with special balancing valves.

The more complicated the heating system, the more closely you need to install it. It is best to instruct an experienced technician to design the connection of an indirect heating boiler using a hydraulic arrow, since it is quite difficult to adjust this system "by eye".

A few words about the benefits of recycling

To not have to wait until cold water in the tap of hot water supply it will be replaced by heated water, use the recirculation system. When it is applied, a loop is created, along which the ox constantly moves and at the same time is constantly heated, i.e., does not have time to cool down. Thus, the user receives hot water almost instantly, as soon as he opens the corresponding tap.

To create a permanent cycle, you will need another circulation pump. A very convenient addition to this system is a heated towel rail.