High pressure pump for water: self-priming and centrifugal, - an indispensable assistant for any country house. Pumps for increasing water pressure - device, types and self-manufacturing

The pump for increasing water pressure plays a key role in the arrangement of an autonomous water supply system. Its main task is to stabilize the pressure in the system. What pumps the modern market offers, and how not to be mistaken in choosing - we will consider in detail.

High pressure pump - unit purpose

Regardless of where the water comes from - from the nearest well or reservoir, with automatic feeding it in a private house an ordinary pump can help. However, for the normal operation of modern appliances in a private house requires a head of water within 2.5-6 atmospheres. This can be achieved only if tenants use a water pump to increase the pressure.

Regardless of where the water comes from - from the nearest well or reservoir, with automatic feeding it in a private house an ordinary pump can help. However, for the normal operation of modern appliances in a private house requires a head of water within 2.5-6 atmospheres. This can be achieved only if tenants use a water pump to increase the pressure.

The device of this kind is used in the case of a very low head of water, which interferes with the normal functioning of household appliances. In practice, it is permissible to install such a pump in the apartment, but only in cases where its residents experience an acute shortage of water.

The most relevant is the operation of such a pump for water supply, the head of which does not exceed 1.5 atmospheres. A compact pump can be installed not only for public water supply, but also for the output to a particular household appliance. For example, a mini pump can be installed on a pipe through which water is supplied to a boiler or washing machine. In the case of installing equipment on a common pipeline, you will have to buy a sufficiently powerful boost pump. If you want to connect the device only to the water supply of a certain household appliance, then you can do with a small, cheap unit.

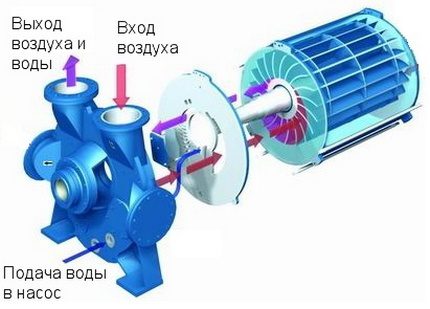

An ordinary pump to increase water pressure has a simple design and consists of several elements.

The principle of operation of the unit can not be called difficult. The injected water enters the impeller through the inlet pipe, which is driven by the motor through the shaft. Getting the required acceleration, the water is pushed through the structure into the outlet pipe, and then - it passes through the water pipe of the house.

To prevent water from seeping through the grooves between the shaft and the walls of the body, they are fitted with special rubber seals. The engine is cooled by means of an impeller mounted above the rolling bearings.

Types of pumps for increasing pressure

Depending on the type of drive, the pumps can be:

- Manual - such equipment works continuously regardless of whether there is a water pressure at a particular time. At the same time, the unit is switched off manually;

- Automatic - these devices turn on automatically when the crane is opened. The sensor is responsible for the adjustment of the automatic pump, which, when the crane is closed, turns off the unit.

By way of cooling the engine, the water boost pumps can be of two types:

- Instruments with a dry rotor - such units have an asymmetric design, which has an advantage in the direction of the power part of the pump. The motor of such a device is equipped with a wing cooler, and does not come into contact with water during operation. The unit of this type is also equipped with a cantilever lock, which allows to fix the device on the wall. Due to the fact that the motor in the design is separated by a gland seal on the axle end, this pump can last much longer than analogues of another type. At the same time, the omentum wears out with time, so it must be changed occasionally;

- Pumps with a wet rotor - these units are cooled by pumped water. The rotor of such a device is in the water, and is separated from the stator by a watertight damper. Such units operate quite quietly, they are often used for fogging. The sliding bearings used in the manufacture of the device do not need regular maintenance. However, such pumps do not create such a high head as the units with a dry rotor. In addition, there are no vertical pumps with a wet rotor, but only horizontal units.

Depending on the design, high pressure pumps are divided into the following types:

- Piston, or plunger pumps - these units are used primarily in the home to raise water from deep wells and wells, less often in the chemical and medical industries. Depending on the number of pistons and their location relative to the drive, such a pump can be one-, two- or three-plunger. Each plunger pump features high productivity and long service life;

- Membrane, or diaphragm aggregates - they relate to overall equipment. On sale you can find appliances with one or two membranes. Each diaphragm unit is easy to use and maintain. With the help of a membrane device, aggressive chemicals can be successfully pumped;

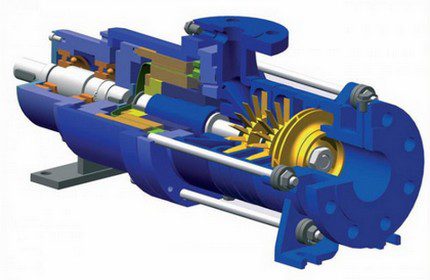

- Sectional pumps - these devices consist of several successively located impellers. Depending on the number of wheels, the units of this type can be single- or multi-sectional. Each sectional unit high pressure It is considered a professional device that gives high pressure of the liquid at the outlet. These devices are used in the industry for pumping water with a high degree of pollution;

- Vortex pumps - these units are used mainly in drilling systems, as well as for pumping liquids with high density. Such devices are small in size, easy to operate and repair;

- Peristaltic instruments are primarily mud pumps of high pressure, used for the purpose of pumping viscous liquids containing a large amount of solids.

Many of the pumps listed are not suitable for household use, since they have large dimensions. For use in a private home, piston devices are the most suitable - they are simple, reliable, but require regular replacement of the oil necessary for lubrication of the pistons.

How to make a high pressure pump by yourself - we study the order of work

The simple design of the pump to increase the pressure makes it possible to produce such a device for everyone. For work you will need:

- Several sheets of steel;

- Plastic container;

- Drill;

- Screws;

- Bulgarian;

- Rubber seals;

- Sealant;

- 2 flywheel from old mopeds;

- The motor from the old Bulgarian;

- Metal pipe;

- Several silicone hoses.

The algorithm of works is as follows:

- First, you need to weld the case - for this, steel sheets are taken and connected using a welding machine. The body must be 2 times the plastic capacity;

- After that, you need to assemble the drive. To do this, you need to take the engine from the bulgarian and connect it with a steel pipe that will serve as a shaft. At the other end of the pipe you need to make a thread and install one of the flywheels - it will serve as a working wheel;

- The second flywheel is attached to the other side of the engine, and will serve as a cooling element;

- After that, the motor is placed inside the plastic container, and all grooves are treated with silicone sealant;

Residents of suburban settlements, whose territories are not connected to the central water mains, the issue of water supply is solved by arranging autonomous systems. In the implementation of this task, a high-pressure water pump plays a key role. His main job is to stabilize the pressure in the system. What kind of water pumps is offered by the market and by what criteria to choose the equipment, we will consider in more detail.

Regardless of where the water is taken - from a nearby reservoir, a specially equipped well, a well, it can be automatically fed to the site using a conventional pump.

But for the normal operation of household appliances, the water pressure in the system must be at least 2.5 atmospheres and at the same time not exceed 6 atmospheres. And this parameter can only be achieved by means of a constant pressure system. For this purpose, a variety of high-pressure water pumps are used.

Image Gallery

When you need a high-pressure pump

The device for increasing and maintaining the head of water in an autonomous system is used when the head is so low that it is not possible to use water for the operation of household appliances. Installation of the pump is permissible, but not particularly recommended for stabilizing the pressure parameters in the apartment circuit, if the tenants are experiencing a real water deficit.

The use of the device will be actual if the pressure in the system is not more than 1 - 1.5 atmospheres. A small device can be installed both on a common pipeline and on an outlet to a separate household unit. For example, connecting to a pipe that feeds water to a boiler or washing machine.

In the first case, you will have to purchase a powerful device with good performance characteristics, in the second you can do by installing a small low-power automatic pump.

The unit can be operated by:

- Manual control - assumes continuous operation of the device, regardless of whether the water supply is currently performed, but provided that the device is switched off manually by force. Applied in the arrangement of "warm floors", where maintenance of pressure in the heating circuits at the desired level is required constantly.

- Automatic mode - the device is switched on by the automation system, for example, when the crane is opened. The work is regulated by a special flow sensor: when the crane is shut off, the pump stops functioning.

The main function of the adjustment system is to turn on the unit when the pressure drops and turn it off when it reaches the specified parameter. Indeed, lowering the pressure in the main and excessive raising it destroys the pipe joints and has a disastrous effect on the work of household appliances.

Alternative measures to increase the pressure

However, the installation of a pump designed to stimulate pressure will be completely useless if the source has a low production rate. It will not help, and if the system from time to time overlap. The optimum solution in this situation will be the use of a self-priming pump station.

The pump station is completed on the basis of the same category of pumps equipped with or without injectors. In addition, it is supplemented by a hydraulic accumulator designed for water storage. It looks like an ordinary tank, only inside is a rubber membrane with air. Controls the set of equipment and devices of the water pressure switch.

During operation of the plant during the period of uninterrupted water supply, the pump fills the storage tank with water, from which it subsequently consumes

The installation of a self-priming pump station is also effective when the pressure in the ground floor of the house is normal, and on the above there is absolutely no pressure.

Accumulated water in the future can be used regardless of whether there is water in the system, which is especially important with frequent interruptions with its supply. A significant disadvantage of such installations is the cumbersome structure due to the presence of a hydraulic tank and the noise of the equipment during operation.

Instead of a hydraulic tank, you can use a conventional storage tank, in which water will be accumulated during the delivery period with a normal head. It can be installed on a high overpass or on the roof of the house, and during the interruptions use a stock.

One of the options for eliminating the problem of lack of pressure is the installation of a storage tank

Types and operation of high pressure pumps

Before the decision to establish stimulating pumping device it is necessary to assess the condition of the pipeline. It is possible that the pressure deficit is due to pipes clogged up by the sediment. If you can get out of the predicament only by installing the device, then with their technical specifics is worth exploring in more detail.

The principle of operation of high pressure pumps, regardless of the version of the working element and the type of construction, is the same. The device during the functioning of the working unit creates a vacuum inside the cavity, due to which the water is sucked.

By creating a vacuum space, water is "drawn" from the source into the chamber, and then, under the action of high pressure, is pushed through the outlet pipe

On sale are models of universal type, suitable for water of any temperature, and those that can be used only in cold or only in a hot environment.

Depending on the method of cooling the running motor, the units are of two types: with a dry and with a wet rotor.

Dry Rotor Units

Modifications with a dry rotor are difficult to confuse with wet analogues. They have an asymmetric shape with an obvious advantage in the direction of the power part of the device. The fact is that its engine is equipped with a vane cooling device. Do not wash in the process of working with water.

Because of the asymmetric shape and displacement of the axis towards the motor, the "dry" models are equipped with cantilever devices for additional fixation on the wall.

Pumping units equipped with a dry rotor are famous for their high level of productivity and are used, if necessary, to supply large areas of water

Due to the fact that the engine in such models from the hydraulic part is separated at the end of the axle by a gland seal, they serve much longer "wet". True, the sealant, like the rolling bearing, has the property of wearing out and needs periodic replacement.

For this reason, units equipped with a dry rotor require more frequent maintenance and regular lubrication of friction parts. Another disadvantage is that the "dry" devices are noisy, therefore the place for their installation should be carefully thought through.

Devices with a wet rotor

Flow-through units assume cooling by pumped water. In this case, the rotor of the device is placed in an aqueous medium and is insulated with a waterproof damper from the stator.

Units with a wet rotor are distinguished by a low level of generated noise interference. They are often used for water supply systems for heating residential premises.

Devices of this type have a modular design, so that they can be easily disassembled into component assemblies if you need to replace a single element

The sliding bearings used in the assembly do not require additional maintenance. However, "wet" pumps serve less and lose to "dry" units in terms of parameters created pressure. There are restrictions in the direction of installation - it can be extremely horizontal.

A significant drawback of pumps of this type is the vulnerability when working with dirty water, foreign inclusions of which are able to disable the device.

Division by the method of creating a vacuum chamber

The mechanism of operation of this type of device is based on the displacement reaction. The pumping process is carried out under the action of changing the dimensions of the working chamber. The magnitude of the vacuum formed directly depends on the degree of tightness of the working chamber.

The amount of vacuum can be adjusted. Due to this, the pressure in certain places of the system can increase, or, on the contrary, decrease.

Vacuum pumps in most configurations are in the form of a cylinder, inside of which a shaft equipped with impeller or an impeller

The shaft is the leading working tool of the mechanism. The impeller equipped with blades performs rotational movements. Under the action of circling blades, the liquid in the working chamber is captured. As the rotation is formed, centrifugal force is formed. It also leads to the formation of a liquid ring. The empty space formed inside the ring is a vacuum.

Depending on the methods by which a vacuum chamber is created, high-pressure water pumps are centrifugal, vibratory and vortex pumps.

Devices of centrifugal type

Centrifugal pumps are the most common type of pumping devices capable of providing high pressure in the system. They pump water by rotating the impeller inside the helical body. The impeller consists of two bonded discs, between which the blades are fixed in the direction opposite to the flow of the incoming liquid.

Centrifugal stations are equipped with hydraulic tanks, providing a supply of water in case of shortage and pressure drops, and automatic control devices

In the process of rotation, a centrifugal force is formed, which also stimulates the displacement of water flows from the center of the chamber, flipping it back to the far areas. Due to this, the pressure level in the center of the rotating impeller is lowered, and water begins to flow into the interior of the housing.

Centrifugal instruments in most versions are supplied with accumulators. With pressure pipelines they are connected with the help of nozzles of different diameters.

If the volume of the pump tank is insufficient, it can be used as an aggregate supplying water to a storage tank

The equipment of the centrifugal type is capable of ensuring uninterrupted supply of water at high head. The only condition of operation is that when the unit is started, it is necessary to fill the housing with water. The centrifugal variety has limitations: they can not pump water from a depth of more than 8 m, but as a supplement in the system of increasing pressure from several pumps and accumulators are quite suitable.

Image Gallery

![]()

Vibration Electromagnetic Pumps

Principle of operation vibrating pumps based on the ability of the magnet by alternating current alternately draw to itself, and then release the tandem anchor-piston. Changing the polarity of the anchor makes alternating movements. Within one second, the position of the anchor can vary several dozen times.

Due to the absence of vibrating type of rotating parts in electromagnetic devices, they are considered to be the most reliable and durable

As a result of vibration vibrations, water is first sucked into the working chamber and then pushed through the valve into the discharge nozzle. Vibration unit can work in pairs with a centrifugal colleague or inject water into the storage tank.

Vortex pump models

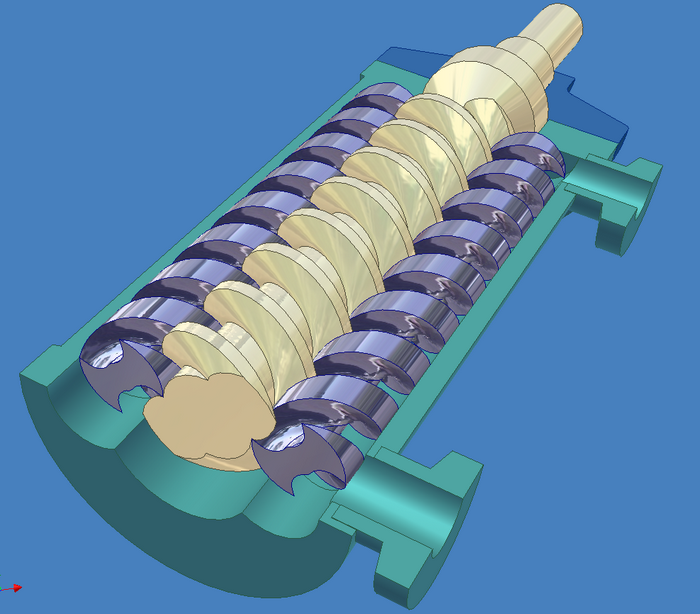

In the cavity of the body of such units is a flat disk equipped with radially fixed blades. Rotation of the wheel with peripheral blades and creates a vacuum.

Under the action of rotation of the disk, the liquid enters the specially designed cavity of the body, and then, passing through the chamber, is pushed outwards

Vortex devices are famous for their high suction power. They do not fear the presence of air bubbles in the water. But they are vulnerable to the presence of suspended particles in the liquid and therefore have a limited field of application. Since vortex devices break down quickly when pumping dirty water, they are not recommended for use in the arrangement of sand wells and wells.

Leading manufacturers and popular models

Among the tested global brands that are most popular, it is worth highlighting:

- «Grundfos» - The Danish company relies on pumps that have circulating system Work that is small in volume.

- CatPums - A feature of the equipment produced under this brand is the low pulsation of the mechanisms at the highest possible pressure.

- Wilo - The German concern specializes in the production of small-sized pumping stations equipped with built-in hydraulic accumulators.

- Sprut - a feature of pumps to increase the pressure of this brand is the requirement for cleanliness and water temperature.

The manufacturers listed above make their products according to the proven technology, which guarantees the reliability of the pumping equipment. They have protection against overloads, cycling and "dry running".

The price range of low-power models of pumps varies between 30-50 USD. More productive samples, equipped with automation system, can be purchased in the area of 70-100 USD. Pumping stations will cost around 80-150 USD.

Compact and small in weight units are convenient to use both in the arrangement of individual water supply, and for operation in an apartment

Among the models of the middle price segment, they proved themselves well:

- «Sprut 15WBX-8» - a single design with a dry rotor has a capacity of 480 l / h with a power consumption of 90 watts. A small-sized small device is placed directly on the pipe.

- «Euroaqua 15WB-10» - the vortex electrical unit can easily cope with a liquid that contains air or gas.

- Cristal 15GRS-10 - the model is famous for its low energy intensity and high efficiency, it is distinguished by its ability to heat the water flow up to 65 degrees.

It is not worth saving and purchasing Chinese counterfeits. Repair their master is not taken. Unfair producers collect them in such a way that the failure of an individual element immediately leads to the need for a complete replacement of the unit.

Features of the choice of equipment

When choosing a pump, it is worthwhile to focus on a number of parameters.

Determining unit capacity

This parameter depends on the task assigned to the pump and the required water flow. When calculating the total water consumption, household and household needs are taken into account, based on the total values of the maximum water consumption of all functioning points of consumption for one time unit.

Determine the ratio of performance and pressure of the device will help the schedule, which most manufacturers attach in the instructions to pumps

The pumps of the middle price segment suffice to raise the pressure by at least 1-1.5 atmosphere. If this is not enough, the system is supplemented with pressure boosting pumps or stabilizing reducers.

Budgetary variant of pressure increase - installation at the point of entry of the system into the house or apartment of the reducer

When choosing an aggregate, it should also be taken into account that the productivity of the transferring device does not exceed the productivity of the well or well. Otherwise, if the source is rapidly emptied and its replenishment is not timely, the equipment will simply run dry. And this can lead to its breakdown.

This parameter specifies the height in meters, on which the unit is capable of lifting water. When determining the required head, account should be taken of the horizontal distance of the water supply and the standard pressure loss during its transportation through the pipeline. If this parameter is calculated using a simplified formula, its value is taken equal to one tenth of the total length of the horizontal trunk.

For example, when building a well 10 meters deep to supply water to the house located 12 meters from the water intake, if the facility is placed on it at a height of 4 meters from the ground, the aggregate head is calculated by summing the values: 10 + 4 + (12:10) = 15.2 meters.

But in order to obtain more accurate calculations, one should also take into account the diameter of the pipeline and the loss of head when lifting water through the pipes, as well as passing it through turns and knots. After all, if there is insufficient pressure, the outlet pressure will be low. For this reason, when adjusting water intake systems, pumps are selected that are capable of maintaining the system pressure within 2-6 bar.

It is not necessary for household needs to choose units with higher indicators, because creating increased loads, they are capable of provoking rapid wear of the pipeline and sanitary equipment

When choosing equipment, it is also worth considering:

- operating temperature range;

- the noise level created during operation.

Electric models and liquid fuel units are on sale. The first eat only from electrical network. They can be two- and three-phase. The second ones are equipped with an internal combustion engine. As a fuel, they use diesel or gasoline.

The presence of an automation system significantly increases the cost of equipment. But the high price of automated mechanisms that have a high level of electrical protection, fully pays off, since devices of this type are more sensitive to changing situations and consuming less electricity.

Video reviews of high-pressure equipment

Video review of the pump to increase the pressure:

The variant of arrangement of the system with the use of a system that increases the water pressure:

The assortment of pumping equipment is on the market in a wide range. But experts recommend buying it in branded stores. Qualified advisers of salons will help to choose the best option depending on the tasks assigned and will provide warranty service, which is especially important when buying expensive equipment.

As you know, without water, and neither there, nor syudy. For residents of holiday villages and not covered by the centralized water supply system of private houses, these are not just words from a song, but a sad reality. And even if there is a water supply in the village, in the summer, life-giving moisture often has to be guarded at night, as there is not enough pressure for everyone in the daytime.

In any case, despair is not necessary. High pressure water pumps installed in the well or installed in the system solve such problems in two counts.

Pumps for individual water supply systems

Regardless of where you get the water - from the well (see), the well or the nearest water body - its automatic feeding to the site and to the house with optimum pressure can only provide a properly selected pump.

Parameters required for selection

You can not go to the store and buy any pump simply because you are satisfied with its appearance or price. It must be selected according to the parameters appropriate to your needs and the source of the water.

These include:

- Performance. It depends on the amount of water you need, which consists of household and household needs. And calculate it based not on the accepted standards, but on the maximum consumption of all points of water consumption per unit time. In other words, you need to add the number of liters that follow in one minute, for example, from a tap in the kitchen, a shower head and a watering cock in the courtyard, add to it the consumption of the washing machine in order to get the maximum flow, provided they are switched on at the same time. The obtained value will serve as a reference point when choosing an aggregate with the required capacity.

Note. The performance of high-pressure water pumps should not exceed the productivity of a well or well. If the source is emptied faster than replenished, it will cause the equipment to run idle and its failure. How to solve this problem, we will tell just below.

- Head. This is the height in meters, on which the device can raise water. But in order to calculate the required head, it is necessary to take into account the distance of its supply horizontally. According to the simplified formula, it is assumed to be equal to 1/10 of the length of the horizontal line.

Example. To feed water from a well 10 meters deep to the second floor of the house, located at a height of 4 meters from the ground and 12 meters from the well, the minimum pump head is calculated as follows: 10 + 4 + 12/10 = 15.2 m.

In fact, it should be higher, because this formula does not take into account the pressure drop when passing water through pipes, nodes and turns, the diameter of the pipeline and many other indicators. But the most important thing is the required outlet pressure.

And it will be low if the pump you select has insufficient head pressure. That is why for comfortable use of the water supply system it is necessary to choose a high-pressure water pump - the device of this unit allows to extract water from great depths and supply it to consumers under sufficient pressure.

For reference. For stable operation of water-separating devices and household appliances, the pressure is considered to be not less than 1.5 and not more than 3 bar. Higher values lead to rapid wear of pipes and sanitary devices experiencing increased loads.

Types of high-pressure pumps

The choice of the unit should be based not only on its technical parameters, but also on the design, the ability to work under certain conditions.

The most popular types are:

- Vibration (see). The principle of operation is based on the ability of a magnet under the action of alternating current to attract and release the anchor connected to the piston. Within one second its position changes several tens times. As a result of such vibration vibrations and pressure changes in the working chamber, water is first sucked into it, and then discharged into the pressure pipeline. The absence of rotating parts makes this type of device reliable and durable.

- Vortex. In the cavity of the body of this unit is a flat disk with radially located blades. Rotating, it displaces the liquid outward. Such pumps have a high suction power and are not afraid of air bubbles in the water. But quickly fail when pumping a dirty liquid with a high content of suspended particles. Therefore, the instruction does not allow their use in wells and sand wells (see).

- Centrifugal (see). Pumped water due to the appearance in the working chamber of the areas of high and rarefied pressure created when the impeller with blades rotates. This is the most common type of pumps that provide high pressure in the network.

All water pumps are classified and by other attributes. For example, there are surface and submersible models (see).

The first work, being installed outside the source of water, on the surface of the earth. The second ones are immersed in the pumped liquid. They have higher values of pressure and pressure.

Also, water-lifting devices differ in the type of actuation to manual, electric, fuel-powered. The most popular ones are electric, operating from 220 V. But there are also models capable of operating from a car battery or other device giving a voltage of 12 V.

Pumps for increasing pressure in a centralized system

If your house is supplied with water from centralized system, but the pressure in the pipes is not enough for normal operation washing machine or a shower cabin, it is possible to correct the situation by cutting a water boosting pump into it.

It is installed on the input and either turned on manually when necessary, or equipped with an automatic adjustment system. It turns on the device when the pressure in the network drops and turns off when it is sufficient.

Note. Such units are also suitable for increasing the pressure in an individual water pipe, if the water-lifting pump does not cope with the provision of a normal head.

There is nothing difficult to install a high-pressure water pump with your own hands. To do this, cut the pipe section and weld to the ends of the adapter with a thread.

But this device will be completely useless if the water is simply turned off for a while during the day or if your source has a low production rate and is not able to provide the maximum flow.

In such cases, pumping station with a storage tank - accumulator. In the period of normal supply, the pump will fill it with water and you can expend it, regardless of whether there is water in the system.

Unfortunately, such a station takes up a lot of space, and during operation it produces a noticeable noise, so installing it in small apartments is problematic. But here everyone decides for himself what is more important for him - silence and spaciousness or normal water supply without interruptions.

Conclusion

Perhaps, this is all that an ordinary consumer should know about high-pressure pumps. Their choice according to the parameters is better still to be entrusted to the specialists, providing them with all available data on the source, water quality, availability of electricity, etc. But, if you want to get more information, watch the video in this article.

Water along with air and earth are elements that are probably the most familiar for us, which, we think, does not need to be studied. But this is not so! The powerful magical energy contained in these natural resources is, indeed, amazing. It is necessary to be able to use it for the good of mankind. High pressure plunger pumps - here is a tool for decorating this element. Using them, a person, as if with the help of a magic wand, creates real miracles.

Plunger pumps for water

Interpump Group is a company that works with water and is the world's largest manufacturer of high-pressure plunger pumps. It was founded in 1977, at the initiative of Fulvio Montipo. He made significant technical changes in the design and construction of high-pressure plunger pumps. They introduced radical innovations, thanks to which, produced by the company plunger pumps for water became more compact, quiet and easy to maintain. Another element of these innovations was the completely ceramic piston group, which provided a higher reliability to the plunger pumps for high pressure washers , in comparison with the analogs in the steel version. Thanks to this approach, the company Interpump Group, to date, is recognized as the benchmark in its field, producing plunger pumps for water. World leadership is maintained due to quality standards, which guarantees full control over the production process, starting with raw materials ending with the finished product.

Pump for washing

The main part of any high-pressure apparatus is washing pump. Without which, no washing machine can perform its functions. It is the pump for washing that creates the necessary pressure, by means of which water turns into a powerful jet. In the assortment of our company you can find pumps for sinks of different characteristics and, consequently, for different purposes. We can offer you both ready-made solutions for popular ATS, and design stationary washer High pressure with any characteristics you need.

High pressure washers for washing

All components of the high-pressure pump for washing are made of high-quality materials that are systematically checked and tested at every stage of production. The audit is conducted with the utmost precision, in order to ensure that the final product is resistant to severe wear during operation in industrial conditions, including car washes.

Scope of sump pumps

Annovi Reverberi produces high-pressure pumps for car washes with pressures from 50 bar to 4000 bar, with power consumption up to 750 kW. High-pressure plunger pumps are used to clean most surfaces. Including surfaces of ships and pipelines. And also for cutting and removing concrete, asphalt, paint, cement or metal surfaces. The ultra-high pressure pump is used in the following sectors of heavy industry: construction, ferrous metallurgy, chemical and petrochemical industry, as well as for water purification.

Among other things, high pressure plunger pumps have proven themselves in the chemical industry. They are used for pumping chemicals, fuel and other corrosive liquids.

A dacha or private plot requires the supply of water. Otherwise, all the pleasure of staying outside the city will be reduced to zero. To create a private water supply line in country cottage ideal is a high-pressure water pump that will cope with lifting and transporting water through the pipeline system.

The use of such powerful, but small-sized equipment allows you to equip the communication system with your own hands, without involving specialists. We will tell you about what kind of high-pressure water pumps there are, and what their characteristics are, in this material.

Important: the main advantages of high-pressure units for the garden, garden and suburban area are:

- A wide range of pumps, which allows you to choose a model that is ideally suited to the specified operating parameters.

- An acceptable pricing policy for each type of unit.

- Economical energy consumption with high enough equipment performance.

- Ease of operation and installation. Install a high-pressure water pump can be done quickly and easily with your own hands.

Principle of operation of units

The unit at the time of continuous operation with the help of the working unit creates a vacuum space in its cavity. In this space, water is taken from the source and subsequently pushed out through the outlet branch pipe under high pressure.

It is important that with the same operating principle, all high-pressure water pumps differ in performance characteristics. Namely: working environment, productivity, ways of creating a vacuum chamber.

Types of high-pressure units

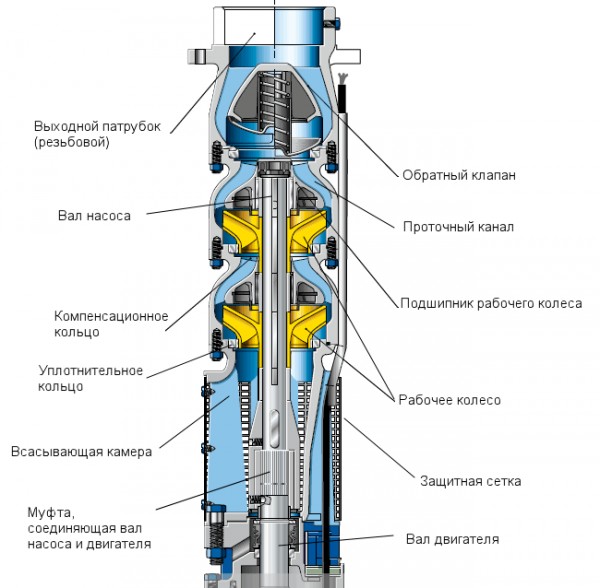

Screw Models

This type of high-pressure pump operates on the principle of rotating the Archimedes screw. A vivid example of such a device is a banal kitchen chopper. The screw in the device is located vertically and produces rotations up to several hundred per minute. Due to this work, water accumulates in the cavity of the pump and is pushed outwards upwards with a predetermined head.

Such devices are most often submersible and are used to lift water from a well or well. Use a similar device for very dirty water, installed by yourself, is not recommended.

The advantages of a screw pump are:

- Low noise level during operation;

- Compact size;

- The ability to pump water from wells with a sandy or muddy bottom. Because the screw-type high-pressure water pump is capable of processing water with a small amount of sand inclusions.

Important: it is the screw pump that has a minimal destructive effect on the walls of the well.

Centrifugal unit

This device is also called vortex. The working pump assembly looks like a horizontally located wheel with blades. At the moment of switching on, the unit makes the maximum number of revolutions per minute, creating water injection into the cavity of the pump under the influence of centrifugal force.

It should be noted that the vortex pumps can be both submersible and superficial.

The positive sides of the centrifugal unit are:

- High performance;

- Possibility to pump water with the inclusion of oxygen bubbles;

- Possibility to install the equipment yourself.

Important: in some models, the impeller may be located vertically. Regardless of the type of construction, all the vortex pumps are bad for water contaminated with particles of sand or silt.

Vibration device

The noisiest of the pumps for water. Here, high pressure is created by the working electromagnetic field, which causes membrane contractions. As a result, water is taken from the well or well to the pump cavity and then transported under high pressure to the water intake pipe.

The main advantages of vibrating pumps are:

- Compact size;

- High performance;

- The ability to install such a device with your own hands, even in the narrowest 4-inch well.

Important: vibrating pumps are quite noisy in operation. Therefore, it is desirable to use such mechanisms in sources located farther from the dwelling. Or to put on a borehole (for a well to mount by own hands a special small house with doors).

Hand pump

One of the most reliable and simple devices that does not require the presence of electricity in the network. For all the simplicity of the construction, such a mechanism manages to supply water from a depth of up to 20 meters, and feed up to 2 liters of water in one pressing cycle. It refers to piston pump, installed by their own hands.

Winged Hand Pump has smaller dimensions and supplies water from the same depth, but in a smaller amount.

Important: hand pumps ideal for self-installation on an Abyssinian well, operated periodically.

In addition to these water devices, circulating pumps and drainage / fecal pumps can also be used. In the first case, the high-pressure pump drives the coolant (water) under high pressure in a closed loop. Thus, the distribution of heat throughout the house is ensured with a uniform index.

Drainage pump (as well as fecal) are called to pump out dirty water from septic tanks, drainage pits, flooded cellars, etc.

Importantly: the average cost of high-pressure water pumps varies in the Russian market from $ 60 to $ 300 per unit (depending on the model). The cost of a particular unit will be affected by its performance, brand and availability additional functions and protection systems.

How to choose a water pump?

High-pressure units must be selected very carefully. Since the pump bought and installed by own hands with improperly selected working parameters not only does not give the expected result, but also will soon fail. Therefore, when choosing a high-pressure pump, consider these points:

- Equipment power;

- The necessary amount of water per day is for your family;

- The production rate of a well or well (since it is silly to require more water from a source with a powerful pump.) The well will simply dry out).

- In addition, carefully approach and to the diameter of the pump. This is especially true for narrow wells. It's unlikely that you will be able to install your own hands a wide pump into a narrow well. And money will be spent.

Remember: a competent choice of a water pump will ensure to you and your households the constant availability of water in the water supply system.

Popular manufacturers of pumping equipment

In the Russian market there are several brands of pumping equipment, which have proved themselves on the positive side.

- The most popular is "Grundfos" from Denmark. The brand has existed for more than 60 years and during this time gathered its regular fans. Products "Grundfos" is distinguished by its reliability, quality and durability with modest dimensions.

- Wilo devices captivated the hearts of consumers with their low-noise operation and low power consumption. Wilo water pumps are successfully used in all sources, featuring high performance.

- The "Körcher" equipment also excels in lifting and transporting water under high pressure. The German quality of the mechanisms makes it possible to provide pumps with a long service life and trouble-free reliable operation.

Important: if you doubt the choice and are afraid that you can not cope with the installation of the pump yourself, then it's better to invite professionals. Specialists will help pick up and mount the pump in the shortest possible time.