Open heating system with natural circulation. Single-tube and two-pipe construction. What it is

Modern homeowners often choose heating systems that function through natural circulation. Modern pumps are expensive, and gravity is a cheap driving force, because of which there is a natural circulation of water in the heating system and water moves through the pipeline. Gravity circuits are used where there is no electricity to power the pump. Sometimes the pump is still present, but in the event of an emergency situation and switching off under the influence of gravity. That is, even when electrical equipment does not work, heating with natural circulation continues to function.

This variant of the heating system is perfect for cottages, the area of which does not exceed 100 sq.m.Minus the design - the inability to use it in rooms with large squares. But for cottages with an area of less than a hundred square meters. m, this option is great. For this reason, many homeowners decide to make heating with natural circulation without outside help.

Principle of operation of a gravity heating system

The principle of operation of heating looks simple: water moves through the pipeline, driven by hydrostatic pressure, which appeared due to the different mass of heated and cooled water. Another such design is called gravity flow or gravity. Circulation is the movement of the liquid cooled in the batteries and the heavy liquid under the weight of its own mass down to the heating element, and the displacement of the lightly heated water into the supply pipe. The system functions when the boiler with natural circulation is located below the radiators.

A natural circulation is also possible in closed system Heating, if it is equipped with an expansion tank with a membrane. Sometimes open-type constructions are converted into closed ones. Closed circuits are more stable in operation, the coolant in them does not evaporate, but they are also independent of electricity.

What influences the circulation head

The circulation of water in the boiler depends on the difference in the density of the hot and cold liquid and the difference in height between the boiler and the lowest located radiator. These parameters are calculated before the outline. Natural circulation arises, because the return temperature in the heating system is low. The coolant manages to cool down, moving through the radiators, becomes heavier and massively pushes out the heated liquid from the boiler, forcing it to move along the pipes.

Circulation scheme of water in the boilerThe height of the battery level above the boiler increases the head, helping water to overcome the resistance of the pipes more easily. The higher the radiators are in relation to the boiler, the higher the height of the chilled return column and with the greater pressure it pushes the heated water up when it reaches the boiler.

Density also regulates the head: the more heated the water, the less its density becomes in comparison with the return. As a result, it is pushed out with more force and the head increases. For this reason, gravity heating structures are considered to be self-regulating, because if the temperature of the water heating is changed, the pressure on the coolant will change, and, therefore, its consumption will change.

During installation, the boiler should be positioned at the very bottom, below all other elements, in order to ensure sufficient pressure of the coolant.

Scheme of installation of gravity heating systems

Since the circulation of water in the heating system takes place without the participation of the pump, for unhindered flow of liquid through the mains, they must have a diameter larger than in the scheme where the circulation of water is provided forcibly. due to the decrease in resistance, which has to be overcome by water: the farther the pipe from the boiler, the wider it is.

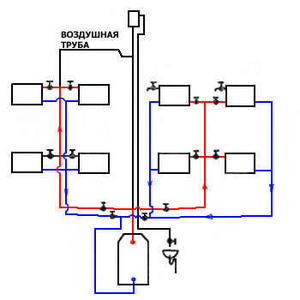

Heating by gravity with a vertical riser means heating the building with several floors. This option is more expensive, but it is protected from the formation of air congestion.

The horizontal riser is an economical option, but when moving, the coolant is mixed with air. This nuance is easy to eliminate: when installing heating with natural circulation by hand, you need to add air to the system.

Advantages of a heating system with natural circulation

The benefits of natural circulation:

- Easy to install and use

- High thermal stability of the circuit

- No noise during operation (because there is no loud pump)

- Economical energy consumption (with proper insulation of pipes and building)

- Autonomy: the system can easily work without electricity

- Durability and durability: with proper care, the self-heating system of heating a private house can work without requiring repair, for 30 years.

Cons of single-pipe natural circulation with pump

Weak points of the gravitational scheme of heating:

SEE VIDEO

- The area of the building that is heated by a one- or two-pipe heating system with natural circulation should not exceed 100 sq.m.

- The length of the contour in the horizontal plane is within 30 m (otherwise there will not be enough head)

- It is not possible to install a one-story house with natural circulation in a building without an attic; an attic tank is located in the attic.

- The high probability of freezing of water, because of which pipes outside living quarters have to be thoroughly insulated.

The heating system with natural circulation is simple and very reliable.

What kind of heating scheme to choose for a private house depends on such criteria as:

- type of boiler;

- access to electricity;

- the amount of the budget for the arrangement of heating;

- preferences of an aesthetic nature.

The circulation of the heating medium in each heating system can be either forced by means of a pump included in the circuit, or natural.

The latter are also called gravitational or gravity. They are the cheapest and simplest in design. As a consequence of this - the scheme of water heating with natural circulation is the cheapest.

They do not include a circulation pump in the circuit. The heat carrier in the pipes moves under the action of natural forces (gravity, above all). Systems of this type are an advantageous solution for money, and also optimal - from the point of view of engineering performance.

This variant of the implementation of heating is no longer used as widely as before. It refers to obsolete decisions and is gradually replaced by more effective schemes. This applies equally to individual construction.

However, open water gravity heating and now continue to be widely used for obvious reasons related to economy and reliability. The transfer of the coolant in the circuit is due to the hydrostatic pressure inside the pipeline.

Heating equipment under this scheme in a small private house is not connected with the purchase of expensive components or materials. In addition, there is no need for a source of electricity. In some cases, this is a rather important factor.

Usually such schemes are realized only in individual construction. Effective gravity heating can be equipped (especially with their own hands) only in a low (one or two floors), as well as in a small building area.

Important! There is a limit on the horizontal radius of the gravity chain. The length of horizontal pipelines should not exceed thirty meters. This is due to the relatively small circulating pressure in the circuit.

However, in favor of implementing this particular scheme, several weighty arguments can be cited.

Benefits

- The most important advantage is the price of materials, equipment, installation, maintenance and operation;

- There is no need for circulation pumps. Consequently, there is no vibration, noise, expensive repairs;

- The average lifetime of such schemes is about 35-40 years (provided that the installation was carried out correctly and the operating manual is not violated);

- Simplicity of repair (usually the user can eliminate almost all breakages in such systems);

- The heating circuit with natural circulation has the capacity for self-regulation. A consequence of this is good thermal stability. The movement of the coolant in the circuit is due to the difference in temperature (and hence density) at different sections of the circuit.

Principle of operation

- The heat carrier moves to the heating devices and back to the boiler due to the change in the thermodynamic characteristics of the fluid in the circuit. How does this happen? Water is heated in the boiler, its density decreases, passing through pipes and radiators, the density of the coolant becomes higher. Cold water under the influence of gravity is replaced by a coolant, which has a higher temperature and less density.

- The water that is heated in the boiler is lighter than the cold, and therefore, under the action of natural forces, it moves up the riser. Along the way, the coolant gives off heat to the batteries and radiators, which are given off warmly in the rooms where they are located. Cooled water from radiators is forced out warm, and under the influence of gravity goes down, where the boiler is installed. This cycle ensures the operation of the boiler.

The main elements of the gravity flow diagram

- boiler;

- pipeline;

- heating devices (radiators and batteries);

- expansion tank.

Principle of installation

Horizontal pipes must be installed in compliance with the slope along the flow of the coolant. This will stimulate the circulation of the coolant. Observe the angles of the slope of the pipes necessary for withdrawal into the expansion tank.

The slope in the horizontal pipeline also provides airflow from the system and prevents airing. In this case, the expansion tank receives an additional stabilization function.

Important! When installing horizontal pipes, the slope angle is defined as follows: for each meter of length the slope should be 5-10 mm in height. This will ensure the necessary circulation.

The hydrodynamic forces, due to which the coolant moves along the contour, depend on the height of the entire contour. Especially important is the difference in height between the boiler and the radiators, as well as the resistance of the pipeline, which depends on the diameter of the pipes.

If the contour is mounted with numerous branches and turns, this will certainly increase the hydraulic resistance. Also, numerous cranes, filters and other fittings, as well as a small-diameter pipeline, will interfere with normal circulation.

Thus, in order to create normal pressure inside the circuit, it is necessary to reduce the influence of all resistance objects or increase the diameter of the pipes.

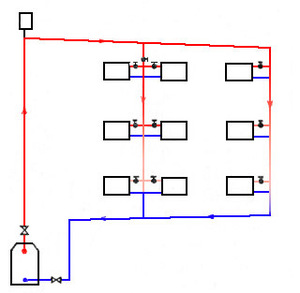

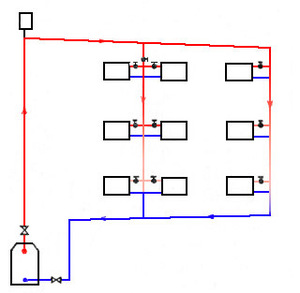

Two-pipe gravity heating system

In this scheme, a structure is realized in which two separate circuits for movement hot water. One part - circulates the heated coolant, the second - cooled.

Sequence of installation of two-pipe system

- From the boiler up the main line is connected, which connects to the expansion tank;

- The expansion tank is installed either in a room under the ceiling or in an attic (which should be insulated);

- From the bottom of the tank, a hot contour pipe is connected, which is connected to the distribution of the pipeline in the room at a distance of one-third of the floor;

- A pipe is piped into the tank to drain excess water into the sewage system;

- From the wiring pipelines are conducted to the radiators;

- From the heating devices (from their lower part) pipes are withdrawn into the return line, which is fed to the boiler;

- The return should be mounted parallel to the straight line through all rooms.

Features of installation of a single-pipe system

The advantage of a single-pipe heating scheme with natural circulation in comparison with a two-pipe system is that the hydrodynamic pressure in such a circuit does not depend on the height of the heating devices.

The expansion tank should be filled only three-quarters of the volume, and the volume of the tank is 25-30 liters.

Video with the sequence of monotube installation can be seen here:

conclusions

Simple and practical heating circuits with natural circulation - a good option for private a country house, if necessary, savings. With heating big house such systems are unlikely to effectively cope if they are not modernized by adding a pump (although the main advantages of such schemes are lost).

A heating system with a natural circulation of the coolant is also called gravity flow or gravity. Its functionality is based on the difference in the density of cold and hot water and the difference in height in the location of the heaters and boiler. With hot water, the density is much lower, so a cooler coolant coming from the radiators displaces it from the boiler and directs it up the riser. After the heat is given to the radiators, cold water moves towards the boiler under the influence of gravitational forces, in its place comes more hot water from the riser.

Gravity systems are installed in apartments with autonomous heating and small houses. They do not require the use of electric power or the use of expensive equipment.

The self-heating system can be single-tube or two-pipe.

It consists of:

- boiler;

- contour (expansion tank, pipes, connecting elements, valves);

- coolant (water or antifreeze);

- heating devices ( convectors , radiators, warm floors).

The main advantage of natural circulation is independence from other communications. If the house is installed cauldron , heating is obtained completely independent even from the supply of electricity (there is no pump), which is quite important in some regions. But such schemes are suitable only for small areas, since the total length of the contour can not be more than 30 m.

When the boiler is at full capacity, the water is very hot, with a low density. In heating appliances, the temperature of the coolant decreases, the density rises. Thus, the flow velocity depends on of water temperature at the outlet from the boiler and the speed of its cooling in the radiators. If the room is very cold, the water cools quickly, the flow accelerates. When the temperature of the air rises, the water cools down more slowly, the flow rate decreases.

You can mount both single-tube and two-pipe gravity heating system, but only with vertical wiring.

Single-circuit gravity heating system

Single-pipe gravity heating can be mounted only with vertical wiring and with series connected radiators. In a house with one floor, a similar scheme is more effective than in a two-story house. Hot water from the expansion tank flows from the top down and fills the heating devices. If the floor is one, then the difference in temperature in the radiators is insignificant.

Single-pipe gravity heating can be mounted only with vertical wiring and with series connected radiators. In a house with one floor, a similar scheme is more effective than in a two-story house. Hot water from the expansion tank flows from the top down and fills the heating devices. If the floor is one, then the difference in temperature in the radiators is insignificant.

In the two-story version on the second floor radiators are hotter than the first. To somehow balance the temperature, you can install on the ground floor more volumetric heating devices. This scheme does not provide for the installation of control valves - if you cut off water on one radiator, its flow will decrease in others. This means that it is impossible to regulate the temperature in the rooms. Besides, you can not turn off the heating on one of the floors.

The efficiency of heating can be increased if bypass (closing area). The diameter of the bypass can be the same as that of a pipeline going to the radiators of the upper floor, or 1-2 millimeters less. If the diameters are the same, the pipeline requires a valve or a three-way valve. This fittings allow regulate speed flow according to needs. For example, if you need the same temperature in all rooms, then the valve opens, and part of the water (past the radiators of the second floor) is sent to the first floor. As a result, it has higher temperature, than in the absence of a valve.

The three-way valve is a modern version of the valve, which can be equipped with an electric drive and a controller for determination of air temperature or coolant. At the slightest changes, he instructs the three-way valve to increase or decrease the volume of the coolant supply to the radiators on the upper floor.

But you can do without a valve, and without a three-way valve, if the diameter of the bypass is smaller by size than the pipe through which the coolant goes to the radiators on the upper floor. The water that comes from above is divided into two separate streams. If the diameters are the same, the water will cease to flow into the radiators of the upper floor - the whole stream will go down - along the path of less resistance.

Features of installation and advantages of single-tube hydraulic system heating:

- low cost of materials, creation and maintenance;

- there is no need to purchase a pump and spend electricity;

- the service life reaches 40 years;

- simple repair (almost all breakages can be eliminated by yourself);

- the system is self-regulating, therefore it is sufficiently heat-resistant.

During installation, special attention should be given to the difference in height between the radiators and the boiler, as well as the angle of the slope of the contour. Slope should be such that for every meter you have to 5-10 mm, which will ensure the proper velocity of the coolant and the air outlet from the system. Great value has and diameter of pipes - the bigger it is, the less the hydraulic resistance and the higher the flow rate. In addition, it is desirable to use a minimum of reinforcement (it reduces the flow rate) during installation.

Two-pipe gravity heating

In the direction of motion of the coolant, two-circuit systems are divided into: with a passing motion and dead-end systems. In a dead-end version, the hot and cooled coolant moves in different directions. When using such an installation scheme, the length of the circulation rings is not the same. This means that for the farthest radiators the ring is much longer than for those that are near the boiler. Therefore, those radiators that are closer to the riser, get warm better.

In the direction of motion of the coolant, two-circuit systems are divided into: with a passing motion and dead-end systems. In a dead-end version, the hot and cooled coolant moves in different directions. When using such an installation scheme, the length of the circulation rings is not the same. This means that for the farthest radiators the ring is much longer than for those that are near the boiler. Therefore, those radiators that are closer to the riser, get warm better.

When using a scheme with a co-moving water movement, all the circulation rings are the same in length, therefore radiators are heated equally. But such schemes are used rarely because of the large consumption of pipe materials. Most often, they try to improve the characteristics of a dead-end system by installing two or more loops instead of one.

The two-pipe system is two separate pipelines, conducted in parallel: one for hot water (from a boiler), the second for a chilled (passed through heating appliances). Heating with the use of two circuits can be established if you use the top wiring and pipes with a diameter 32 mm or more.

The water from the boiler rises to the distribution tank, from which it descends to the heaters by gravity. If the diameter of the pipeline is too small, a high hydraulic resistance, which prevents circulation.

Mounting Features

A pipe is connected from the boiler to the expansion tank, which is installed on the insulated attic or under the ceiling in one of the rooms on the upper floor. In order to reduce heat loss, It is desirable to warm the riser. From the bottom of the tank a pipe with hot water, connected to radiators. In the tank, there must also be a drain through which excess water escapes into the sewer. From each heater, a pipe is withdrawn, through which chilled water is removed, and is connected to a discharge circuit directed towards the boiler. Both circuits (feeding and discharging) are mounted in parallel.

A pipe is connected from the boiler to the expansion tank, which is installed on the insulated attic or under the ceiling in one of the rooms on the upper floor. In order to reduce heat loss, It is desirable to warm the riser. From the bottom of the tank a pipe with hot water, connected to radiators. In the tank, there must also be a drain through which excess water escapes into the sewer. From each heater, a pipe is withdrawn, through which chilled water is removed, and is connected to a discharge circuit directed towards the boiler. Both circuits (feeding and discharging) are mounted in parallel.

There are also schemes for the installation of a two-loop gravity system with a lower wiring, but they are practically not used. In many respects they are similar to schemes top wiring, therefore require a large number of pipes. Ramps have to be installed in living quarters, so all advantages are lost lower wiring. In addition, radiators need install air drifts. When using these schemes, expansion tanks are installed in the system, which communicate with the external environment and take air out of it. Therefore, bleed the air every week, and sometimes even more often.

Advantages and disadvantages

Advantages include:

- non-volatility;

- simplicity and ease of installation;

- easy and fast input;

- no vibration and noise generated by the pump;

- long service life;

- simple maintenance;

- high maintainability;

- self-regulation (with a decrease in air temperature, the flow rate increases).

Disadvantages of gravity:

- limitation of the volume of heated premises;

- high inertia;

- the need to comply with the installation slope;

- the piping layout can only be open;

- need to constantly monitor the level of coolant in the expansion tank;

- low efficiency, which increases the cost of heating;

- need for installation of a pipeline with a large diameter;

- danger of freezing (low flow rate).

A two-circuit gravity heating system can not be installed in a house without a basement of sufficient depth. If the distance (in height) from the center of the boiler to the heating devices of the first floor is less than 3 meters, radiators will not be heated. Also, it is not necessary to mount a complex system in a small single-storey house, in which one can completely dispense with a single-tube gravity structure.

Before choosing a scheme for wiring the heating system, it is worthwhile to learn about the advantages of using the pump:

- possibility to use pipes with small diameter;

- the pump prevents temperature fluctuations in the system;

- it is possible to adjust the temperature of the heat carrier by adjusting the flow rate.

But circulation pump will make heating dependent from the supply of electricity and create a certain level of noise in the house.

Despite the technical progress and constantly introduced innovations, the scheme of heating a private house with natural circulation has not outlived itself. The secret of longevity of this type of water heating circuit is in the ease of installation and independence from other sources of energy (electricity). An article on how heating works under gravity flow of a fluid, and what kinds of schemes it includes.

What causes the fluid to move - a little bit about the laws of physics

The basis for independent movement of the liquid along the heating circuit without the use of pumping devices (circulation pumps) is convection. This physical phenomenon is based on the fact that any medium, when heated, loses density, that is, it becomes easier. Actually this is also for liquids, so the colder water in the closed loop tends downward, pushing the hotter upward. Heated in the heat exchanger of the boiler, the coolant rushes up the vertical riser, its place is occupied by the cooled liquid that has come through the return pipe.

This creates an overpressure sufficient to overcome gravity and pipe resistance. As a result, the coolant circulates by itself, using only thermal energy, allocated energy source used for boiler operation. The circulation of water in a heating system of this type is not very fast, so the heating of the heated room at the initial start-up of the boiler is slow. Increase the speed of water movement allows such features of the gravity heating system, which are taken into account when constructing the circuit:

- the use of large diameter pipes (usually 50 mm or two inches) in order to minimize the resistance of the pipeline;

- the boiler is mounted as low as possible with respect to the horizontal layout of the first floor;

- make an overclock loop (a high vertical riser, from which a pipe goes to the top point going to the batteries);

- the horizontal wiring patches settle down under a gradient (3-4 degrees) towards the boiler, using gravity to accelerate circulation.

In addition, for the normal velocity of the coolant flow through the pipes, a temperature difference between the outlet from the boiler and the inlet return pipeline not less than 25 degrees. The longer the circuit (more number of battery sections), the higher the temperature difference.

The heating system with natural circulation has one more feature - it can not be closed type. In gravity flow, only an open expansion tank is supposed to be installed above the upper point of the booster. The compensating tank has two functions - to remove the bubbles of the generated gases from the system and to smooth the pressure drops, which in the gravity heating circuit are significant. The closed tank of membrane type, which is installed in systems, mounted according to modern schemes with forced circulation, will not be able to completely smooth out the pressure jumps, which will inevitably lead to emergency situations.

It should be borne in mind that heating with natural circulation due to the large diameter of the pipes assumes a much larger volume of coolant, which, expanding when heated, forms a significant amount of "excess" liquid, and it fills the open expansion tank.

Heating with gravity circulation - evaluate the advantages and disadvantages

In fact, the gravity system is less perfect than the modern contours, where the movement of the fluid provides circulation pump. But the heating systems there is an indisputable advantage - for natural circulation, there is no need for electricity, from which the pump operates. No matter how long there were interruptions in power supply, this will not be reflected in the heating of the premises.

To the advantages of gravity heating circuits can be attributed and their inertia. This is true if a classic solid fuel boiler is used, which is characterized by such an operational feature as large and frequent temperature differences in the furnace. The large inertia of the contour with the natural motion of the liquid smoothes out temperature jumps in this situation, making the heating of the rooms more even.

On this, the advantages of gravity heating systems end and their minuses begin, which are much greater.

- 1. The use of large cross-section pipes and their mandatory installation under a slope do not provide an opportunity to make a hidden laying of heating communications, therefore all elements of the system will be in sight. In practice, only metal pipes are used to build a gravity circuit (plastic ones do not withstand high temperatures and pressures, they assume a lot of sudden transitions that increase the resistance of the pipeline). And this is the complexity of installation (welding) and the need for annual painting of communications. In addition, bulky pipelines, laid in plain view, do not fit well with modern interiors.

- 2. Limited choice of heating batteries. For natural circulation, the diameter of the inner holes of the radiators, their ability to withstand pressure and high temperature is very important. Such requirements are best matched with cast iron products, which most often are equipped with gravity contours. Aluminum "weak" about the pressure and quickly oxidized (the corrosion rate directly depends on the temperature of the coolant), bimetallic batteries have narrow clearances, the steel is made in the form of monoblocks (non-separable construction), so it is difficult to select the required heat output of the radiator.

- 3. The need to maximize the boiler. To do this, you have to make a platform, located below the general floor level to half a meter. As a result, the boiler is inconvenient to service (especially solid fuel) and to bring pipes to it when tying the heat generator. It is clear that the operation of modern boilers wall installation is not talking.

- 4. The area of heated rooms is limited. Considering that the pipes are located under a slope, they will not be able to lay them for a long length. In addition, the longer the contour, the greater its resistance, hence, the lower the circulation speed. If the communication length is long, the extreme points (batteries) will not heat up well, and it will not be possible to achieve high-quality heating even by adding sections.

The heating system with natural circulation is not perfect, including aesthetic. However, the possibility not to depend on electricity supplies has attracted some homeowners so far, especially in regions where electricity is often a problem. For those who prefer reliability to technical perfection, several schemes of the gravity flow circuit are proposed.

Basic piping layouts - choose the best option

Heating circuits that involve a natural circulation of the coolant have two basic versions (circuits) of the device:

- one-pipe, when the supply and drainage of liquid from the batteries occurs through one pipe;

- two-pipe - the supply of coolant and its removal from the radiators is carried out by various pipelines.

Single-pipe circuit is easy to install. From the boiler, the riser leaves, which is raised as high as possible within the room. From the upper point of the riser, the accelerating tube descends and almost descends to the level of the floor, gradually converting into the supply pipeline. To the communication on its way, the batteries are alternately connected by means of two small diameter nozzles (with a two-inch pipeline, ¾-inch bends are usually used). "Served" all the radiators, the pipeline turns into a "return", which goes to the boiler. The wiring is good only for the simplicity of the device and the relative aesthetics (tubes in sight, but are located low). Further one lacks.

Due to the fact that the cooled coolant from the batteries runs into the same pipe from which the hot liquid comes from, the temperature of the water after passing through each radiator falls fairly quickly. If the communication to the first battery is delivered by a coolant temperature of 85 degrees (for example), then the heater from the boiler can only be counted at 60 degrees. Hence the uneven heating, which has to be compensated by adding sections to batteries moving away from the boiler, so the outermost radiators are often cumbersome and heavy (especially if cast-iron ones).

Connect the batteries with single-pipe wiring only from the bottom (input and output), and this is the most inefficient way to connect the radiators (they warm up unevenly, which affects the quality of the heating). Diagonal connection of radiators is possible if the supply pipe is laid above the batteries, but this is already a two-pipe scheme.

With a two-pipe wiring from the riser, a feed pipe is located, located under the ceiling. From it drop the nozzles to each battery (connect in the upper position). At the bottom is the second, return pipe, into which drainage pipes from the radiators flow (they are attached to the lower position diagonally). From the point of view of aesthetics, the picture is not very, but in terms of efficiency, such a system is much better. For each battery, a liquid of the same temperature is suitable, which ensures an even heating of all rooms, plus there is the possibility of connecting more heaters.

The heating system with natural coolant circulation is arranged in private houses most often. Such designs have many advantages, and their installation is extremely simple. However, some rules are still necessary for assembling such equipment.

Design Features

The heating circuit with natural coolant circulation is very simple. The design includes a heating boiler that can be either gas, electric or solid fuel, water pipes, radiators and expansion tank. In heating systems with forced circulation, the coolant flow is provided by a special pump. This increases the cost of equipment and complicates its installation.

In systems with natural circulation, the coolant moves along the pipes in a self-current flow. The point is that the density y heated water higher than that of the cold one. Passing along the mains and radiators, the heating medium heated by the boiler gradually cools down. Cold water in the outflow tube at the same time replaces a new portion of hot - in the supply. As a result, the cooled coolant again passes through the boiler, after which the cycle is repeated.

Expansion tank in such a system is necessary to adjust the water pressure in the pipes. When it is increased, the excess coolant enters the tank, partially filling it. When the pressure decreases, the water flows back into the pipeline.

Advantages and disadvantages

To the pluses of such structures as a heating system with natural circulation, it is possible to attribute, first of all, cheapness. Equipment is not so much to buy. In addition, the advantages of such systems include a high degree of maintainability. Due to the simplicity of the design, replace the worn out items if desired, including by own strength.

Reliability is another undeniable advantage of such systems. The pluses can be attributed to long term their service - about 30 years.

Disadvantages of constructions of this type are:

- Low efficiency. Fuel for the functioning of a system with natural circulation needs relatively much.

- Great inertia. The system begins to work only when the coolant warms up sufficiently well.

- Impossibility hidden wiring pipes. With the help of such a system, sufficient efficient heating private house. The natural circulation, however, assumes a fairly high degree of cooling of the coolant when moving along the mains. Therefore, the pipes must pass in the open air.

Use heating systems of this type can only be used in houses of a small area. The fact is that as the number of turns and knees increases, the resistance to the heat carrier increases significantly. As a result, the system starts to work extremely inefficiently.

Single-pipe and two-pipe construction

There are only two types of heating systems with natural circulation. The two-pipe system consists of two circuits: the supply and discharge circuits. The first coolant is fed to the radiators, the second - is taken back to the boiler. In private houses, however, one-pipe heating with natural circulation is more often used. This system is easier to install and quite effective. In this case, the coolant moves along a single tube to which the radiators are connected, in a circle.

Design

When calculating the heating system of this type, you need to decide on:

- the number of radiators required;

- power of the boiler;

- diameter and material of pipes;

- the volume of the expansion tank.

How to Calculate Boiler Power

This procedure is actually very responsible. After all, the efficiency of heating the room depends on how correctly the boiler output is selected. Calculations are made primarily based on the fact that 10 m 2 of the house requires 1 kW of power. At the same time, the correction factors for regions are also taken into account:

- for the north - 1,5-2,

- for the middle band - 1.4,

- for the southern regions - 0.8.

You can also calculate the power, based on the volume of the room. This figure is simply multiplied by 40 watts. For the private house on the pile foundation a correction factor of 1.4 is adopted. On each door to the received power is added 300 W, for each window - 70-100 W.

How many radiators should there be?

Continue calculating the heating system by determining the number of required batteries. Radiators in this case, you can choose any. Most often, owners of country houses mount inexpensive and sufficiently reliable bimetallic models. Their number is calculated based on the area of the premises. For every 10 m 2, 1 kW of radiator power is needed. The figure obtained as a result of calculations is multiplied by another 1.5. This stock is needed to compensate for heat leakage through windows and doors. The power of one section of a battery of a particular brand is indicated by the manufacturer in the technical passport.

Backbone

The internal surface of the pipes selected for a heating system with natural water flow should be as smooth as possible. This will reduce the resistance to a minimum. In addition, sediments and silt should not accumulate in the pipelines. The most complete all these requirements meet the metal-plastic pipes. Also often in systems with natural circulation, polypropylene lines are used. Steel in such structures is not recommended.

As for the diameter, it should be large enough. The specific figure depends primarily on the number of knees in the main line and various types of stop valves. Usually in private homes are installed pipe diameter in 32-40 mm (internal). For piping to radiators use pieces with a diameter of 20-24 mm. You can use for this purpose pipes of the same number as the main ones.

Selecting the expansion tank

Typically, a heating system with natural circulation is equipped with an open-type expansion tank. Such models can perform at once three main functions:

- safety valve at overpressure,

- the point of supply of the system with additional portions of the coolant,

- removal of excess gases generated by heating water.

When selecting an expansion vessel, the following factors should be considered:

- Total volume of coolant (C). The capacity of the tank depends on this index. It is determined by adding the boiler volumes, pipes, radiators and other structural elements, if any.

- Coolant expansion coefficient (E).

- Initial pressure in the tank (Pmin.).

- The maximum permissible pressure (Pmax).

- Coefficient of filling under given working conditions (Kzap). You can determine it by special tables.

Calculation of the tank volume is carried out according to the formula V = (E x C / 1 - Pmin / Pmax) / Kzap.

Basic installation rules

In order to heat the house with natural circulation of the coolant in the system was effective, the following recommendations should be observed during assembly:

- Pipes should be installed with a slope in the direction of the water current of at least 6-7 g. This will ensure better circulation.

- The boiler is installed below the level of the mains. Usually it is placed in the basement. If there is not one, a utility room with a pit is set up.

- The expansion tank is mounted in the attic. The pipe connecting it with the boiler is insulated.

- Radiators are installed parallel to the pipes (on the bypass). They can not be cut into the main lines themselves.

- Place the batteries as high as possible.

Build order

Installation of heating systems of this type is carried out as follows:

- The boiler is installed. At the moment, in country houses Gas models are most often used. The chimney can be installed independently. To connect the boiler to the main line, you will have to call specialists. It's forbidden to do this by regulations.

- Suspended radiators. It is best to place them under the windows. This will ensure a natural circulation of air in the room. The distance from the radiator to the wall should be at least 2.5 cm, to the floor - 8 cm.

- Mount the highway (with a slope).

- The radiators are connected. The single-pipe system uses a lower connection.

- The expansion tank is installed. Most often it is connected to a branch line. An additional branch to the sewage system is installed on the pipe of the tank.

- The main line from both sides joins the boiler nozzles.

- Installed cranes of Majewski. They are necessary for venting air from the coolant, for example, when crimping.

- Another necessary shut-off valve is installed: chokes, thermo valves, etc.

- At the lowest point of the highway, a drain cock crashes.

As you can see, installing heating systems with natural current is not particularly difficult. To assemble a similar design, especially one-tube, can be literally per day.

Water heating with natural circulation is quite effective. However, it is still necessary to supplement the design with a special pump. They can be used from time to time, increasing the efficiency of the system. It is mounted on a branch pipe. The fact is that the supply temperature of the coolant is very high, and this can lead to the failure of its structural elements.

A circulating pump is installed on the bypass, equipped with valves. Directly in front of it is mounted a special filter. The latter prevents dirt, silt, etc. from entering the pump.

When installing radiators, make sure that they are at the same level. This will ensure optimum circulation of the coolant. Before each battery is to install a shut-off valve. It is useful in case of emergency shutdown.

Trial run of the system

So, we have found out how to make a natural circulation of heating (system). After all the elements of the construction are assembled, a trial run must be carried out. Filling can be done either with a pump, or with a make-up tap connected to a water pipe. The pressure of water entering the system should not be too strong. Otherwise, a lot of air gets into the pipes.

After filling, you should wait half an hour. During this time, excess air will leave the system. Then you can start the boiler. If the system after a while earns - then everything is in order. But sometimes it happens that the coolant does not start circulating through the mains. In this case, you need:

- check all pipes for leaks;

- measure the angle of slope of the roads.

If necessary, the defects are eliminated.

Sometimes the cause of the malfunction is the usual air jams. Therefore, in addition, you should try to remove them. The procedure in this case will be as follows:

- open air vent on all radiators;

- turn on the system with a weak pressure;

- the drain is opened and a long run of the coolant is performed.

Often the cause of inactivity of the system are clogged radiators. In this case, the batteries must be removed and rinsed.

If none of the above does not help, then the reason is most likely in the weakness of the boiler or its malfunction.

Heating system with natural coolant circulation - the equipment is reliable and at the same time inexpensive. With the right selection of components and compliance with all recommendations for installation, you can get a durable and very effective design, and therefore, significantly and permanently improve the comfort of living in the house.