Disassembled pump station. Problems and malfunctions of pumping stations and their correction. Why the pumping station does not turn off for a long time?

Repairs pumping station do it yourself - one of optimal options out of the situation when there are any problems in it. Today the market of equipment for water supply is oversaturated with offers for every taste. Two water supply systems have positive feedback on reliability - the Marina pumping station and the Dzhileks station, whose structure is identical.

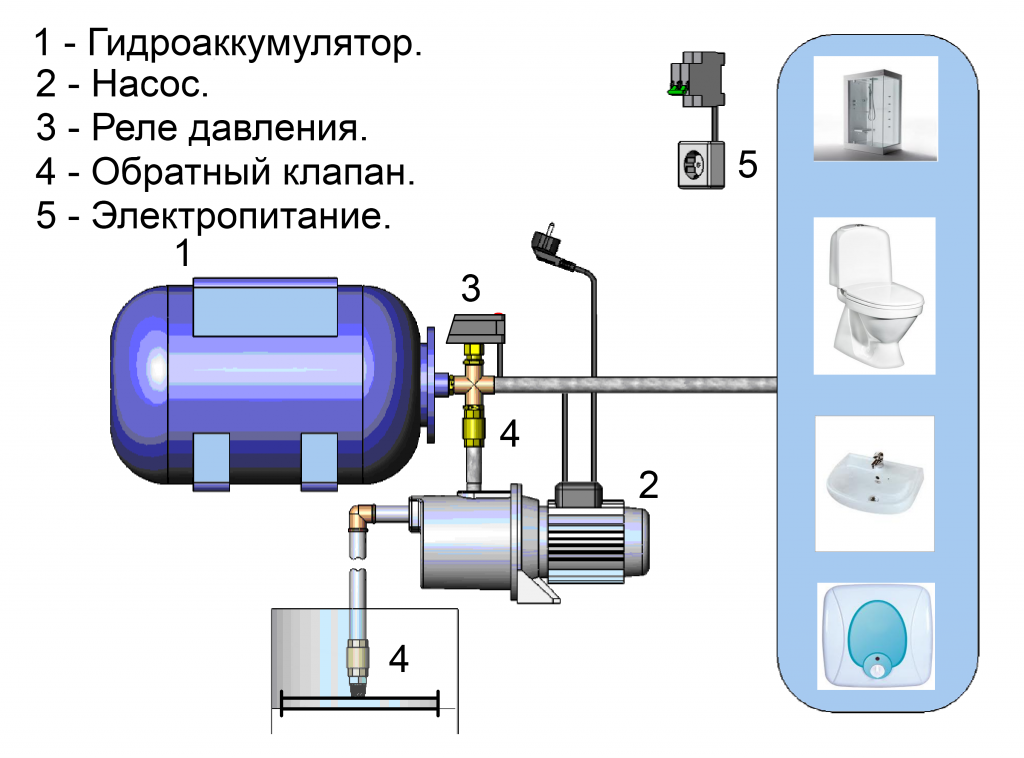

What does a pump station consist of?

Owners of their own water supply system on the territory of a private house or cottage often face various kinds of malfunctions. Basically pumping stations contain the following elements:

- water pump;

- hydraulic accumulator;

- relay;

- pressure gauge.

The main task of the water pump is the intake of water from the desired source. Popular among consumers are surface pumps, installed or in special rooms of the house, or in the caissons adapted for this. The pump must have sufficient power to raise water from the well, move to the house and lift to the upper water point of the housing.

An important component is a hydraulic accumulator (storage tank) with a capacity of 20 liters or more. A hydroaccumulator is a metal tank, whose task is to keep constant pressure in the pipelines of the station. Successful battery model in the form of a metal cylinder with a rubber membrane inside. The membrane expands and reverses depending on whether the pumping station is working or not.

The relay switches the pump on and off, determining the need for it to work with the water level in the tank. The manometer is intended to indicate the level of pressure in the water supply system. The presented set of units and equipment of the water supply station can work as a single system, and each individual element can also work by itself. On the market niche are presented pumping stations in the form pumping deviceinstalled on the pressure accumulator. A single frame contains an automatic control device.

Basic information about the operation of the pumping station

The pumping station works according to the following scheme: receiving power from the source, the suction pump starts drawing water, water goes into the tank, filling it to a certain level, after which the pressure switch stops the suction device. When a person consumes water, the level of liquid in the membrane tank drops, the pressure switch gives the command to implement the process of water extraction again.

Usually, when buying a pumping station, the warranty period is specified. And what to do when the pump does not pump water after the expiration of such a period? There are certain approaches to the implementation of work related to the failure of the station, allowing you to find the cause of failure, and ways to repair the pumping station with your own hands. In many cases, this does not take as much time as it may seem at first glance.

Solving problems related to the lack of water in the system

The first step is to check the tightness of the pipelines and the presence of water in the system. When there is no water, there could be a problem check valvelocated between the wellhead and the inlet of the pumping station. This part ceases to work as a result of clogging of the valve with foreign objects. Another consideration is the unsuitability of the spring controlling the operation of this element.

The clogging of the valve is eliminated by its cleaning after removal, and in the event of breakage, it is necessary to make a complete replacement of the check valve, but this will require a significant amount. With long-term idle pumping station there is a situation of water disappearance at the junction of the well and the pump. A special filling hole eliminates the problem.

If there is a problem of seasonal lowering of the water level, the solution will be to place the pump inlet circuit deeper into the well shaft. With a deep immersion of the input circuit increases the likelihood of clogging, to prevent this, a filter is installed.

Insufficient mains voltage is also the reason for the lack of water when the supply system is working. This is determined by the power tester. Wear of the pump blades is eliminated according to this plan:

- dismantling the pumping device using special means to facilitate the removal;

- inspection of the impeller condition, if necessary - replacement of a broken blade;

- if it is impossible to replace a broken part (it all depends on the manufacturer), the pump completely changes.

Pump is turned on too often

When the pump is turned on frequently, the water supply is jerky. The reason is a breakdown of the operation of the automation unit (pressure gauge). Pressure gauge measures pressure. The readings of this element can fall sharply, then the water will flow in spurts. This happens if the pressure accumulator membrane, which changes its size depending on the volume of water, has become unusable.

Breakage is determined by pressing on the nipple that makes access to the membrane. When the air goes out of him, it is working. In the event of water entering, the hydroaccumulator membrane must be urgently replaced. To change the element, it is necessary to disassemble the battery case by unscrewing the bolts.

There is no water intake by the pump.

When it was found that the pump does not pump water, one of the reasons may be that the pressure in it is not properly adjusted. The elimination of the problem is carried out according to the scheme:

- the pumping station is turned off from the power supply network;

- water is drained from the water tank;

- measured air pressure in the tank through the nipple of a car pump with a pressure gauge or compressor, its optimal value - 90-95%;

- pumped air into the water system.

- water is poured into the station;

- connects to the network with pressure control.

The air in the water supply system is pumped as follows. The cover is removed from the pressure switch by removing the plastic screw and changing the tightening force of the existing assembly springs. By turning one nut, the lower value of the pump is turned on. Clockwise rotation increases the pressure, and counterclockwise rotation causes the pressure to drop.

Turning another nut adjusts the pressure range between the lower and upper limits of the values. The boundaries of the range are changed by turning the element clockwise to expand, against - to reduce it. After the steps have been taken, the pumping station is switched on to the power grid and its operability is checked.

Other common problems

There are several other types of pumping station breakdowns. For example, there is a constant injection of water, it happens when the adjustment relay stops working due to wear. To eliminate the malfunction, it is necessary to clamp the stretched relay springs and, if necessary, clean it from clogging.

When the pump does not pump water from the well, the first step is to check whether there is electricity in the circuit. If everything is in order, the cause may be the winding of the electric motor. During winding breakdowns, the motor does not work, and the smell of burning insulation is felt. The elimination of the problem consists in the complete replacement of the engine.

Another case of system malfunction is a sound release without rotating the pumping device. The culprit is a long simple. The rotor wheels “freeze” on the inner surface of the station. To begin with, the pump shaft is developed by turning it with its hands, if necessary, the impeller is cleaned of debris.

Since the pump casing also has a diffuser with a connected guide, the hydrophore stops even if it fails. The solution is to replace diffusers for pumping stations and then collect the pump in the reverse order.

This failure occurs when the terminal box capacitor stops working. The electrician's tester identifies a malfunction that often occurs in three-phase motors. When the capacitor closes, it melts or darkens, the only way out is to replace the part. The main thing is to make sure that the wires are securely fastened, otherwise the capacitor will be inoperative.

Almost all breakdowns of pumping equipment stations are eliminated, and repairing a pumping station with your own hands is not a myth.

To reduce the likelihood of malfunctions in the operation of the pumping station, specialists are strongly recommended to perform the provided maintenance and preventive inspection of water supply systems.

The installation process itself and the independent maintenance of pumping stations require a lot of time, a significant initial investment of money, but they pay off by the absence of payment for consumed water.

The pumping station, like any unit, has a warranty period of operation, in case of a device breakdown during this period, the customer service will eliminate it free of charge. But often, pumping station breakdowns occur after the expiration of the warranty period, and the cost of repairing a breakdown in the service department can cost half its cost, since it is often practiced instead of repair of an aggregate-nodal replacement, which is expensive. . However, repairing a pumping station with your own hands is possible without the help of specialists.

Causes of breakdowns and how to eliminate them

Consider the options for breakdowns and how to eliminate them on the example of a very popular pump station "Jumbo" manufacturer Dzhileks, although these failures can be attributed to the majority of existing pumping stations. The peculiarity of this station is the presence of a built-in ejector, which allows raising water from a depth of up to 9 m. The Jumbo pumping station consists of the following nodes:

- centrifugal pump with integrated ejector;

- hydroaccumulator;

- pressure switch with pressure gauge.

| Type of fault | Cause of failure | Remedies |

| 1. The pumping station is working, but does not supply water. | 1.1. There is no tightness at the butt joints of the suction pipe or does not hold a check valve, which is installed at the end of this pipe. 1.2. The water level has been exceeded (more than 9 m) and the pump simply cannot pump water. 1.3. Most of the working chamber of the pump and impeller due to the high content of abrasive particles in the water, or damaged impeller. 1.4. Low voltage in the network, and the engine can not develop momentum, although it works. | 1.1. Check the tightness of all connections on the subsea pipeline, repack and tighten the screwed connections as necessary, check the check valve, if it is leaking water, it may be a grain of sand, and the valve does not close tightly. 1.2. It is necessary to reduce the lift height by lowering the pump below, or replace the pump with a submersible one. 1.3. With a large output, the pump will work for itself, in which case the housing with the impeller should be replaced. 1.4. If the voltage under load is below 200 V, then a transformer should be installed. |

| 2. The pump is often turned on, jerky | 2.1. The most common cause of this failure may be the leakage of the membrane of the tank or of the tank itself, or there may be no air in the hydroaccumulator. | 2.1. To verify the integrity of the rubber membrane, you need to press the spool through which air is pumped into the tank, if water flows from there, it means that the rubber bulb is torn and needs to be replaced. If there is no water, it is necessary to check the air pressure in the accumulator, it should be 0.2 bar less than the lower pump start pressure, approximately 1.5–1.8 atm. If the membrane is intact, but the air pressure is constantly falling, you need to check the valve and the tightness of the tank body, there are cases that cracks appear in the welding joints, you can determine them using soapy water, missed all the joints. If a crack is found, it can be fixed with cold welding or tin with a soldering iron. |

| 3. The pump is running and does not turn off. | 3.1. The relay is set to very high pressure. 3.2. Pressure switch inlet clogged. 3.3. Suction lift exceeded. | 3.1. Need a little loosen the small spring in the relay. 3.2. It is necessary to disconnect the relay from the pumping station, unscrew the membrane cover and clean the hole. 3.3. See p.1.2 |

| 4. The pump does not create the necessary pressure. | 4.1. See Clause 1.1 4.2. The relay is set to very low pressure. | 4.1. See Clause 1.1 4.2. Press a little small spring. |

| 5. Pump not working | 5.1. Lack of power at the pump connection terminals. 5.2. Failed pump motor. | 5.1. Check the tester voltage at the pins of the pump, perhaps the cause of burning contacts in the pressure switch, you need to clean the contacts. 5.2. Often the cause of the failure of the engine is the combustion of the stator winding, due to the ingress of water through a worn gland, or jamming of the shaft bearing, which can be felt by a specific smell. Such a failure is eliminated either by replacing the motor or by winding the winding. |

Replacing the gland bearing

A frequent cause of serious damage to the pumping station becomes improper operation, namely:

- the pump is operated in a room with high humidity, which leads to oxidation of the contacts or seizure of one of the bearings of the pumping station;

- operation of the pump without water for more than 3 minutes leads to failure of the gland, which, in turn, can lead to the closure of the stator windings due to the ingress of water into the engine.

Guess in advance that you need a replacement gland , can be due to extraneous noise, which publishes the pump, as well as the flow of the pump. To replace the gland, remove the front cover of the pump, the rear protective cover and the engine cooling impeller, fix the shaft with a gas wrench or vice and unscrew the nut that holds the impeller. Remove the impeller, under it on the shaft is the gland. To extract the gland, remove the retaining ring and the first part of the gland, using a screwdriver, “pick out” the second part, replace the gland, smearing the gland and shaft with liquid soap. If the gland has failed, due to the pump running dry, it is necessary to check whether the water inlets and the impeller cover are deformed, if the deformation is present, then these parts must be replaced.

The seizure of the bearing is fraught with combustion of the engine itself, since the rotor shaft is blocked.

Bearing failure can be detected by twisting the engine fan at the back (it will not turn), or the shaft play, and the pump with worn bearings is very noisy during operation. Disassembly of the pump to replace the bearing is based on the principle of replacing the gland. It may be difficult to remove the plastic impeller and bearings, for this you need a special puller. After replacing the bearing, you need to run them in, let the engine work by turning it on 2-3 times for several minutes. Before installing the impeller, the shaft must be cleaned of rust and salt deposits.

Video

This video is about how to repair the water station with your own hands:

This video shows the repair of a clogged pump station pressure switch:

Virtually every home water pressure creates its own pumping station. But any design is subject to breakage. This problem may be faced by every person who owns a well or a well. To resume the supply of fluid, it is necessary to make repairs.

The pump station can be fixed by hand

Every homeowner wants to quickly deal with a breakdown, but save money on services. How to be in this situation? There is an exit! It is necessary to repair the pumping station with your own hands. To cope with the breakdown autonomous systemIt is necessary to know some skills in repairing the presented type of structures.

The principle of operation of the pumping station

How does the pumping station work? The answer to the question must be known to all consumers, then the malfunctions of the pumping station and their elimination will be independently available to every person.

This installation consists of three components: a pump, a reserve tank and a management relay. Where is the interaction of all parts. The pumping unit pumps fluid from the borehole opening into the tank or battery. The pressure sensor regulates the degree of substance in the containers. When the tank is minimally filled with liquid, the sensor connects the pump and turns it off when full. The tank element is equipped with a mechanical sensor (float), and the hydraulic accumulator is electronic. These devices take the water given by the pump, accumulate it and return it to the consumer composition.

All parts of the unit are very important. Indeed, the failure of only one part can lead to a malfunction of the entire device.

Types of typical station breakdowns

Pumping station does not work due to the following problems:

- Frequent power outages. Without power, the pump and individual sensors will stop functioning.

- The variability of the water substance. The debit resources of some wells cannot allow stations to operate with full capacity. In addition, the level of water flow may drop to the marginal point of the fence.

- Relay or float valve part does not work. Then the pump does not turn on.

- The pump stops functioning. Therefore, the water stops falling into the reserve capacity.

- The tank element or battery is sealed. In such a situation, the water conduit remains without substance, which will lead to a flood of premises.

The main reasons are known to us. Therefore, try to provide in advance a quality supply of electric lines and the required degree of water in the wells. Repair the parts in a timely manner.

Frequent turning on of pump station, jerks and interruptions of water

If the pumping station is often switched on, then it threatens an emergency equipment breakdown. Therefore, as soon as this symptom was detected, it is necessary to proceed with the repair work. But first it is necessary to find out the reasons for the frequent switching on of the device and the jerky supply of water resources:

With frequent switching on of the pumping station, it is necessary to carry out repairs quickly.

- The pumping station is often switched on if the volume of the accumulator is small (24–32 l). In such a tank, the liquid reserve is not more than 50 percent. That is, instead of the prescribed 24 liters, the reserve of substance is 12 liters. This amount of water is quickly used, so the pump is connected in frequent mode. What to do? Install an additional tank, connect it parallel to the entered tank.

- Incorrect activation of the relay. Under these circumstances, increase the delta, build a squatting threshold for connecting the pumping device. The pressure in the hydroaccumulator should not be lower than the set connection. Be sure to repair the pressure switch of the pumping station, because very often this breakdown leads to frequent switching on of the equipment. The air pressure in the hydroaccumulator of the pumping station can be adjusted with the assistance of the nipple of the automobile pump with a pressure gauge or compressor. The onslaught of air must be ninety, one hundred percent of the required switching pressure of this equipment.

- Check valve is clogged. In this case, it stops closing the liquid, so it leaves the system, the pressure drops and the pump is connected. It is necessary to clean the valve, if the problem is not eliminated, then change this part.

- The diaphragm for the pumping station can cause rapid onsets and jerky supply of water resources. If the station is functioning, the pressure of the liquid is large, when the equipment is turned off, the water pressure immediately drops. Verdict one: the replacement of the membrane or fold. It is necessary to remove the accumulator and eliminate the damage!

- The pumping station is jerky due to a broken spool located at the top of the accumulator. Breakage can be eliminated by removing the diaphragm and replacing the faulty nipple with a working one.

- Carefully inspect all the joints in order to prevent the flow of fluid.

- Water can be supplied at a random interval if the pumping station sucks in air. Check the degree of water resource in the well opening (pipes that run from the well to the pump). The suction level should not exceed nine meters.

The station does not turn on, what to do

Why is the pump station impossible to turn on? Initially do some checking. electric power and network voltage. And also should be inspected plugs, sockets, cords on the oxidation of wires.

If all the items are controlled, and the equipment still does not work, then the problem is in the engine compartment.

In this case, the water station should be shown to experts. The service center will quickly fix this problem.

How to replace pears in a pumping station

The first sign of damage to the membrane is the constant inclusion of equipment. Fluid delivery occurs in short shocks. How to determine that the membrane is damaged? On the nipple is a stub, remove it. If liquid flows from it, the part is damaged. In this case, you need a new pear for the pumping station.

We make replacement pears independently. Initially turn off the station, release pressure, flush water. After that, unscrew the bolts, remove the flange, get a pear. Be sure to flush tank from sediment. After that we put a new membrane in the reservoir of the accumulator. We press down the flange, tighten the bolts and turn on the equipment. Do-it-yourself pump station repair!

What to do if the pump hums, but does not rotate

It happens that the sound made by the pump is heard, but the blades do not rotate. The pump may not work for a number of reasons:

- Pumping device may buzz due to prolonged downtime. If in country house people live only in the warm season, respectively winter period the device is retracted in the barn or garage. There he is without access of liquids and water. As a result, the impeller is glued to the body part. Therefore, try to rotate the rotor wheels yourself, if necessary, to clean all the blockages. Then connect to the network and check the performance of the structure.

- The pump may buzz, but not spinning when the hydrophore is faulty. The pump body is equipped with a diffuser, which is connected to the rail. Hydrofor can jam. In this case, replace the diffusers. After that, reset the pump in reverse mode.

- Pumping equipment may not work when a condenser fails, which is located in the engine's branded box. Using the tester, you can determine the fault. If the capacitor is closed, it will melt and darken. It is possible to correct the situation only by replacing this part.

The pump works, but there is no water, what to do

Many owners of their wells observe the situation when the pumping unit is working and the fluid does not enter the system. These problem points may occur if the pipeline joints are depressurized. The second reason may be the lack of liquid composition in a spring or pump installation. How to eliminate such failures?

Fill the pump compartment with water and start the equipment. If the substance does not re-enter, check the level of liquid crystals in the crinise. If it is below the water intake point, then it is necessary to pump the intake area of the pipe with water. The problem is not solved? Then check the integrity of the pipe system. Remove the pipe and inspect it. If tears and flaws are noticed on the pipe, replace the damaged areas. Do not forget to check the voltage in the sockets. Pump may not have enough power. In the sockets should not be less than one hundred and seventy volts.

Unfortunately, even the most expensive and high-quality device can not exist forever.

All devices come to malfunction sooner or later. Repairing pumping stations on your own is easy, if you follow the instructions above.

Repair of a pumping station is a typical operation, with the help of which the efficiency of an autonomous water supply source is maintained. That is, sooner or later, any owner of a well or a well will face similar work.

Therefore, every homeowner whose dwelling is equipped with an autonomous water supply system should master at least the primary skills of repairing pumping stations.

In this article we will look at the diagnostics of typical faults and the subsequent repair of household pumping stations. Moreover, all the repairs discussed in this article can be performed by any person with at least the rudimentary skills of plumbing.

The design of the pumping station consists of three nodes:

- The pump itself (vibration or centrifugal type).

- Storage capacity (tank or battery).

- Control relay (float type or pressure sensor).

And all the above-mentioned nodes interact with each other as follows:

- A pump pumps water from a well into a tank or battery.

- The pressure sensor turns on the pump at the minimum water level in the tank or the battery and turns it off at the maximum level. Moreover, a float-type mechanical sensor works in the tank, and an electronic pressure sensor functions in the accumulator with an elastic membrane.

- The tank or battery takes water from the pump, accumulates it and gives it to the consumer. That is, it is this part of the pumping station that is connected to the inland waterway.

|

|

And, of course, breakdowns or malfunctions of at least one node will lead to the shutdown of the entire station. Indeed, each structural element of such an aggregate has an equivalent impact on its functionality.

Typical failure of the pump station

Typical system failures include the following problems:

- Power outages. Without it, the pump and some sensors will not work.

- Interruptions in water. The debit of some wells does not allow the stations to operate at full capacity for a very long time. Yes, and the water level at the source can simply decrease, dropping below the end of the water intake pipe.

- Failure of a pressure switch or float valve. In this case, the naos simply does not turn on.

- The failure of the pump. In this case, no water enters the tank.

- Depressurization of the tank or battery. In this case, the liquid does not flow into the inner conduit, and the surrounding room will most likely be flooded.

That is, to maintain the station in working condition, it is necessary, at a minimum, to take care of supplying electricity and matching the water level in the well to the immersion depth of the intake pipe. Well, the full service cycle involves the timely repair of each station node.

Ways to eliminate typical damage

For the full functioning of the pumping station, it is necessary to periodically inspect and repair all components and mechanisms of this unit. Moreover, routine inspection is carried out with a specific frequency, and breakdowns happen anytime.

Before fixing a breakdown, it must also be diagnosed, by identifying, by indirect evidence, the cause of the failure. And further in the text we will consider typical indirect signs of breakdowns and ways to eliminate them.

Malfunction in the supply pipeline

The pump rotates, water does not enter the system - this situation is familiar to many owners of autonomous wells. The reasons for this failure lie in the depressurization of the pipeline joints, the failure of a check valve or an ejector. In addition, these symptoms may indicate a lack of water in the source or in the pump chamber.

The elimination of such a failure occurs as follows:

- First, with the help of a special expansion tank Water is poured into the pump, or rather into its working chamber. After that, the station starts again. Did not help? Then go to the next procedure.

- Secondly, the water level in the well is checked. If it is below the water intake point (the end of the intake pipe), then you will have to increase the intake section of the pipeline or wait until the water rises to a static level. Isn't that the reason? Then go to the next step.

- Thirdly, the integrity of the pipeline is checked. That is, it is removed from the well and inspected for breaks and other defects. Damaged areas are replaced with new ones.

In addition, these problems can be triggered by failures in the electrical network, when the pump simply does not have enough voltage to reach full capacity. Therefore, before all the above manipulations, just check the voltage in the outlet. And if there is less than 170 volts, then the problem lies on the side of the power engineers.

Failure of the hydraulic tank (accumulator)

With this breakdown, the pumping station is jerky. That is, it turns on, pumps water into the tank and turns off after a very short period of time. Moreover, this cycle repeats and repeats, provoking irritation of the owner of the unit.

The reason for this failure is only one - depressurization of the accumulator. That is, the membrane has burst in the storage device or the battery case itself has leaked. And to diagnose such a breakdown can be very simple: click on the nipple of the drive - if water comes out of it, then the membrane burst, and if the air goes, then problems are somewhere in the case.

Accordingly, the membrane is replaced by a new one (sometimes with a hydroaccumulator), the casing is sealed (in a problem area). And air is pumped into the internal cavity of the accumulator (through the nipple).

Pump failure

This is the most serious damage. Moreover, its consequences may look different. For example, if the pump does not turn on, then the cause of such a failure may be the lack of electricity in the network, and burnt contacts, and a burnt anchor. Therefore, we first check the light by turning on the light bulb, then loop through the contacts in the connection box, and then go to the anchor.

Well, if the pump is turned on, but it does not rotate, it is likely that the condenser in the start system has burned down, or the impeller of the centrifugal system has stuck to the case. To eliminate this problem, you just need to “spin” the impeller. And if the unit starts working and continues to function even after switching on / off, the problem is eliminated. Otherwise, you need to "sort out" the capacitors.

Pressure switch malfunction

This problem occurs when the pump is running continuously and does not turn off. And since its operation is controlled by a pressure relay, the whole problem is a malfunction or failure to adjust this unit.

A faulty relay is replaced with a new one, and an upset one is re-adjusted.

Moreover, the adjustment of the pressure switch is as follows:

- The body of the control unit is opened, opening access to two control springs — a large one, with which the lower pressure is set, and a small one, with the help of which the upper pressure is set.

- The adjustment itself is carried out by turning the tensioning screw or nut. Accordingly, a clockwise rotation increases the adjustable value, and against it decreases the variable parameter. And manipulations with a large spring allow you to raise or lower the minimum pressure in the system, and adjusting the small spring changes the difference between the minimum and maximum pressure.

It should be noted that all the above manipulations should be carried out only by experienced specialists, and only under the condition of complete control of the pressure at the outlet of the system with the help of a pressure gauge insured by a safety valve.

Moreover, the lower pressure should not be less than 1.5 atmospheres, and the upper should not be more than 5.5-6 atmospheres. Otherwise you will lose all plumbing and appliancesconnected to a poorly regulated pipeline.

Pumping station is an excellent solution for organizing water supply in a private household. The unexpected breakdown of this complex of devices can cause a lot of trouble for the owners. Fortunately, most breakdowns are typical, they can be easily repaired at home. How to carry out the repair of equipment with your own hands, you should know in advance. We will talk about this now - stay with us and you will learn many new things!

How to ensure stable operation of the water supply system

In order for the plumbing system to function successfully, it is necessary to ensure a certain level of pressure and water pressure. When there is no access to a centralized water supply, this problem is easily solved with the help of a pumping station. It usually consists of:

- pump;

- membrane storage tank;

- automatic control unit (pressure switch, pressure gauge, etc.).

The pump pumps water that enters the tank. When the pressure in the tank reaches a certain maximum level, the pump shuts off. Gradually, the water from the tank is consumed for various needs and the pressure drops. At the minimum pressure level, the pump turns on again and water enters the tank. The process is controlled automatically.

With the help of such a unit it is possible to provide water supply for a house, a bathhouse and other buildings located on the site. Having studied the principle of work, you need to begin to study the possible damage and ways to eliminate them.

Common causes of pumping station breakdowns

In the world, as the classics reasonably claim, nothing lasts forever, this also applies to equipment. Unexpected malfunctions in the operation of pumping equipment, its stopping or incorrect functioning can be caused by a number of reasons, such as:

- lack of electricity;

- lack of water in the system;

- pump breakdown;

- membrane tank failure;

- damage to the automatic unit, etc.

The device of household pumping units is not particularly complex, and this allows you to do the repair yourself. In some cases, you need to disassemble the pump and replace the damaged part. Sometimes you need to seal the crack in the tank, and sometimes it is enough just to check the availability of electricity. In each case, you need to determine why the pump does not pump water, and find a "recipe" for solving the problem. If you could not find an acceptable solution to the problem, you need to contact the specialists.

Typical faults and their removal

Below we consider a number of problems and malfunctions that may arise during the operation of a pumping station.

The pump rotates, no water enters the system - the check valve is not working properly

Cause: Violation of the tightness of conductive pipelines, the check valve does not work properly, there is no water in the pipeline or pump.

Solution to the problem: First you need to check the presence of water in the pipeline or pump. If it is absent, you just need to add it to the pump through the designated hole or lower the suction hose (or the pump itself). The maximum allowable distance between the pump and the water level must be maintained.

Now you need to check the status of the check valve and the tightness of the joints, and then fix the problems found. If all these measures did not help, it is possible that the pump is damaged by abrasives, such as sand. In this case, you have to disassemble the pump and replace it with the impeller or housing. In some cases, you need to install a new pump.

Please note that before starting work does not hurt to check the voltage in the mains. If it is insufficient (typical situation for countryside), the pump will not pump water, although it will turn on.

The station is jerking - damaged hydraulic tank

Cause: The answer to the question of why the pumping station is turned on too often, most often lies in the fact that some part of the hydraulic tank is damaged. Because of this, the equipment is not gaining pressure.

The hydraulic tank of the pumping station consists of a casing and a membrane located inside

Solution to the problem: First you need to click on the nipple located on the back side of the tank. If water flows from it (air must escape), it means that the inner membrane is torn, it should be replaced.

Another possible reason why the pressure in the accumulator of the aggregate does not correspond to the normal value is a violation of the body tightness. It is necessary to find a crack or a hole and seal it. Sometimes, to solve a problem, simply pumping the missing amount of air into the tank with an ordinary pump. The standard pressure value in the tank is 1.5-1.8 atmospheres.

Swap in membrane tank missing air is possible through a standard threaded nipple

It should be noted that sometimes water comes intermittently due to a leakage at the joints of the suction pipe. It must be checked along the entire length and repaired the detected cracks.

Video: do-it-yourself hydraulic tank repair

Not included

Cause: No power supply.

Solution to the problem: It is necessary to check and possibly clean the burnt contacts of the pressure relay, check the integrity of the winding. The fact that the engine burned, it will become clear by smell, characteristic of burning insulation materials.

Turns on but does not rotate - cause in a condenser or impeller

Cause: broken condenser or impeller "stuck" to the pump casing. This situation often arises for pumps that have been idle for several months.

Solution to the problem: To start the locked impeller, just manually scroll it a couple of times. After that, the pump should turn on. If the capacitor is broken, it will have to be replaced.

The unit does not turn off and runs continuously - the relay is not adjusted

Cause: Pressure switch malfunction.

Solution to the problem: Needed. To do this, use two springs located on the relay: large and small. The large spring is responsible for regulating the lower pressure limit, and with the help of a small one they regulate the difference between the minimum and maximum values. All manipulations with the pressure switch must be done very carefully.

To find out the reasons why the equipment does not turn off, be sure to check the status of the inlet of the pressure switch. Sometimes it is clogged with particles and sediments contained in the water. In this case, the hole must be cleaned and check the operation of the pressure switch.

A few words about the pressure switch adjustment

It should be remembered that the control of the pressure switch of the pumping station should be treated with great care. If this node is adjusted incorrectly, it can lead to a serious breakdown of the entire station, and the manufacturer’s warranty obligations do not apply to such cases.

First you need to achieve the correct pressure in the accumulator. To do this, the device is disconnected from the network, and the tank is completely drained of water. Then, using a pump with a pressure gauge or a household compressor in the hydraulic tank, the required level of pressure is created. Now you need to unscrew the plastic cover on the pressure switch to gain access to the control springs.

Adjusting the minimum pressure to turn on the pump is carried out using a large spring (2, see figure). Turning the spring clockwise allows you to increase this figure, and turning it counterclockwise decreases it. To set the required range between the maximum and minimum pressure limits, you must rotate the pressure differential adjustment spring (1, see figure). Turning the nut clockwise expands the range, and turning it counterclockwise narrows it.

The pressure switch of the pumping station is regulated by a large and small spring

Then the cover of the pressure switch must be installed in place, pour the required volume of water into the pumping station and connect the power supply. The maximum pressure value in the system should be no more than 95% of the maximum possible outlet pressure, which is indicated by the manufacturer in the data sheet.

Video: how to regulate water pressure switch

Knowing about these faults, you will be able to figure out in time why the pumping station does not work, and fix the problem yourself.