Water heating in a private house from the stove. Water heating from a wood-burning stove - a scheme and proper installation

Effective home heating is one of the most important tasks for every homeowner. An interesting option for solving this problem can be steam heating in a private house. This is not the simplest version of the heating system, but it has the right to exist and is worthy of close examination.

When water boils at constant pressure, it keeps its temperature constant. The steam produced as a result of this boiling has a significant amount of thermal energy. At the moment of condensation, i.e. when a vapor is converted to a liquid, this energy is released and transferred to the environment.

This principle is used in the operation of steam heating systems. The water boils in the boiler, the steam moves through the pipes to the radiators, there it condenses and parted with heat, thereby heating the air in the room. The water obtained during the condensation process continues to flow through the pipes and returns to a special storage, and then comes to the heater in a natural way or by force, using a pump.

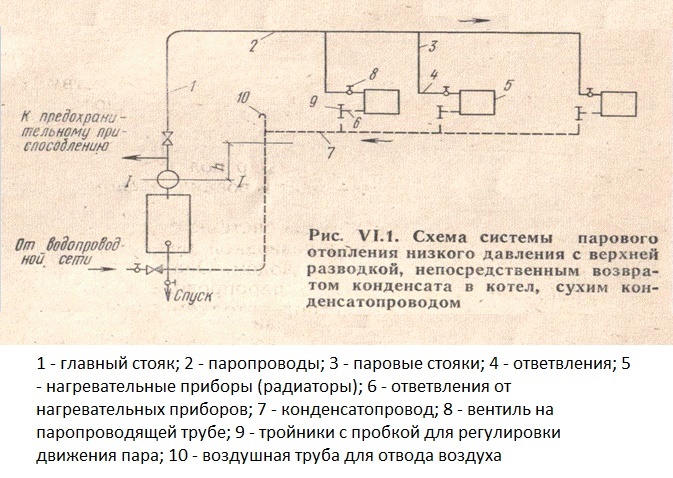

This diagram demonstrates the principles of the distribution of steam heating. The heating device should be located lower than the radiators, the condensate line is given a slope

Such systems usually use so-called dry saturated steam, which does not contain suspended water particles. The amount of steam in the system is reflected in its operation. If the steam is too low, this will create problems for the free flow of condensate, and cold air will collect at the bottom of the heater. A sufficient volume of steam improves the process of drainage of condensate, which is pushed to the walls and flows down over them in the form of a thin water film.

Depending on the pressure inside the steam heating system, they are divided into:

- vacuum-steam;

- low pressure;

- high pressure.

In the first, the pressure is less than 0.1 MPa, in the second - even lower - to 0.07 MPa, and in the third - more than 0.07 MPa. Open low pressure systems have access to air from the atmosphere, but they can also be closed, i. E. completely hermetic.

In closed systems, water immediately after condensation enters the heat exchanger, but often open systems are used in which the coolant is first collected by the storage tank and then pumped to the boiler for heating. The condensate can completely fill the pipes through which it moves for heating or only partially. The latter option is preferable, because when the system is shut off, the pipes in it will remain dry.

If the heat carrier of steam heating after condensation moves directly to the boiler for subsequent heating, the system is called closed. If the condensate is first collected in a storage tank from which it is pumped into the boiler by a pump, the system is classified as open

Features of low pressure systems

A widespread version of such a system is a closed one, using a gravity return to the condensate boiler, which fills the pipes not completely, with the upper piping being applied. First, the system is filled with water to the required level, then heating begins. The condensate flows down the common riser and is forced out to the boiler when it reaches the predetermined level.

In the same system with lower wiring, it is recommended to install pipes with a slight slope in the direction of the steam movement to reduce noise effects. At the point of condensate drainage, a loop-shaped hydraulic lock is arranged to prevent steam from moving to the condensate line.

The speed of steam in such systems should be moderate, not more than 0.14 m / s. Otherwise, the steam will also capture the particles of moisture that have accumulated on the walls. As a result, the system works with a lot of noise, the risk of water hammering increases.

Combined wiring, i.e. combination of top and bottom wiring, apply if pipes are laid under the floor of the upper or middle floor of the house. The lumen of the pipes, through which the water returns to the boiler, in this case will be closed with condensate.

If the pressure in the system exceeds 0.02 MPa, it should be made open. The air is removed through the condensate accumulator, and the steam trap or the water trap is installed to prevent the steam from leaving the steam. Water from the storage tank is pumped to the heat exchanger by the pump, which allows the drive to be installed below the level on which the heat exchanger is located.

The heating medium for heating a private house with a boiler room is heated in a heat exchanger located in the boiler room. When the operating temperature is reached, the steam moves to the manifold separating the flow into two circuits: for the main rooms and for the boiler room (+)

Evaluation of advantages and disadvantages

What is good about a steam heating system? It is relatively easy to do even on the basis of a conventional wood-burning stove. This is especially true in areas where centralized gas supply is not available, and firewood or other solid fuels are readily available. Steam as a coolant is significantly ahead of water. The heating rate of the rooms is three times higher.

In addition, the steam heating system can hardly fail during the winter cold due to the lack of heating. If the furnace is burnt out, the water from the system will collect in the storage tank or in the heat exchanger, and the pipes and radiators will remain empty. With water heating, the freezing of the coolant, which is filled with the entire circuit, is known to lead to rupture of the pipes.

Finally, the dimensions of the radiators for steam heating should be significantly less than for water systems, since the amount of the resulting thermal energy increases several times. This will slightly reduce the cost of installing a heating system at home.

Decorative grilles for radiators of steam heating are not only an element of interior design, but also a means of protection from burns

This concludes the list of advantages of the steam system, and one can proceed to its shortcomings, which are quite significant:

- high risk of burns;

- increased noise level during operation;

- complexity with the adjustment of the system;

- the need to purchase expensive pipes, etc.

Norms of safety, steam heating is not recommended for living quarters, because it poses a high risk to the health and life of people living in the house. So, the working temperature of the radiators will be very high, when you touch them you can get a serious burn. Therefore, all radiators have to be closed with reliable decorative grilles.

Conventional PVC pipes for such a system will not work, because they must withstand high pressures and temperatures of more than 100 degrees. The same requirements apply to the rest of the system. Pipes of steam heating should be copper or made of galvanized steel.

Copper pipes - an ideal, but not cheap option for communications for steam heating systems. To connect these pipes you will need a welding machine

In any case, this point is not budgetary. Security issues should be given the closest attention. All installation works, for example, welding of copper pipes, will require the highest possible quality. If the connection breaks and a steam jet escapes into the hole, one of the tenants of the house risks serious burns.

Pipes made of stainless steel are capable of withstanding such loads characteristic of steam heating systems as high temperature and high pressure in the system

Another shortcoming of steam heating is an increased noise level. To solve this problem, you must properly mount the radiators. They are suspended on special anti-noise brackets. The boiler or oven is best placed in a separate room. In addition, copper pipes can be placed in the thickness of the walls, which will also reduce the noise level.

Finally, it is slightly difficult to regulate the heating temperature in rooms with steam heating. You can not install a thermostat and simply reduce the amount of steam. It will be necessary to reduce the amount of fuel, which is not always easy, or to ventilate the premises. Before starting the installation of the steam heating system, all these points should be taken into account.

Design of a steam heating system

Even for a small room, it is best to design a project. The system made on "maybe" with a high probability of soon will require a rework, and the scheme drawn up on paper will immediately reveal weaknesses and correct them. For example, in order to create a system with a natural circulation of the coolant, the heat exchanger, and accordingly the heating device, should be located at the lowest point of the house.

The steam pipeline and the condensate line of heating systems with a natural type of coolant movement are arranged with a slope towards the direction of its movement (+)

This means that the stove or boiler should stand below all radiators, as well as pipes that stand not vertically, but horizontally or at an angle to the vertical. If the heating device is not placed in this way (there is no basement in the house, the basement is used for other purposes, etc.), preference should be given to heating with forced circulation.

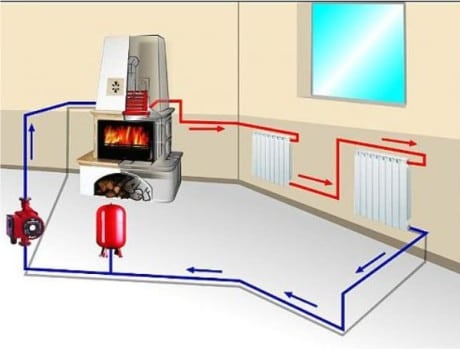

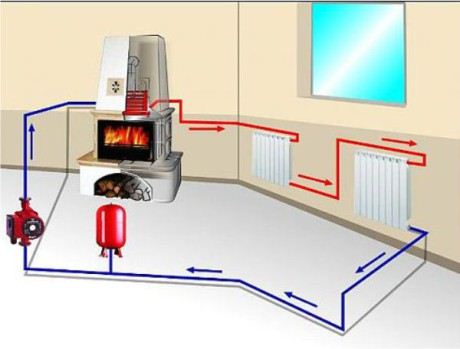

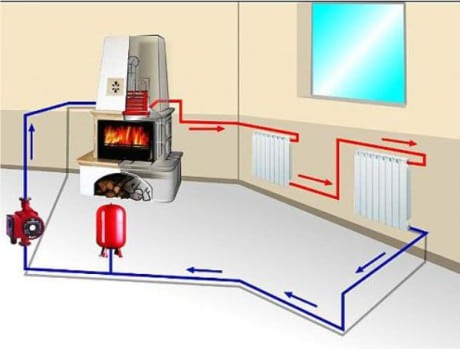

The diagram shows the heating system with forced circulation. for its installation, a circulation pump and a storage tank

Therefore, it is necessary to include a pump in the circuit, which will pump water into the heat exchanger. An important point in the design of the heating system is the connection of radiators. A series connection or a so-called single-pipe system involves the connection of all radiators in order.

As a result, the coolant will move sequentially through the system, gradually cooling down. This is an economical version of the connection, which is easier to install, and at a cost will be cheaper. But the uniformity of warming up in this way will suffer, since the first radiator will be the hottest, and the last coolant will be delivered to the already half-cooled condition.

Single-pipe connection of radiators, as can be seen from this scheme, assumes a series of installation. The coolant enters the last radiator already cooled down

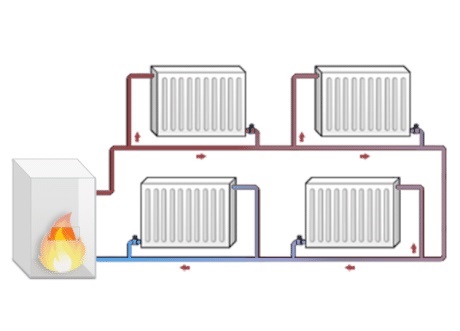

One-pipe solution can be acceptable only when connecting the steam heating in the cottage or in a small house, on an area of less than 80 square meters. m. And for a spacious cottage or a two-storey building is more suitable two-pipe system, in which the radiators are connected in parallel. This scheme ensures a simultaneous, rather than a consistent flow of coolant in each radiator, and the heating of rooms is carried out more evenly.

But with a two-pipe circuit, two pipes must be connected to each radiator: a straight line and a "return". Such a system is more difficult to implement, and it will cost a little more than installing a single-pipe system. However, the vast majority of water heating systems are made on a two-pipe scheme, despite the difficulties, and it functions quite successfully.

This diagram shows a two-pipe installation system for radiators for steam heating. Each radiator is connected to a common riser and has a return pipe, which ensures an even distribution of the coolant

If a wood-burning stove is to be used as a heat source, a special heat exchanger should be immediately calculated and designed. It looks like a coil welded from metal pipes. This element is integrated directly into the furnace design, and not installed separately.

Therefore, the design of the new furnace should also be considered at the design stage. You can use the existing furnace, but it will have to be partially disassembled in order to install the heat exchanger inside. To obtain 9 kW of heat, a heat exchanger with a surface area of about one square meter is needed. The larger the heated area, the larger the dimensions of the heat exchanger.

If you heat a room with a boiler, everything is a bit simpler: you need to buy and install it. Usually for steam heating in the house it is recommended to take the water-tube model of the boiler as the most effective. Although fire-tube, smoke or combined smoke and fire-tube models can also become a very acceptable option.

Sometimes for the organization of steam heating a homemade boiler is used, in which the used engine oil is burnt. But this option is considered suitable for use in utility rooms, for example in a garage. For an apartment house this option is not very good.

Mounting on the basis of a wood stove

If the project is compiled, it's time to stock up on the necessary materials and tools. Calculate the required number of elements of the system will allow the previously compiled project. It should be marked with all the turns, joints, tees, places of installation of radiators, etc. In addition, you need to purchase pipe clamps, as well as brackets, which will be installed radiators.

The boiler of the steam heating system, arranged on the basis of a wood-burning oven, is installed directly in it. The boiler is connected to a steam pipe and a condensate line

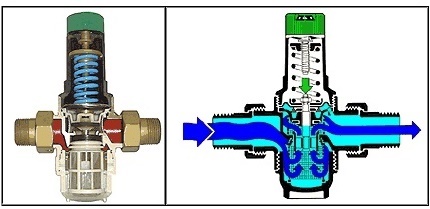

The length of the pipes is also calculated according to the scheme. In order to reduce the vapor pressure in the system if necessary, a pressure reducing valve is required. A hydraulic shutter is needed to ensure complete drainage of the system for cleaning, maintenance or repair.

Before each radiator is recommended to install a shut-off valve, which will disable it for repair, rinsing or replacement. Also, the radiators are fitted with Mayevsky cranes to release the air that has entered the system. Although vapor is a gaseous rather than a liquid substance, the presence of air in the system can negatively affect its efficiency.

In order for the condensation process to occur in the radiators, rather than in the accumulator or in the riser, it is recommended to install a tee with a stopper through which only water will pass. If a forced circulation system is planned to be installed, a circulation pump will be required. In addition, you need a container to collect condensed moisture.

Gravity systems in such devices do not need. But the pipe through which the water is directed to the heat exchanger must be wide enough to allow rapid movement of the liquid for further heating.

The absence of a reduction valve in the steam heating system, the device of which is shown in the diagram, can lead to serious damages due to excessive pressure

In addition to the usual mounting tools, you will definitely need a welding machine for connecting copper pipes. Structures made of galvanized steel usually have threaded connections, which should be carefully sealed. If you plan to install steam heating from the oven, you'll have to start with the manufacture of the heat exchanger.

The heat exchanger for steam heating, built into a wood-burning oven, consists of a system of hollow metal pipes, through which water circulates. The element may have an arbitrary shape corresponding to the size and shape of the furnace

It is made from metal pipes 2.5-3 mm thick or even slightly thicker. The heat exchanger can be made both in the form of a coil, and in any other form. The main thing is that the device should fit inside the wood-burning stove, and also that its surface is large enough to heat the water and steam.

The quality of the heat exchanger welding should be ideal without exaggeration. Even microscopic caverns in the seams are unacceptable, since the device will be exposed to increased pressure from hot steam. After the heat exchanger is ready for installation, each welded seam should be checked.

To do this, first all the seams are plastered with white chalk. After that, one of the heat exchanger holes is closed, and the second is filled with kerosene until the device is filled to the top. Now you need to wait a bit, and then assess the condition of the stitches. If there are cracks, kerosene will seep through them, and in such places the chalk will darken.

The identified flaws are corrected, and then the test is repeated to ensure the integrity of the device. Now it should be washed, and then start laying a wood stove. The heat exchanger is securely built into the furnace, and pipes are connected to its inlet and outlet, which are then used to connect the heat exchanger to the heating system at home.

Laying of the furnace is completed in the usual way for such structures. Then, the pipes and radiators of the heating system are installed in accordance with the draft previously compiled. First install radiators, using the brackets, which will extinguish noise from the operation of steam heating.

For each radiator the Mayevsky cranes are installed so that air can be released. The shut-off valves will need one more than the radiators, since you need to install one common shut-off valve at the very beginning of the system. Before this valve put also a pressure reducing valve and a reduction-cooling unit.

In the end, if it is provided for in the project, a coolant storage tank and a circulation pump are installed. For systems arranged with natural, rather than forced circulation, a tank and pump are not needed. But the pipe that leads to the heat exchanger, you need to give a slight slope, about 3 mm per meter.

Modern boilers for steam heating in the house are reliable devices operating on various fuels and equipped with automated control systems

Systems with a steam boiler are mounted approximately the same way: in accordance with the design and with the correction for the equipment features. For example, a pressure reducing valve and a chiller will most likely not be needed, since the pressure and steam temperature monitoring system is already built into the boiler.

When installing a steam heating system, remember that all of its elements must withstand a high temperature, more than 100 degrees. For example, a conventional membrane expander as a drive will not work, because its maximum is 85 degrees.

The chimney of the furnace, in which the heat exchanger is integrated, will become more dirty than the conventional stove. Therefore, cleaning the chimney must be planned and performed more often.

A furnace with a heat exchanger can also be used for cooking, if desired, but this is not very convenient. In the summer, when heating is not needed, this furnace can not be ignited. We'll have to look for an alternative. It's easier if there is a separate convenient oven for the kitchen in the house.

Video on steam heating

Practical experience on reworking a wood-burning stove in a steam-heating boiler is presented on this video:

Continuation of the process of installing steam heating can be viewed in this file:

The difference between forced and natural circulation in heating systems is described in detail here:

Steam heating is not the easiest option for an autonomous heating system. But with proper design and installation with steam, it is possible to provide your house with the necessary amount of heat efficiently and relatively inexpensively.

How to arrange a safe steam heating in a private house from a brick oven with your own hands

In remote villages, many, weighing all the pros and cons, prefer heating to stove. Autonomy has a lot of advantages, but it is difficult to warm the house more than 50 m 2 with a furnace evenly and evenly. Unless, if you install a heat exchanger in it, to which you connect the batteries. If water circulates water as a coolant in such a system, it will be called water heating if steam is steam.

Sometimes these two kinds of heating are confused. However, they have their differences, advantages and disadvantages. In addition, steam heating has long been banned in residential buildings because of unsafe exploitation. But it is much cheaper than water and, moreover, there are protective measures. True, one can not say about the simplicity of installation, on the contrary, to arrange steam heating in a private house, and even from a brick oven, it is necessary to exert a lot of time and effort. But first things first.

Heating radiator connected to the oven

Differences between steam and water heating

Steam heating works on the principle:

- first, the water is heated to a boil and converted into steam;

- steam through the pipes passes into the radiators, giving off heat;

- in the batteries steam condenses, turning again into water;

- water flows down the outlets into the expansion vessel and returns to the heat exchanger.

In contrast to water heating, steam generates a large heat emission, three times faster warms up the room, has ergonomics. It requires small-sized equipment, which, in fact, reduces the price of the system as a whole. Another plus: in the abandoned house pipes in the cold season do not freeze. Therefore, it is easy to start steam heating, arriving in the winter at the dacha, and when leaving, make sure that the fuel is completely burnt.

By the way, as a generator for steam heating it is possible to use not only furnaces, but also boilers operating on waste oil. But usually such a system is installed in garages and outbuildings for reasons of environmental friendliness.

The device of the boiler operating on waste oil

Disadvantages of steam heating and how to eliminate them

- radiators from steam are heated above 100 ° С, because of what they are dangerous, especially for children and animals;

- the system of steam heating works noisily;

- temperature control is difficult;

- impossibility of installing water-heated floors.

The first drawback can be eliminated by protecting the radiators and lead pipes with screens. There is a huge selection of these decorative interior elements made of wood and plastic.

![]()

Wooden screen protects against accidental contact with hot radiators

The noise effect in the system can be significantly reduced if you use anti-noise brackets for radiators for their installation, and the steam generator itself is arranged in a separate room.

The third point is difficult to eliminate. But for the fourth solution is - water warm floors if you want you can replace the film infrared.

Attention! A brick oven with a steam generator is undesirable to plan simultaneously for heating and cooking, as in the summer it will still be impossible to use. Or, you have to come up with an alternative for a warm period. For example, make a summer stove outdoors.

Also, plastic pipes can not be used in the system, they can not withstand the temperature regime.

Scheme of installation of steam heating from the furnace

- The natural and forced circulation system

The system, which operates on the principle of natural circulation, requires the location of the heat exchanger below the level of the radiators and all pipes at an angle. For the forced system, a pump is required to ensure the uninterrupted circulation of the heat exchanger.

Scheme with natural circulation

Circuit with forced circulation

Schemes are also single- and double-tube.

- Single-pipe scheme of steam heating of a private house

This scheme operates on the principle of the successive connection of radiators. The coolant moves through the tube, passing from one battery to another. As a result, the first radiator turns out to be the hottest, and the last one - practically cooled down. Therefore, it is recommended to use such a scheme for rooms with a small area - from 40 to 80 m 2.

Single-pipe heating scheme

This system is more suitable for houses with large areas, two-story cottages. It differs in that the radiators in it are connected in parallel, with the help of two pipes: supply and discharge (condensing). In this scheme, the coolant is supplied to all radiators with the same temperature, since it does not have time to cool down.

Two-pipe heating scheme

How to arrange steam heating from a stove with your own hands

Equipment and materials

For the device of steam heating you will need:

- radiators (for each window);

- heat exchanger - in fact, a water tube boiler or steam generator;

- pipes for steam and condensate drainage - preference should be given to materials resistant to high temperatures: galvanized steel or copper;

- knee, connectors, pipe clamps, brackets for radiators, shut-off valves: valves, air bleed valves;

- hydraulic shutter, used for the purpose of drying steam pipe;

- pressure reducing valve to reduce system pressure;

- reduction-cooling unit;

- welding machine;

- a container for collecting condensate;

- pump.

Pressure reducing valve for reducing system pressure

Expensive equipment is better to rent.

Heat Exchanger

The heat exchanger for a brick kiln will have to be made independently or ordered. To do this, you need pipes made of metal, a wall thickness of 2.5 mm and a welding machine. You can connect them as in the figure or in the form of a coil. The main thing is to monitor the quality of welded seams. The calculation is approximately as follows: 1 m 2 of the coil surface gives up to 9 kW.

After the construction is made, it is necessary to check it. To do this, you should pour water into it and make sure that there is no leakage. However, this method is not very informative, since welded seams can have slag inclusions that, if there is no excess pressure, will not be detected.

It is best to check the quality of seams using the "kerosene to chalk" method. To do this, it is necessary to chalk all the welded seams and pour kerosene into the construction. In the event of a shallow pore, the chalk will darken, since kerosene will leak into it.

Contour for a brick oven

Another version of the heat exchanger for the furnace

Sequence of work

The heat exchanger is built into the furnace at the stage of its laying directly into the furnace

The heat exchanger is built into the furnace

It should be taken into account that if it is planned to make a brewing furnace, then there should not be pipes in the upper part, otherwise they will interfere. Then it is better to make a heat exchanger according to this principle

Further, according to the scheme, radiators are mounted under the windows. They connect the supply and discharge pipes. For natural circulation - with a slight slope of 3 mm per meter. Each convector should be provided with a crane to vent air.

For safety reasons it is advisable to install stopcocks in front of each radiator and one in front of the entire system. In the beginning, you should also put a pressure relief valve and a cooling unit.

At the end of the system, a condensate collection tank is installed, from which water also flows back to the heat exchanger under a slope. It is not desirable for this purpose to use a membrane dilator, since it is designed for t up to 85 ° C.

In the forced circulation system, in the return pipeline, a pump is installed in front of the furnace.

Nuances when using steam heating from a stove

In brick furnaces with a heat exchanger, more soot is formed in the chimney than usual, and it often has to be cleaned.

With a gravity-based system, the furnace will have to be built in a basement room so that the condensate can flow freely to the lower point.

Do not neglect the installation of valves - they are necessary for safety and accident prevention. Since the pump requires electricity, it must be taken into account that in the event of a power failure, it will be impossible to stop the operation of the furnace.

Heating in a wooden house

Steam heating in a wooden house is installed on the same principle as in a brick house. It is necessary only to observe fire safety measures - to protect wooden surfaces from overheating.

In remote villages, many, weighing all the pros and cons, prefer heating to stove. Autonomy has a lot of advantages, but it is difficult to warm the house more than 50 m 2 with a furnace evenly and evenly. Unless, if you install a heat exchanger in it, to which you connect the batteries. If water circulates water as a coolant in such a system, it will be called water heating if steam is steam.

Sometimes these two kinds of heating are confused. However, they have their differences, advantages and disadvantages. In addition, steam heating has long been banned in residential buildings because of unsafe exploitation. But it is much cheaper than water and, moreover, there are protective measures. True, one can not say about the simplicity of installation, on the contrary, to arrange steam heating in a private house, and even from a brick oven, it is necessary to exert a lot of time and effort. But first things first.

Differences between steam and water heating

Steam heating works on the principle:

- first, the water is heated to a boil and converted into steam;

- steam through the pipes passes into the radiators, giving off heat;

- in the batteries steam condenses, turning again into water;

- water flows down the outlets into the expansion vessel and returns to the heat exchanger.

In contrast to water heating, steam generates a large heat emission, three times faster warms up the room, has ergonomics. It requires small-sized equipment, which, in fact, reduces the price of the system as a whole. Another plus: in the abandoned house pipes in the cold season do not freeze. Therefore, it is easy to start steam heating, arriving in the winter at the dacha, and when leaving, make sure that the fuel is completely burnt.

By the way, as a generator for steam heating it is possible to use not only furnaces, but also boilers operating on waste oil. But usually such a system is installed in garages and outbuildings for reasons of environmental friendliness.

The device of the boiler operating on waste oil

Disadvantages of steam heating and how to eliminate them

Imperfections of the system:

- radiators from steam are heated above 100 ° С, because of what they are dangerous, especially for children and animals;

- the system of steam heating works noisily;

- temperature control is difficult;

- impossibility of installing water-heated floors.

The first drawback can be eliminated by protecting the radiators and lead pipes with screens. There is a huge selection of these decorative interior elements made of wood and plastic.

Wooden screen protects against accidental contact with hot radiators

The noise effect in the system can be significantly reduced if you use anti-noise brackets for radiators for their installation, and the steam generator itself is arranged in a separate room.

The third point is difficult to eliminate. But for the fourth solution is - water warm floors if you want you can replace the film infrared.

Attention! A brick oven with a steam generator is undesirable to plan simultaneously for heating and cooking, as in the summer it will still be impossible to use. Or, you have to come up with an alternative for a warm period. For example, make a summer stove outdoors.

Also, plastic pipes can not be used in the system, they can not withstand the temperature regime.

Scheme of installation of steam heating from the furnace

- The natural and forced circulation system

The system, which operates on the principle of natural circulation, requires the location of the heat exchanger below the level of the radiators and all pipes at an angle. For the forced system, a pump is required to ensure the uninterrupted circulation of the heat exchanger.

Schemes are also single- and double-tube.

- Single-pipe scheme of steam heating of a private house

This scheme operates on the principle of the successive connection of radiators. The coolant moves through the tube, passing from one battery to another. As a result, the first radiator turns out to be the hottest, and the last one - practically cooled down. Therefore, it is recommended to use such a scheme for rooms with a small area - from 40 to 80 m 2.

Single-pipe heating scheme

This system is more suitable for houses with large areas, two-story cottages. It differs in that the radiators in it are connected in parallel, with the help of two pipes: supply and discharge (condensing). In this scheme, the coolant is supplied to all radiators with the same temperature, since it does not have time to cool down.

Two-pipe heating scheme

How to arrange steam heating from a stove with your own hands

Equipment and materials

For the device of steam heating you will need:

- radiators (for each window);

- heat exchanger - in fact, a water tube boiler or steam generator;

- pipes for steam and condensate drainage - preference should be given to materials resistant to high temperatures: galvanized steel or copper;

- knee, connectors, pipe clamps, brackets for radiators, shut-off valves: valves, air bleed valves;

- hydraulic shutter, used for the purpose of drying steam pipe;

- pressure reducing valve to reduce system pressure;

- reduction-cooling unit;

- welding machine;

- a container for collecting condensate;

- pump.

Pressure reducing valve for reducing system pressure

Expensive equipment is better to rent.

The heat exchanger for a brick kiln will have to be made independently or ordered. To do this, you need pipes made of metal, a wall thickness of 2.5 mm and a welding machine. You can connect them as in the figure or in the form of a coil. The main thing is to monitor the quality of welded seams. The calculation is approximately as follows: 1 m 2 of the coil surface gives up to 9 kW.

After the construction is made, it is necessary to check it. To do this, you should pour water into it and make sure that there is no leakage. However, this method is not very informative, since welded seams can have slag inclusions that, if there is no excess pressure, will not be detected.

It is best to check the quality of seams using the "kerosene to chalk" method. To do this, it is necessary to chalk all the welded seams and pour kerosene into the construction. In the event of a shallow pore, the chalk will darken, since kerosene will leak into it.

Contour for a brick oven

Another version of the heat exchanger for the furnace

Sequence of work

The heat exchanger is built into the furnace at the stage of its laying directly into the furnace

It should be taken into account that if it is planned to make a brewing furnace, then there should not be pipes in the upper part, otherwise they will interfere. Then it is better to make a heat exchanger according to this principle

Further, according to the scheme, radiators are mounted under the windows. They connect the supply and discharge pipes. For natural circulation - with a slight slope of 3 mm per meter. Each convector should be provided with a crane to vent air.

For safety reasons it is advisable to install stopcocks in front of each radiator and one in front of the entire system. In the beginning, you should also put a pressure relief valve and a cooling unit.

At the end of the system, a condensate collection tank is installed, from which water also flows back to the heat exchanger under a slope. It is not desirable for this purpose to use a membrane dilator, since it is designed for t up to 85 ° C.

In the forced circulation system, in the return pipeline, a pump is installed in front of the furnace.

Nuances when using steam heating from a stove

In brick furnaces with a heat exchanger, more soot is formed in the chimney than usual, and it often has to be cleaned.

With a gravity-based system, the furnace will have to be built in a basement room so that the condensate can flow freely to the lower point.

Do not neglect the installation of valves - they are necessary for safety and accident prevention. Since the pump requires electricity, it must be taken into account that in the event of a power failure, it will be impossible to stop the operation of the furnace.

Steam heating in a wooden house is installed on the same principle as in a brick house. It is necessary only to observe fire safety measures - to protect wooden surfaces from overheating.

Video: combined heating system of a private house

Despite the appearance of modern building materials with high technical characteristics, some owners of private houses choose water heating from a stove on firewood, rather than modern ones.

Water heating from a wood-burning stove is chosen not only because of availability and financial profitability, but also because of the large choice of fuel, stylish appearance and the possibility of using heat units in conjunction with other heating schemes.

Schemes of water heating from the furnace

Traditional heating is a structure built of bricks and having a chimney, furnace niche, and also a box for ash. It is necessary to pay attention to the smoke extraction system, since the heating of the room is due to heat, which "radiates" the carbon monoxide that has passed through the channels of the system.

This scheme is suitable for small houses, as a traditional oven is not capable of heating a large area (actual water heating from the furnace will be relevant here).

In order to build such heating, a heat exchanger is placed in the furnace niche, which will heat the coolant. In general, this kind of system can increase the heating efficiency and increase the heating area. The U-shaped design of the stove is the simplest - the heater is made of a sheet of metal, the thickness of which is not less than 4 mm.

- scheme: the coil is installed in the form of a register, which is made by welding pipes. Conditions: the diameter of the pipe is 50 millimeters, the minimum wall thickness is 0.35 centimeters. The register with the heat exchanger is heated in the furnace from the burning flame, after which the combustion products come up and make three moves, while heating the brick walls.

Double-plate hob layout

This design does not have long chimney ducts, since heat comes from combustion products through a water boiler. The power of the heater should be about 9 kW, and the dimensions of the heat exchanger - 1030х650х780.

In the process of burning wood, the coil is directly heated, which receives additional heat from the flue gases, after which the flue gases enter the duct that is located between the oven and the hob, go around the oven and exit through the chimney.

"Two-chamber furnace with water heating K.A. Dmitrieva "is the most common scheme of all possible. Such a system is provided with separate ducts for the chimney and two fireboxes, one of which is designed to heat the oven, and the second - to provide water heating from the wood stove. unite into one. The furnace parameters in this version are 1500х680х770 (the last figure is the height), and the power - 9.5 kW.

When the first furnace niche is operating, the flue gases envelop the oven and then go to the flue below it. The water heater, at the same time, does not participate in the process, which is very convenient for the summer period. The second chamber begins to heat with the onset of cold weather, when it is necessary to effectively warm the house.

Installation

You can install a furnace with a water circuit in two ways:

- "From scratch" (laying a new oven by the dimensions of the heat exchanger).

- The installation of the heat exchanger can take place in the already existing furnace compartment. Unlike the first variant, the heat exchanger is made according to the dimensions of the structure, and not vice versa.

It is important to know that the size of the radiator (in both cases) along the inner contour should not exceed 3 cm - this is necessary in order to avoid boiling water in the event that the circulation is weak. The thickness of the walls of the radiator should be in the range of 3 to 5 millimeters. If the thickness is less, the walls can burn out, and the radiator can stop working. Only coal and wood are used as fuel.

Between the wall and the boiler should be a distance equal to one centimeter. If the radiator is made of steel, the distance can be reduced by 50 mm. If tubes were used to make the radiator, then the clearance should be 1.5 cm. Also, care must be taken to ensure that the plate can be removed to clean the register.

Heat exchanger installation

You can install the heat exchanger in an erected furnace in two ways:

- Do not dismantle the upper part. This method is relevant in those cases where it is possible to remove the hob, the structure itself, while not considering at all. In order to do this correctly, it is necessary to make holes for the pipes of water heating in the walls of the firebox, which would be connected to the boiler.

- Deconstructing the upper part of the structure. After installation of the boiler, the installation and restoration of the structure to the old form is carried out.

The number of chimneys and their direction during installation can be changed, the main thing here is not to overdo it. If the thrust is normal, then nothing needs to be changed.

It is quite possible to make the dismantling of the stove by one's own hands - for this you must first make a sketch of the arrangement of the bricks in all rows, which is necessary in order that in the future you can easily assemble the structure back.

- When building private houses, the boiler room is of particular importance, since it must fully comply with a variety of building codes and regulations ....

- Natural gas is not only the most economical and efficient, but also the most risky in terms of fire safety and explosion safety type of fuel - that's why the device ...