Homemade block crossbow. Block crossbow

Now it has become fashionable to hunt with a bow and a crossbow. Although it is forbidden in our country, but you can still shoot at targets, practicing in this difficult task. You can make a crossbow with your own hands at home for training. After all, good models from well-known companies are very expensive. And can be made "by itself". It is worth remembering that if the weapon will be with a tightness of more than 20 kg, then it is considered a melee weapon. Therefore, when creating a crossbow, this important nuance should be taken into account.

There are classic models, they are similar to the ancients, and their construction is simple. There are also modern crossbows, they are called "block". Such a weapon has a more complex structure because of the blocks and other innovations that enhance its power. Such a crossbow at home will be much more difficult to do, but the description of this process and the drawings that will be presented in detail in the article will help you with this.

The crossbow has many parts:

in some modern models there are blocks at the ends of the bow.

trigger mechanism;

What to make a crossbow

The main material from which the crossbow is made is wood. A bed and a bow are made from it. The trigger mechanism in powerful specimens grind out of iron. And those in which the tension force is less than 20 kg can be made of solid wood, it will fully withstand. Also used for onions spring metal and various composites.

Common Crossbow of Wood

To begin, consider how easy it is to make a crossbow with your own hands, and begin with its simple form. This is a standard design of ancient weapons, and it can be used not only for shooting, but also as a spectacular piece of furniture, hanging on the wall.

Which tree to use

To create a crossbow you need to choose:

All these breeds are dense enough to withstand enormous loads that will affect the bow and crossbow bed.

Material preparation

For a weapon to shoot long and powerful, its material must be properly dried during the year. Cutting off the necessary trunk or branch, both saws must be painted over. You can use any glue, paint or varnish. If the cuts are closed in this way, the moisture will not be able to quickly get out of the workpiece, so the wood will dry more slowly and evenly. So in the material there are no internal cracks, and a crossbow with your own hands at home will serve for a very long time.

After this, the log is placed in a dry place where the sun's rays will not fall on it. So it should lie year. As time passes, the bark is removed from the workpiece, so it dries for another week. Then the log is cut in half. So it lies another week, only after that you can start creating a crossbow.

Crossbow Tools

Sandpaper of different grain.

Joiner's tool.

Chisel.

Make a bow

On the blank, choose the side in which the annual rings of the tree are thinner. This is the north side, the fibers on it are denser than in other parts. That is what we will use, creating a crossbow with their own hands at home. From this part you need to make a bow.

Outline the middle, from it in both directions lay about two centimeters, marking the part that will click in the bed of the crossbow. This will be the thickest spot of onions. From it begin to cut the material, moving gradually to the edges. Chip the workpiece gradually on both sides, while checking until it starts to bend at least a little.

After that, you need to take a strong rope, make loops at its ends. This will be a test string. It is necessary to check the tightness of the bow. It is very important that his shoulders bend evenly. Wearing an improvised string and pulling onions, you can see in which places to shoot the material. They are marked, carefully cut with a knife. So you need to continue until the product begins to bend evenly on both sides.

Knot processing

Very often there are knots on the material: some are visible at once, others can open during the processing of the material. What they are dangerous about is that they can form chips. Therefore, you need to handle such places well sharpened knife. If there is no confidence or experience, it is better to tinker a little longer and sand them with sandpaper. Also for this purpose you can use the file.

Bed

When the bow is ready, it is set aside and proceed to the manufacture of the bed. To begin with, they choose where the chute will be, along which the arrow will fly, make this place ideally even. It will depend on him how accurately the crossbow will shoot. To understand everything, it is better to see the drawing of the crossbow. How to make his bed, is shown in detail here. After that, the chute is cut to the required length. Usually it is about 30 cm. Then they make an indentation for the bow and the trigger mechanism. It is convenient to cut them with a chisel and carpentry knife.

Trigger mechanism

As mentioned above, it can be made from dense wood or, if the crossbow is powerful, from metal. The most is the so-called "nut". It consists of a cylinder, where, on the one hand, there is a hook for a string, and on the other, an emphasis for the trigger. In powerful crossbows, the descent is more advanced for easier pull on the trigger under load.

As mentioned above, it can be made from dense wood or, if the crossbow is powerful, from metal. The most is the so-called "nut". It consists of a cylinder, where, on the one hand, there is a hook for a string, and on the other, an emphasis for the trigger. In powerful crossbows, the descent is more advanced for easier pull on the trigger under load.

We reviewed in detail, a master class with drawings, we hope, will help to understand all the intricacies.

This is the usual medieval model. Now we learn how to make the same weapon, only the modern model.

Block crossbow

Such a device is much more difficult to do; it will require many more tools than for an ordinary one. So, we create a crossbow with fiberglass at home. This material is ideal for the manufacture of onions, because biting and yet light. It can be cut from a single piece of fiberglass 1 cm thick or you can make it yourself. If you are not too lazy to tinker, it is better to make yourself.

Making fiberglass shoulders for crossbow

You need to take fiberglass or Kevlar and cut into strips. They need from 30 to 40. In general, it is better to try everything empirically. These strips are glued with epoxy so that everything becomes monolithic when cured. You also need to think about how to put this whole “sandwich” under the press. It is best to use the boards between which to place the shoulders, clamp all clamps.

B should be less thickening agent than usual, ranging from 8 to 10%. Everything freezes in 24 hours, but if it is cold in the room, the time may increase. When everything is frozen, the shoulders are finished, cutting off the protruding edges with a knife and polishing with sandpaper.

Now we will analyze in detail how to make a crossbow with your own hands at home and what additional elements of its design you need to make.

Now we will analyze in detail how to make a crossbow with your own hands at home and what additional elements of its design you need to make.

We make a figure bed

To do this, you need to take a board with a thickness of at least 4 cm. Mark out where the butt, grip, trigger and attachment for the shoulders of the bow will be. In general, all according to the drawings. After that, you need to drill all the necessary holes and cut.

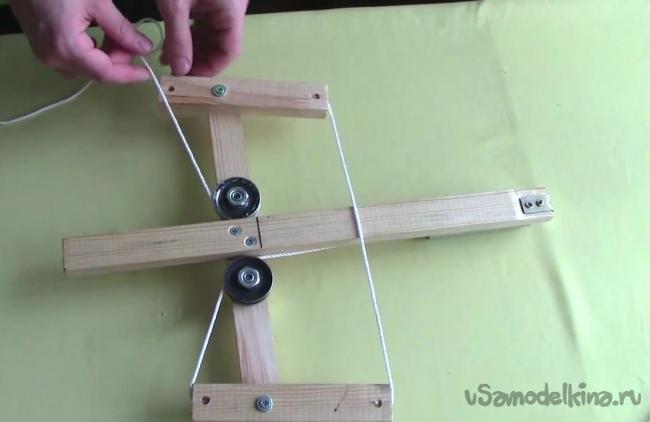

Blocks

They can be made of aluminum. It is better that they were on the bearings. Perfectly suitable middle parts of the wheels for roller skates. They are strong enough to withstand heavy loads, besides their size is ideal. Axes for them are needed in 5 mm thick. You can take them from the rollers or make yourself.

Fastenings are made from sheet steel or similar strong material. You can also make the ends of the bows thicker before pouring epoxy onto the shoulders of the onions, to install the blocks, in which case the fasteners will not be needed.

After that, on the crossbow with your own hands at home, you need to install the trigger with the trigger and the arrow holder. In general, all parts are connected by bolts, washers are required. They will allow to twist everything more tightly without damaging the material.

In block crossbows the bowstring is longer and stretched differently. It seems to intersect, and with a tight fit, this system allows you to give the arrow two times more energy to fly than in the case of a regular crossbow with the same bow.

In powerful block models, the bowstring is the only one capable of withstanding tremendous sharp pressure when fired. In crossbows, whose power is not more than 40-50 kg, it can be woven from kapron threads.

Making a bowstring for a crossbow

In the described way, you can make a bowstring for both recursive and classic crossbow. Just their length will be different due to the peculiarities in the designs of both models.

They take a plank with a length of a planned bowstring, drive in two pegs, which are wound round in circles. When the thickness of this long oval becomes 5 mm, it is wrapped, making a gap of 2-3 mm between turns. Near the pegs you need to braid without gaps, because there will be loops for the hook.

As for the bowstring, it can be said that if you make it too thick, then the power of the crossbow decreases. However, thin can break. So in this case you need to choose an intermediate thickness. It is better to study similar sports models with the same tightness and make a string of their thickness. When this is done, the two halves are joined and wound together. Again, near the loops need special care. Then swathe the middle, where the string will hook and push the boom. This place is also being done carefully, because friction force of enormous power will be placed on it. All trimmed edges of the threads need to fluff glue. This will make them more dense and monolithic.

This article provides drawings and descriptions of how to make a real crossbow at home. This is not so difficult, especially if you make wooden weapons. If the product is made for hunting in order to achieve great power, then you should choose a block model. Its design is a bit more complicated, you may need a machine for the manufacture of some parts.

Fans of homemade weapons are encouraged to sit comfortably, because in this material we will present an overview of the manufacture of a crossbow of a reverse design. First of all, we will explain why the design of this crossbow is called the reverse: the fact is that its bowstring is stretched in the opposite direction, which makes it possible to get much more power.

What do we need for making such a crossbow:

- wooden plank 15 mm thick and 28 mm wide;

- ruler;

- pencil;

- hacksaw;

- drill;

- bolts, washers and nuts;

- two rollers;

- spring;

- two metal corners;

- nylon rope;

- door hinge;

- metal plate.

We take the bar, which must be used to cut four blanks. The length of the first billet should be equal to 43 cm, the second - 31 cm. The remaining two blanks should be equal to 15 cm.

Next, we take two short blanks and make 1 cm marks from each edge. We also make one mark of 5 cm from one edge of both blanks.

The next step is to take the middle bar and make a mark of 1.5 cm from both edges.

We make holes in the marked places.

At the edges of the short planks, we make through holes going to the holes drilled in the previous step.

Further to the very length of the bar at around 25 cm we fix the middle bar. We will do this with the help of bolts, washers and nuts.

For greater reliability, the author of the idea puts a layer of glue between the two planks.

Now we take two rollers, which are also used for the manufacture of block onions, and fasten with the help of bolts next to the middle bar, as shown in the figure below.

After that, we take the spring, which can also be purchased on the car market, and fix it on the crossbow with the help of a metal corner.

The corner should be installed on the edge of a long strip with self-tapping screws, however it will interfere with the boom. To avoid this, we make a small indentation on the bar.

The next step is to take the short strips, which are fastened on the basis of our theme with a crossbow bolt.

Next, take another piece of rope, fasten it to one of the shoulders, pass through the roller, then through the spring, through the second roller, attaching at the end to the second shoulder. The length of the rope must be such that the spring with difficulty reaches its middle.

We turn to the manufacture of the trigger mechanism. To do this, fully stretch the crossbow string and make a mark at the end point.

Making a hole in the mark.

We take a metal plate and cut out from it a blank similar to the one that can be seen in the figure below.

Fasten the plate so that the hole on it coincides with the hole on the crossbow.

Take the door hinge and connect it with a metal corner with a bolt.

We fix the resulting workpiece on the reverse side of the plate.

Next we need another bolt. We grind the thread at its edge and fasten it to the corner so that it passes through the holes on the crossbow and the metal plate.

We put on the corner rubber. Thus, it is possible to make an uncomplicated trigger mechanism, which operates according to the following principle. On the ledge of the bolt is attached to the string, and when you pull the trigger, the bolt goes down and releases the string.

Finally, you can make a guide for a crossbow. And you can make it from the usual ruler, which should be simply divided into two parts and fixed at the edges of the slat.

The holder for the arrows can be cut from a conventional can, and the handle can be made from a piece of wood, which should simply be screwed onto the crossbow with a self-tapping screw. If you wish, of course, you can paint the crossbow in any color.

Beginners who want to make a sample of ancient weapons themselves always face the questions: where to start, how to do it at home; how to repeat the work of ancient masters; who can help. If you set out to make a crossbow yourself, no need to get lost. Work is perfectly feasible in modern conditions, if you are a person who loves and knows how to work with his hands, has the necessary tools.

You will need a hacksaw, a hammer and a screwdriver. But this is not enough to create a serious crossbow model. It is convenient to assemble it in parts (Fig. 1). Take the bed as a basis and attach a bow and trigger to it. Attach a stirrup to the bow, sights to the trigger mechanism. And even this is only an approximate scheme, in your case everything can be different.

Some parts of the crossbow can be bought or ordered at the relevant production facilities: auto repair, metal and woodworking workshops, workshops, factories, firms that produce products made of glass and carbon, other organizations and institutions. Before constructing anything, let's see what technical characteristics we want to get, where and how the assembled structure will be used.

Fig. 1. Scheme for creating a crossbow.

Box and crossbow guides

In the manufacture of the box and crossbow guide should take care of the combination of aesthetic beauty, convenience and durability. As the basic materials for the manufacture of the bed now, either natural wood materials such as beech, birch, ash, walnut, rosewood, or molded plastics are used.

The wood of these species is not warped from moisture, it is rather viscous, it does not prick and is beautiful if it is polished and varnished. The initial blank is a board about 30 mm thick. You can make a rigid metal frame and attach plastic (wooden) lining to the place of the forearm, handles, butt on it. The stock of most modern crossbows have an anatomical lightweight shape that gives the crossbow not only ergonomics, but also modern design. Sometimes the shape of the bed is specially carried out in strict accordance with ancient samples and contains artistic carving or inlay.

The guide in modern crossbows is significantly different from the old analogs

In modern crossbows, the guide is mostly made of another material (metal, fiberglass) and mounted on top of the bed. Sometimes the crossbow guide is a rounded metal slats, along which the arrow moves like on rails. Such a system provides high accuracy and durability.

As for the distance between the guides (width of the groove), it depends on the diameter of the tube (shaft) that will be used for the manufacture of arrows, as well as the height of their tail. As a rule, the groove width with the chamfered edges should be such that the axis of the arrow intersects the center of the string, which, in turn, lies (without vertical force) on the guides and, when fired, moves parallel to them.

![]()

Sports bow.

Block bow crossbow

The block bow of a crossbow differs from the classic one in that it has at least twice or even three times the reported speed of the arrow. A block bow is always more powerful and faster than a classic or recursive bow (with the same tension of the bowstring and the material of the shoulders). The difference is that “compounds” - block bows work not only by the force of elastic elements - shoulders. They provide the power of the shot in the same way as on its predecessor, the recursive bow.

But the initial speed of the boom depends mainly on special eccentric blocks located on the upper extremities of the shoulders, which are interconnected by a system of cables for synchronous work. This system of blocks and cables allows you to accelerate the string (and, accordingly, the boom) to high speeds.

The system of blocks, in essence, is a system of levers, thanks to which, by reducing the force transmitted to the string, its speed increases. At the very end of the stroke of the tensioned bowstring, the blocks provide a significant reduction in the effort required to hold them. These include the following: the complexity and bulkiness of the design, its greater (compared to a recursive bow) weight, a half to two times longer course of the string (and, accordingly, a longer bed), more stringent requirements for accuracy and reliability of the parts produced .

Fasten the bow on a crossbow bow

Attach the string to the bow of the crossbow in various ways. One of them is the use of blocks. The block consists of a bearing on which a ring with a groove for a bowstring pierced in it is put on. The bearing rotates freely around an axis fixed to the end of the shoulder. The axle is also wearing metal pieces, to which the string is attached.

Well-proven simplified scheme without a bearing. The end of the string is fastened around one of the axes, then the string goes along the groove of the opposite ring, fits into it, returns to the original axis, twists around the ring groove and finally fastens on the opposite axis (Fig. 2). What is the use of such a design?

First, two blocks and a 3-fold elongated string give a gain in strength. To pull such a bow is several times easier. Secondly, after the trigger is released, the string will slide on the bed surface 1.5-2 times faster. This means that the initial speed of the flight of the boom will increase by the same amount. Draw your own conclusions. When designing, the main difficulty lies in how to attach the blocks to the ends of the bow (Fig. 3).

Fig. 2. Fastening the bowstring on a crossbow (dimensions in mm): 1 - bed; 2 - sighting device.

Fig. 3. Fastening the blocks to the ends of the crossbow's bow (dimensions in mm): 1 - the handle; 2 - elastic element; 3 - the trigger mechanism.

The shoulders of modern crossbows

Bows, or more correctly, the shoulders of modern crossbows are made from a variety of materials: steel, aluminum, fiberglass laminate, composite materials, carbon. The shoulders of a composite, which is a multi-layered structure of fiberglass and carbon, have proven themselves best.

The fiberglass structure of the shoulders gives them a high energy intensity, and carbon fiber - reinforcing properties. The shape of the shoulders, depending on the destination, can be either straight or recursive, that is, with a characteristic bow-like bend. Crossbow shoulders at the ends have the so-called ending - seats for a bowstring. The big advantage of the shoulders of the last generation is their “tirelessness” - they maintain the stability of their characteristics even after several thousand shots.

Make a quality crossbow

If you want to make a quality crossbow with your own hands, you need to start with a bow, which is made from springs. You need to take the "grinder" and grind the spring so that in the middle of the thickness was 4 centimeters, and at the edges - 1-2. If you did not have to cut the metal before, ask someone experienced.

Do not forget that the spring may break and the fragments will fly in different directions and can seriously cripple. Therefore, before you shoot, wrap the entire spring (it will be a bow) with insulating tape, several layers of adhesive tape, or skin over it - the insurance will not hurt (Fig. 4).

Crossbow block

The crossbow block is a detail that connects the shoulders to the crossbow bed. This detail in your crossbow may not be. For example, in the Middle Ages in general, a bow was tied up or tied to a crossbow. In modern models, the block is made of steel or aluminum alloys (to facilitate construction). Block (or cross) cast or milled.

You can make it out of wood. Its presence makes it easy to disassemble and transport the crossbow, to have one bed and several interchangeable arms of different tension forces to it.

Fig. 4. Fastening the crossbow.

Crossbow bow

A bowstring crossbow during a shot gets a significant pressure to stretch and tear, therefore one of the conditions imposed on it is its ability to withstand a large number of shots, i.e. durability and survivability. In addition, the string should be light and low-stretch. Lavsan, Dacron, Kevlar, Daynema, CBM, fastflight and other threads of synthetic fiber are used for its manufacture.

At the same time, it is necessary to have a simple fixture consisting of a wooden plank, in which there is a slot on one side and a threaded moving rod that allows to install and fix it in different places, on the other end of the plank there is a V-shaped piece made of plywood or wood about 10 mm. At the ends of the part are permanently fixed two rods. V-shaped part is fixed in two positions. In the absence of such or similar devices, the string winding can be made between two nails hammered at the required distance along the length of the string. The winding of the thread produced by a circular motion of the hand with a uniform tension. The number of threads depends on the strength of the bow.

After the string is wound, make the safety winding loops and the middle. The safety winding is performed with a twisted silk, nylon, nylon, cotton reel thread. In the manufacture of bowstrings from Kevlar threads, it is necessary to strengthen the loop, either by making an additional pad of threads and weaving them into the string, or doubling their number in the loop. After winding the middle of the loop, the V-shaped plate is turned to its original position and the winding of the end of the string is made. Thus, the second loop is also wrapped. At the same time it is necessary to precisely keep the middle of the winding. The bowstring, worn on the bow, should not have sagging threads, the presence of them indicates a poor-quality production of the bowstring. As a rule, this happens if the winding is not produced with the same tension.

The safety winding in the middle of the bowstring is done at the moment when she is put on the bow. It should not be too tight: it significantly lengthens the life of the bowstring. To protect from moisture, the string is lightly rubbed with beeswax. Rub wax should be careful to thread the strings while not torn and not deformed. Experts especially note that the lubricant increases the weight of the string and reduces the speed of the boom, so lubricate it with a small amount of wax. The threads from which the string is made, provided that the shoulders work, extend (from Dacron or Dacron by 2-3%, from Kevlar - by 0.8%). In this regard, when making bowstrings from Kevlar, it is recommended to make it slightly longer than from Dacron and Dacron.

Crossbow.

The practice of firing involves replacing the string in 5000-10000 shots.

Bows from Kevlar serve much less and withstand about 2000-5000 shots. Twisting the string, you can change its size until the accuracy of shooting is satisfactory. The maximum number of revolutions for changing the length of the string is 30. If more revolutions are required, it means that the string is too long and a new one should be made.

Crossbow trigger

Locks, or release devices of modern crossbows are made with the help of precision equipment from high-strength metal, most often from weapon steel (Fig. 5). Such locks are able to withstand huge loads and are practically resistant to wear. The designs of the locks themselves can be different - from simple, elementary, similar in their structure to medieval walnut-type locks, to sophisticated sports with adjustable descent effort.

On expensive match crossbows are often used locks with electronic descent, triggered by a light touch of a finger. With independent production, this component of the crossbow is most demanding on the accuracy of manufacturing parts. Otherwise, spontaneous descent of the string, premature wear of parts and frequent breakdowns are possible. No need to pursue complex structures, it is better to make it easier, but safer. The greater the number of parts, the faster their natural wear and loosening will occur.

Fig. 5. The trigger mechanism.

When designing the trigger mechanism should pay attention to the simplicity and convenience of design; durability and wear resistance of parts; prevention of spontaneous shots, breaks in the string; reliable fixing of the mechanism in the crossbow bed; the presence in the design of the strap for mounting sights, springs, boom holder and fuse (even better - self-earthing fuse). The shank of the boom should be able to touch the bowstring (otherwise, when the tension of the bowstring is over 20 kg, the accuracy of shooting may worsen and the shank of the boom may be destroyed when fired).

Crossbow Sights

You can, of course, do without them. Aim and shoot intuitively, let your hands and body choose the position of the crossbow in the space when fired and accurately hit the target. If you do decide to install (or make yourself) sights, then know that the most important feature is the ability to install them at different firing ranges, as well as maintaining the consistency of the installations made in the process of firing and when transporting weapons. Taking into account all the above requirements, it is difficult to make a high-quality sight, it is easier to buy it.

You can use any standard sight.

You can use any standard sight: mechanical, optical, collimator, diopter or laser designator. Many modern crossbows have a dovetail mount, and you can install everything you need on it. In the cocked position, the string is hooked onto the ledge of the lever. From turning the lever holds the trigger. When you press the hook lever is released and the string, rushing forward, sends an arrow.

Moving the lever limits the stop. To soften the blow on the support should wear a rubber tube. The position of the stop is chosen so that the protrusion of the lever in the extreme position is located below the guide surface of the bed, thereby not preventing the bowstring from sliding. After the shot, the lever in the extreme position holds the spring. When the crossbow is tightened, the string rotates against the ledge and rotates the lever to its original position. At the same time, the trigger rotates under the action of the spring and fixes the lever and the bowstring.

To eliminate the possibility of accidentally jumping off the string from the ledge, the trigger mechanism is closed with a lid. Between the lid and the bed leave a gap for the passage of the string. A flat spring is attached to the lid that holds the boom on the guides when aiming. The bearing, mounted on the end of the trigger, significantly reduces the pull force. The required amount of trigger effort can be selected by sawing through the surface of the lever that rests on the bearing.

Mechanical sights crossbow

The mechanical sights of the crossbow include a fly and a sight. The sight is usually a sight (i.e., an open sight) or a diopter. The rear sight is a plate of complex shape with a slot, and a diopter is a wire ring or a circular hole in the plate. The rear sight also should not create glare that falls into the eyes of the shooter, and the edges of the rear sight of the rear sight should be vertical and parallel to the front sight.

Vertical corrections are carried out entirely, reinforced near the trigger, and horizontal corrections are carried out by a spot fixed on the pad bracket. Fly can be open or closed, enclosed in a ring or a semi-ring. On a crossbow, as a rule, there are several of them. This is due to the boom flight path other than firearms. The trajectory of the crossbow's arrow is high enough, so the rear sight should be set well above the front sight. The angle of excess of the sighting line depends on the weight of the boom, the tension force of the string, the shooting distance, etc.

Crossbow Tensioners

Non-mechanical crossbow tensioners include the formula: “stirrup + hand strength”. The shooter pulls the string with his hands, holding the crossbow to the ground with his foot using a stirrup (material for manufacturing is wire with a diameter of 5-6 mm). The method is acceptable for athletic developed people and the bow tension force is up to 60-70 kg.

Half-Hook Crossbow

It does not change the applied effort, but only transfers it from hand to foot, because the muscles of the legs are 3 times stronger than the muscles of the arms and much more resilient.

The essence of the method is that the shooter puts on a belt to which a rope of a certain length is attached to the front with a hook at the end. Squatting, the crossbowman hooks with a hook to the string, and, straightening his legs, pulls the string upward until it engages with the trigger mechanism.

Tension bowstring

There are three types of mechanical means of tension of the arbalest bowstring: a leash platoon of the “goat’s foot” type, a slatted-gear (German) gate, a block-pulley (English) gate. "Goat's leg" (Fig. 5). The lever platoon of simple type consists of two wooden bars - a platoon lever and a tension lever. The plunger lever is designed so that by pressing it, the crossbowman can, through the second lever, produce tension on the string. At the lower support end of the platoon lever a small hook on the axle is fixed.

When a bowstring is cocked, it serves as a support for the platoon lever, therefore it is limited in its movement in relation to it. The tension arm is connected to the platoon arm by means of an iron axis at some distance from its support end. For the platoon of the bowstring, the crossbowman set the tensioning lever on the string, for which special cuts were made on it, and the hook on the supporting end of the platoon lever was inserted into a metal ring reinforced in front of the crossbow arc. Having set the “goat's foot” on the crossbow, the shooter begins to move towards the couch / platoon arm, rotating it around the support, which was formed when the hook hooked to the metal ring. As a result of this action, the tension arm, converting the rotational movement of the platoon lever into a translational motion, pushes the bowstring before connecting to the lock.

As a rule, the achieved increase in the applied force approaches 5–7, i.e. If the shooter applies a force equal to 5 kg to the platoon lever, then a force of about 30 kg will develop when the bowstring pulls. But if the crossbowman puts pressure on the lever with a force of 20 kg, the “goat leg” will increase it to 120 kg. A feature of the “goat foot” of the folding type is that the lever arm in the process of tension changes its length, so that at the final stage of tension (when the tension is close to the maximum) the ratio of the length of the levers is also close to the maximum.

At the initial moment due to the difference in the length of the two levers, platoon and tension, the tension force increases by 3-4 times, and at the final stage - by 7-8 times. The productivity of a folding “goat foot” is approximately equal to the usual one, but its low weight, size and portability contributed to its wide distribution during the Middle Ages.

Fig. 5. “Goat leg”.

Arrows and bolts crossbow

A good shooter will be able to achieve stable shooting even from a bad crossbow, if his arrows are good, but when the arrow is bad, nothing will make the shot accurate. Their durability, accuracy and range of fire, safety of the shooter and those around them depend on the quality of the manufacture of arrows.

Arrows are made of dural, carbon, aluminum tube, fiberglass and wood.

If you are going to do them yourself, you can remake the arrows from the sport bows, weighting them and reducing the length. Approximate parameters of arrows for crossbows: length - 300-400 mm, diameter - 6-9 mm, number of feathers - 3 or 4 pcs., Pen length - 50-70 mm, pen height - 10-12 mm, weight

arrows - 15-40 g.

A set of arrows for crossbow

A set of arrows for a crossbow must meet the following requirements: all arrows must be of the same length and thickness; have identical weight and plumage; have the same rigidity (deflection of the boom under load); have the same distance between the center of gravity and the middle of the arrow; The boom rod (tube) should have a minimum bending deformation.

Currently, there are three types of stickers plumage to the arrows: straight, angular and helical (spiral) of three or four feathering. The smaller the diameter of the shaft, the length of the boom, the thickness of the tail, the less will be influenced by external forces (wind gusts), the aerodynamic drag will decrease, the flight range will increase. The crossbow of the crossbow arrow is flat, butt end - without eyelet for bowstring.

Crossbow Arrows

In modern conditions, the shafts for crossbow arrows can be done like this: take a straight-layer bead, cut off a little, clamp into an electric drill and drive through a gauge - a die for threading. Then polish the boom sandpaper. And be sure to check for straightness with a shot without a tip into the wall.

Arrows with an oblique layer can not be used, since when they strike a hard surface they may break, their tail part may break off. For better protection from moisture (so that the arrow does not “lead” the arrow), it is recommended that the arrow be coated with wax (preferably natural, but paraffin is also suitable) by rubbing it evenly with a thick cloth. It is better than varnish or paint, because wood breathes.

Crossbow arrowhead

The quality of the boom, its behavior during the flight depends largely on the tail. Correctly chosen and precisely fixed on the arrow the tail determines the stability of the flight of the arrow, the accuracy of hitting the target and significantly affects the result of the shooting.

The plumage is subdivided: according to the material of manufacture, the shape of the plumage, the size and number of feathers fixed on the arrow, and the type of sticker. According to the material, the plumage may be from feathers of birds, hard plastic, paper, cardboard, synthetic or similar material.

Arrowhead.

Crossbow Arrowheads

The crossbow's arrowheads can be cap-shaped (the tip is put on the arrow shaft), vtulchatye (the tip is inserted into the boom tube), mortise (a cut is made in the arrow, into which the tip is inserted, after which everything is wrapped with thread or wire, glued).

Mortise tips are less durable compared to the others and more laborious in manufacturing. For arrows with a wooden shaft, the cap tips that can be easily manufactured in large batches on a lathe are optimal.

Centering shaft arrow

While the shaft of the arrow is not fully trimmed, it's time to check the alignment. The arrow can be balanced in the middle (for range) or one third of the tip (for accuracy). Arrows are often lost, they can be difficult to find in the grass, leaf litter.

A shot from a crossbow

The shot of a crossbow, as a single event, and shooting, as a process, depend, first of all, on three factors - a crossbow, arrows (or arrows) and an arrow. Each of these factors is very important. Crossbow shooting is made on the target. You can start from a short distance of 5-8 meters, gradually increasing the distance to the goal, until you achieve the desired result. The main purpose of the adjustment is to adjust the sight so that it understands the distance at which point the arrow will be. Amendments to the position of the sight should be with uncharged and unloaded crossbow.

Keep in mind that by shooting a crossbow with one type of arrow, you will have a different result when using a different type of arrow. Shooting accuracy is reduced when using deformed and bent arrows, when firing projectiles of different mass and different center of gravity, loosely fixed and bowed. Do not forget to reliably fix all the elements of the sighting mechanism so that no parts of it dangle or move out, otherwise you will have to shoot the crossbow again.

For all crossbows, regardless of type, there are rules developed over the years that should never be broken. In no case can one shoot idle - all the energy of the bow will go not into the arrow, but into the shoulders, and they can simply crack. It is necessary to position the fingers of the hand holding the crossbow for the forearm so that when firing at them the bowstring does not strike.

Crossbow.

Do not shoot at hard objects.

You can not shoot at solid objects - an arrow, falling into a solid surface, or changes the direction of flight, or simply collapses.

The platform for shooting a crossbow (bow) must be specially equipped, have one line of fire. In front of the firing line, targets (shields) are set perpendicular to it at the required distance. To the right and left of the site, safety zones are measured, and behind the line of targets they provide at least 25 m of free space or install a fence or shaft.

Back from the firing line, measure a distance of 5 m parallel to the firing line, forming a waiting area. In the open air shooting is carried out in the direction of the north. The center of the target is established in this way; so that the base of the perpendicular, lowered from the center of the target, is on the line of targets at a height of 130 cm. The shields are installed with a slope of 15 degrees from the arrow.

It is also necessary to strictly observe safety precautions.

It is also necessary to strictly observe safety precautions (when shooting in the open dash). Archery can be conducted only in specially designated and equipped places with fencing. The platform is limited to safety zones from the sides of at least 10 m, behind the shields - 25 m. Shooting at various distances must be done from one common line of fire.

You can insert an arrow only if the target area and the space in front of them is free. Directing a crossbow with a loaded arrow is allowed only from the line of fire and in the direction of the target. It is forbidden to talk or turn to the side with the cocked crossbow and the nested arrow. It is not recommended to hail or touch the arrow aiming at the target. It is not recommended to shoot in the air, up. The shooter is responsible for any incident resulting from a violation of his safety rules.

A hunting crossbow is a fairly effective weapon that, if necessary, can serve as a worthy replacement for a rifle. The main advantage of the weapon is noiseless shooting. Therefore, in the course of its application is quite difficult to scare the beast.

Design features

What is a crossbow hunting? The photos presented in this material make it possible to see that the following components can be distinguished in it:

- The hull is the main power unit to which the load falls when the bowstring is lowered. It serves as the basis for the installation of functional parts.

- The pads are part of the construction for setting bowstring tension arcs.

- Lodge - a detail of the crossbow, which is used to accommodate the arrow.

- Bowstring - a functional part that serves to propel the used projectiles.

- Shoulders - elastic structural element, which gives energy when tensioning the bowstring.

- The stirrup is a detail that facilitates the charging of a crossbow.

- The trigger mechanism is a device by which the lock is opened and the bowstring is released when fired.

- The sight is mounted on a crossbow to facilitate aiming at the target.

Hunting crossbow with wooden shoulders

It is a simple design. As follows from the definition, the shoulders here are made of wood. Such a crossbow can not be called a model of reliability. Products in this category are frankly short-lived and therefore are not in too high demand. Most often, such a hunting crossbow is used as a collection, decorative weapon.

It is a simple design. As follows from the definition, the shoulders here are made of wood. Such a crossbow can not be called a model of reliability. Products in this category are frankly short-lived and therefore are not in too high demand. Most often, such a hunting crossbow is used as a collection, decorative weapon.

Metal Crossbow

Extremely common option. Hunters pay attention to such crossbows, as they demonstrate high power when firing. Hunting bows and crossbows with metal arcs are suitable not only for training, but also for use in field conditions when tracking down prey. For manufacturing, both solid arcs and composite structures are used, which are assembled from several symmetrical parts.

Recursive crossbow

Classic version with curved shoulders. Such a hunting crossbow is extremely easy to use and convenient to use the device. It has a small size and improved performance. Easy to disassemble and transport.

Recursive crossbows contain reinforced shoulders, the tension force which can reach about 50 kg. This, in turn, opens up the possibility of hunting for small and large animals.

Block crossbow

The design includes a whole system of eccentrics, thanks to which work facilitates the process of charging the weapon and ensures boom acceleration. Compared with recursive models, the block hunting crossbow is more compact. Power ratings are also high.

The design includes a whole system of eccentrics, thanks to which work facilitates the process of charging the weapon and ensures boom acceleration. Compared with recursive models, the block hunting crossbow is more compact. Power ratings are also high.

Minor dimensions are provided by installing short arcs. The use of this solution helps the owner to easily overcome areas covered with bushes and bushes.

The characteristics of a block-type hunting crossbow provide a simple platoon of bowstring and low recoil, which is achieved by rational distribution of the force vector.

Pistol type crossbow

- thanks to the reduced dimensions, they are an extremely convenient weapon during transportation;

- have high power and allow you to hit targets both at medium and long distances;

- they are characterized by less destructive force compared to block systems, however, they emit arrows with greater speed;

- in addition to arrows, they can produce darts, harpoons, metal balls.

Sights

The main feature of crossbow shooting is a significant shift of the aiming line. In other words, after firing a shot, the projectile fired quickly enough to land. Therefore, it is advisable to install optics with a special crossbow grid on such a weapon. For effective aiming at the target crossbows enough to equip optical sights with a 4-fold approximation.

Some hunters prefer collimator systems, which also manifest themselves quite effectively. Moreover, this option makes it possible to hunt both during the day and in the evening. Collimator sights are extremely convenient to use when aiming at moving targets.

Hunting crossbow with his own hands

Having decided on the necessary parameters and characteristics of the future weapon, it is worthwhile to proceed to the development of the corresponding drawing. As a sample, you can use the finished circuit or make the last one yourself. Whatever it was, made a hunting crossbow with his own hands will eventually have to customize for themselves.

Having decided on the necessary parameters and characteristics of the future weapon, it is worthwhile to proceed to the development of the corresponding drawing. As a sample, you can use the finished circuit or make the last one yourself. Whatever it was, made a hunting crossbow with his own hands will eventually have to customize for themselves.

During the preparation of the drawing, one should be guided not only by personal wishes, but also take into account the availability of the necessary materials, proceed from their cost, complexity of processing.

How to make a hunting crossbow with your own hands? Usually a bed is prepared for the beginning, on which later the shoulders, the stirrup, the guide mechanism, are fastened. Difficult for self-manufacturing element of the arc. Therefore, in some cases it is better to purchase them in the finished version.

They will help to make hunting drawings, examples of which are shown on the photos below.

Housing

The base on which the bed and shoulders of the product are fixed is the body. It is desirable to cut it from a metal billet with a thickness of about 2.5-3 mm.

In the central part of the body and at the end with the help of bolts the crossbow bed is fixed. The use of such a solution contributes to the rapid assembly of weapons for combat and disassembly during transport.

A stirrup welded to the body at the bottom. The latter provides the ability to hold the crossbow with his foot while pulling the string. As a material for the manufacture of stirrups, it is recommended to use wire with a diameter of 6 to 8 mm.

Shoulder

The material for the manufacture of a structural element can serve as a car spring. In such metal shoulders, semicircular recesses for bolts are made, with the help of which the part will be screwed to the body.

A common opinion is that the use of metal springs as the basis for the manufacture of shoulders is a rather dangerous decision. And in fact, when using an improvised crossbow in conditions of low ambient temperature, the likelihood of a break in the part increases, especially at the mountings. Such cases are accompanied by the release of small fragments. Therefore, the idea should be applied at your own peril and risk.

Blocks

Ready-made drawings of a hunting crossbow often include block devices. The latter facilitate tension and give an advantage in strength. Bringing such a crossbow into a combat state is easier than with a simple connection of the ends of a bowstring with the ends of the shoulders. Moreover, during the descent, the starting speed of the boom increases, which is reflected in an increase in the range of the weapon. The main drawback of installing a block system is the complexity of manufacturing and the increase in the total weight of the crossbow.

Bowstring

As a bowstring, you can use a metal cable with a diameter of about 2-3 mm. A thicker string will be harder to fasten on the weapon, and a thin one will stretch as the product is used.

As a bowstring, you can use a metal cable with a diameter of about 2-3 mm. A thicker string will be harder to fasten on the weapon, and a thin one will stretch as the product is used.

To fix the string at the ends of the shoulders, it is enough to make an ordinary loop. Under the cable anchorages, it is better to place pieces of leather or any other dense material in advance. This solution allows you to avoid rubbing the strings when in contact with metal shoulders.

Lodge

For the manufacture of parts, you can use easily processed wooden blank in the form of a board about 30 mm thick. It is worth noting that, despite the high strength, oak is not very suitable for these purposes due to its considerable weight. As for spruce and pine, the latter are not sufficiently resistant to mechanical damage and warp when in contact with moisture. Therefore, the type of wood should be selected depending on the goals and conditions of future use of the crossbow.

How to make a hunting crossbow really practical? Particular attention in the manufacture should be paid to the guide in the form of a groove for the boom, which should be tried to make as smooth, smooth and polished as possible. The state of the groove is largely reflected in the accuracy of shooting. It is desirable that the width of the bed is equal to the diameter of the arrows used. It can be cut using a circular saw.

As a means to hold the boom it is rational to use a spring, which will press the projectile against the bed and will not allow the latter to slip out of the groove before the shot is fired.

Trigger mechanism

The material used to manufacture the parts will be sheet iron. It is desirable that its thickness was not less than 6-7 mm. The drawing of the mechanism is presented in the following diagram:

All parts are laid directly in the box. A special slot is cut here, through holes are made under the axes of the mechanism, on which the elements of the trigger are subsequently installed. An example of the descent installation is shown in the figure below.

Sight Optics

As a crossbow sight you can use the factory optics from a firearm. Quite a practical solution - the use of front and rear sight. With the latter, you can make vertical corrections. Horizontal adjustments are conveniently performed using a fly, reinforced at the intersection of the shoulders and the bed.

To ensure the convenience of transporting the crossbow, it is worth making the sighting device removable. To do this, the weapon can be installed so-called Picatinny rail, which provides the ability to mount individual sights of the factory assembly.

Finally

Hand-made production and operation of a hunting crossbow is a rather radical solution. Often, in the absence of experience of this kind of activity, the quality and reliability of home-made devices leave much to be desired. In reality, even crossbows of the budget category of factory production, the cost of which is about 3000-4000 rubles, turn out to be much more efficient, more convenient and more practical than the creations of their own hands.

Hand-made production and operation of a hunting crossbow is a rather radical solution. Often, in the absence of experience of this kind of activity, the quality and reliability of home-made devices leave much to be desired. In reality, even crossbows of the budget category of factory production, the cost of which is about 3000-4000 rubles, turn out to be much more efficient, more convenient and more practical than the creations of their own hands.

As you can see, to make a hunting crossbow is quite real. However, acquiring a weapon in a specialized shop, the user receives guarantees of its safety, reliability of assembly. When operating the self-made crossbow, you can only rely on yourself.

Drawings corporate crossbow Horton

Original Horton Crossbow Design Drawings

Well, well, searches on the Internet yielded results. I finally found the normal drawings in compliance with GOST.

With the availability of material and some equipment, it will be easy to make a real (or almost real).

At the end of the page posted photograph of a homemade crossbowmade according to these drawings from scrap materials.

Naturally, he cannot replace a purchased crossbow (after all, the build quality and structure of the material in the factory version is not an example above), but to shoot at

So, before you the general scheme of a self-made crossbow.

What does this type of crossbow consist of:

Bed, shoulders, butt, trigger, sighting device, a system of blocks.

It is best to make a bed of natural hard wood, solid or glued laminated timber. Choose the size at your discretion, but

Shoulders and decks at the crossbow

If there is a bed of small arms, then this would be the ideal solution, but you can try to plane Buratino and yourself.

Block crossbow design facilitates the cocking of a bowstring, but perfectly retains power and allows you to carry it in the cocked state for a long time.

The handling of the guide boom must be performed particularly clearly. Lines must be smooth and straight. The accuracy and

boom range. It is best to do it on a milling machine, and then carefully handle the sandpaper. Then polish the groove.

It is better to make a cross with shoulders mounted from the end of the bed of an aluminum plate, but you can also make a wooden one

Do not forget to make the aiming device, consisting of a pillar and front sight. You can make a mount for an optical sight.

where you can order the execution of any drawings.

It remains to take the tool in hand, charge a good mood and take up the implementation of the goal. Good luck!

P.S.

The article is a rewrite. The administrator is not responsible for the accuracy of the information. Everything you do, you do at your own peril and risk.