Cast iron radiators and calculation of their capacity for the room. How many kW in the radiator: calculations, number of ribs, thermal power of the batteries of cast iron, aluminum and bimetallic products

Radiators made of cast iron are radiators that have survived to our time since the far 70s of the last millennium. Today they are more modern, they are almost impossible to distinguish from bimetallic or aluminum radiators, covered with enamel. Cast iron radiators are able to work with the temperature of the coolant up to 110 0 С.

Pretty big size and the impressive weight is compensated by the inertia, which allows to regulate the temperature. They are ideal for any room, reliable and durable, can be used with any boilers and coolants. Many people are interested in the question - how many kilowatts in one section of the cast-iron radiator? The answer to this question you will find below.

Cast-iron radiator

Cast Iron Radiators M-140

Radiators type M-140 have a fairly simple design and are easy to maintain. The material used in their manufacture is cast iron. It has a high resistance to corrosive processes and can be used with any coolant. A low level of hydraulic pressure makes it possible to use radiators for both gravitational and forced system circulation of the coolant. The high threshold of counteraction to hydraulic impacts allows to operate them both in two-storeyed buildings and in nine-storey buildings. Pros M-140 - ease of maintenance, reliability, long service life and low cost.

Cast iron radiators MC-140-500

Widely used to heat buildings with a coolant within 130 0 C and a pressure of 0.9 MPa. The capacity of one cavity is 1.45 liters, the volume of heated area is 0.244 square meters. The material used for making sections is SCH-10 (gray cast iron).

Cast iron radiators MC-140-300

Radiators used for heating rooms with low windowsills and pressure 0,9 MPa. The capacity of the cavity is 1.11 liters. The weight of the cavity, taking into account the components, is 5700 g. The calculated heat flux is 0.120 kW.

Cast iron radiators МС-140М-500-09

Radiators of this model are used for different premises with a coolant temperature up to 130 0 C and a pressure of 0.9 mPa. The mass of one cavity is 7100 g. The material used for manufacturing is gray cast iron. S heating with one cavity - 0,244 m 2.

Important! Choosing a radiator for housing, be sure to pay attention to its characteristics and make all sorts of calculations in advance, so how to exchange the purchased goods will be almost impossible.

Pros and cons of using cast iron radiators

Stylized cast iron radiator

Any existing heating system has both pluses and minuses, we will consider them.

The nominal value of the thermal power of each section is 160W. Approximately 65% of the heat flux generated warms the air that accumulates in the upper part of the room, and the remaining 35% warms the lower part of the room.

- Long period of use, ranging from 15 to 50 years.

- High level of counteraction to corrosive processes.

- The possibility of use in heating systems with gravitational circulation of the coolant.

- Low efficiency of correction of the heat transfer coefficient;

- High level of labor for installation;

Important!In order not to encounter a problem with the installation, be sure to take into account the above pluses and minuses of cast iron radiators. Their installation is not cheap, and repeated installation works will require a lot of financial resources.

Calculation of sections (cavities) of radiators

And so, how many kilowatts in the 1 section of the cast-iron radiator? To calculate the number of sections and their power, you need to determine the V room, which will later appear in the calculations. Then choose the value of thermal energy. Its values are as follows:

- heating of 1m 3 houses from panels - 0,041kW.

- heating 1m 3 houses made of bricks with double-glazed windows and insulated walls - 0.034 kW.

- heating of 1m 3 of the premises constructed according to modern construction norms - 0.034 kW.

The heat flux of one cavity of MC 140-500 is 0.160 kW.

Then the following mathematical actions are carried out: the volume of the room is multiplied by the heat flux. The value obtained is divided by the amount of heat released by one cavity. The result is rounded up and gets the required number of sections.

How many kilowatts in the cast iron section? Each type of radiator has a different value, which the manufacturer counts upon their manufacture and indicates it in the accompanying documentation.

We will make an approximate calculation of the available data.

The room has the following data: type of premises - panel house, length - height - width - 5x6x2.7 m, respectively.

- Calculate the volume of the room V:

V = 5 x 6 x 2.7 = 81 m 3

- Amount of required heat:

Q = 81 * 0.041 = 3.321 kW

- On this basis, the number of radiator sections is as follows:

n = 3.321 / 0.16 = 20.76

where 0.16 is the thermal power of one section. Indicated by the manufacturer.

- We round the value to the larger side, from which the number of necessary sections is equal to 21 pieces.

These devices look modern and are inexpensive. They are capable of the correct installation and operation for a long time to perform their functions. In order to fully utilize all potential possibilities, it is necessary to accurately calculate the power of the aluminum radiator, which will be required for high-quality heating of housing in the most difficult weather conditions.

Constructive and technical features

Quality products from this metal are created using casting. This makes it possible to produce solid solid heating devices in which there are no separate elements, their connections. This technology is quite complicated. To eliminate the appearance of marriage, it is necessary to strictly observe many production modes, control the absence of hidden defects, cavities. The cost of these radiators is slightly higher than the prefabricated models. But they can withstand without damages a large increase in pressure in the supply lines of the coolant.

The second common technique is based on extrusion. Metal under pressure fills a special shape. The workpiece is cut into pieces. The connection of individual elements is done by welding. In this case, relatively inexpensive production processes are used. But it should be borne in mind that finished products are less durable and reliable than the first option.

Aluminum radiators of the right size are created from separate blocks so that the total capacity is sufficient for a certain room. Below are the ranges of values of the main characteristics of devices of this type:

- Permissible maximum pressure in the heat supply system: from 6 to 24 atm.

- Coolant temperature (max.): Up to + 110 ° С.

- Service life of the appliance: 10 to 20 years.

Parameters of one section:

- power - from 0.08 to 0.210 kW;

- the volume of the coolant is from 0.2 to 0.5 liters;

- weight - from 0,9 to 1,5 kg.

How many sections of an aluminum radiator you need to heat one room

The simplest and, correspondingly, not an exact calculation, can be made using the following proportion: for each square meter of the room, a thermal power of at least 0.1 kW is needed.

To find out how many sections you need, let's do the following:

- For heating one room with an area of 30 square meters. Requires a power of 3 kW: 30 * 1 = 3.

- If the power of a single element is 0.15 kW, then 20 sections are needed: 3 / 0.15 = 20.

- This amount is too large for one radiator, so it will be necessary to create and install two batteries in the room. Each of them will be made up of 10 sections.

A more accurate result can be obtained if the following factors are taken into account:

- climatic conditions in the area;

- height of ceilings;

- number of window and door openings in the room, external walls;

- presence of heated floors from below and above;

- general insulation characteristics of the structure.

For each of the parameters, correction factors are used. Their meanings can be found in professional reference books. Substituting them into the general formula, it will not be difficult to find out what power is required in the kW section and the device as a whole for a particular room. If you do not get an exact figure, then rounding should be made in the direction of increase. Corrections when setting up equipment are easier to produce correctly if it is purchased with a certain margin of opportunity.

How to properly mount and more profitable to operate aluminum radiators

The main advantages of devices of this type are not difficult to understand from the above data.

Nevertheless, we list them separately:

- The prefabricated design allows you to select the number of elements quite accurately so that the heating power is sufficient.

- The light weight facilitates the production of transport and installation operations. It does not create unnecessary load on the fasteners, the structure of the building.

- Small internal volumes and excellent thermal conductivity reduce inertia. This means that it is permissible to share such devices with individual regulators, and also to integrate them into modern systems automated maintenance of comfortable temperature conditions. Such equipment will reduce the cost of energy resources in the process of operation.

- The neutral appearance of most models fits well with different designs.

- The low cost of the devices makes it possible to create new or modernize old heating systems without much expense.

They are suitable for simple single-tube and complex collector circuits. They are suitable for working with gravitational, or forced movement of the coolant.

The following features should be considered during installation:

- All devices must be equipped with valves for air discharge.

- They must be fixed in a strictly horizontal position.

- When the hydrogen index of the heat carrier (Ph) is out of the range of 7 to 8 units, reactions that destroy aluminum will occur.

- This metal is coated over time with a protective film of oxides, which will prevent the above processes. However, it itself can be damaged by sand and other mechanical impurities. Remove such impurities by using a standard main filter.

- In urban conditions it is difficult to prevent the emergence of emergency situations associated with a sharp increase in pressure. It is recommended to install heating devices designed for increased pressure.

To heat the home was effective, you should buy quality items. Before this - to make a correct calculation of their capacity.

Calculations are made taking into account:

- the area of the room;

- the height of its ceiling;

- number of windows,

- length of the room;

- features of climate in the region.

Right choice

- The capacity of the heating devices should be 10% of the room area, if the height of its ceiling is less than 3 m.

- If it is higher, then 30%.

- For the end room it is necessary to add an additional 30%.

Necessary calculations

After determining the heat loss, you need to determine the performance of the device (how many kW in a steel radiator or other devices should be).

- For example, you need to heat a room with an area of 15 m² and a ceiling height of 3 m.

- We find its volume: 15 ∙ 3 = 45 m³.

- The instruction says that for the heating of 1 m³ in the conditions of the Central Russia, 41 W of thermal performance is needed.

- Hence, the volume of the room is multiplied by this figure: 45 ∙ 41 = 1845 W. This capacity should have a radiator.

Note!

If the dwelling is located in a region with severe winters, the figure should be multiplied by 1.2 (the coefficient of heat loss).

The final figure is 2214 watts.

Number of ribs

From it you will learn how many kW in one section of a bimetallic radiator and aluminum analog is 150-200 watts. Let's take the maximum parameter and divide into it the total required power in our example: 2214: 200 = 11.07. So, to heat the room you need a battery of 11 sections.

Thermal power

In the photo - an approximate heat transfer of cast iron.

In the room, heating appliances are placed at the outer wall under the window opening. Because of this, the heat emitted by the device is distributed optimally. Cold air coming from the windows is blocked by a heated flow going upward from the radiator.

Batteries made of cast iron

Cast-iron analogs have such advantages:

- have a long operating life;

- have a high level of strength;

- they are resistant to corrosion;

- excellent for use in communal systems operating on a low-quality coolant.

- now manufacturers make cast-iron batteries (their price is higher than conventional analogues), having an improved appearance, thanks to the use of new technologies for casting their casings.

Disadvantages of products: large mass and thermal inertia.

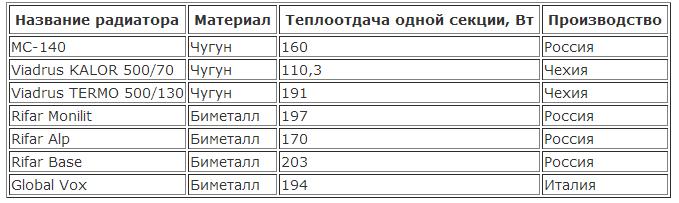

The bottom table shows how many kW in a cast iron radiator, based on its model.

Note!

To heat a room of 15 m², the power, that is, the kW of the cast iron radiator, should be at least 1.5. In other words, the battery should consist of 10-12 sections.

Radiators from aluminum

Products made of aluminum have a greater thermal power than analogues of cast iron. When the question of how many kW in one section of the aluminum radiator, experts say that it reaches 0.185-0.2 kW. As a result, 9-10 sections of aluminum sections will suffice for the standard level of heating of the 15-meter room.

Advantages of such devices:

- a light weight;

- aesthetic design;

- high level of heat transfer;

- the temperature can be controlled by hand with the help of valves.

But aluminum products do not have such strength, like cast iron analogs, for example an oil cooler of 2 kW. Therefore, they are sensitive to operating pressure jumps in the system, hydraulic shocks, excessively high temperature of the heat carrier.

Note!

When water level pH (acidity) is elevated, aluminum releases a lot of hydrogen.

This negatively affects our health.

Proceeding from this, such devices should preferably be used in a heating system in which it has a neutral acidity.

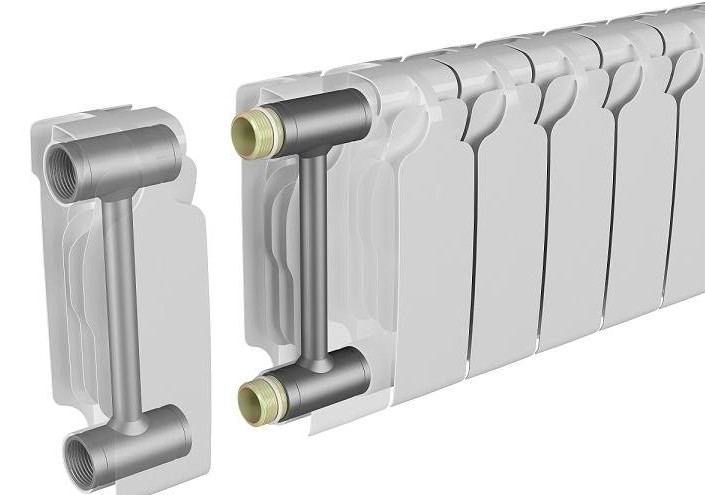

Bimetallic products

Before determining how many kW in the bimetal radiator section, it should be noted that such batteries have similar performance parameters with aluminum analogs. However, they do not have cons, they are peculiar.

This circumstance determined the design of the devices.

- They consist of copper or steel pipes, through which the coolant flows.

- The tubes are hidden in an aluminum plate housing. As a result, the water circulating inside, with aluminum shell does not interact.

- On this basis, the acid and mechanical characteristics of the heat carrier for work and the state of the device in no way affect.

Thanks to the steel pipes, the device has a high strength. Increased heat output is provided by external aluminum fins. Trying to find out how many kW in a steel radiator, please note that the bimetal has the highest heat output - about 0.2 kW per one edge.

Conclusion

Having found out how many kW in 1 section of a steel radiator or analogue from another metal, you can calculate the heat transfer of the purchased products. This will allow you to equip an effective heating system in his home.

The video in this article continues to visually inform you on the topic.