How to check the cooling fan

The internal combustion engine installed on the machine operates in difficult high-temperature conditions. The increase in temperature is caused by the placement of combustion chambers in the cylinders of the block and the distribution of the generated heat to all parts of the engine, as well as from the friction of the pistons in the cylinders and various bearings (rolling and sliding) when reciprocating and rotating parts.

Why is the radiator fan not working?

An uncontrolled increase in temperature leads to the destruction of rubbing parts and complete engine jamming. To avoid such troubles, the engine has a cooling system, the purpose of which follows from its name.

On internal combustion engines, the following types of cooling can be used: air (open type); liquid (closed type); combined (air-liquid). The purpose and operation of fans of all types of cooling are approximately the same. They differ in rotation drive and operation control. According to rotation baits, there are: mechanical, electrical, electromagnetic and hydraulic drives for fan rotation.

Mechanical drives for fan rotation include V-belt drives and those driven by a timing belt. The disadvantages of these drives include: their constant operation (with the engine running), and, accordingly, power take-off and excessive fuel consumption; low efficiency of temperature control due to the inability to regulate the fan speed or ensure its shutdown; a large load on the coolant pump, leading to its rapid failure.

Hydraulic, electric and electromagnetic drives are devoid of the disadvantages listed above. These drives are controlled automatically, maintain the specified temperature regime of the engine, reduce dynamic loads on the blades, and reduce noise when the vehicle is moving. The disadvantages of these drives include: design complexity, high cost of units and repairs in general.

There can be many failures in the operation of mechanically driven fans. Let's take a look at the more typical ones:

The tension of the belt (belts) of the fan drive has weakened due to poor-quality adjustment or belt stretching;

Belt slip due to lubricants getting on it;

Weakening of the belt (belts) due to the loosening of the nuts securing the generator or tension roller;

Jamming of the coolant pump shaft bearing (bearing failure due to lack of lubrication, increased static load on the bearing due to overtensioning of the fan drive belt ...);

Bundle drive belt;

Broken drive belt.

WARNING! Disconnect the battery negative terminal before diagnosing electrically driven fans. If a fan with an electric drive does not come into operation, then during diagnostics, first of all, it is necessary to exclude mechanical damage to the fan and the destruction of the fan shaft bearing.

When checking the electrical part of the fan drive, it is necessary to verify the integrity of the fan fuses, check the integrity and appropriate length of the motor brushes, and also verify the integrity of the electrical wiring; check the health of the collector and motor windings. A malfunction may occur due to a malfunction in the operation of the temperature sensor, relay or loose contacts in the connectors, as well as the electronic control unit. Another reason for the fan not turning on may be a thermostat failure. The reasons for the failure of hydraulically driven fans can be the same as those with a mechanical drive, plus the failure of the fluid coupling.

How to check the radiator fan yourself.

Checking the mechanically driven radiator cooling fan is not very difficult. During the operation of the car, it is necessary to monitor the coolant temperature gauge, preventing it from overheating (especially boiling). In order to make sure that the fan is working reliably, it is necessary to make a visual inspection and make sure that the belts are intact (no breakage, delamination), no oiling of the belts.

Check the tension of the fan drive belts, and if it is loose, make sure that the generator (tension roller) is securely fastened, that the belts are not stretched. Check the absence of jamming when the fan rotates (check with the belts removed), its jamming, the absence of play in the coolant pump bearings.

Checking the performance of an electrically driven fan requires basic knowledge of working with electricity. The check must begin with an analysis of the readings of the coolant temperature gauge. If an increase in temperature is detected, its cause must be determined. WARNING! Disconnect the battery negative terminal before diagnosing electrically driven fans.

Checking the performance of an electrically driven fan requires basic knowledge of working with electricity. The check must begin with an analysis of the readings of the coolant temperature gauge. If an increase in temperature is detected, its cause must be determined. WARNING! Disconnect the battery negative terminal before diagnosing electrically driven fans.

After making sure that there are malfunctions in the operation of the fan, proceed to troubleshooting. First of all, check the operation of the mechanical part, that is, the absence of visible damage, make sure that the fan rotates freely, without jamming, and also check the operation of the thermostat. After that, proceed to check the electrical part. First of all, it is necessary to check the integrity of the fuses. If the fuse(s) are blown, look for where the short circuit occurred. If all the fuses are intact, we check the operability of the fan motor (fans).

The operation of the electric motor can be checked by emergency turning on the fan, for this it is necessary to disconnect the terminals from the temperature sensor and start the engine - the fan should work. A more reliable check of the electric motor can be made by connecting the battery directly to the engine. If the electric motor does not work, check the serviceability of the electric brushes, the integrity of the winding, the health of the collector. If the motor is running, check the fan switch relay is working.

To do this, you need to remove the block from the fan switch relay. Having activated the emergency switching on of the fans, we pull out the relay one by one from the socket, by turning off the fans we determine their performance. We check the serviceability of the negative and positive wires, their integrity, the absence of insulation melting, the exposure of the wires, the reliability of the contacts in the connectors.

Check for a negative coming from the ECU to the fan relay. If faulty parts are identified, they are replaced, as well as further checking the health of the electrical wiring in order to prevent repeated failure of the fans.

What you need to check the radiator fan.

No special equipment is required to test a mechanically driven radiator fan. The integrity and serviceability of the fan drive, as well as itself, is determined by a careful inspection using the tool that the machine is equipped with. Suitable spare parts are required for repairs.

To check the fan with an electric drive, in addition to a car tool, you must have an indicator (to check the health of the electrical wiring), a tester (to check the health of the electrical wiring, as well as measuring the voltage and resistance of parts). This work does not require high qualifications, but it takes a lot of time to detect a malfunction (the less experience, the more time is required), as well as strict adherence to safety measures.

Subscribe to our feeds on Facebook, Vkontakte and Instagram: all the most interesting automotive events in one place.

Was this article helpful?

auto.today

How to check the cooling fan on the VAZ-2114: photo and video

Overheating of the engine threatens with serious consequences: the piston will jam, it will pierce the block gasket, which will turn into a major overhaul of the power unit. Therefore, the cooling fan is an important element that protects the power unit from extreme heating.

Causes of a malfunction on the VAZ-2114

The engine cooling fan may not start under the following circumstances:

Video on replacing the fan switch sensor

Checking the operation of the cooling fan motor

The easiest way to check the operation of the fan is to throw two straight wires on it: minus and plus.

Plus is taken from the battery, minus from the car body. If it does not work when the circuit is closed, then the problem lies precisely in it. When starting the blades, we are looking for a problem elsewhere.

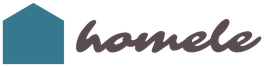

The scheme of the cooling fan

Basically, when a non-working fan is detected, several reasons are identified:

- The electric motor burned out, a break in the winding;

- Wear of carbon brushes;

- Seized or broken bearing.

If in the last two cases the problem is solved, so to speak, with little bloodshed, the first one involves replacing the electric motor.

Important! When wiring, the main power supply of the electric motor must be disconnected.

Procedure for verification

The operation of the fan on the VAZ-2114 is tied through 2 fuses. One of them is also responsible for the sound signal. You can check it by clicking on the horn. If there is no sound, replace with a whole one. It is located in the mounting block, it is 20 amp, marked F5.

Check and, if necessary, change the fuses

The second one is under the dash, on the passenger side. Under the casing there are 3 relays with a fuse for each. The middle pair is responsible for the operation of the cooling fan. Replace the blown element with a new one (the fuse can be “ringed” with a multimeter or limited to visual inspection. An ohmmeter is required to check the relay’s performance). Checking their condition, at the same time make sure that the contacts are in a good condition, clean them if oxide is found.

Important! Having found a blown fuse, you should not be limited to replacing it with a new one. It is imperative to find the cause of the break, as in the near future the new one will burn out again.

Checking the fan on sensor

If the cause is not found, the next step should be to check the operation of the fan enable sensor. It is not difficult to do this. Disconnect it and turn on the ignition, while paying attention to the fan. The rotation of the blades indicates that the cause of the problem is in the sensor.

Checking the cooling fan switch

Due to the fact that very often the sensor starts to fail, giving erroneous signals, it is recommended to check it in another way. To do this, you need a container with antifreeze or antifreeze, a thermometer and a multimeter. Wires from the measuring device are connected to the sensor terminals, the threaded part of the sensor is immersed in the liquid. Heat the contents of the container to the temperature of the fan operation (on the VAZ 2114 - 92 degrees). When the contacts are closed, the multimeter will beep. So the sensor is working, if this does not happen, you can safely throw it away and buy a new one.

Healthy! Before installation, it is advisable to check the performance of the purchased sensor in the same way.

Video about checking the sensor for turning on the cooling fan

Final check

After fixing the problem, start the engine of the car. The fan motor should start after about 5 minutes of idling. If this does not happen, and the temperature has reached the desired norm, carry out troubleshooting again.

Video about the reasons why the cooling fan on the VAZ-2114 does not turn on

carfrance.ru

Radiator cooling fan sensor: how to check the response temperature yourself

The radiator cooling fan is one of the key elements that save the motor from possible overheating. It should turn on when the coolant is too hot and not cool enough as it passes through the radiator. For example, this situation occurs when the engine is idling or the vehicle is moving at low speed, especially when the ambient temperature is high.

The radiator cooling fan is one of the key elements that save the motor from possible overheating. It should turn on when the coolant is too hot and not cool enough as it passes through the radiator. For example, this situation occurs when the engine is idling or the vehicle is moving at low speed, especially when the ambient temperature is high.

The sensor is responsible for turning on / off the cooling fan. It should work at high temperatures, activating the fan. If it doesn't, the sensor will need to be replaced. In this article, we will look at how to determine that the radiator cooling fan sensor has failed.

Table of contents: 1. How the radiator cooling fan sensor works 2. Where is the radiator cooling fan sensor located 3. How to check the radiator cooling fan sensor

To understand how to check the sensor, you must first understand its principle of operation. The radiator cooling fan sensor is arranged very simply, but it is somewhat different on carburetor and injection engines.

To understand how to check the sensor, you must first understand its principle of operation. The radiator cooling fan sensor is arranged very simply, but it is somewhat different on carburetor and injection engines.

In the carburetor, it has two contacts and a bimetallic plate. When the bimetallic plate is heated to a temperature determined during the production of the sensor, the contacts close, and current begins to flow through them to the fan, turning it on. On the injector, the sensor activation system is almost the same, except that the engine control unit sends the turn-on command, analyzing the need to activate the fan based on information from several other sensors.

Sensors on carburetor engines are triggered when a certain temperature is reached, and the driver can look at the markings on the body of the device to determine in which temperature range the sensor will work. Usually, such sensors are activated at a temperature of 92 to 97 degrees Celsius. If the driver is worried about the possible overheating of the engine, he can find a sensor on sale that works at a lower temperature and install it. On injection engines, the sensor response temperature is flashed into the “brains” of the vehicle control unit.

Where is the radiator cooling fan sensor located?

Manufacturers determine the location for installing the fan activation sensor, depending on the design features of the engine. Most often it is placed at the bottom of the radiator, but sometimes it is more expedient to place the sensor near the thermostat and cylinder block.

How to check the radiator cooling fan sensor

Recommended reading: Radiator cooling fan does not work or does not turn off: what to doThe methods for diagnosing the sensors in question will differ, depending on which motor they are installed on and how they are turned on:

The options with a complete failure of the sensor are considered above. In this case, situations are possible when it fails partially, for example, it works at the wrong temperature. This can also be checked in the following way:

Depending on the results obtained, a decision can be made about the serviceability or malfunction of the sensor. If it worked at a temperature below the declared temperature, then such a sensor has some problems, but it can prevent the engine from overheating by turning on the fan in advance. It is much more dangerous if the sensor is triggered at a temperature higher than the declared one, in which case it will need to be replaced.

OkeyDrive.ru

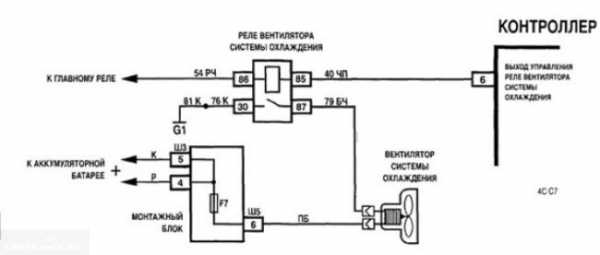

Checking the condition of the cooling system fans and their switching circuits, replacing fans

EXAMINATION

2. If the motor is in order, check the condition of the fuses for the cooling fan (the fuses are placed in the mounting block located on the left under the instrument panel, on V6 models check fuses # 3 and # 6, on 4-cylinder - # 4), sensor (s) - fan(s) switch(es), cooling system fan relay, A/C fan relay (mounting block in the engine compartment) and connecting wiring of the corresponding circuit.

| 3. For check of serviceability of functioning of any of gauges-switches of the fan of system of cooling, disconnect a socket of its electroconducting. Start the engine and use an ohmmeter to make sure that there is no continuity between the terminals of the sensor-switch when the engine is cold (below 88 ° C there should be no conductivity). The closing of the sensor-switch should occur after the coolant has warmed up to a temperature above 92? 96 °C. The closing temperature of the sensor-switch of the K / V capacitor is 108 ° С. In case of violation of the described dependence of the presence of conductivity, replace the faulty sensor-switch. The opening of each of the sensors-switches should occur at a temperature of 3? 8 degrees below their closing temperature. |

4. On 4-cylinder models, there is only one thermal sensor-switch that controls the operation of the fans of both systems (refrigeration and air conditioning). There are two such switches on V6 models - one for each of the systems.

2. Make sure there is continuity between the black wire terminal and ground. If there is no continuity, check the continuity of the ground loop. 3. Check for battery voltage at the terminals of the following wires: white, black-yellow-1, black-yellow-2, yellow-white and yellow. If there is no voltage, check the condition of the corresponding fuses in both mounting blocks (under the instrument panel and in the engine compartment). 4. Switch on the ignition again, restoring the original wiring connection. Ground the green wire terminal to ground. If the fans do not work, check for an open in the green, yellow and yellow-white wires 5. Measure the voltage at the white-green wire terminal. The required value at an engine temperature below 107 °C is 11? 12 V, - otherwise, check for a short circuit to the body ground, evaluate the condition of the control module and the temperature-sensitive sensor-switch.

6. Before testing a new module, disconnect both fan relays and check for continuity between the yellow/yellow-white wire terminal and ground (set the ohmmeter to 20 kΩ). If conduction occurs, the new module will also fail when switched on.

1. Disconnect the negative cable from the battery.

2. Apply the parking brake and chock the rear wheels of the vehicle. Jack up the front of the car and place it on jack stands. If equipped, remove the lower radiator splash screen. 3. Inserting a small screwdriver into the connector, release the locking tab and disconnect the fan wiring.

9. Installation is carried out in the reverse order.

carmanz.com

Why the cooling fan does not work on Kalina

The radiator fan is used for forced cooling of the engine radiator when it overheats. When the car is in motion, the radiator is cooled by the oncoming airflow.

At low speeds, or when the car is just standing still, the radiator is unable to cool the liquid on its own, therefore, when it reaches a certain temperature (101-105 degrees), the sensor is triggered, thereby transmitting the corresponding signal to the controller.

The latter analyzes the received information and turns on the fan.

The fan itself is a structure consisting of a casing (housing) with a built-in electric motor with an impeller. The fan is attached to the inside of the cooling radiator.

Cooling Fan Malfunctions

The reasons for the failure of the fan may be:

- faulty temperature sensor;

- failure of the relay or fan fuse;

- breakage of electrical wiring or lack of contact in the connectors;

- defective fan motor.

How to find the reason

Start testing with the motor. To do this, disconnect the electrical wires from it, and connect it directly to the battery, observing the polarity. If the fan does not turn on, the problem is in it. If it worked, you need to look for another reason.

Check all the contacts on the connectors, and after the relay and fuse. They are located in an additional mounting block, which is located to the right of the instrument panel near the lower air duct of the stove.

The fuse (50 A) can be checked with a tester, it is better to take a known working relay and install it in the appropriate socket. If the problem is not solved, move on.

Checking the temperature sensor. To do this, warm up the engine to operating temperature, turn it off and turn off the sensor. It is located on top of the thermostat housing. When the sensor is disabled, the controller must independently start the fan for continuous operation.

Start the engine and wait for the fan to turn on. If the coolant temperature has reached a critical value, and the fan does not turn on, you need to look for a break in the wiring.

Do I need to change the fan

If you have determined that the problem is in the fan itself, or rather in its electric motor, you can try to repair it. Most often, it stops working due to failure of the brushes, or due to problems with the rotor bearings. Less often, the collector becomes unusable or a break occurs in the winding.

If the fan is beyond repair, it must be replaced.

Under no circumstances should you drive a vehicle with the fan not running. Overheating of the engine will inevitably lead to the destruction of the rubber hoses of the cooling system, gaskets, and also threatens to fail the parts of the piston group.

The price of the cooling fan and the cost of work to replace it

Prices for a cooling fan for Lada Kalina (an electric motor with an impeller) vary between 1500-2500 rubles. Replacing this node at a service station will cost 300-400 rubles.

When buying a new fan, pay attention to its manufacturer and part number. This part may have the following numbers:

- 1118-1308008;

- 1118-1300025;

- 21230-1300025-00;

- 2123-1300025 (with two motors for Kalina 2123);

- MOD285 (BM grades);

- BMMOD285 (Pilenga brand).

Replacing the cooling fan Lada Kalina

It is not necessary to go to a workshop to replace the cooling fan. You can do this without much difficulty and on your own.

Required tools:

- ratchet head or ring wrench for 10;

- box or open-end wrench for 8;

- screwdriver with cross bit;

- pliers.

Work order

- Park the vehicle on level ground.

- Raise the hood, disconnect the ground wire from the battery.

- Using a 10 wrench, unscrew the two air filter mounting bolts.

- Disconnect the MAF sensor connector by pressing the release tab.

- Disconnect the purge valve connector located on the air filter housing.

- Having unscrewed the bolt of the clamp fixing the air duct with a screwdriver, remove the corrugation.

- Remove the 4 screws securing the air filter cover.

- Remove the cover, remove the filter element.

- Unscrew the nut securing the air intake with an 8 wrench, and dismantle it.

- Using a 10 wrench, unscrew the two nuts securing the fan shroud on the right in the direction of travel of the car, and then with a 8 wrench, two nuts on the left.

- Disconnect the fan power connector.

- Carefully, so as not to damage the radiator lamellas, remove the fan together with the case.

- Using a 10 wrench, unscrew the 3 bolts securing the electric motor, and remove it from the housing.

- Install a new impeller motor in its place.

- Screw the casing assembly with the fan to the radiator.

- Plug it in.

- Carry out the rest of the assembly work in the reverse order.

Conclusion

After replacing the cooling fan, check its operation. Start the engine and warm it up until the fan turns on. This may take 3 to 5 minutes.

When turning on the fan, do not turn off the engine immediately, wait until the fan turns off.