Clamps, terminals and other methods of connecting wires

Those who are independently engaged in the repair of home electrical wiring constantly have to deal with such a concept as connecting wires. There are many ways to do this - from the old-fashioned twisting method to modern terminal blocks. Whether you're doing a major overhaul of a household electrical network or connecting a new element (switch, lamp or socket), the connection must always be reliable. This directly affects the safety of your home. Let's talk about what is still stronger and more profitable - use wire clamps or twist them and solder them?

Twist does not go out of fashion

The modern market in such a variety presents terminals for connecting electrical wires that it would seem that it is high time to forget about twists. But among electricians, this method stubbornly continues to be popular, despite the fact that factory connectors provide safety and reliability. In addition, the terminals are much more convenient to use and look more aesthetic than twisted wires rewound with electrical tape.

Twisting has another very significant drawback. If we consider this method objectively, it does not fit into any concept - detachable connection or one-piece. Logically, it is clear that the ends of a detachable can be repeatedly disconnected. But twisting cannot be called a full-fledged detachable connection, because each time after unwinding and re-twisting, the ends of the wires will deteriorate. Twisting also does not fit under the concept of a permanent connection, because it does not have the necessary stability, strength and reliability.

How to make a good twist is described in this video:

But if you can’t get out of the habit of twisting wire strands, then at least use convenient and safe connecting caps instead of insulating tape.

PPE caps

Caps are also called connecting insulating clips (abbreviated as PPE).

Design

Outside, the body of the cap is made of plastic. This material has a number of positive aspects:

- under the influence of an open flame, the combustion process does not support;

- able to withstand operating voltage up to 600 V;

- has good insulating properties.

The plastic case, in addition to isolating the junction, also protects it from mechanical damage.

Inside the cap is equipped with a crimp spring made of steel and having the shape of a cone. When a wire twist is inserted into the cap, the coils of this spring additionally compress it.

When using caps, it is very important to correctly cut the ends for twisting. The insulating layer must be cut off so much that the bare metal is not outside the cap, but completely falls under the compression spring.

Preparing wires for caps

Now in the electrical world it is already considered a mistake to expose a wire or cable from the insulating layer with a knife. Professional electricians use special tools - insulation strippers.

This device has calibrated holes for each standard core diameter (the holes have a cutting edge). The insulation stripper does not break the conductive surface layer, which maintains its strength.

Nobody cancels the monter's knife either. The main thing is to position it at an angle to the direction of the cut when removing the insulation so as not to hook the metal core. The location of the knife during the removal of the insulating layer at a right angle is not allowed, since there is a high probability that you will make a circular incision, as a result of which the core may then break.

When choosing PPE caps, special attention should be paid to the dimensions of the compression springs. The main contact is created in its smallest conical part. It is very important that it matches the connected wires. If the strands are thin, the compression by the conical spring will not be tight, and thick twisted strands, on the contrary, will not enter the cap to the end.

Core connection

The connection of wires using PPE caps in practice is carried out in two ways:

- No prerolling. Two cores, identical in diameter, must be inserted into the spring with force. Then vigorously rotate the cap in a clockwise direction. Thus, twisting is done to the length of the bare metal strands of wires.

- If it is necessary to connect three or four cores, they must first be twisted with pliers, bite off the twisted tip, and then put on the cap, turning it clockwise with effort.

Remember! In order for the PPE cap to fit tightly on the surface of the twist, you need to rotate it only clockwise, but not in the opposite direction.

Put on the cap with force, so that due to this, the coils of the crimp spring move apart and reliably squeeze the wires to be connected.

Never use PPE caps to connect strands of different materials. To a greater extent, this applies to copper and aluminum, between which the passage of an electric current causes a galvanic process.

How to connect with caps is shown in this video:

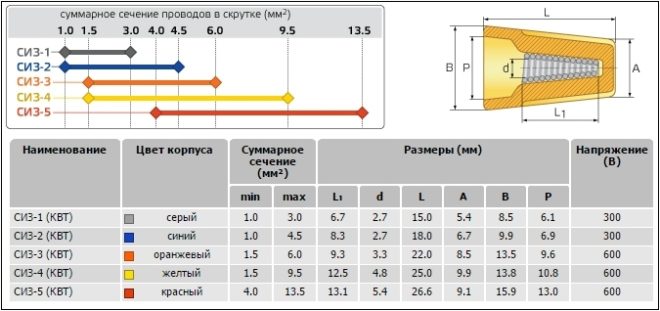

Types of caps

Many electricians have a negative attitude towards PPE caps. But this attitude can be due to two reasons. Either the caps were chosen incorrectly, or they were ineptly installed on the wires to be connected.

To correctly select caps for wire sizes, manufacturers have introduced a special color marking:

- SIZ-1 - connects two wires with a cross section of 1.5 mm 2 (gray);

- SIZ-2 - connects three wires with a cross section of 1.5 mm 2 (blue);

- SIZ-3 - connects two wires with a cross section of 2.5 mm 2 (orange);

- SIZ-4 - connects four wires with a cross section of 2.5 mm 2 (yellow);

- SIZ-5 - connects eight wires with a cross section of 2.5 mm 2 (red).

True, there are no uniform international standards for such color marking. Therefore, for manufacturers from different countries, it may differ. Be careful when buying, check with the sales assistant for the required dimensions.

Terminal clamps

Terminal blocks for connecting wires give one indisputable advantage, they can connect wires of different metals. Both here and in other articles, we have repeatedly reminded that it is forbidden to twist aluminum and copper wires together. The formed galvanic couple as a result will lead to the occurrence of corrosive processes and the destruction of the connection. And it doesn't matter how much current flows at the junction. Sooner or later, the twist will still start to heat up. The way out of this situation is precisely the terminals.

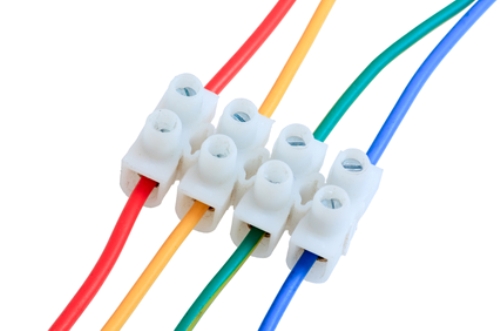

Terminal block

The simplest and cheapest solution is polyethylene terminal blocks. They are not expensive and are sold in every electrical store.

The polyethylene frame is designed for several cells, inside each there is a brass tube (sleeve). The ends of the cores to be connected must be inserted into this sleeve and clamped with two screws. It is very convenient that as many cells are cut off from the block as it is necessary to connect pairs of wires, for example, in one junction box.

But not everything is so smooth, there are also disadvantages. Under room conditions, aluminum begins to flow under screw pressure. You will have to periodically revise the terminal blocks and tighten the contacts where the aluminum conductors are fixed. If this is not done in a timely manner, the aluminum conductor in the terminal block will loosen, lose reliable contact, as a result, spark, heat up, which can result in a fire. With copper conductors, such problems do not arise, but it will not be superfluous to make a periodic revision of their contacts.

Terminal blocks are not intended for connecting stranded wires. If stranded wires are clamped into such connecting terminals, then during tightening under pressure of the screw, thin veins may partially break, which will lead to overheating.

In the case when it becomes necessary to clamp stranded wires into the terminal block, then it is imperative to use auxiliary pin lugs. It is very important to choose its diameter correctly so that the wire does not pop out later. The stranded wire must be inserted into the lug, crimped with pliers and fixed in the terminal block.

As a result of all of the above, the terminal block is ideal for solid copper wires. With aluminum and stranded, a number of additional measures and requirements will have to be observed.

How to use terminal blocks is shown in this video:

Terminals on plastic blocks

Another very convenient wire connector is a terminal on plastic pads. This option differs from terminal blocks by a smooth metal clamp. In the clamping surface there is a recess for the wire, so there is no pressure on the core from the twisting screw. Therefore, such terminals are suitable for connecting any wires in them.

In these clamps, everything is extremely simple. The ends of the wires are stripped and placed between the plates - contact and pressure.

Such terminals are additionally equipped with a transparent plastic cover, which can be removed if necessary.

Self-clamping terminals

Wiring using these terminals is simple and quick.

The wire must be pushed into the hole to the very end. There it is automatically fixed with the help of a pressure plate, which presses the wire to the tinned bar. Thanks to the material of which the pressure plate is made, the pressing force does not weaken and is maintained all the time.

The internal tinned bar is made in the form of a copper plate. Both copper and aluminum wires can be fixed in self-clamping terminals. These clamps are disposable.

And if you want clamps for connecting reusable wires, then use terminal blocks with levers. They lifted the lever and put the wire into the hole, then fixed it there by pressing it back. If necessary, the lever is raised again and the wire protrudes.

Try to choose clamps from a manufacturer that has proven itself well. WAGO clamps have especially positive characteristics and reviews. ».

The advantages and disadvantages are discussed in this video:

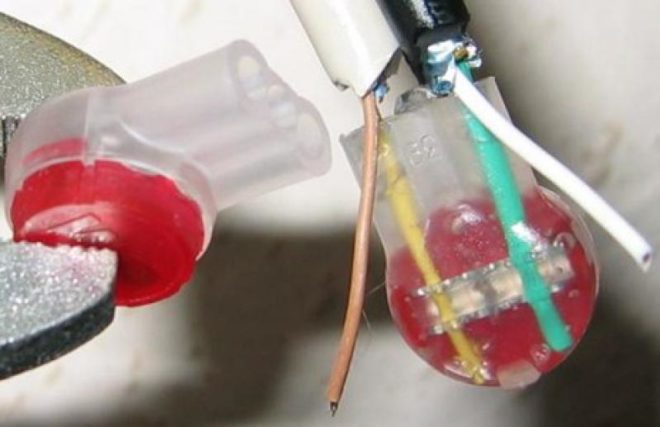

scotch lock

Couplings of this type are disposable. They are used for wires with low operating currents (telephone lines or wires for low power LED lamps).

Such clamping couplings carry out the connection by means of a mortise contact. The wires do not even need to be stripped before connecting. Right in the insulating layer, they are inserted into scotch locks and crimped with pliers. The plate, which has cutting contacts, cuts into the insulating layer, due to which there is contact between the cores.

In addition to the fact that stripping of the cores is not required, scotch locks have a number of other advantages:

- low cost;

- universality;

- no special tools are needed, crimping is done with ordinary pliers;

- water resistance (there is a hydrophobic gel inside the coupling, which protects the contact connection from moisture and corrosion).

- If the scotch-lock sleeve needs to be replaced, it is simply cut out, and a new one is mounted in its place.

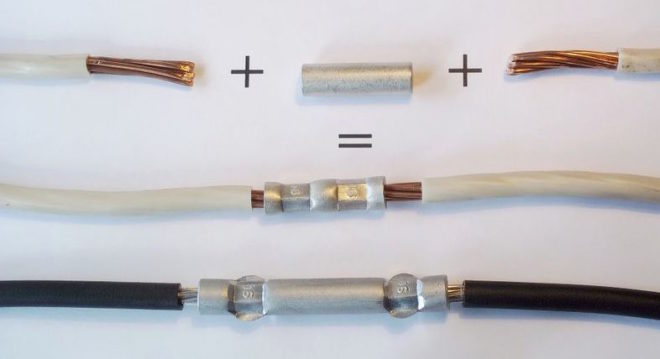

Sleeves

When powerful clamps are needed for several wires, sleeves are used. They are a tinned copper tube, or a flat tip with a hole made for fastening.

It is necessary to insert all the wires to be connected into the sleeve and crimp using a special crimper tool (crimping pliers). This wire clamp has a number of positive aspects:

- It is very convenient to use lugs with holes when there is a need to fix the wire knots on the housings with screws.

- Crimping at the junction does not contribute to increased resistance.

As you can see, there are a lot of wire clamps, each with its own advantages and disadvantages. Choose based on which wires you need to connect, where the junction will be located. But do not forget that the most important thing in electricity is reliability and safety.