Film on the warm floor. Infrared film heating floor: customer reviews.

The most modern type of space heating, gaining increasing popularity, to date - a film warm floor. To compete with the familiar systems of warm floors they allow easy installation, high productivity and positive impact on the human body. Let's consider what the principle of the action of a film warm floor is based on, what operational characteristics it possesses, and also we will find out how much the installation costs and whether it is possible to produce it with our own hands.

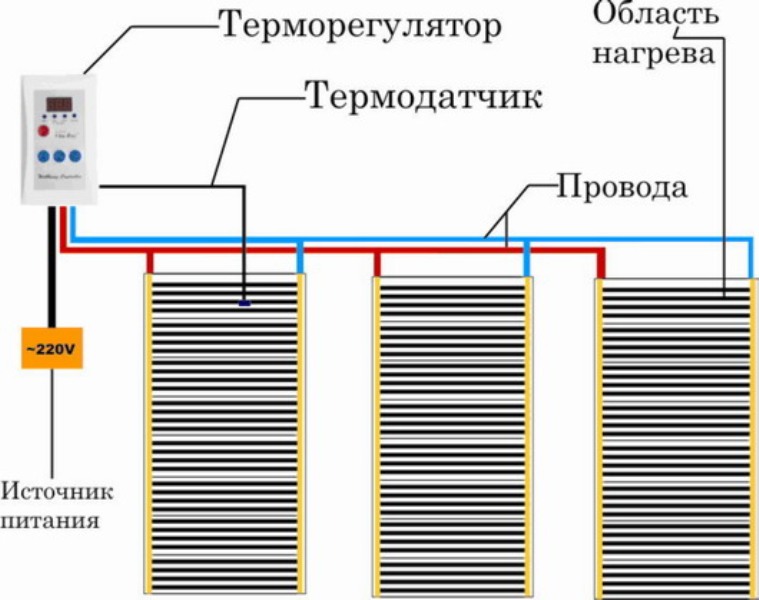

The film warm floor is a heating element (carbon strips), sealed in a film. Their heating is carried out by means of copper conductors with a silver coating on which an electric current is conducted. For heating, the film floors use infrared radiation, the source of which are carbon bands. The temperature regulator monitors the floor temperature with the help of a temperature sensor, and switches off or turns on the heating according to the set operating mode.

The difference of such a system from the more familiar cable and water heated floors is that the heat from the IR radiation primarily heats the air around rather than the air. This principle is similar to natural solar heating and is most comfortable for a person. The beneficial effect of infrared radiation is undeniable, which can be judged by the presence of such systems in medical and recreational facilities.

Mounting the film-warm floor by own hands

The film warm floor, thanks to its design, is easily mounted under any floor covering, from linoleum to ceramic tiles. Unlike heating mats or heating cables, the film does not require the filling of the screed. This allows you to easily dismantle the warm floor, and rearrange it in another place, for example, when moving or re-planning. The entire process of laying the infrared floor can be broken down into several stages.

Substrate laying

Mounting the substrate is not an obligatory procedure, but it allows to significantly optimize the work of IR floors. The substrate minimizes heat loss, and also creates an additional leveling layer for laying the finish coat.

Variants of substrates:

- plates of fiberboard in combination with foil coated;

- expanded polyethylene;

- lavsan;

- expanded polystyrene.

The most optimal are the substrates that combine insulating and reflecting properties, for example lavsan. In addition to the preservation of heat, this material allows you to direct the heating in the desired direction. That is, the heat energy will not heat the neighbors from below, but remain in a particular room.

Do not neglect the recommendations of manufacturers of infrared floors. It is extremely undesirable to use aluminum foil as a substrate, which can contribute to overheating of the system, the failure of some components, and, under certain conditions, leads to a short circuit.

Lay the substrate recommended on a prepared, flat and cleaned surface. It is recommended that the screed be filled in the level, and did not have small irregularities, to avoid bending the film. The hotel material sheets should be placed upside-down with a reflective side, overlapping, joining joints with a construction tape. If the substrate is decided to be made from fiberboard, then the reflective foil must be laid before laying.

Mounting the thermostat

The thermostat is mounted on the wall, for which purpose it prepares a recess for the podrozetnik and Strojba for wires. Thermoregulators have standard mounting dimensions, so they can easily be attached to the usual electric pads. To the thermostat the supply wires from the apartment electrical panel, the wire of the heat sensor and the ends of the film warm floor should approach.

IR film laying

Before laying, it is necessary to draw an approximate scheme, taking into account that under the places where furniture is planned to be installed, the warm floor is not installed to avoid overheating. Since the producers of IR warm floors, for example Caleo, supply the material mainly in rolls, it will need to be cut into separate parts. Places where the film can be cut are marked with the corresponding symbols. Select the cut line yourself - it's forbidden.

According to the technology, the strips should not reach the walls about 10 cm from each side. The film is laid on the floor with a copper bus down, with the contact clamps placed at the wall where the thermostat will be placed. Separate parts of the film are connected in series, and the connection points are insulated with bituminous gaskets, exactly as well as the cut places, on the opposite side of the strips. To ensure that the isolation places do not bulge, you can locally cut the indentations in the substrate.

How to connect a temperature sensor

The temperature sensor is a necessary element of any system of warm floors, without which the automation of the process of heating the room is not possible. The installation site is best selected in accordance with the manufacturer's recommendations. Usually it is mounted near the thermoregulator.

The wire to the sensor and the sensor itself is placed in the prepared groove under the film. The entire wire, right up to the thermostat, must be laid in a corrugated pipe, and the end of the pipe must be securely insulated. This will make it easy to remove the sensor and replace it with a breakdown. Rotations of the corrugation should be smooth to prevent strong bending of the wire.

Wiring and testing the system

The final stage of the installation involves connecting the wires to the terminals of the thermostat. It is necessary to securely connect the wires from the warm floor and the temperature sensor, as well as the supply wires. About how to connect them to the thermoregulator you need to learn from the electrical wiring diagram presented in the passport to the device. The terminals of the thermostat can be screwed or self-clamping. The nominal value of the circuit breaker for a warm floor must be calculated according to the power consumption of the infra-red floors.

Before proceeding with the laying of the floor covering, it is necessary to make sure that the system is mounted correctly and functions. For this, a test inclusion is made, in which the absence of defects is visually checked. It is also necessary to test the various operating modes using the thermostat settings. If the heated floors are heated and switched off in accordance with the displayed program - the work was done successfully.

The main technical characteristics of a film warm floor

Infrared warm floors have many advantages over other systems. In many respects it depends on the technical characteristics:

- the power consumption of a square meter of film varies from 150 to 400 W;

- maximum heating temperature from 45 to 60 C;

- coefficient of efficiency about 98%;

- film thickness up to 0.5 mm;

- the width of the film is 0.5, 0.8, 1 m;

- the melting point is 130 ° C.

The main advantages of film warm floors, allowing them to compete successfully with cable and water systems:

- the highest productivity in comparison with other types of warm floors - 98%;

- compatible with any finish flooring;

- possibility of safe use in wet and wet rooms (showers, saunas);

- ease of installation, allowing you to cope with this work with your own hands;

- possibility of installation on walls, ceiling and other surfaces;

- the absence of electromagnetic radiation during operation;

- the possibility of dismantling for subsequent laying elsewhere;

- ecological cleanliness of used materials.

In order for these claimed advantages of infra-red warm floors to correspond in practice to the actual state of affairs, you should carefully study the technical passport for the product and follow all recommendations for installation.

Installation price of infrared heated floors

The bulk of the cost of installing an IR warm floor is the price of the film. Prices per square meter start at 2 thousand rubles, and do not significantly increase depending on the capacity of the equipment purchased. For example, a square meter of film from the manufacturer of Caleo with a capacity of 170 W will cost from 1900 to 2500 rubles, depending on the store.

Manufacturers supply the film with rolls of different lengths from 1 to 20 m, so picking the right size will not be difficult. Depending on what area will be equipped with a warm floor depends the total estimate for the work. Also the cost of the choice of temperature controller. The market offers various types of these devices - from simple mechanical to electronic and programmable.

The thermostat is selected depending on what requirements are required to automate the heating of the future system. Rough in the adjustment of mechanical devices with an adjusting wheel stand on average 2 - 4 thousand rubles. The price of electronic and programmable controllers with a liquid crystal or touch screen can reach up to 10 thousand rubles. Their setting is more accurate, and besides it allows you to set a different mode of operation by hours and days.

For the work of specialists on average take about 500 rubles per square foot of the film plus 1000 rubles for the installation of the thermostat. With large volumes, the price will be significant, but you can not worry about the quality of the work performed and in case of breakage make a claim. If you have confidence in your abilities and free time, you can do everything yourself, especially since the simplicity of the work allows you to do this.

Comfortable temperature in the house is one of the main components of the concept of "comfort". After all, you will agree, no matter how beautiful the walls were, and no matter how comfortable the furniture was, if it was cold in the house, it would not be possible to fully relax and relax here. Not hoping for the smooth operation of public services, more and more of our compatriots install alternative heat sources in their apartments. The most popular of them are all kinds of warm floors. Unfortunately, the installation of water or electric floor heating requires large-scale concrete works. What to do if the cosmetic repair in the apartment or the house is already over, and somehow the installation of the "warm floor" has somehow been forgotten. The only way out of such an unpleasant situation can be an infrared warm floor.

What is infrared heating and how does it work?

The film warm floor represents two layers of a dense polymer, between which there is a heating element - a carbon nanostructure with unique properties. Carbon atoms formed in a hexagonal lattice several nanometers in size, give the material the ability to emit in the far infrared spectrum. Infrared radiation - part of the light spectrum invisible to the human eye with a wavelength of 5-20 microns. Such radiation is recognized not only harmless, but even beneficial for human health. It is often this type of radiation used in surgery, dentistry and sports medicine.

Infrared film warm floor consists of the following elements. Strips of carbon material with a width of about 1.5 cm are connected together by copper busbars with a silver coating, which conduct electric current. The heating element is laminated on both sides with a dense polymer that does not retain infrared radiation and provides excellent protection against moisture, breakdowns and fire.

Advantages of the infrared system over other variants of the warm floor:

- This type of floor heating is very convenient in installation. It does not need to be covered with a concrete screed, which will allow you to lay it at any time, even when the repair is completely finished.

- Film warm floor has no restrictions on the choice of finishing flooring. It can be used under laminate, parquet, carpet, ceramic tile and any other decorative coating.

- The thickness of the film is, as a rule, 0.2-0.4 mm. With its use, the level of the floor does not practically rise, which allows you to do without steps and rapids when you decide to arrange a warm floor in only one room.

- Low inertia allows the film to heat up quickly and to stop heating just as quickly. So, you do not have to specifically monitor the thermometer readings: they are frozen - turned on, warmed up - turned off.

- Infrared radiation warms the room evenly and does not create a temperature drop from floor to ceiling.

- The film can be used in premises that assume a significant load on the finish coat, such as gyms, offices, public premises.

- Due to the special design of the heating element, the installation of an infrared warm floor helps to save considerably. For such heating, 25-30% less energy is spent.

- Easily connects to the smart house system.

- Such a heating film practically does not create an electromagnetic field that negatively affects human health.

It is also important to note that not only installation, but also dismantling of the system is easy. If necessary, when moving, you can take it with you.

You can strengthen the infrared film not only on the floor, but also on the wall or ceiling. Its application is possible even in the car's interior

Technical characteristics and scope of use

If you have already decided to use an infrared warm floor for heating, the specifications below will help you to accurately calculate the amount of material required and the future costs of heating:

- Width - from 0,5 to 1 m;

- The length of the roll is 50 m;

- The thickness of the sheet is from 0.23 to 0.47 mm;

- The power consumption of one m 2 of the film is 25-35 W / h;

- The temperature on the surface of the film is 33 ° C.

It should be remembered that if an infrared thermal film is used as the main source of heat, it should cover at least 70% of the floor surface. Such heating is not recommended in areas with a harsh climate. In these regions, infrared heating can be used only as an additional or emergency. If there is an accident in the central heating system or the heating season has not yet come, and the outside is already cold, installing a warm floor of the floor will not let you freeze.

All you need to connect a warm floor - this is what the classic package looks like

Cut the thermo film only in specially marked places, take this into account when calculating the required amount of material. As a rule, the distance from one place of a possible cut to the other is about 25 cm. In order not to buy unnecessary, specify the details from the seller.

In addition, it is possible to use infrared heating not only in the house, but also in most household buildings, where the central heating is difficult. It can be a garage, a greenhouse or a barn for animals. In severe frosts, the use of a thermal film will help to prevent the pipeline from freezing or the icing of the porch.

Technology of installation and connection of the system

As a rule, sellers underfloor heating recommend that it be commissioned by specialists. In this case, you will receive a guarantee for the work performed about 1 year. But the services of the masters are not cheap, but there is nothing difficult in this work.

Even if you are completely "not friends" with electricity, you can lay the film yourself, and the electrician is instructed only to connect it to the network:

- First, you need to determine the location of the thermostat and install it.

- Clean the floor of debris and dust. Installation of a film warm floor should be done on a dry, clean and durable coating.

- If the rough surface of the floor is wet, it is necessary to ensure the waterproofing of the thermal film. This can be done with a polyethylene film with a thickness of at least 50 microns.

- The next layer should be thermal insulation based on polypropylene or metallized lavsan film. It is not allowed to use heat reflectors based on aluminum foil.

- Now it is necessary to cut IPO into strips of the necessary length. When working in a large room, it should be borne in mind that the length of one strip should not exceed 10 m. Step back from each wall 20-30 cm and spread the film on the floor so that the copper tires are at the bottom and secure with adhesive tape. At this stage of work, special care is required - do not step on the film and do not let the instruments fall.

It is important to note that the imposition of one sheet of IPO on another is prohibited. This can lead to premature failure of the system.

If you still decide to use the services of an electrician, it's time to call for help. If your choice is to do everything yourself, use the following algorithm for connecting the floor to electricity:

- To begin with, it is necessary to clean the end of the wire (8-10 mm) and insert it into the shank of the terminal clip.

- Then fasten the clamp with the wire to the IEP so that one side of it is located on the copper bus and the other side is inside the IPO.

- Isolate the lines of cutting the tire and the place of connecting the wire with pieces of vinyl-mastic tape.

- When all the ends of the thermal film sheets are connected, it is necessary to measure the electrical resistance of the circuit at the ends of the wires that will be connected to the thermostat.

According to the formula W = V2 / R, where R is the resistance, and V is the voltage in the mains, calculate the load and compare it with the maximum allowable for your model of thermostat. If the resulting figure is at least 20% smaller than the one indicated on the thermostat, you can proceed with its connection. - The pieces of thermo film to the thermostat must be connected in parallel. Try to do it so that the bundles of wires can be hidden under the baseboard. To avoid damage to the wire, some of its parts can be hidden under thermal insulation.

- The set of the thermostat must include a special temperature sensor that will monitor the heating of the floor covering. It must be installed under the carbon strip. If you plan to use a soft material as the finish coat, install the sensor in the place with the least load.

- Now connect the thermostat to the mains and test the system. There should be no sparking or heating of the contacts along the entire surface of the floor. Set the desired heating temperature.

The installation of the warm-film floor has been completed. It remains only to lay the finishing decorative coating.

We fix the clamp to the copper clutch - press the clamp with pliers so as not to allow arcing

Wiring plan of infrared warm floor

Laying of the finish coat

Laying carpeting, parquet or laminate on infrared film is carried out according to the standard scheme, but it has some features. The laminated surface of the film can disrupt the adhesion of the tile adhesive to the rough floor. To improve it, it is recommended to lay a mounting grid with a cell up to 20 mm on the floor and fix it in places where there is no IPO.

The popularity of the warm floor is constantly growing, and manufacturers are developing all new types and types of such heating systems. The novelty of the construction market is a film warm floor. Manufacturers describe this system with the brightest colors, but practice shows that in reality everything is not so rosy.

Moreover, there are the most amazing rumors about the harm or benefit of such designs, at times, quite the opposite. And yet the film systems of the warm floor have many advantages, so to get acquainted with this material is as close as possible. With proper installation and application, it will make the house comfortable with minimal time and effort for repairs.

The warm floor in the form of a film is arranged quite difficult, at home, such a system is not produced. The heating element is a unique nanostructure made of carbon materials in which the carbon atoms form a hexagonal lattice. This material has the ability to generate infrared radiation invisible to the human eye.

The heating element of the infra-red warm floor is a hexagonal carbon nanoret, enclosed in two layers of a strong polymer coating and connected by copper tires covered with a layer of silver

The heating element is placed between two layers of dense polymeric material. These strips, whose width is approximately 15 mm, are connected by special conductive copper busbars protected by a silver coating.

The polymer layer protects the heating element from moisture, mechanical attack, ignition and other negative factors, but also perfectly passes the infrared rays.

Advantages and disadvantages of film material

Among the positive moments that happy owners of film floor systems can enjoy, most often note the following:

- Extremely simple and convenient installation, in which there is no need for a concrete screed.

- A short time, which is required for installation work, is only a few hours.

- The ability to combine the system with virtually any floor covering: ceramic tiles, laminate, carpet, parquet, etc.

- A thin film thickness (less than half a millimeter), which does not change the calculated thickness of the floor finish.

- Low inertia of heating, in which the element quickly heats up and also quickly stops heating.

- The ability to transfer increased loads to the finish coat (for example, in gyms, public buildings, offices, etc.).

- Uniform heating of the room, no temperature drop in the direction from floor to ceiling.

- Relatively low cost of installation works.

- The ability to reduce the power consumption for heating the room by about 25-30% (in comparison with similar systems of the warm floor).

- Possibility to introduce heating of a premise in system "the clever house".

- Low intensity of the electromagnetic field, which is generated by the operation of infrared heating systems.

- Absence of negative influence on people's health.

- The ability to remove from the room unpleasant odors.

- Air in the room is not overdried, keeping the optimum level of humidity, while its ionization occurs.

- It is believed that film systems can have anti-allergic effects.

The film floor is easy not only to install, but also to dismantle. If desired, the owners can remove the floor covering, remove the foam of the warm floor and re-install it in a new location.

Infrared film can be used with a variety of floor coverings, for example with a laminate, which is not recommended for installation on other underfloor heating systems

Manufacturers do not often mention the shortcomings of their product, in addition, the positive characteristics of the film floor systems are sometimes somewhat overestimated. To avoid unpleasant surprises during the installation of the film, the following points should be considered:

- Installation of a film floor can take longer than the manufacturer claims, even if it is performed by an experienced professional in strict accordance with the recommended technology.

- Cutting the film and placing it in the room of big problems usually does not cause, the difficulties are connected with the competent connection of silver contacts.

- Incorrectly made clamp leads to weak connection of the floor elements, and for reworking it will be necessary to take a new contact.

- Although to lay this floor does not need a concrete screed, yet the surface of the base should be almost perfectly flat, a noticeable curvature of the base can cause tearing of the film even after laying the floor covering.

- The thickness of the film floor is less than one millimeter, but it may require a "pie" 20-35 mm thick (plywood or chipboard base, substrate, polyethylene film layer, floor covering, etc.) to lay it.

- The system demonstrates high reliability only with absolutely exact observance of all instructions for installation and professional performance of works, and any initiative or low quality level can lead to rapid breakdowns.

- The possibility to save about 20% of the cost of heating in comparison with other systems of electric underfloor heating is actually observed, but only in houses with good centralized heating and with high-quality insulation of the premises.

- The presence of the film floor does not dry the air, however it does not moisten it, when using traditional centralized heating, the problem of humidity level will have to be solved somehow.

As for the ionization of air and removal of unpleasant odors, this effect is really present according to the reviews of the owners of the film floor. Ions have the ability to block molecules of substances that produce unpleasant odors, this effect is widely used in industry, for example, for cleaning clothes, upholstered furniture, etc.

The diagram shows a variant of the correct device of the infra-red floor, which includes the primary floor, the layer of thermal insulation, the film and the floor covering. Sometimes waterproofing is necessary

But there is no direct antiallergic effect, although people prone to allergies feel better in an ionized and humidified room than in a dry, dusty and smoky place.

Where and how are film systems used?

That the decision on the use of infrared film floor was well-founded, it would not hurt to get acquainted with its approximate technical characteristics:

- the width of the film is 0.5-1 m;

- length of a roll of film - 50 m;

- thickness of the material - 0.2-0.4 mm;

- the power consumption of a square meter of material is 25-80 W / h;

- the working temperature of the surface of the heating element is 30-50 degrees.

The film floor can be successfully used as the main heating of an apartment or a house, but at the same time it is necessary that at least 70% of the floor is covered with this material. Unfortunately, in places with cold winters this way of heating does not cope with the increased load.

Here, the infrared floor can only be used as an additional method of heating the room.

Infrared film is supplied in rolls, the width of the material can be from 50 to 100 mm, and the price largely depends on the characteristics and popularity of the brand

Another interesting application for infrared warm floor - emergency heating. Tearing of pipes in frosty weather is not a rare phenomenon.

If the central heating system for some reason is out of order, but the electric energy enters the house, it will be possible to keep it in the living areas with a warm floor if it is not a comfortable temperature, acceptable for normal life and protection from hypothermia.

Infrared warm floor systems are suitable for mounting on a wide variety of surfaces. If desired, the film can be laid on the wall or on the ceiling, while respecting the manufacturer's recommendations

An advantageous sphere of application of infrared heating systems is heating of office premises and outbuildings. The system has practically no effect on the size of the room, and it can only be turned on if necessary. This is also one of the best options for installing bathroom heating.

The tiled floor will always be warm, and the air in the bathroom will warm up to the desired temperature, which will make the water procedures as pleasant as possible. Infra-red floor can be laid not only under the floor covering, but even on open areas, however in this case special protection is required.

Infrared flooring and security

Reviews about film systems on the Internet are very diverse. Some assure that the infrared radiation emits extremely dangerous to human health electromagnetic radiation.

Others assure that this radiation itself has an extremely beneficial effect on the body and copes with a variety of common diseases.

Infra-red film systems of a warm floor in the course of heating allocate insignificant quantity of electromagnetic radiation. The intensity of this radiation is small and does not represent a health hazard.

In fact, neither the one nor the other are wrong. The intensity of the electromagnetic radiation of such a device is negligible, so it can not have any negative impact on the human body. Cable electric floor shows higher intensity indices of electromagnetic radiation, while it is considered quite safe for health.

Because of the low intensity, the positive effect of radiation on the human body is also small. The matter is that electromagnetic fields can positively influence health only under condition of coincidence of temperature of an infra-red wave with temperature of a body of the person.

Provide this option at home is quite difficult. Much more positive impact owners of the film floor get from staying in a uniformly heated room with acceptable humidity.

When installing an infrared film floor on large areas, it should be taken into account that the length of one continuous film strip should not exceed 10 meters

Another myth: infrared film can not be put under linoleum or laminate, because such materials simply do not pass the radiation. All right, infrared rays through the layer of this coating do not pass, but this does not mean that the room does not warm up. In this case, first heats up the laminate (or linoleum) and only after that the heat energy is transferred to the air in the room.

When using other coatings, the air warms up immediately over the entire height of the room. The maximum temperature of heating the laminate or linoleum is rather moderate - about 40 degrees. Therefore, the temperature in the room will be quite acceptable, but there will be no overheating of the air or the floor surface.

Stamps and the best producers

The choice of an infrared floor in the form of a film on the market is quite wide. The cost depends on the amount of film, as well as on its quality, brand awareness and bundling.

Variants are very diverse - from a film of European production, which is completed with everything you need right up to a self-regulating system and an antisuke grid to inexpensive Chinese counterparts. In general, experts note that this is not the cheapest method of installing a warm floor in comparison with other options.

The popular Korean brand HeatPlus, whose capacity varies between 150-220 W / m2, is successfully used for installation in rooms with a high level of heat loss (balconies, loggias, cellars, tambours, etc.). If desired, the film can be laid even on walls or ceiling. The width of the film, depending on the species, is 0.5, 0.8 or 1 meter. The material is provided with a reliable anti-spark multi-layered protection. Manufacturer's warranty is 15 years.

The Korean brand Caleo Gold is extremely popular and is considered a rather expensive variant of the warm floor. Material with a capacity of 170 or 230 watts per square meter. (the latter is recommended for cold rooms) is equipped with an anti-leak screen, has a self-regulating effect. Warranty obligations of the manufacturer are 15 years.

Another Korean brand - RexVa - is distinguished by an increased level of safety and resistance to breakage thanks to a special anti-spark line. This material demonstrates the ability to withstand voltage surges in the network. The width of the film is 0.5 m, and the power reaches 150 watts per square meter. m. Guarantee, as for other Korean brands, is 15 years.

Infrared flooring from the manufacturer Okondol (Korea) can be heated to 50 degrees, a film with a width of 0.5 or 1 meter is supplied. The manufacturer guarantees perfect operation of the system for 50 years, of course, if the recommendations for installation and operation are observed.

In addition to the above brands, infrared film Calorique, PowerFilm, UNOSI, IN-TERMA, SkySun and others are offered on the market.

What do I need to consider when installing?

Sellers and manufacturers recommend charging the installation of infrared floor specialists, but some masters are quite successfully coping with this task yourself. To properly lay the film floor, you must follow these steps:

- Step 1:Make a layout plan for the layout of the film, choose a location for the temperature sensor and thermostat.

- Step # 2:Install the thermostat in a suitable place.

- Step # 3:Prepare the foundation, which should not only be even, but also dry and clean.

- Step # 4:If the base is uneven, you may need to lay plywood on the floor (the recommended thickness is 10 mm and higher) or chipboard.

- Step # 5:Lay a protective waterproofing coating, whose role is successfully performed by a film with a thickness of 50 μm or more.

- Step # 6:Lay the heat-insulating layer of the lavsan film, both a metallized and polypropylene variety of this material is suitable.

- Step # 7:Cut the film into strips of the required length along special lines.

- Step # 8:Lay the film in accordance with the scheme of the tires down and fix it with adhesive tape.

- Step # 9:Connect the elements with special contacts.

- Step # 10:Install the temperature sensor.

- Step # 11:Connect the system to the power supply and thermostat.

- Step # 12:Install the floor covering.

Do not use materials with an aluminum foil base as the thermal insulation layer. It is strictly forbidden to lay strips of film overlap.

After the film is spread out, it is necessary to move around it with great care, so as not to damage the heating elements. Do not also drop a construction tool on its surface.

The diagram clearly shows the connection of the infra-red warm floor. Despite the simplicity, it is recommended to connect the heating element to the thermostat and the power supply to instruct a professional electrician

Sometimes the best option is a combined option: the owner of the house independently conducts preparatory work and laying of the floor covering, and the installation and connection of the film itself entrusts professionals.

Layout of a warm film floor should be carefully thought out and drawn up the appropriate scheme. It is necessary to indicate the places of installation of stationary pieces of furniture on it, since it is not recommended to place them on the floor with film heating.

For furniture that fits snugly to the floor, you need to pick up a meta-permanent installation, and put everything else on the legs or hang on the walls. Failure to observe this instruction can lead to overheating of the floor, damage to the film, furniture and flooring.

Infrared film should be laid in butt, the overlap of the film strips during installation is unacceptable. It should be securely fixed with adhesive tape, avoiding damage

It is important to install the temperature sensor correctly so that its readings are correct. In this respect, there are also clear manufacturer recommendations, which must be adhered to.

Lay the film only on a flat and clean floor, especially if a laminate is chosen as the floor covering, one of the most whimsical floor options in combination with floor heating systems.

To connect a film infrared warm floor to the power supply system, you can use special rivets or a method of soldering with copper wire

After laying the laminate, do not immediately turn on the warm floor. It is necessary to wait a while for the floor covering to warm up to the level of the air temperature in the room. Only after this can you safely turn on the heating. Compliance with this rule will not be harmful when working with other types of flooring.

Nothing so invigorates as the touch of the feet to the cold floor. Especially since morning. At these moments, we recall all the ancient mantras, enviously calling on the head of a more fortunate neighbor a variety of misfortunes. In fact, his feet are not freezing, shoes in the hallway dry naturally, he lives in a wonderful world. But this is not a miracle, but a warm film floor. A system that you can fully implement with your own hands. The good news is, in the modern market there are many almost ready-made floor heating systems.

On this page you will find detailed information about this floor heating system, as well as step-by-step instructions for installing yourself with photos and video materials.

First about the pleasant. The advantages of this heating system are manifold, we list only a few of them:

Low price.In fact, such material is relatively inexpensive. Depending on the manufacturer and material of manufacture, the cost for 1 square meter will be from 350 to 1300 rubles. For comparison, the material and installation of a warm water floor will cost two to three times more expensive.

Low electricity consumption.The most powerful film floor consumes about 200 watts per square meter of space. On average, this value is lower: 150 W per m 2. If to compare with the "gluttony" of the cable floor (180-220 W) - the benefit is obvious. About the classic water floor, you can not say: the gas consumption for heating water, plus electricity consumption by a circulating pump - you get a decent amount.

Read the tact: The most economical of all -!

Ease of installation.Knowing the basic rules, to lay the floor with heating can almost any owner.

Beneficial features.Yes, this is not a myth or a miracle. The film floor ionizes the air, kills unpleasant odors, creates a favorable microclimate in any room.

As you can see, there are so many positive qualities that I want to run for purchase right now. However, it would be dishonest to keep silent about the shortcomings of these systems. So, what is "uncomfortable" in a warm film floor?

You can not put furniture on top.This is true for bimetal material, carbon film warm floor is not so demanding. The minus is obvious: if the room is planned to be reshuffled, it is difficult to guess which floor area you can lay a film on, and which one you can not.

Need a flat surface.That is, additional costs for surface leveling will be required. Imagine a situation where the film lies on uneven surfaces and is pressed through with a coating. The insulation is broken, a short circuit occurs. As a result - ignition. Extremely unpleasant thing.

Some works can not be done on their own.You can prepare the surface, lay the film floor, even connect the power cable to it. But here the installation of the thermostat, RCD and quality control can only be performed by a qualified electrician.

Having dealt with the advantages and disadvantages, you can consider under what coverage it is possible to lay a film warm floor.

![]()

For what flooring is suitable?

The main question that worries many people sounds like this: "Is it possible to lay a film floor if there is a tile on top?" It is possible, but only carbon. Bimetallic floor for these purposes is absolutely not suitable.

In general, if you study the numerous reviews, you can find out that the film floor is good for different types of floor coverings:

- wood (laminate, parquet);

- linoleum. More details;

- cork sheets.

The only condition is the installation of a thermostat, which keeps the temperature evenly throughout the floor area, within 27 degrees. Why this value? If we consider the physical properties of a wooden coating, it becomes clear that a change in its structure occurs at a temperature of 28 ° C. That is, when the floor is heated above 27 degrees, the material will deform.

Substrate laying

After the surface is finally dried, we lay the substrate on the place where the film warm floor will unfold. If you want to make the entire surface of the floor heated with a carbon film, then spread out the substrate, retreating 10 - 30 cm from the walls. Joints must be fixed with the help of paint tape.

Before installing the film, carefully inspect the entire surface to ensure that the substrate is well fixed and does not stick to anything.

Mounting the film-warm floor by own hands

It is believed that bimetallic film can be stacked as you like, cutting it into strips of arbitrary length and shape. In fact, this is not so. There are a number of rules.

The ratio of the width and length of the bands.You need to know what the size of your material is, because the width is the maximum allowable length:

- width 500 mm - maximum 9 running meters;

- 800 mm - 5, 5 p / m;

- 1000 mm - 4.5 p / m.

Minimum of joints.The more joints - the lower the reliability of the coating. Therefore, the decision on how to lay the electric warm floor, either along or across the room, depends on its dimensions, as well as on the width of the material itself.

Correct cutting.This material can not be cut as a substrate, in any order. To understand where you can cut the film, take a closer look at its surface. As a rule, it is divided into square sections with dark (graphite) sputtering. In these places, you can not pierce the material and cut it. In addition, it is forbidden to damage copper veins (they are also perfectly visible).

Sequence of actions for laying the film

- We stack sheets in parallel to each other, not allowing an overlap (butt). Spread the film only with copper wires down. Important! If you accidentally punched (pierced) the film through and through - you need to insulate this place from two sides.

- The opposite side from the one to which the connection will be made must be insulated. For this, bitumen insulation is used, which has great reliability and protection of the coating. Cut the insulation a little more than required in size, this will ensure greater reliability. To ensure that the insulation does not protrude above the general level, it is necessary to cut the cavity in the substrate and hide the insulated edge there. For better fixing, it is necessary to glue the insulated edge to the substrate with paint tape.

- In the same way, using adhesive tape, we fix the sheets between ourselves and the edges of the infrared warm floor.

- Install the thermostat. How to choose it, read below.

- Using the wire and copper clamps, we connect the mats of the warm floor to the thermostat. The connection must be consistent: like joining strips in a sheet of warm floor.

- Copper clips cling to the places that are indicated in the instruction. At this stage, it is important not to break through the material. To do this, carefully insert one side of the clamp between the film and the copper core. Another part of the pliers or light blows of the hammer gently presses against the film. In the same way we do with each sheet.

- Now you need to connect the thermostat to the network and check the working capacity of the warm floor. This job is best entrusted to a professional electrician for several reasons. The specialist knows all the nuances and can connect the entire system to the network with a quality guarantee. In addition, a bimetallic film floor is characterized by a lack of grounding. To protect yourself and your loved ones, you will need to install an RCD (protective shutdown device), which will de-energize the circuit in case of a short circuit. Installation of such equipment should be done by a specialist.

- A system performance check usually takes 15 minutes. This time is enough.

Installation of building mesh

If the floors are warming evenly, and there is no complaint to the work of the warm floor, you can start installing the building mesh. What is it for? This material serves as a fastening base for the floor covering.

Regardless of the material selected, it will shift slightly, expand from a temperature change and so on. However, it can damage the warm floor.

Attention! If the laying of tiles is planned (in the case of carbon film flooring) - the laying of the metal mesh is strictly forbidden. The best option, as mentioned above, will be fiberglass.

The net is better attached to the floor. For this, dowels are used, which are inserted into the drilled holes. Drilling is necessary in those places where there is no black graphite spraying.

How to choose the right thermostat?

Manufacturers produce temperature regulators of various types: both mechanical and electronic. The latter type is in great demand due to its functionality: some models support work on a given program. That is, heating can turn on in the morning when you just woke up or in the evening. Saving electricity is obvious: you can, for example, set the program and the film warm floor will be turned off for the night, if the heating at this time of day is not needed.

The main thing that you need to pay attention to is the correspondence between the power of the temperature regulator and the power of the floor. Calculate this value is fairly easy: you must multiply the area of the infrared floor by its power. Let us give an example. Let's say that the floor area is 15 sq.m and the floor power is 1 meter square - 180W. We multiply 15 by 180 and get the number 2700. Hence, a thermoregulator of 3 kW is required.

Tip: if the power of the thermostat is more than 2.5 kW, it is desirable to install a separate circuit breaker. In the event of system failure, it will disconnect the electrical circuit.

Conclusion

The work on the installation of the warm floor is finished, you can start laying the finishing floor. In order not to cause unpleasant situations when using a film floor, follow the following recommendations:

- The space between the laying of tile or ceramic granite tiles on the graphite floor and the start of the heating system should not be less than 28 days. During this time, all moisture from the adhesive composition is completely evaporated, which will help to avoid a short circuit.

- On a bimetallic heating system you can not put furniture. Remember this when rearranging the room.

- Do not disregard the installation of additional equipment, for example, RCDs. This will protect you from a fire from the system and from electric shock in the event of a malfunction.

Observing all the instructions prescribed by the manufacturer and our advice, you will be able to create a miracle no worse than that of a neighbor. Let now he envies you: he certainly has a water heating system that requires large monthly expenses. I wish you success in the repair and warm floor under your feet!